CNY_Dave

Members-

Posts

2032 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Gallery

Store

Everything posted by CNY_Dave

-

It is most likely simply low on refrigerant, my 03 H6 needed a can at 160,000 or so. If it doesn't last a season or two I'll chase down where the leak is. It could be other problems, such as the rev sensor or even the clutch itself. First step is to get a gauge on the low-pressure side, I have to imagine you could get a garage to just check that and then do nothing more for not much money. If it has enough pressure that it should be running, try pressing on the A/C clutch/pulley with a stick of wood, try to force the plates together. If it runs when you apply pressure the clutch needs to be maybe cleaned, maybe needs to have a shim removed.

-

My legacy/outback manual says the nut (which is supposed to be replaced) is 137 ft lbs, the bolts are 181 ft lbs. It also says there is supposed to be a gap on both sides of the bushing, 1.5mm in front and 1mm in back, gap adjusted by moving the bushing on the arm and using the oval holes in the bushing mount. It also says to scribe a line across the old bushing onto the control arm, then align the marks on re-assembly. For a new bushing I guess you have to transfer the mark from the old to the new bushing.

-

Could be they didn't adjust them enough, does the lever show some resistance when you yank it up? How many clicks? Could be the shoes or the drum are contaminated, you might try driving slowly, holding the button down, and pulling the lever up to where it has some resistance to scuff the shoes and drum a bit.

-

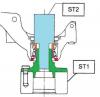

Here's a pic from the manual I colorized. It shows the pressing operation partway through. There are no instructions on how far to press the parts together, and the only way the pressing operation will stop is if a) ST2 hits the hub (green) when the orange race is flush with the hub or the bearing race (purple) bottoms on the flaring part of the hub. Now, if the hub were to bottom against ST2 then there would be no preload on the bearings because ST2 is just a stand-in for the axle, so it stands to reason yuo keep on pressing until you achieve (. The oil seal is colored red.

-

This shows what I mean even though it's for a bimmer, and shows ball bearings not rollers. For the preload to be set, the outboard inner race "1b" must contact the lip on the hub, and the inboard inner race "1a" gets pressed against it by the axle itself, until the inner races touch. If you don't drive the outboard inner race "1b" all the way to the lip where the hub widens, it'll happen when you tighten the axle nut, assuming the race slides on the hub before you reach full torque on the axle nut. So I believe the correct answer to 'how far' is 'till it won't go no more'.

-

Maybe this explains it- the part of the race that 'grips' the hub then flares out a bit, and that part fetches up against the wide part of the hub. http://imageshack.us/photo/my-images/87/dsc04785s.jpg imageshack.us/f/87/dsc04785s.jpg from http://legacygt.com/forums/showthread.php/front-wheel-bearing-diy-walkthrough-86994.html?p=3240125