Gloyale

Members-

Posts

10955 -

Joined

-

Last visited

-

Days Won

86

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Gloyale

-

Power for the headlights does not run through the switch. Ground does.Power goes straight from frusible link,through relay, through fuses 7 and 8, then straigh on out to headlights.Red w/Black(RB) wire gets grounded by the switch for Low beams. Red w/White(RW) wire get's grounded for High beams. Instead of testing for power through the 12v side of the cicuit, test for high resistances in the grounding part of system. RB and RW wires at each lamp should have continuity to ground when Headlight switch is in each respective position.

-

Specs I have show that the 85 carbed car would have a 9.0 compression, not 9.5 like the SPFI. This may be something here. Slightly lower compression might be just enough to increase reliability.

-

Seems like you should be fine to drive it. But the Hazard thing is the most alarming thing you have mentioned. As far as removing the dash, it's not as hard as it sounds. It's held by 3 bolts along the top(pry off little covers to get access)And 2 bolts under radio area, and one at each end, low. The center shifter cover/console has to come out to get access to the 2 in the middle. There are 2 cables, one for the drivers vent(easy to get once the dash is out slighlty) and one for the heater that's get's unclipped on the drivers side of the center hump, up near gas pedal. Then all the big electrical plugs at both ends of the dash need disconnected. Now undo the 2 bolts that hoild the steering column, and lower it. Your dash is ready to come out. I like this way because all the wiring and switches all stay inplace in the dash. This will give you the most access to really assess any corrosion and leaking issues. However, just a though, the hazard flasher could be malfunctioning in such a way that it is grounding the 12v power when you hit the button. I would think the fusible link would then blow and the car would die. So it is worth checking/testing that relay before going to extremes to solve. Is there any problem when you use the Turnsignals? the hazard/turn system uses the same flasher. I imagine that you're problem is somewhere in the Fuse no. 5 circuit. It is the 12v source for the hazards as well as for the ignition relay. Blow fuse 5, car dies. If he turnsignals do nothing, then I am guessing the Hazard switch itself may have a short? But if in fact you're problem is corrosion, then dash removal will make finding it(and sealing the firewall) Much easier.

-

Cant find the right shocks for my 1987 gl wagon

Gloyale replied to glwagonman's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I am not sure what Tom is talking about excactly. Am I misunderstanding what mean? Are you talking about the coil-over rears on wagons? or are you talking about the ea81 hatches and brats and the like? EA82's don't have "cartridges" to swap. they are a modern sealed onepiece strut, with a springseat for the coilovers. Disassembling the coilovers without spring compressors is dangerous. If you really need to do it without compressors, here's how. With the vehicle on the ground, reach up to the top of strut and undo the 2 locknuts at the top of strut shaft. then slowly raise the vehicle with a jack. This will slowly let the force of the spring off. then you can remove the strut the rest of the way. But I don't wanna hear of anyone getting hurt. -

The Final Cut. And Thanks

Gloyale replied to robertwheeler's topic in Old Gen.: 80's GL/DL/XT/Loyales...

O2 sensors for ea82s cost like $17. simple one wire generic bosch O2 sens. That coolant temp sensor is a bit more. How'd you get to $133? -

Disconnect those connectors. they are not supposed to be plugged in during normal driving. With BOTH of them plugged in you are in "clear memory" mode. you won't get any codes but the model designation code. 5= SPFI MT With both unplugged(u-check), the light will flash current codes. With just the green ones plugged in, run it at 2000 rpms for more than a minute, the ECS light will flash. This make the ECU do a diagnosis of everything and output codes. this is D-check. With just the white ones plugged in(read mode) you can output stored codes from the past, that may not be active now. This is good for tracking down connection issues. Code will set briefly when there is bad contact, then go away. but it will stay stored in "read mode" Plugging both in at the same time and running the car for 45 seconds clears all codes.

-

FSM shows the following LH relay plug as Green 4 poles plug. Wires in it are: thin Black wire, Relay ground fat black wire, Ignition 12v Black w/ white wire, 12v from Fusible link 2(red) Black w/red wire, 12v output from relay, feeds fuses 6 and 7 RH relay uses a black plug. wires are as follows. Thin Black wire, Relay ground Fat black wire, Ignitoion 12v Black w/ white wire, 12v from Fusible link 2(red) Black w/ yellow wire, 12v output to fuse 8 BR and BW wires that feed the fiuse panel are the ones you should check for continuity between relay and fuse. Hopefully this helps locate the relays

-

It's kinda hard to get them down, but there up there. If you remove the lower dash panels, and then remove the 4 little screws that hold the fuse box and let it dangle down, it's pretty easy. All that's needed is a phillips and alot of Yoga.

-

Diff lock and manual instrument cluster

Gloyale replied to Caboobaroo's topic in Subaru Retrofitting

You could still scavenge all you need as far as a shifter with pushbutton 4wd switch and use it as your diff lock switch. Grab all body harness too pigtails to plug all your solenoids, D.Lock (4wd)switch, Diff lock indicator switch(on trans), etc into. Wire you're stand alone setup with that, so it can all go into something else(crawler) later. In a similar but less complicated swap, I just recently relocated my "1 hold" switch on my 4EAT GL. I used a shifter and button from a PT 4wd 3spd. It's great to have those essential shifting buttons ON THE SHIFTER. Funny how that works. No more grabbin second only to abrubltly get first. -

I think johnceggleston might be on to something. Nipper is correct that th square wave generated by the rear speed sensor is not replicaple by a resistor. However the sensor does have a simple resistance value, and placeing a resistor of that value in it's stead would make the TCU think it was still there. It wouldn't see a wave from it, so it would assume rear driveshaft speed as zero. I am not sure how this would affect the TCU's control of the split? I guess I'll have to try it. Too bad all the snow is gone for a real test. I'll have to go find some mud!

-

dang it... car wont idle again

Gloyale replied to misledxcracker's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The A/C relay is mounted above the pass side strut tower. The fan realy is next to it. Have you tried adjusting the idle screw? it may be backed out too far, and as it tries to die, the ECU compensates? Idle screw is on throttle body, just behind the IAC. right side off throttle chamber, between throttle bore and IAC. Warm it up and disconnect the IAC connector before adjusting. Also when you are setting the timing, are you disconnecting the TPS? -

starts but wont stay running?

Gloyale replied to 1slow_si's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Test MAf -

Relays are way up under dash, mounted in a bank of 4, hard to see but they are up there, to the left of steering column, mounted to back of dash face. Kinduv up above the fuse box.

-

Diff lock and manual instrument cluster

Gloyale replied to Caboobaroo's topic in Subaru Retrofitting

How about wiring it through a part time 4wd switch? Both are the same type off SP/DT no off switch. The diff lock switch just has 2 extra wires for illumination of the switch and those can be ignored for this purpose. I'll bet you've got a Part time shifter assembly sittin around right? The solenoids for diff lock are the same as the ones for part time shifting, and use the same connector in harness(F96) This would accomplish the switching action. For illuminating an indicator, the diff lock Ill. switch, mounted on trans, can be plugged right into the harness wherte the 4wd indicator switch plugs in. FSM shows them as the same connector(e24). Then you're 4wd or diff lock light will illuminate depending on which cluster you use. If you are swapping into a S/R PT4wd car it should be EEEEEAASY. If Car was originally D/R, you'll have to add wiring for the solenioids and light switch. But solenoid can all be got from a S/R PT4wd -

I think there is confusion. At least I'm confused. Are you talking aboput Physically welding toghether 2 engines into one? or are you talking about externally coupling the 2 into one drivetrain? I think welding toghether is the coolest Idea I've ever heard of? Didn't Subaru produce a flat 12 for Formula1 for a short time?

-

You're measuring the resistance of that circuit of the ECU The Black w/Red(BR) wire should have full continuity to ground. The White w/black(WB) wire should have a similar continuity to ground as it does with BR wire. 1.75 ohms for CTS? that is nearly full conductivtity? that is way low? the CTS should measure as follows: temp=resistance 14f = 7-11.5k Ohms 68f = 2-3k Ohms 122f = 700-1000 Ohms Runnning Temp for D-check(approx. 190f)= MIN. 100 ohms. 100 Ohms is the lowest resistance value the CTS should ever have even at running temp.

-

Motor Trend 1979: Wagoneer v.s. DL

Gloyale replied to kevinsUBARU's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I wonder if they happened to keep track of gas milage and cost? yikes! -

This is one of the few ways you can actually destroy an ECU. But the fuel pump not working with battery voltage? That sounds strange. I'm guessing the ECU still. Do you get all the indicator lights before starting? Meaning, ECS, Charge, Oil, Stop,etc.. with the key on/ eng. off? If not, then you may still have a no power/no ground issue. Check the fuel pump relay perhaps? it's mounted to the steering column, may be obscured by the ecu, just unbolt and lower the ECU for access. If everything has power, and the relay works, then you should get a flashing ECS light and the fuel pump should cylcle in time with that when green connectors are connected. The white "read" connectors are under the dash. SPFIs had that peculiarity of the seperated read and test connectors. Swap ECU's from somewhere? I would try to jumper that fuel pump again with a good 12v and ground, Blue is +, White is ground on pump wires. Hope this helps Dleo

-

dang it... car wont idle again

Gloyale replied to misledxcracker's topic in Old Gen.: 80's GL/DL/XT/Loyales...

This could be a line pressure issue in the transmission? 3AT I am assuming? High line pressure will cause the clutches in the tranny to remain engaged so the engine is basically fighting the stopped drive train to stay running? This is just a speculation on a possiblity, not a diagnosis. The Fan thermoswitch may have failed? Or the relay? Has someone wired it "on" in the past? There's also a chance it could be the A/C switch assembly or the A/C relay failed? Does the A/C compressor clutch engage whether or not the A/C is on. -

Could it be your power steering pump.It could be it bogging down that try's to stall the motor. Happens at full lock right? It could be that another part of the PS system is overloading the pump. But it is making the Pump squeal. And the pump is located on the right front of engine.

-

It is also very important to note there are three different thickness of rotors for EA82 pumps. The most common is the one stamped "B"( and you thought that meant block, I did 10 years ago) as that is the depth Subaru spec'd for the recess in the block. Variations in the milling process required the use of sizes "A' and "C" in order to match inconsistant blocks. Also so that slight wear can be compensated for by bumping up a size when replacing. Rotor thicknesses: A=13.90 +-.01mm B=13.91 +-.01mm C=13.92 +- .01 mm I wonder how many people actually measure? Use the wrong one and you could end up with low pressure still. or tearing up the pump recess in the block. I'd hate to see a C stuffed in an A. (actaully I have, it's nasty)

-

1. On an EA82, Oil pump shaft RPMs are excactly the same as crankshaft RPM. their respective timing belt pulleys are the same size. 2. I don't know about your 83 EA81 FSM, but my in my 85, 86, 88, and 89 ea82 FSM's there is a flowrate given. 2 ltrs/min @550, 31.2ltrs/min.@ 5000rpmsAlso in 88 and 89 FSMs there is an additional chart specifically titled "Reference pressure with oil pump equipped on the engine is as follows" Conditions: oil temp=212 f cooling fan off 10w-30 Oil Values 2000 RPMs = 14-26 psi 4000 rpms=34-46 psi Note that the values are in a range that is around that of the intitial pump "bench test" chart. It figures they would match the test conditions to running conditions. They would have to in order to gain and publish valid data. Hopefully this helps complete the picture for everyone.

-

Not too big of a deal. Can't really harsh on it for that. Just be SURE the screw is tight and use blue threadlocker and it'll never happen again. whoever installed the last rotor didn't do it right, or it had been neglected way too long and worked loose. Seriously? car dies everytime you hit the hazard lights? Instantaniously? or gradually? Pull the dash. The whole thing. (there is a good write-up in the USRM under heater core swap that descibes the process. Then all the wiing totally clearly and easily accessed to look for damaged wiring. And get in there with sealer of some sort. on that leak while you're at it. Ohh,,,and I guess that,,,, or and don't hit the hazards. It would STILL be very helpful to know the Model, year, and engine setup. ie: Carb, MPFITurbo,SPFI

-

Hey man, pass the Air conditioning to the left.

-

Wrist pins blocked. Shifted cylinder liner?

Gloyale replied to Gloyale's topic in Old Gen.: 80's GL/DL/XT/Loyales...

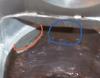

Here are some pics of the cylinder walls with the block split. Blue outlines where the notch in the sleeve should be. Red shows where the notch in the sleeve is now sitting. This is the only one that did not spin. this is what they should all look like