-

Posts

5087 -

Joined

-

Last visited

-

Days Won

87

Content Type

Profiles

Forums

Gallery

Store

Everything posted by DaveT

-

87 GL EA82 wagon - new to me running problem

DaveT replied to DaveT's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yeah, we are just going to have to get more creative to keep these old ones running as time goes by. -

Subaru Brat EJ22 running issues

DaveT replied to alexbuoy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

You might have better luck in the newer forum, since what you are dealing with is an EJ engine problem. It probably has little to do with the body it is installed in. Outside of checking all the wiring involved with fuel and the throttle body, I can't say much else. I've never had an EJ. -

87 GL EA82 wagon - new to me running problem

DaveT replied to DaveT's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Starting to seem like a common 30yr old part to fail... -

I have a dual range transmission that needs a home.

-

Can't remove bolt in EA82 Crank Pulley

DaveT replied to 3crows's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yes, but the heat will expand the bolt, more than the hole in the crank, making it tighter. While making the bolt weaker. When I've most often used the torch method successfully, it's when heating the "nut" side of things. In this situation, the nut expands more than the bolt, making a looser fit. Not identical to this situation - I have found that especially when dealing with steel bolts in an aluminum block, getting the engine up to normal operating temperature before trying to loosen the bolts helps a LOT. I've gotten many out that would have snapped if attempted at room temperature. If the engine can run, that's the quickest way, but a few times, I used a space heater and a heat gun, while watching a thermometer in contact with the area near the bolt. -

Can't remove bolt in EA82 Crank Pulley

DaveT replied to 3crows's topic in Old Gen.: 80's GL/DL/XT/Loyales...

That should hold it, just feather those valves carefully... -

87 GL EA82 wagon - new to me running problem

DaveT replied to DaveT's topic in Old Gen.: 80's GL/DL/XT/Loyales...

There is only one fuel pressure regulator, it is held onto the throttle body by 2 screws. The only thing I can guess you may be misidentifying are the dampers - they smooth pulses / surges in the pressure. There is one on each line under the hood, and one on the OEM fuel pump. Good to know, about the adjustable ones. They go inline? Then I just have to figure out how to make the dead stock one go full open? -

Can't remove bolt in EA82 Crank Pulley

DaveT replied to 3crows's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I would not get a it past normal operating temperature, 190 degrees F. That's working against the problem anyway. 3/4" drive socket from McMastercarr.com or mscdirect.com and a breaker bar. And a pipe. -

83 GL Won't start. SOS subie noobie

DaveT replied to Sir_wankel's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Is the choke closed when it's cold? From one of the earlier posts, you said it was pouring fuel into the intake? It's badly flooded. It takes a long time to clear that. Give it a 2 second shot of carburetor cleaner in the primary, holding the throttle open. Then go give it a crank, holding the gas pedal about half way down. If it fires momentarily, you know everything is ok except lack of fuel / or mix. -

87 GL EA82 wagon - new to me running problem

DaveT replied to DaveT's topic in Old Gen.: 80's GL/DL/XT/Loyales...

hmmmm.... Well, I probably should investigate what is wrong with the bad regulator, and figure out what to do to fix it. Since I have no doubt that they are NLA, since the fuel pumps are NLA. Other thing to note - The stock pump draws less than 1.5Amps, and the Carter P5000 draws a hair over 5Amps. -

87 GL EA82 wagon - new to me running problem

DaveT replied to DaveT's topic in Old Gen.: 80's GL/DL/XT/Loyales...

OK! I replaced the fuel pressure regulator. I have a spare SPFI manifold I traded for the carburetor one I had on my 86 GL. Took the regulator off that spare one, which looks like it wasn't very old / low miles /indoors most of it's life. Car fired right up. Pressure nice and steady, at 24PSI - which is a little high. Drive to the bottom of my safest "test" hill. Checked the vacuum line to the bottom of the pressure regulator, oops, I left it off. Connected. Pressure more normal 22PSI. Still nice and steady. Drive up the hill, NO PROBLEM! Loop around for another test, and no problem. Took a run up the steeper bigger higher speed hill nearby, and no problem. Pressure now at 20PSI, but it is running fine as it always has. -

Just for the information, the risk in using the old existing wire is that it is not sized for the higher output of the modern alternator. The stock fusible link should cover most failure modes ok, but not allow the full use of the higher output.

-

Brat Starter Electrical issue. Help

DaveT replied to ajslacker's topic in Old Gen.: 80's GL/DL/XT/Loyales...

On the back / side of the starter is a single wire, tat triggers the solenoid. Use a test lead or piece of wire to get 12v to this terminal. If it cranks, the problem is high resistance in the circuit feeding it. The "relay mod" is the easiest way to fix this. If the starter clicks, but does not crank the engine, the contacts need to be replaced. -

Hydrocarbons = running rich. Too rich for emmisions, but not enough to screw up drivability, which takes more. The catalytic converters are involved with hydrocarbons and no. How did they test it? As an 83 or what is expected of an EJ? Probably good to read the codes, since the ecu should give a clue about the rich condition.

-

87 GL EA82 wagon - new to me running problem

DaveT replied to DaveT's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Test run done. It's not the fuel pump. Last night, I ran the new pump, pressure looked good,etc. Today, I started the car and the pressure was bopping up and down again, 20 to 22 PSI. Ran great and normal, until I got it warm and decided to take the bigger risk of a main road with a steep uphill grade, when the sputtering began under load. Made it home ok at least. Debating next move... Swap the pressure regulator, or the injector? I installed the Carter P5000 in the space between the rear set and the floor, so it is not in the weather. -

87 GL EA82 wagon - new to me running problem

DaveT replied to DaveT's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I should have a chance to get a test run in over this weekend. The only thing left to do now is solder the 2 wire from an old Subaru connector to the new Carter connector. A whole list of other things going on has been making my progress on this a bit slower than typical. -

87 GL EA82 wagon - new to me running problem

DaveT replied to DaveT's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I got a Carter P5000. -

87 GL EA82 wagon - new to me running problem

DaveT replied to DaveT's topic in Old Gen.: 80's GL/DL/XT/Loyales...

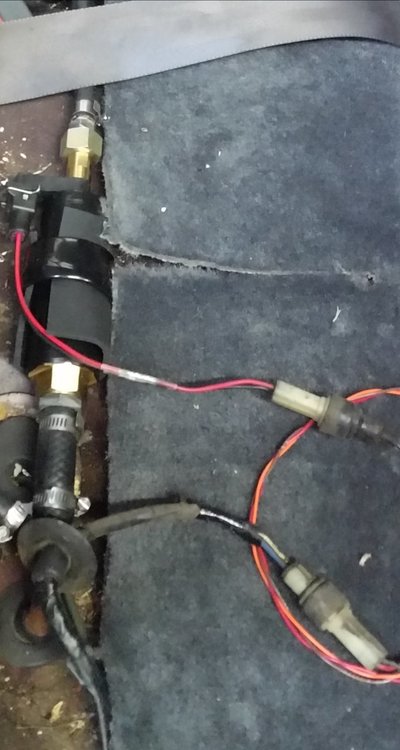

Another update. The new pump is hooked up fuel line wise. I'll add pictures once it's mounted and wired. -

valve grinding/lapping paste grrr

DaveT replied to jono's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I've only used one grit, whatever it was I bought years ago at NAPA. It does seem to get finer as you go, never had any problem with it. The bigger pieces of grit probably get worked out of the way first, as you twist the valve. -

EA82 Intermittently hard to start. ECU Code 6?

DaveT replied to Brianmitchtay's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Normal pressure with it running, T'ed after the filter, is 21PSI, steady. You can unplug the wires from the pump, under the car, and wire 12V directly to the pump for testing, if the engine won't stay running. If you block the output of the pump [only momentarily] the pressure should pop up to 50 PSI. Block it by pinching the hose after the pressure gauge T with smooth pliers / pad the jaws to avoid damage to the hose. -

EA-71 coolant leaking around head stud

DaveT replied to DPM's topic in Historic Subaru Forum: 50's thru 70's

Coolant should not get into the space where the stud is. Bad head gasket, mating surface not flat or a crack.- 1 reply

-

- 1

-

-

6 fast is the no code code. All codes for trouble are 2 digit.

-

88 GL oil filler cap positioning

DaveT replied to YnotDIY's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yes, I remember that also. Metal fatigue. Some grades / alloys tolerate more bend cycles than others. -

Not if it is a press fit.

-

88 GL oil filler cap positioning

DaveT replied to YnotDIY's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Keep an eye on the cap with the re bent tabs. I did that once, long while back. Eventually, one of the tabs broke off.