Leaderboard

Popular Content

Showing content with the highest reputation on 09/01/21 in all areas

-

Indeed the past month or so I did exactly that. Saved money using the internoogie and picked up at the counter. Now I’ve got around $700 worth of brake parts to install ... damn!1 point

-

could the clunk actually be coming from the drive shaft/u joint complex? had that issue with my 051 point

-

I have been working through a torque bind issue myself, and have tried a couple of things along the way which have had some effects, which might be educational for some. They certainly have been for me. BACKGROUND: I upgraded all my suspension bushings to polyurethane, but not my diff carrier and subframe bushings. I also gave a little 1" lift via King springs and put on larger tires (215/70R16, +1.78" diameter). After this work I started experiencing torque bind. I assume that the increased resistance to flex and rotation made evident a problem that was already brewing but not yet apparent. While figuring out what my problem was (starting with the assumption that it was low-grade wheel hop), I drove about 800 miles with little degradation - the problem only evidenced when accelerating from a stop, and especially while cornering from a stop. Then, while driving around the steep hills of Tacoma, WA, with many stoplight turns onto uphills, the problem worsened considerably. I then drove the car home, another 800 miles, without too much more degradation, and I started figuring out what was going on. After research, my expectation was that I have a failing transfer clutch or solenoid, neither of which I've yet tried to address. I have tried other things with my ATF, though, which have had some effect. MY WORK: I started with some fresh ATF, and discovered very dark fluid. Not black, but pretty ugly. I'd made a couple of trailer hauls out to a storage unit over a couple mountain passes, and now wish I'd checked the ATF each time. Live and learn. A single drain and fill didn't change anything for me. I'd read another person alleviated their torque bind with a SeaFoam Trans Tune cleanup, so I drained a bit of fluid, added a can of Trans Tune, then got my hot fill level to full again. This made an immediate great improvement, within 1/2 mile of driving. Unfortunately, it quickly degraded back to what it was before, maybe a little bit better. Was the improvement because the Trans Tune thinned the oil and it now had better pressure through a failing solenoid / valve-body? Was it due to cleaning of the clutch plates or valve body? I have no idea, curious to hear opinions there. I added a 2oz tube of LubeGard Shudder Fix, for science, and that made no difference. I then performed another drain-fill, the fluid was still pretty ugly, not sure how much of that was due to the Trans Tune cleanup vs the leftover from the original abused ATF. No noticeable improvement to my problem. Also, after another 50 miles my tranny was making a loud metal-metal clunk when switching between D-R and R-D. After those 2 drain-fills and the Trans Tune cleanup, I did one more drain-fill and changed the external screw-on filter. This did improve things quite a bit, but there is still a shudder on acceleration from stop, maybe not quite as bad as right after my suspension and wheel work. Also, the D-R / R-D clunk has mostly gone away. I WONDER: I have one hypothesis: The Trans-Tune improved things, either by cleaning my transfer clutch pack or solenoids or valve body, or by viscosity change. Or maybe friction modification? Dunno. But then debris was freed and accumulated in the filter, decreasing pressure and degrading valve body and/or transfer clutch function. I'm guessing. I have some reason to believe some of the problem was pressure related, based on the improvement after changing the filter. Is this a sane conclusion? For the problem which remains, I'm curious how much is related to the transfer solenoid and/or fluid pressure, vs transfer clutch? I can't test with the FWD fuse, because my car doesn't have one - VTD involves a planetary front-rear coupling which can't be disengaged, even though it still has the rear transfer clutch. There's also a locking clutch which locks the center diff, establishing a 'solid' linkage between front and rear. All the posts I see on torque bind talk about the transfer clutch and its solenoid, usually in a 4EAT context, but could the locking clutch and solenoid also be responsible for torque-bind-like symptoms? FUTURE WORK: After I buy another 2005 3.0 L.L.Bean I'll pull out this tranny and look inside, hoping to find a clearly worn transfer clutch. Maybe I'll go deeper. I've never been inside a tranny, despite years in the SF Bay Area (*ahem*) so I will be posting my findings for feedback when I do. Worst case, this car becomes spare parts, and I'm OK with that, I made the 200K club.1 point

-

Good news for any local buyers here in CT. shopping at SubaruPartsForYou.com online seller of Dan Perkins Subaru in Milford, CT. Great prices and very informative staff. There is an option at checkout for local pickup at the counter to avoid paying shipping charges and get it as soon as you can get there. Just wait for the confirmation email and head on over.1 point

-

Yea, I don't think you can access any dealer settings with anything that cheap. Any ELM bluetooth dongle (I've bought a couple for ~$15) and an android app can do a lot of diagnostics. ActiveOBD is a subaru-specific app that can read transmission temperature, AWD %, and more on the newer models (was invaluable when diagnosing a torque converter solenoid on my mom's 2012 CVT Impreza).1 point

-

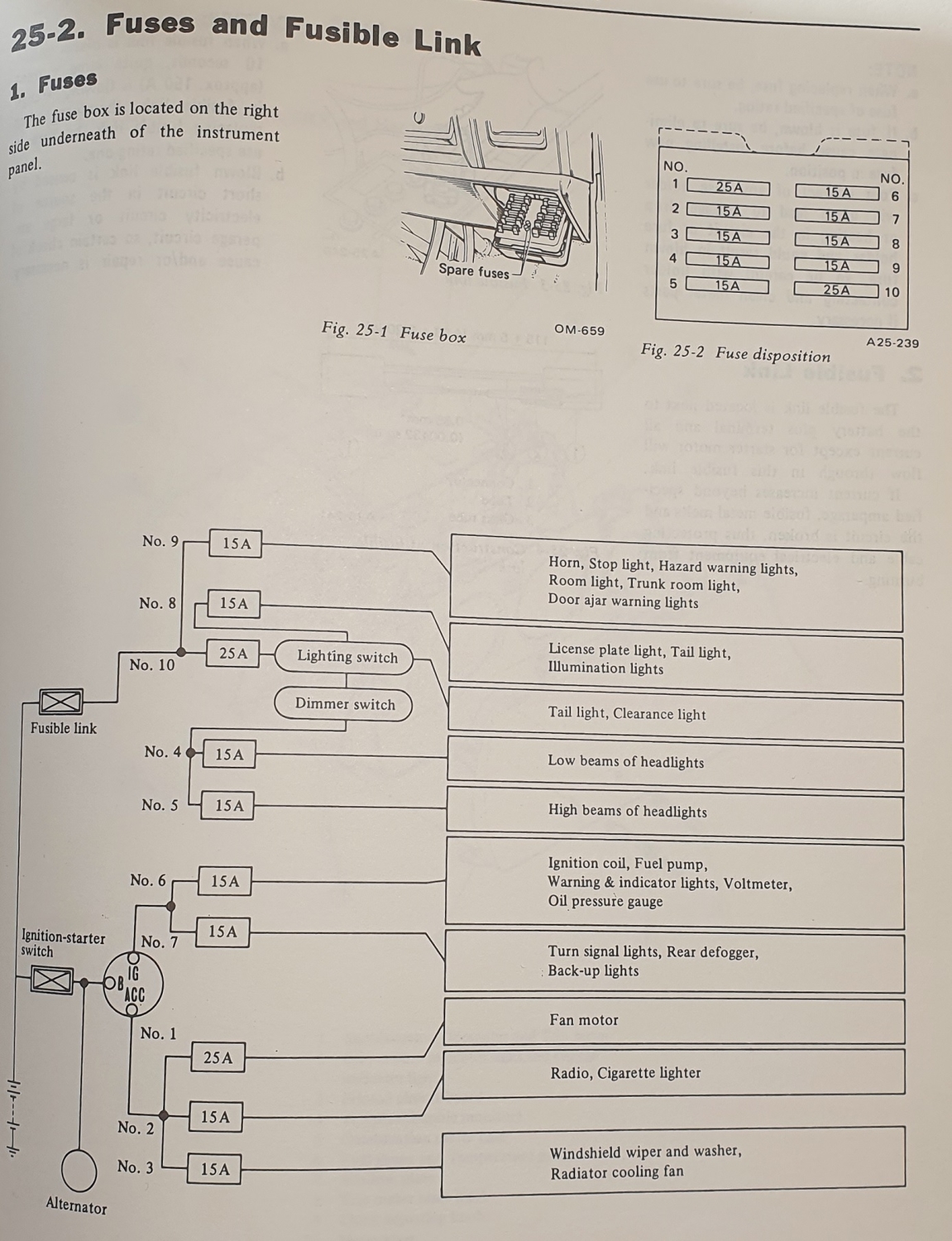

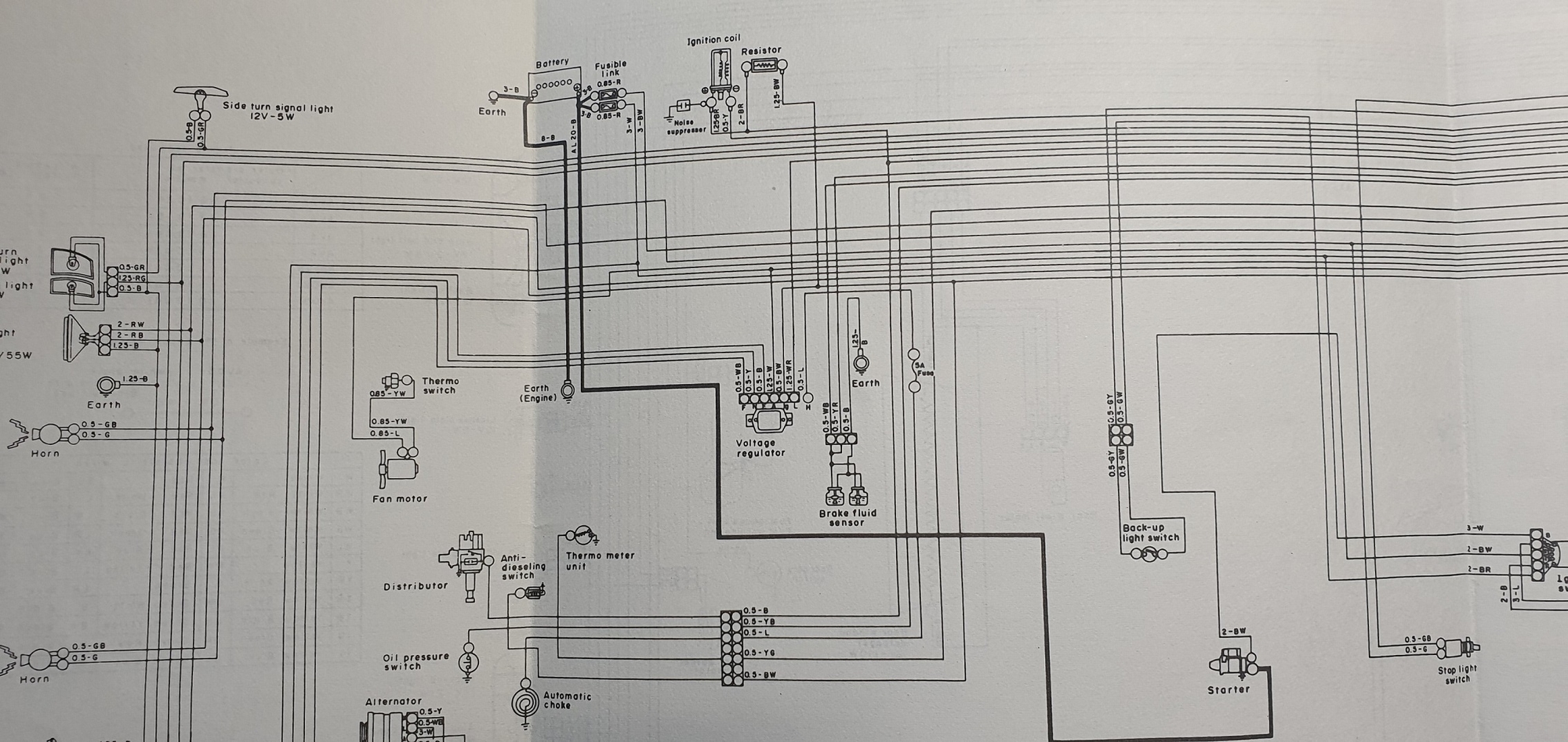

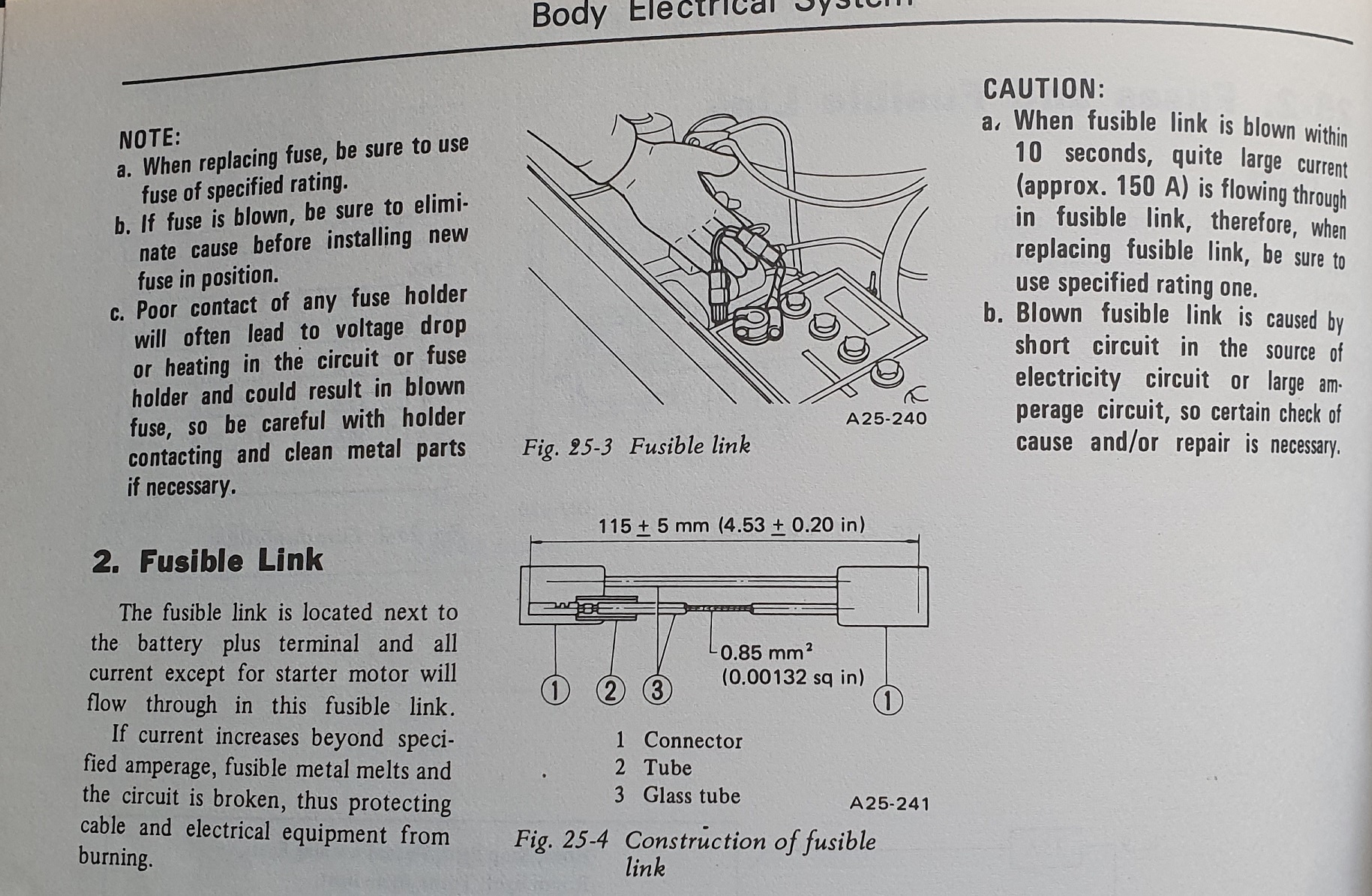

My guess is the previous owner has added that relay to bypass the ignition switch (they do get crusty and stop working at this age or have big voltage drop) I've found a couple of pages that might help, if the detail comes across in the pictures (2MB size limit means it's difficult to get high detail images across) The first one shows how the power should flow to the electrical equipment, all of the things you said weren't working at the start all come from the same line from the ACC switch. Second pic shows the overall wiring diagram in the battery area (this is an Australian/RHD model, might be different to yours) Dunno if this helps or not, I can't find that round connector (that the relay piggy backs onto) of yours in the wiring diagram I have here.1 point

-

Something that hasn't been mentioned in here yet, 1981 model most likely did not have the black/grey fusible link box as has been shown in a few of these pics. I have a 1981 wagon and the original loom did not have it, the fusible links were literally two pieces of cloth covered wire coming directly from the battery + terminal. My 1984 ute has/had the fuse link box, I'm not sure when they brought it in. Before you ask, there's no point in me posting a pic of the wiring in my wagon since I've completely re-wired it. I've got a March 1981 factory service manual in my possession, I'll look through it to see if there is any helpful diagrams for OldieSubie. A question from me; what does the fuse box under your dash look like? Does it have blade fuses or glass tube fuses?1 point

-

There are wiring differences between 1990 and 1987.. when you go back further, the differences get more significant the further back you go.1 point

-

Mine is a 1990 model - and remember it’s a RHD model. I didn’t think there would be any difference between the LHD and RHD models but I could be very wrong on that. I haven’t looked into what wires go to/from the brown fusible link box. I know there’s one main wire from the positive of the battery to the brown box to supply 12v to the fusible links. Cheers Bennie1 point

-

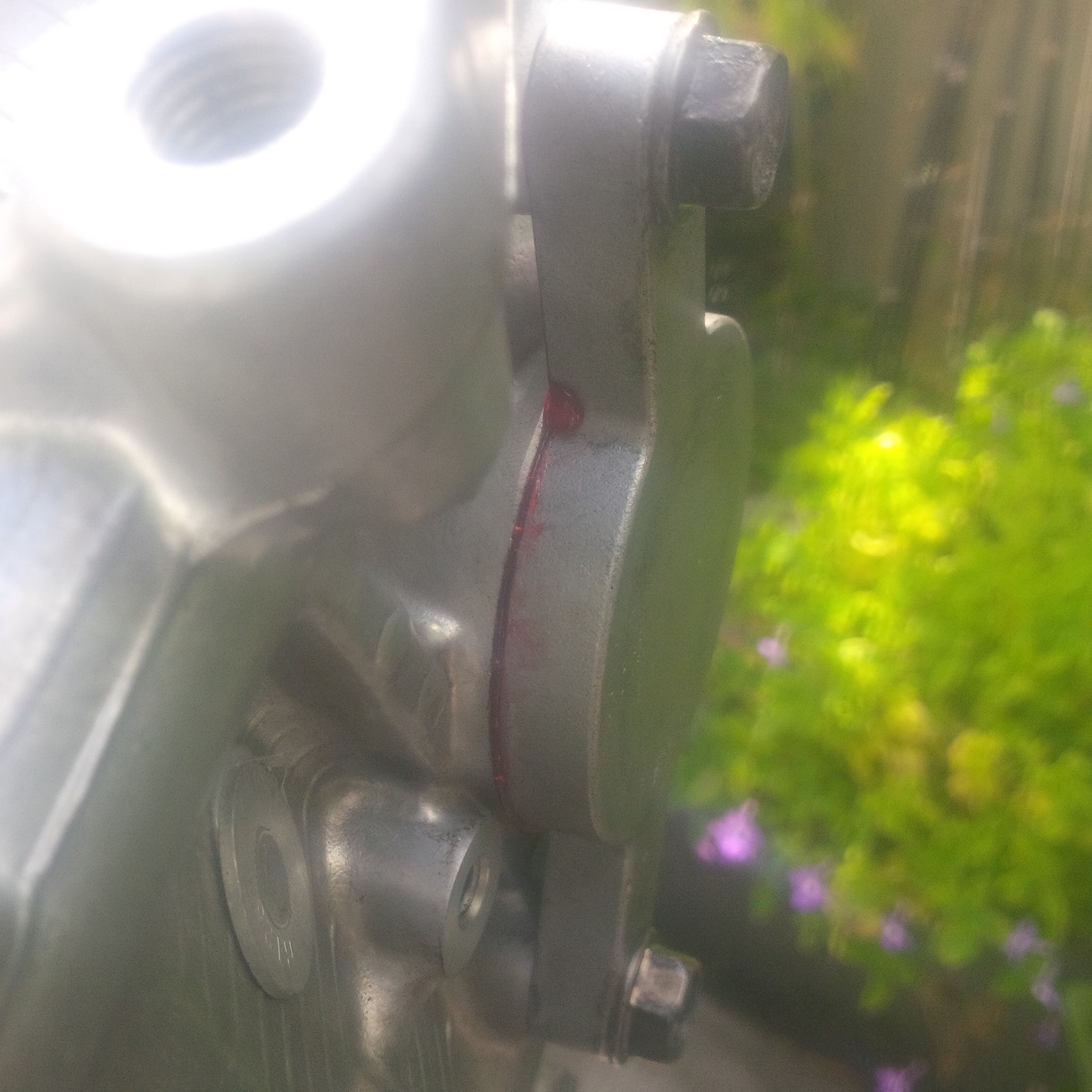

I've used Gray RTV, a light bead at the 90 Degree before the o-ring is put on. When you install the cap the RTV will be pushed out between the engine and the cap.1 point

-

1 point

-

Are the ears notably offset and not sitting flush if installed without bolts right now? Can you get a feeler gauge in there? Can you mic for flatness? Check distance from engine side end/base to each ear and compare? appropriately placed RTV would sure it up if you think installing normally won’t work. They can be hard to seat. Oil it up well for lubrication to assist seating, ensure it’s going in flush, then lightly twist back and forth with the ears to rock it back in place.1 point