dburton97128

Members-

Posts

72 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Store

Everything posted by dburton97128

-

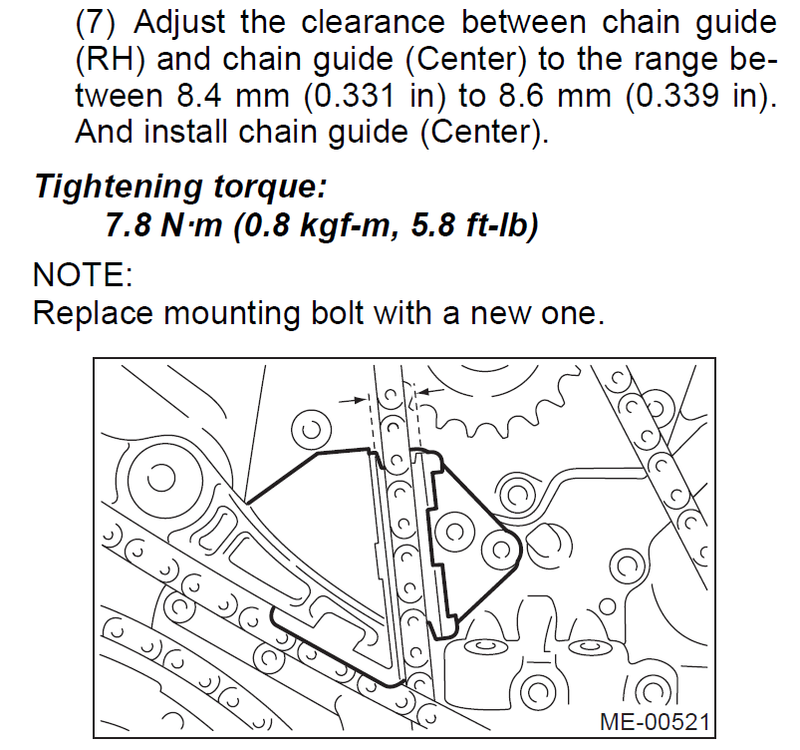

In replacing the center small guide a spacing of 8.4-8.6 mm is specified. From the dwg in the manual it's not totally clear to me the reference planes for that measurement. It looks like the back of the bushing on the right side, and I'm not quite sure on the left, though it looks like the front face of the guide (if that's a small gap between the face of the bushing and the chain in the diag.

-

I did find several suppliers ranging from $700 for a more stripped engine to $1300-1700 for a complete engine. I decided I don't really want to swap an engine so I'll replace everything in this one that looks like it would be iffy to go another 100k miles and hope for the best. While I have the tensioners and pressure relief plate off I'll back flush whatever passages I can to make sure they are clear and see if any residue comes out. Is there anything I need to be careful about while doing that? I'll use 0W-20 oil for that. After re-assembly I'll run it a day then do an engine flush and then a fresh oil change. I'll check the pan with a bore scope camera and if it looks like there is any build up in the pan I'll drop that and clean it up as well. Here's to hoping for the best.

-

It looks like I don't get to check (or replace) the oil pump. Those bolts are ridiculously tight. Supposed to be put on with 4.7FP, but even with 30-40 FP they aren't coming loose. One began to cam out so that ends that. No room for an impact driver in there, if that would even work. I see older year H6 motors from JDM on ebay, but my security says they have malware and won't let me go to their web page. No warranty on those motors unless I am a certified mechanic doing the install. Maybe I'll just do what I can on this one and go for a replacement later if it doesn't hold up.

-

Makes sense. But back to the cam chain tension issues: I'm copying this from another forum post in case anyone over here knows about it. --- I'm checking my oil pressure relief valve and pump and finding very sparse info about the PRV. Is there a procedure for checking the relief valve? I can pressurize one port with air until it starts to flow. What should the relief pressure be? Do I dare take the end cap off to clean and inspect it? Those are NLA so a good check and restore of this one is in order. *** There is a protrusion with an orifice that spays oil on the chain. The oriface was not plugged, but there is a small plastic piece behind it with a tiny screen. That screen is no more. A remaining fragment proved to be basically decomposed and turned to dust at the slightest touch. This part does not appear in the parts guides. Must be a part of the NLA PRV assembly. I can't imagine them making you buy a $200 part to replace a $3 screen though. Any info on that screen? Thanks.

-

How about the Amsoil 5W-50? That seems it would help alleviate the cold start issue some, though you are probably using the 'racing' oil for other reasons as well. The 40C viscosity is still higher than the other oils, but I didn't see data for actual cold temperatures. I thought I saw a graph of real data somewhere that showed Amsoil 5w-30 vs 10W-30 and there was no difference above about 20F.

-

I believe that is a legitimate point. The article gives quite a bit of rational for increasing hot viscosity as engines age older. His point though is that you need to be monitoring oil pressure vs rpm at operating temperature to be able to make that decision correctly. I'm thinking if there is chain rattle at low rpm or a situation as you described above then increasing weight a bit until it resolves would be a good thing, though at the expense of a bit of fuel economy. A key point he makes though is to use an oil that retains the proper low viscosity at low temperatures so you get good oil flow when cold. There are great options today with 0W-30 even up to 5W-50. I'm sold on good synthetics even more now since seeing all the varnish in my current car. I've run synthetics in all cars for the last 35 years and never had an engine lubrication related failure. My truck has over 200k mi and I started it on synthetic after the first oil change with a bypass filter. I changed oil 3 times in 200k mi, and each time the oil was still good for continued use. I notice things like my valves never need adjustment. The gaps remain the same, in my imagination indicating minuscule wear in the engine. The only exception has been my Toyota Cressida which my daughter ran out of oil and drove until it seized.

-

I read the whole thing. Took about 1/2 hour. I think there is a lot of eye opening information about temperature performance of various oils vs temperature, if you can make it through. I think he is spot on about how people misunderstand oil weight ratings and the effect in an engine. One issue not addressed (since it's not really a lubrication topic) is the viscosity/rpm/pressure issues related to keeping adequate chain tension. When I hear chain rattle I think that has to be accelerating wear on those parts.

-

Read this thread about oil weight. This oil expert claims lighter weight is better lubrication and increases flow and reduces engine noise and clatter, though one thing I wonder about is the effect on the chain tensioner pressure, which seems could suffer with light weight oil at low rpms. https://www.subaruoutback.org/forums/61-general-discussions/34372-informative-oil-write-up.html

-

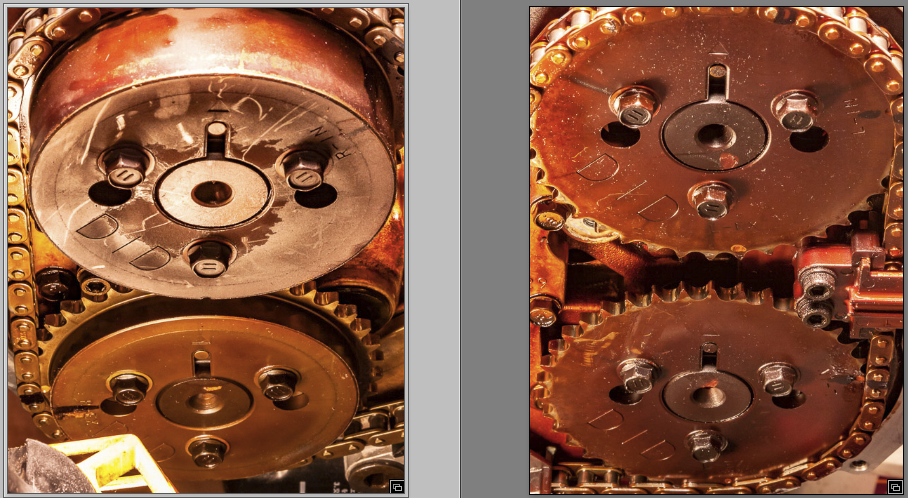

Hi, I am wondering what you think of the wear on my chain guides. Link: https://flic.kr/s/aHsmrkFZZE I had a diagnosis of worn chain guides and a recommended replacement quoted at $2300. These all look fine to me though the tensioner pads show more wear than the smaller guides. Even so it looks like they could go another 200k. (115k mi on these right now). I don' see any excuse for the chain rattle sound which was heard fully warmed up at idle and went away when the throttle was goosed a bit. Poor functioning tensioners seems the only explanation though they look totally fine out of the car. Chains look fine and there are no marks indicating they have contacted anything other than the guides. Don't want to put it all back together and not have it fixed. Could be low oil pressure, but that seems low probability. But is there something else I should check while it's open this far? Thanks.

-

Well I finally got a chance to follow up on this. I blocked it up on ramps, chained it to my truck, and looked at the mounts as clutch force was applied. I didn't see much but it seemed the passenger side front differential mount had a bit more movement than the right side. (The one right in front of the rear wheel) I took the bracket and bolt out and the mount looked intact, but when I looked closer I saw a good portion of the rubber was cracked away. I cut some 1/4" thick fiber reinforced rubber washers from some heavy duty radiator hose and sandwiched them above and below the mount to keep the diff mount from being able to move far enough to hit the frame. This fixed the problem. Seems a mount swap is pretty simple here, but how do you get the old one out? Seems some high force press is needed which probably means disassembling the entire differential and mount from the car. Not worth it. The rubber washers I made should last a fair while. If one were to want to change the mount bushing, is there a way to get it out without removing the whole diff mount? Maybe some special tool?

- 6 replies

-

- clutch

- drive train

-

(and 2 more)

Tagged with:

-

Being worse in reverse does sound like it could be indicating the trans mount doesn't it. ??

- 6 replies

-

- clutch

- drive train

-

(and 2 more)

Tagged with:

-

My 95 manual trans Legacy has a bad vibration that occurs when releasing the clutch. It feels like the drive training is 'bucking'. If clutch is released carefully it is smooth with no vibration, but if a bit more torque is applied I get the bucking. I think it might not actually be the clutch since when released carefully it is totally smooth with no vibration. It's been tough to pin down since it only does it excessively when actually driving, more when starting from a stop, but also when shifting gears if motor speed is not matched to next gear. I've tried blocking the car or holding the brake while letting the clutch out to slip a bit under torque and I don't get much doing that. I'm imagining this might be a motor mount but haven't seen good access points to check that. It seems particularly bad when starting in reverse, especially if backing up a hill a bit. Any ideas on how to troubleshoot this or check the mounts without having to tear it all down? Thanks.

- 6 replies

-

- clutch

- drive train

-

(and 2 more)

Tagged with:

-

Doesn't look so good to me. Looks like Aluminum, maybe something rubbing on a casing? Mine has 210,000 miles and after 10,000 mi the oil shows no wear contamination at all. My magnetic drain plug has a bare film of super fine black magnetic mush on it. Much less than I've seen on many other drain magnets. It's even been run with way too low oil when the cam seals fell out. I got lucky on that one. I've always used synthetic oil and high grade filters with about 12kmi between oil changes. Ditto on the oil test advise, since it doesn't look like enough to cause a noticeable engine problem (yet). You do need some miles on the oil for a good test result though, don't try to test new oil.

-

I don't recall the seal source. Probably not Subaru, maybe NAPA.. Never have trouble with NAPA seals in any other application. Don't see how oil pressure can cause this. No oil pressure behind the seal, and even if the drain hole is obstructed there's only about 1/8" of oil that can collect behind it anyway. I thought of the PCV and did check for crankcase pressure, but it's OK. A direct check of the PCV seems OK as well. I probably lubricated these seals with a good grease before pressing them in. Maybe that was a bad idea. I should probably stick to a thin oil in the future. I wouldn't want to use any adhesive, except maybe RTV so it doesn't make it harder to replace next time. In this case the seals are leaking again, but not fallen out. (that happened a few years ago but not again). I think it might mainly be the crank seal that is leaking now, which has also been replaced in the past (9 years ago?) Do the Subaru genuine seals really work better or last longer than NAPA? Thanks.

-

I've had a problem in the past with cam shaft oil seals working their way out and laying loose on the shaft. They seemed to fit plenty tight in the bore during installation, as expected. What's the deal with this, and is their a good preventive measure to stop it happening again? Adhesive,....? It looks like I have increasing oil leaks and need to do these again, and probably the crank seal as well. Hope I can get it out. Thanks.

-

Great. Thanks for that. Looks like there are 8 total and all should be replaced. What's the consequence of running without these?

-

I magnetized the plug myself. Parts are about 1" across. I always run synthetic oil. Oil is free of any metal fine contaminants. Nothing on the magnet. (Except those big pieces)

-

Hi, We drained the oil today and some metal parts came out. Looks like halves of some flat spring washer of some sort. Can anyone identify these parts? Does this mean my engine is dead? No other metal or grinding are present in the oil. One of these pieces cam out on the magnetic drain plug. I fished 3 more out with a magnet taped to the end of a wire. Does that account for all of "them" or could there be more in there? Photo attached. My son needs to drive this back to Utah next week. Too much to hope that it's something harmless I suppose. I might be able to drop the pan but I'm not sure if I can get to all the bolts around the frame mount without removing the motor. 1995 Subaru Legacy L wagon. 2.2L motor I think. Thanks.