-

Posts

5252 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Gallery

Store

Everything posted by porcupine73

-

Thanks, the rear pads and slider service fixed the squeal in the turns. Plus as a bonus the braking is much improved. I don't think the rears were braking much at all and were just along for the ride. The pin that siezed up it looks like water got in around the rubber boot. I cleaned the rust up on the outside of the pin. Something is wrong with the caliper bracket too. The rubber piece that goes on that pin was stuck inside the bracket and I couldn't get it out. So I nipped the end of the pin (where the rubber bushing goes) off with bolt cutters. I wasn't sure if that would work but it seems to be OK so far. I find I have to grind down the pad 'ears' on all my Subaru's, else the pads are too tight in the bracket. I remember there was a TSB out about that many years back. If you grid too much it will sometimes then make a 'click' when first applying the brakes but it isn't too bad.

-

Thanks, I took a look. The sound was from the left rear. When jacked up if i even rotated the wheel slightly it squealed like crazy. The pads were still pretty good but I replaced them. The bottom guide/lock pin was siezed. The pads were pretty well seized in the brackets too. I replaced them. Not sure what was actually squealing since the pads were still at maybe 50% and the little wear indicator things weren't there so it wasn't those.

-

Thanks, I am going to have to check it out. I think now that you mention it, in the fall, that was what I found, one of the pads was seized in the bracket. I think I filed it down a bit and got everything freed up, but maybe it is acting up again. It wasn't squealing at that time, just something I noticed during the check up.

-

2000 Outback wagon 180k miles, 2.5L n/a, AT. Lately it has been making a metal on metal squealing sound in right turns. But not in left turns. I am pretty sure it is coming from the rear brakes. What to check? If I press the brake medium hard in the turns, there is no squealing. It isn't the parking brake because the squealing is still there if I pull the handle in a right turn. I'm 90% sure it's from the rear brakes, I don't think it's from the front but it is possible. No sound in left turns. Lug nuts and everything seems tight; no obvious looseness anywhere.

-

If you're looking for a really quick and dirty fix, if you clean the area and put good duct tape or Gorilla tape on it that might help at least. But it probably won't withstand even the slight vapor pressure of the gasoline and you may smell gasoline around the vehicle. The only real fix is to replace the tube.

-

Finally got the new one in. I have to say off any car work I've done, this is the one I thought would take the least amount of time but has ended up taking 10 times as long as I estimated. Wrangled the new ball joint into place by unhooking the sway bar link and those huge bolts on the a-arm to shove it down really far. I was trying to jack up the rotor, but once the ball joint is out, wow that thing just becomes a wobbling mess and wants to move out away from the vehicle. Then I ended up getting in a hurry and frustrated at the same time and ended up with a nice gash on my head. I have to finish fixing the threads in the pinch joint. I had it all tapped, but when I drilled it out, something got messed up, and the threads don't line up with the other side of the pinch bolt. I messed up the new bolt for the ball joint by sticking it in the hole and since it wouldn't start, I put the impact wrench on and spun it really fast. It rounded most of the threads over against that indent on the pinch bolt. So I put a 3/8" drill bit into the hole and started drilling, and the bit caught in the hole and snapped it right off. Fortunately the bit came right out of the hole. So I put what was left of the drill bit back in the hole, it caught again, except this time my face was right next to the battery on the cordless drill. It hit me in the face and pushed my head into something sharp under the vehicle leaving a nice gash. So I quit the job for that day and just relaxed a bit. Being both frustrated and in a hurry is a bad combination on any job.

-

Thanks, yes I think that was part of the problem. I assumed/thought the whole bearing housing was tapered like the ball joint to help hold it in. I was surprised in some photos to see the bearing housing is actually smooth at the exterior, and it's just friction and the pinch bolt that hold it in there. Seems a bit odd but apparantley it works, unless you're trying to climb rocks maybe.

-

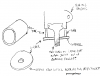

The lug nuts are metal. Haha just kidding. I don't know must be steel of some sort. They do seem a little soft, especially in the tapered portion. Interesting, the all-thread, do you mean you have that in M12x1.25? I was just thinking that a M12x1.25 bolt or threaded rod would let you couple it directly to the ball joint stud using say a lug nut, rather than have to drill out a larger size bolt and then tap the inside to M12x1.25. The snap-on tool from what I can tell, the external 'shell' tube part, has a female threaded hole through the end. Into that is threaded the 'coupler', which then has M12x1.25 threads to mate up to the ball joint stud. Then when you turn the 'coupler', it threads against the female threaded hole and puts tension on the ball joint stud, thus pulling it out of the bearing housing. It doesn't matter if the ball joint stud actually turns at this point - there will still be positive thead displacement against the female threaded hole to generate the tension. it's not entirely unlike the FWD wheel bearing tool kits.

-

For the ball joint tool. Hm I think that would work, if a M12 x 1.25 bolt can be found to go with it. Then thead a lug nut onto the M12x1.25 bolt, place it through the washer. Then screw a lug nut about 1/2 way onto the ball joint stud. Then place the pipe/tube over the ball joint, then thread the bolt/washer combination onto the ball joint stud end. Then use a wrench to hold the lug nut outside while turning the bolt to pull the joint out. Basically the same as the other homemade tools, except you wouldn't have to drill and tap a bolt. | M12x1.25 bolt |lugnut|washer|tube|lugnut|ball joint stud end| Hm threaded rod in M12x1.25 well even the cheap stuff isn't cheap. I have this local farm shop near me that has a wide selection of cheap hardware, I'll have to see if they have anything like that. Or some other Subaru bolt that is fairly long and has that thread, maybe the camshaft socket bolts?

-

I don't think it matters if the ball joint stud spins with the snap-on tool, because the threaded rod in the tool is still going to apply tension as it is turned to pull the ball joint out. Trying to find anything already tapped to M12x1.25 is tough, 1.25mm thread spacing is considered extra fine thread pitch for an M12 I think. Most stuff out there is threaded 1.75mm thread spacing in M12. I was hoping to find a piece of threaded rod that was alerady tapped to M12x1.25 but I haven't seen that kind of thing anywhere. Looks like the snap-on tools is fairly new, this was from June 2012:

-

Ah good point I didn't think of that. That would explain why the Snap-on version has its own built in screw to do the extraction. Usually all the good snap-on tools there's a cheap Chinese knockoff, but I haven't found one for this tool. Hm google search shows many different versions of a 'homemade' version such as http://www.subaruoutback.org/forums/99-do-yourself-illustrated-guides/46826-homemade-ball-joint-puller.html

-

The bull pin I believe you would drive in between the a-arm and the bearing housing. So it would work sort of like a pickle fork. Since I didn't have that bull pin, I used a cold chisel and a piece of metal stock to make up the difference, and drove it in there with a jack under the rotor, than let the jack down, I think that's what started to free it up finally. The snapon tool looks pretty slick. It comes up at $125 on their site, maybe off a truck or a dealer who sells online and ships it could be less? Didn't see any on ebay. How about a homemade tool something like this? I think it would be similar to the snap-on tool, except it would use the ball joint's stud itself to pull the ball joint directly. The tube could maybe even be just a piece of black iron pipe if there's a size with the right diameter. The washer could maybe be one of those washers from a wheel bearing tool. Maybe if one of the adapters in the wheel bearing kit is the right size that could be the tube, but I think they are too large.

-

YAH finally got it to come loose. Thanks for the tips. This thread maybe should get merged with the ball joint thread in the USRM? For me I think it was a combination of two things. First severe rust. Second, after, drilling out the pinch bolt, I think I didn't quite get it all out, and the residual metal was holding the pinch joint closed a bit. I used a metal jigsaw bit and 'cut' the reminaing material out of the pinch joint. Then pried it open a bit more. Then jacked under the rotor, and then crammed a piece of metal stock and a chisel between the bearing housing and a-arm (replicating the bull pin effect). Then I hammered around a bit, and put a chisel on the ball joint itself and hammered, and hammered on the stud end. Then I let the jack down and jumped on top of the rotor. I heard something let loose, and looked under and the ball joint was starting to come out finally! But it was still stuck. So I applied more Kroil, and then put the jack under the stud part, and jacked it back up, and jumped on the rotor again (trying to shove it back into the bearing housing now with more Kroil). It went in a bit, so then I jacked under the rotor again, and put a pry bar between the a-arm and bearing housing and really laid on it and it FINALLY CAME OUT!!!!!!!!!!!!!! ahhh dang it feels good when something finally works. Thank you!!! I find it odd all the commercial tools seem to be geared toward getting the stud part out of the a-arm, sheesh that's the easy part!

-

Thanks, I just ordered that bull pin, it comes on Friday. I have some bull pins but nothing nearly that large. It sounds like that would similar to how Ivan says he uses the axle shaft. I think I returned all my axles as cores but if I have one left I will try it. I ordered the OTC ball joint extractor, it should arrive today, but I don't think it will work because I think it's made more to pull the stud end out of the a-arm (rather than out of the bearing housing). That seems to be what the pickle forks I have do too. I soaked the whole area in Kroil again last night hoping it will seep up in there. I'll try spreading the pinch point open a little more. Maybe I don't have it open enough. At first I think some of the remaining bolt material I drilled out was keeping it from opening, but I think I have that all cleaned/drilled out now. On the plus side, so far, I have managed to not burn a whole in or tear the cv joint boot. Haha, I assume this is the gift for the person who has everything, a bull pin holster!

-

Thanks for the tips. So far ball joint = 1, me = 0. I've used a mapp torch, pry bar with a pipe on the end, pickle forks, the acura trick, beating the sides with a hammer, lots of Kroil, and it still won't let loose. I think I'm going to have to pull the whole bearing housing and take it somewhere to get the ball joint pulled out. I have the LIsle impact pickle fork set. Looking at it, I think it would help only pull the ball joint out of the A-arm, and not out of the bearing housing. I think it was a mistake to have tried that, since the ball joint stud feels really loose now. I put the lug nuts on backwards on the rotor, and jacked it up until that side just lifted off the jackstand, stuck a breaker bar between the bearing housing and a-arm, let the jack down, and started jumping on top of the rotor but it didn't do anything. I think my ball joint is majorly majorly rusted into the bearing housing. I may try the mapp torch again, I gave it as much as I felt comfortable giving without the cv joint boot getting damaged, and without a huge ton of smoke coming from the grease and ball joint rubber boot. I was almost thinking of putting some conrete anchors into the garage floor, and then wrapping some heavy aircraft cable around the a-arm and securing it to the anchors, then trying to jack up the rotor to see if that might hold enough force to rip it out? Oh wait a minute, how about a piece of strong chain around the frame of the floor jack and around the a-arm, then the jack pushing up on the rotor? That seems like it might do something, could put maybe 6 tons of force. Can the wheel bearing withstand that kind of force though without damage.

-

Hi, I can't seem to get the ball joint to come out of the bearing housing. I have the pinch bolt out (had to drill it out), and I put a chisel in the pinch opening and opened the pinch point a little bit. I put a large prybar between the A-arm and the bearing housing, but I can't get the ball joint to pop out. I could put a pipe on the pry bar and apply a ton of force but I almost feel like the stud part of the ball joint is going to rip out the ball end and leave the ball end in the bearing housing, is that possible? Is it just rusted in there and that's why it's stuck? Did I maybe not 'pry open' the pinch point enough with the chisel? Do i just need a ton of heat and penetrating oil? Thanks!

-

Thanks, it has never had a true 4 wheel alignment such as on a laser rack. I have done the toe and camber on all wheels myself, but that was probably three years ago. It does seem to pull to the left a bit, and the front left tire, well it is in rough shape, but it was somewhat like that when I put it on (borrowed the tires from a different vehicle). It might not even match the make/model of the other tires (but I run in FWD mode most of the time). I am happy at least that I didn't turn up anything suspiciuosly loose, other than that ball joint, in the shakedown. That tells me it's probably not unsafe to drive. The feeling is slight, it's very strange, noticable to me that it is different than normal but hard to quite put a finger on how to describe it.

-

Well my '94 and '96 Legacies have been treating me well. However they're really starting to get eaten up by rust. They're starting to get holes in the body panels. And the rear subframe is rusting out a bit, though it is still plenty thick and safe. But mechanically they're in great shape. I've repaired every little thing and taken good care of them. So I'm nowhere near ready to let them go. I'm not really into spending a ton of time on body work. I did some Bondo on the '96 and it's better than it was and is holding up pretty well, but it would be a losing battle to try to keep it rust free. It's just the way it is on a nearly 15+ year old car in this rust belt/salty area. I don't mind at all driving them. I love them. In fact in many ways I like them better than a new car. But sometimes at work I feel like people are looking at me like wow why is he driving that piece of junk. Not that I care so much what they think but the vehicle is definitely out of place. Maybe I just overthink things too much. Some other people have winter beaters there but mine man on the outside they're really starting to look rough. I've been using paint to paint over the rust areas. That doesn't look the best, but it's a quick touch up and i think it looks a lot better than rust stains leaching down the side of the body. What do you think?

-

Hi, in the last week I've started to notice a strange feeling in my '96 Legacy Brighton 2.2L AT 130k miles. It's hard to describe. It seems like it feels slightly fishy on the highway, like it will drift in the lane just a bit. It's not very bad, and it has been pretty windy the last week, but it just feels odd. In turns it feels funny too. It almost feels like inside rear weel in the turn is going to lift off the ground. I know it isn't going to but it just feels strange. It doesn't feel unsafe at all, it is just something different from normal. Do not feel any strangeness or freeplay in the steering wheel. Now a couple of the tires are in a bit of rough shape, tread really worn down, definitely need replacing. Not sure if that's it. I shook the entire suspension down. Everything is tight, struts and springs in good shape, tie rods inner and outer good, wheel bearings no looseness, strut mounts good, sway bars and end links good. Lug nuts all tight. I always check that first because I've had them loosen up on me a couple times in the past. That was when I was trying to use a torque stick instead of a torque wrench though. Acts the same in AWD or FWD. The one thing I did notice is the right ball joint is loose. It has noticeable freeplay when using a pry bar on it. Could that be causing this feeling?

-

Thanks for all the great tips, I appreciate them. I'll have to see what I can come up with. I want to build a nice size walk in coop for ducks, like 8'x8' at least or 10'x10' maybe. But it looks like to build that out with plywood covering would cost more than just getting say a metal shed of the equivalent size. Though I hear the cheap sheds tend to rust out within five to seven years.

-

Can you carry 4'x8' sheets of plywood in/on a Subaru wagon? I have a 94, 96 and 00 Legacies. I think they might fit inside the tail at an angle, but with maybe 2 feet sticking out the back. How about on the roof rack? Can you somehow strap them down tightly enough to make it home without losing them if driving carefully? I was thinking something like these ratchet straps? Maybe keeping it to just one to three sheets at a time to keep the weight up there down? I did it once with an Explorer many years ago but I just was afraid I was going to lose them on the road the entire time. The local store wants $69 minimum for truck delivery so I'd like to avoid that if possible.

-

I was going to replace the switch on mine but the limited access with the exhaust in the way made me just bypass it. Mine eventually got so bad that sometimes I would have to hold the key in start and keep moving the shifter from park to neutral really fast until it would finally crank. I put in a heavy duty pushbutton from NAPA with a fuse off batt +, to the pushbutton, then to the starter solenoid. It's been working great so far. Maybe not the best idea to bypass the neutral safety, but I'm the only vehicle driver so I don't have to explain how it works except when I go in for inspection. On mine I think the ECU thinks it is always in gear, it does slightly funny things with the idle.