Leaderboard

Popular Content

Showing content with the highest reputation on 07/28/21 in all areas

-

Pull the oil pumps, sell those on ebay, load the EA82 in the trunk and send it to the scrap yard. $300 is more than anyone will likely give you for it. GD2 points

-

To run at 3k RPM with the throttle closed it's getting air from somewhere - you need air for the engine to run at that RPM so it's getting it somewhere. If the throttle is closed you have a leak. And that means unmetered air which means it's going to be running lean and that will drive up the temp and run the fuel trims positive if it's even attempting closed loop operation. Fix the vacuum leak first. Or swap in an EJ22 and get more power without the messy unreliable turbo EA garbage. Or.... yeah..... burn it and get a V8. Although I would sell it to some other sucker and forgo the weenie roast. GD2 points

-

Bennie has been giving solid advise, as always. I have a '82 GL Brat that I could take some photos of the wiring... it is LHD. Half of my 80's Subies have a toggle switch for the radiator cooling fan. The sensor in the radiator ends up going bad or getting corroded. Instead of paying $50 some dollars for the sensor through Subaru, it is easier to wire a toggle somewhere within reach of the driver seat, and to monitor the engine temp during the hot months. In the winter, the cooling fan is rarely needed1 point

-

yeah, really doesn't seem like a sensor/ECU issue, seems like something more 'physical'. as said, triple check cam/crank timing. Locate the 'tooth count' for that engine. Bring the crank/cam marks to their 'belt install' positions and count the teeth between everything. Something may be a tooth off. Wonder if a 'dropped' valve guide could come-and-go??? maybe some odd vacuum leak comes-and-goes??? - maybe try some vacuum gauge readings - may have to rig a way to do that while revving/driving?1 point

-

This sounds like a good one... a few things: - timing, yes I know you said you double triple checked it. Which markers did you use to line up the cams (don’t use the arrows, always the tabs on the rim of the cam wheel)? And this is a DOHC engine? - after reconnecting the battery did you let the engine idle for 5-10mins before touching the throttle? - after a drive when it was “normal” then not, are there any stored codes? - the spark plugs and leads new, if so, what was used? - fuel pump healthy or quite old? And on that one, fuel lines connected correctly? It’s easy to get a return line mixed up with the IN line on the fuel rails I hope some of these suggestions help or give you something to look at further. Cheers Bennie1 point

-

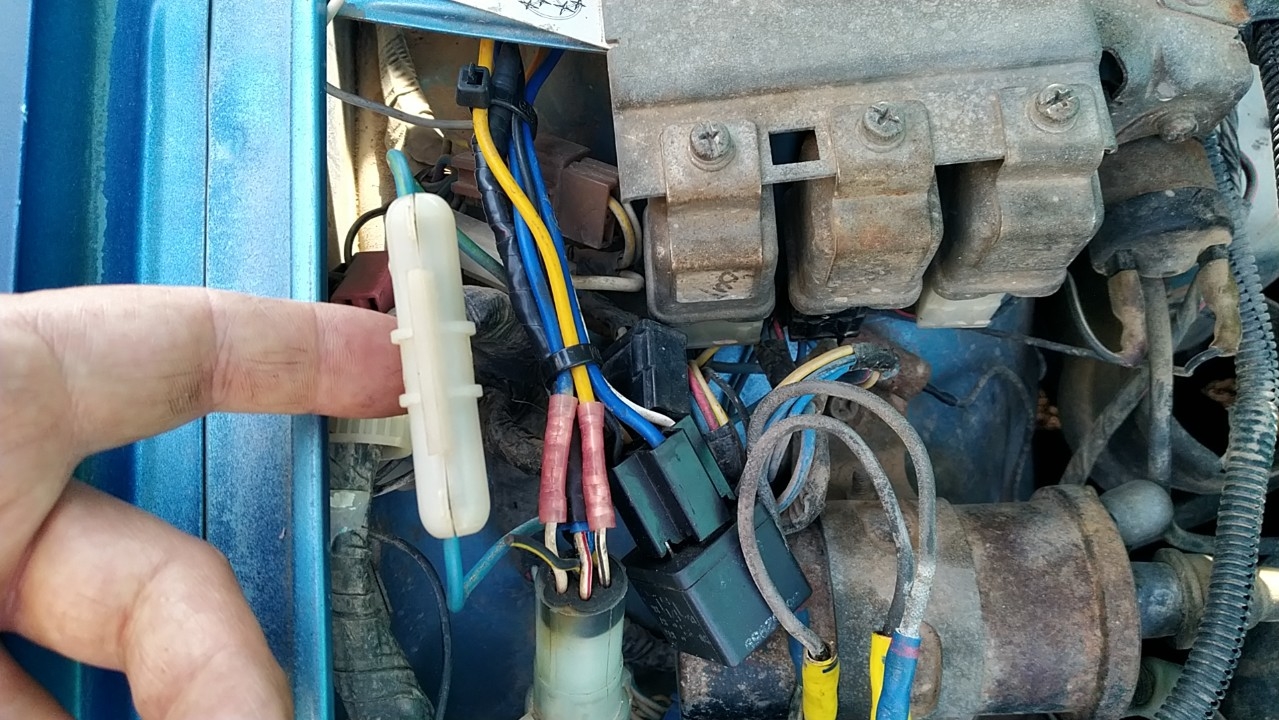

You need to try and meet up with someone who has a Subi of the same era without the butchered wiring to cross reference. That tube fuse holder with the blue wire is a factory unit. Bugger it, I just ducked outside and grabbed these pics from my Brumby: Looking at your pics, it seems that someone has added that second circular plug. As per my pics mine is one side white and the other side blue - I had an inkling this was the case but didn’t want to give you a bum steer. I also wonder what those plugs further up the line are for - the pink one caught my attention as I don’t have any of them there, just neatly wrapped wiring. It’s either a LHD vs RHD difference OR someone may have attempted to splice two loom sections into one for some unknown reason. You might have to pull all the wires from that relay, record their colours and what they do - that will require some investigative work - but it would give us the best way to work out how everything is laid out in a factory wired vehicle by comparing what I and others have with their EA81’s. That’ll give you something to work on for now though! Cheers Bennie1 point

-

We've been getting the 99 Outback ready for the Vegas to Reno. Replaced the rear wheel bearings and front brake pads and put on new tires and new (to the car) wheels. Already shipped a set of spare tires out to the pit service. Safety wired and cotter pinned all the suspension and brake bolts. Welded up a few cracks too. If I try to keep this car much longer that front crossmember will just be solid weld. After pressing together one of the rear wheel bearings it initially wouldn't turn. I had to put a bar on the wheel studs to break it loose but then it spun easily and smoothly. I've never had that happen before, has anyone else experienced that? Test drove the car for about an hour, at least half of that was at about 80mph. Couldn't tell if the wheel bearings or tires were making noise but didn't seem much louder than usual. Tire temps were all four the same and the rear wheels didn't feel hot when I got home. We got more parts for the dual range too. We need to assemble that and put it back in B's car but that will probably have to wait until after the V2R. Ditto the new long travel struts. If anyone wants to meet us at the Vegas to Reno let me know.1 point

-

High time for me to reset my password in order to get back in here after device change . 87 is flat manifold ? How is the (hard as ) rubber air transfer hose from above the thermostat housing to inlet manifold? If you have one The 25 DBTDC is interesting, as all our Oz turbo EA82 are 20 according to bonnet sticker and manuals. I say easier to resolve this than EJ it Did you check the coolant transfer casting internals when you had it off, and replace the tiny welsh/freeze plugs you see when it removed? Those little bastards rot after 20 years1 point

-

1 point

-

@el_freddo yeah, that was my bad. I thought the forum might post the vehicle I had someplace in the left column, considering it asked. But, like I said, the rocker arm markings were my main concern. Have tolerances and what not for everything else.1 point

-

I got most of that stuff figured out. Was mostly interested in the difference between the rocker arms, considering the markings.1 point

-

So on a whim, I pulled the fuse holder and placed a jumper wire between the two ends....and everything started working! Radio, AC fan went on when I turned the blower on, the blower turned on! Front wipers worked! And the washer sprayers too! Only the rear wiper wasn't turning, I'll have to investigate it. Also, from what I saw I had two fusible links1 point

-

I like to say Jesus come quickly! I know that he’s going to return in his time. Yeah the world is coming to a VERY sad state of affairs. It has been 6 years now since I was seeing DEAD PEOPLE literally every day. Then I had a stroke. That got me out of the morgue, almost put me on a table there in the process. God wasn’t done with me yet here on this plain. I know that through this process I have been an inspiration to many other people. I say well this is just another bump in the road and I carry on with what needs to be done. I’m able to do quite a bit with only one good hand. I’m not driving YET, I think that has been the biggest thing I miss between that going basically NO where by myself. Any who I’m glad to still be here for this and that. I’m looking forward to being able to walk again with little to no assistance. I’ve come a long way from where I was after I got out of rehab (couldn’t wipe my own rump roast) to now where I don’t need hardly any help at all.1 point

-

You could have a number of issues. Before GD says it, burn it and get something old school GM Serious now... you could have an issue with your HGs depending on when they were done last; there could be an air leak in the system or a stuck thermostat - or both! 25 deg BTDC is a bit much isn’t it? The MPFIs over here were all set at 20deg with some plugs connected under the dash while adjusting so the computer didn’t mess with the timing while you were adjusting it. Other things to look at, what’s the condition of your water pump? It could be worth getting the nose as high in the air as safely as you can, run for a minute then let it cool down. Check the coolant level. If it’s down it could be worth pulling the thermostat housing to see what that’s doing. Test it in some water (hanging from wire in the water, not sitting on the bottom of the pot while it’s being heated). Replace if dodgy. While that is out full the engine with coolant through the thermostat hole if coolant is needed. Squeeze the heater hoses to try and displace any air in there and top up as needed again. Refit thermostat and rad hose, back fill rad hose and connect to radiator. Turn engine on and slowly/steadily fill the radiator with coolant. Monitor temp etc and continue filling with coolant in small amounts when it lets you. Throw rad cap on, hold some revs for 10-20 seconds, let idle then shutdown. Let it cool. Check coolant level and top up as needed. The other thing to look at is your coolant temp sensor and TPS - make sure they’re working within spec and that the throttle cable isn’t holding the throttle open a little. If it is back this off and see if idle changes. Let us know how you go. Cheers Bennie1 point

-

The blue/grey plug, are you talking about the circular plug for the engine wiring loom? That looks intact and fine to me. That black relay taped to the circular plug is not factory. You’ll have to trace those wires to find out where they go. It could be a relay for the fan(s) or it could be for some driving lights. As for the fusible link box, I can’t find an image with it in there and definitely can’t find one of the wiring setup in it either. This is the best I can come up with to show the brown box for the fusible links: You can see it tucked in behind the battery and hemmed in from the side with the coil. There will be quite a lot of wire tracing (label everything if it helps you) in your future at this point in time. Cheers Bennie1 point

-

1 point