-

Posts

118 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Gallery

Store

Everything posted by dirty_mech

-

Thanks Numbchux for the heads up about the possibility of this being an oil pressure issue, as well as the guide on how to identify dropped valve guides. I do track and do all my oil changes with top quality materials and I do use a thicker oil weight. I can't rule out the possibility of either. But based on the recent discovery of the same vibration at times in lower gear, I'm starting to bet on a powertrain or suspension issue. I'll still ask the shop about checking my oil pressure, which sounds like a great idea regardless. Guide clearance was set correctly to my knowledge; the timing belt came with a guide tool for that purpose, which I reused when I did the water pump.

-

So I haven't replied about this for a month because I've been trying to fix it the whole time. I was waiting to solve the issue so I could come back to you guys with a neat little story to share. Unfortunately it's been a wild goose chase and now believe the problem isn't an engine issue at all. So let me share something I previously left out because I didn't think it was relevant. About 30 miles before this whole mess started, I hit something on the freeway pretty hard. It was night and I was going 80 and it felt like I hit something about the size of a 4x4" piece lumber laid across the freeway in the dark. Sent my front end flying up into the air for a second. Stopped to take a look and didn't see or detect any obvious damage. Figured I'd have to get my alignment done in the near future just to be safe, but it didn't seem to cause any problems so I just kept going. By the time that vibration developed later down the road, it didn't even occur to me that hitting an object on the road much earlier could've been related to it. The issue was behaving so much like an engine problem, even getting better if I parked and let the car cool down. You guys know I checked the timing belt and found nothing. Since then, I checked and replaced the spark plugs which hadn't been replaced since August 2020, 30k miles ago. A couple of them were heavily worn, with a gap of over .060 compared to the maximum 0.43". I also adjusted the valve clearances, most of which were out. Between those two major issues I was sure that must be the problem! The engine certainly ran noticeably better afterwards. I also did the oil and air filters and checked basic stuff like the battery cables. All seemed good for a bit. I was about ready to write back here that I'd fixed it by tuning the engine. However the problem developed again on the freeway. That's when I remembered hitting that object on the freeway the night the issue developed. So I checked my front tires and noticed each tire had only one weight. Had the tire shop rebalance them and sure enough both were way out. They rebalanced the tires (dynamically with two weights). The car began vibrating less overall. However the vibration during acceleration and heavy engine load is still there, and got worse during extended driving just like before. So I tried replacing my ignition coil and spark plug wires. Can't tell if that made any difference to the sound and performance of the engine (maybe a little), but the vibration is still there. Even checked the cylinders with a boroscope; the ones that had bad spark plugs were a little more carbon encrusted but fairly comparable to the others. Then I started my car one morning and drove off. While hitting the gas pretty hard in first gear, I felt a big wobble and vibration as the engine transmissitting power to the wheels. The same damn type of vibration I feel when I get on the freeway. This is what made me all but sure it's a powertrain or suspension component issue. I must have caused some sort of internal component damage when I hit that object going fast on the freeway. Les Schwab looked under the car and didn't see anything wrong. I also just went under the car and didn't see anything wrong either. Saw a couple of places that might show where I took impact damage from the object on the underbody shell, but there isn't any visible damage or even impact marks anywhere near the suspension or powertrain components. So I'm about to finally take this tin can to a Subaru mechanic and hopefully they can pinpoint what is going wrong. I've got some guesses but at this point I'm getting tired of guessing. If you have an idea what could be causing all this, save it for the new thread I'm about to make. This one is so old and on such a different premise that I think it warrants a fresh start.

-

After owning a 2000 Legacy L wagon for 7 years so far, I don't regret it. However I wouldn't do it again due to all the age-related maintenance. Your daughter has a 1995 model so I suppose you both have an idea of what you're getting into? I love my 2000, still own it, but sooo much damn maintenance and parts failures. If you're a young mechanic then maybe, but be prepared to do unscheduled maintenance on the regular. If and when I get a new car it will be another Subaru, but I'll be looking in the 5-10 year age range. From 15 years on you get a lot of components that start to go bad. Starter, alternator, fuel pump, starter relay, fuel pump relay, both oxygen sensors, the catalytic converter, hydraulic clutch cylinders, several different suspension bushings and the water pump have all gone out on me. The timing belt is rubber and a regular maintenance item too which you will need to either be certain when it was changed or change it right away. I've also changed out countless small things like the turn signal indicator, the control for the driver side windows, the hydraulic shocks for the rear hatch, rotten rubber hoses and many other small things. I've also had to do age related things like restore the headlights and nuke the cabin air ducts with fungicidal spray to clear out the mildew smell. On top of all these age related mechanical issues you have the age related cosmetic and interior issues. The foam in the seats ages and starts to crumble in some areas, and the paint is cracking like alligator skin. Sure nothing particular to a Subaru but why deal with all that when you can just buy a newer car? Any extra you save on the price will be lost paying for unscheduled, age-related maintenance costs. If you're paying a retail mechanic for maintenance then forget about it - older will be more expensive over time. I can't even imagine how broke I'd be if I couldn't work on this car myself. I'm in California where there's also no real salt or rust to deal with, so my Subaru was in relatively good condition to start. I made the mistake of trusting the last owner who said he recently changed the timing belt, which snapped. Not the car's fault but I did replace the valves clutch and head gasket in a major job during first year of ownership. I also replaced the struts twice, once when they went bad and a second time with Outback struts for the height gain. Legacies are low to the ground and will scrape a lot of stuff if you live in an area with uneven terrain, potentially causing additional damage and maintenance (scraping busted my cat). Did the clutch again because a standard grade clutch wasn't strong enough (Exedy 15801 proved an excellent upgrade). Did the head gaskets again because a combination of poorer quality non-OEM gaskets during the first job and not changing the coolant soon enough rusted them out. Coolant also protects the cooling system from rusting until it gets too old (2 year change interval). If you notice your coolant turning red, it's probably from your MLS head gaskets rusting away. It's what happened to me and I'm pretty sure this is a major source of the infamous Subaru head gasket blowouts. Very religious about my timing belt and coolant change intervals now! The car is great when it doesn't break down, which is reasonably infrequent - perhaps once a year on average. It did also teach me a lot about working on vehicles. I'd recommend it as a starter car for a mechanically inclined teenager or college student, or anyone on a limited budget with free time on their hands, or as a backup or project car. Your 21 year old daughter might find it a nice upgrade if there's someone in the family who can help out with maintenance. The handling and extra bit of engine power would be a definite upgrade over an earlier EJ22 Legacy. But if you can afford it then consider a newer model Subaru. The components will last longer. A lot of stuff goes bad after a car gets past 15 years old. If you're going to buy one of these older Subarus and aren't in a hurry to make a purchase, then I'd try to buy one that's already broken down or on auction for cheap. 2K is what I paid in 2014 for my 2000 Legacy. It didn't have a leaking headgasket either, but I guess that' s the cost of inflation these days? I don't know about external leaks; mine was an internal one between coolant jacket and cylinder, so lots of white smoke. As an aside, it is possible to replace the headgaskets without removing or even unbolting the engine, it's just an awkward angle that's rough on the back. At least be ready to invest in maintenance because it will need it soon enough.

-

OK so I'm considering hanging onto it for the weekend to do valve check and adjustment as needed, to at least eliminate that as a possible cause of the problem. I think I actually did do the adjustments when I replaced the valves because I had the whole engine out of the car and was very meticulous about the steps. But still it's been 7 years and 70k miles since then. Could improper valve clearance cause these issues? An engine tapping noise that gets worse with heat and engine load?

-

Well I just wasted a bunch of time doing very little. Had a new timing belt and tensioner ready to go, uninstalled the old belt and checked everything, then decided it all looked good and put it back together. No issues detected. The new tensioner is identical to the old one, which makes me think that Gates perhaps got the tensioner for their kit 7 years ago from them: I also discovered that the "microabrasions" on the Dayco belt are from the AISIN water pump I installed back in December after the old one sprung a leak. The AISIN water pump pulley has a grooved surface, which imparts the grooves to the belt. I presume it doesn't hurt the belt, but it does annoyingly remove the branding and timing marks, making it harder to reinstall later. Not easy to see the surface in this photo but it's there: So now I'm all out of ideas. My best guess is it is a valve issue or engine control component if I'm lucky, or possibly a fatal issue requiring a rebuild. I'll probably be humbling myself tomorrow and bringing it to a Subaru specializing shop to diagnose. Will let you all know what I find out.

-

It's more of a rhythmic thumping vibration noise. I used the word knock but not in the sense of predetonation. I've had a spark plug wire go loose on me so I know what a nonfiring cylinder sounds like. And I've had my timing belt improperly installed on an old EJ22 so I know what misfiring like that sounds like. These are neither. Engine performance doesn't seem to be affected except for the vibration. My underbody is pretty impeccable. I've replaced the front CV axles, all the struts and shocks, and every damn bushing I could identify. Many control arms replaced. I've put a lot of time into getting the underbody in good shape to eliminate possible sources of weird annoying noises and to ensure my alignment is good. I wouldn't rule out a differential or even the manual transmission going bad, but all the small stuff has been buttoned down. I see no difference when turning. This seems completely unrelated to turning, road speed, or engine speed, only engine load, which is what makes me suspect an engine mechanical or engine sensor / ignition device issue.

-

The noise is completely undetectable at engine idle or coasting downhill on the freeway in neutral. If I were to rev the engine, then I might hear a faint hint of it mixed in with the normal engine background noise, but the only thing that makes it loud and vibrate is heavy engine load after being run hard for several minutes. Once the noise becomes prominent, it can still be detected in the background at lower speeds and engine load, but it's hardly noticeable. When it first started, I thought I had hit a rough patch of refinished road that you will sometimes hit on heavily used freeways. That's what it felt like at first, but I soon realized it was an engine issue and not the road or my tires. It's entirely possible that it's something like pre-detonation, low compression, or excessive oil consumption. I didn't have my heads machined when the timing belt snapped in 2015, so compression could be bad, but it's been running 7 years without issue so far. It does certainly consume oil too, but isn't that pretty normal with an old Subaru like this? I thought I noticed it consuming a little more than usual recently, so I will keep an eye on that oil level. It normally consumes about half a quart every 3 fill-ups, so perhaps a quart every 1500 miles? It will consume less with freeway driving; street and heavy traffic driving are what eats a lot of oil for me. I filled up about 50-75 miles before this started happening, at a Shell station. I doubt the gas quality is the issue. What I DID do before this happened was a 200 mile roadtrip and some driving in the town I visited. The noise started on the way back. I actually drove it nearly 200 miles home with that noise, keeping revs high and my gears and speed low to mitigate how bad the sound was getting. I was stopping every one or two freeway exits to check the timing belt and other items under the hood. Once I realized the timing belt wasn't deteriorating, I drove it the rest of the way home, moderating my speed and gears to minimize the noise and vibration. My O2 sensors were both replaced in the past 2-3 years; my catalytic converter is a brand spanking new one from Bosal and I made sure the O2 sensors I used were new. My upstream O2 sensor went bad about 3 years ago, causing me to stall out on the freeway, so I'm familiar with that issue. Both O2 sensors are Denso brand; I see I replaced the upstream O2 sensor first in April 2019. I've never had my valves adjusted. Literally never. Maybe I did it when I had to reassemble the heads after the timing belt snapped, but I don't recall doing so. So I'm guessing you recommend I should get it done. Is that something I could do myself, or is it better to have a shop mechanic do it? When the cam belt snapped there were no significant marks on the face of the pistons. They left cosmetic marks but no substantial indents, and I didn't detect any damage to the cylinder heads either. The valve heads were just bent off to one side at the base of the stem. That's why I felt confident in replacing the valves to fix the issue, and it worked.

-

It's not an old belt, I changed it less than 2 years / 30k miles ago when I redid my head gaskets. The surface of the belt should still have visible branding (it's a Dayco) but it's completely rubbed off. Something is going on inside the timing case. I'll be opening it up tomorrow or possibly Friday night. If I'm able to detect a defective idler pulley, there's multiple junk yards I can source a used OEM one from nearby on the spot. I checked my records and the timing belt kit I used 7 years ago was a Gates TCK307. I'm less worried about the belt being aftermarket because I check it regularly and change it early out of paranoia anyways. That and Gates seems to be the best aftermarket available and has good reviews. But maybe Mitsuboshi is better. I didn't realize that was an actual brand and not some Chinese knockoff.

-

Yeah that is weird. My tensioner is definitely a cheap aftermarket one from a kit I bought 7 years ago, so the tensioner failing would not be a surprise at all. I think the wear pattern on the belt is an indicaiton there is likely something going on inside the timing housing to cause the noise. Maybe its a bearing in an idler pulley rather than the tensioner. Hard to tell. I'm going to at least start by replacing the belt and tensioner (AISIN BTF-500 tensioner and Gates T307 belt).

-

I suspect this is the issue. The smooth side surface of the timing belt doesn't look normal - it appears to have microabrasions as if it's rubbing against something or contacting a surface it shouldn't. I'm also pretty sure I noticed more slack in the timing belt when it was hot vs when it was cooler, but it was difficult to say. I'm going to pay more attention to it with the cover off hot vs cold, and will also try revving it while hot and see what it looks like. Will update soon on the result. I don't think it's the cv joints because the noise is completely absent when the engine isn't absolutely piping hot from extended driving.

-

The EJ251 doesn't have rods, it has rockers that contact the cam lobes and valves directly: But yes I agree it sounds like an engine mechanical sound. I just don't get why it takes so long to develop when driving. That part makes me wonder if it could be an external component like a pulley or an electronic component, but the noise is definitely mechanical. Maybe i just need to pull the valve covers off and look at it while rotating the crankshaft or something. I'd like to try your test with the oil pressure gauge. However the noise mostly only occurs on the freeway, and certainly only when moving. No engine load when at idle so no sound. =( Still I'm glad to know that it wouldn't be a timing belt tensioner. That's my # 1 fear. I've already replaced all the valves in this engine once when the belt snapped in 2015.

-

Hi guys. I got a weird one this time. My 2000 Legacy wagon M/T 230k has developed a knocking / thumping / vibration noise that only occurs under certain conditions. First the engine must be warmed up a lot - not just operating temperature but 5+ minutes of freeway driving. The sound will begin as a tiny vibration like a tire lost a weight or started to go flat. Then the vibration will get stronger and the knocking in the engine background noise becomes more distinct. The vibration can be felt very well thought the stick shift, and it gets strong enough that I'm afraid it will lead to engine damage if I push it. This just started last night. I ended up stopping a lot on my long trip home, giving the engine time to cool which seems to temporarily reduce the knocking. I also ended up using 4th and even 3rd gear on the freeway at high RPMs to reduce the strength of the knocking noise. The noise is probably an engine noise and not a suspension or drivetrain noise. It doesn't really increase with speed or RPMs, only engine load after being very well warmed up. My first thought was a bad timing belt tensioner or idler pulley. I was very careful of this possibility coming home last night; I checked the belt multiple times while making stops. It seems to be holding up but there may be a wear pattern on the surface of the belt that could indicate a defective pulley. I'm not sure if its appearance indicates a problem or not so I've attached a photo below. I'm also considering the possibility of a defective or misadjusted engine part such as a ring, bearing, or valve. However there is no noise when the engine runs cold, and not even when it's fully warmed up, but only after it's been running for a good while. This leads me to believe it is more likely something external to the engine such as a timing belt pulley or perhaps an ignition component such as a bad coil. I suspected the possibility of a clogged air or oil filter, and changed both with the oil today; no change. Does anyone have experience with such a type of engine noise? It sounds like piston slap, a misadjusted valve, or something similar. Does my timing belt photo indicate any problem? Thank you for any help or ideas. I'll post the answer here once I find it.

-

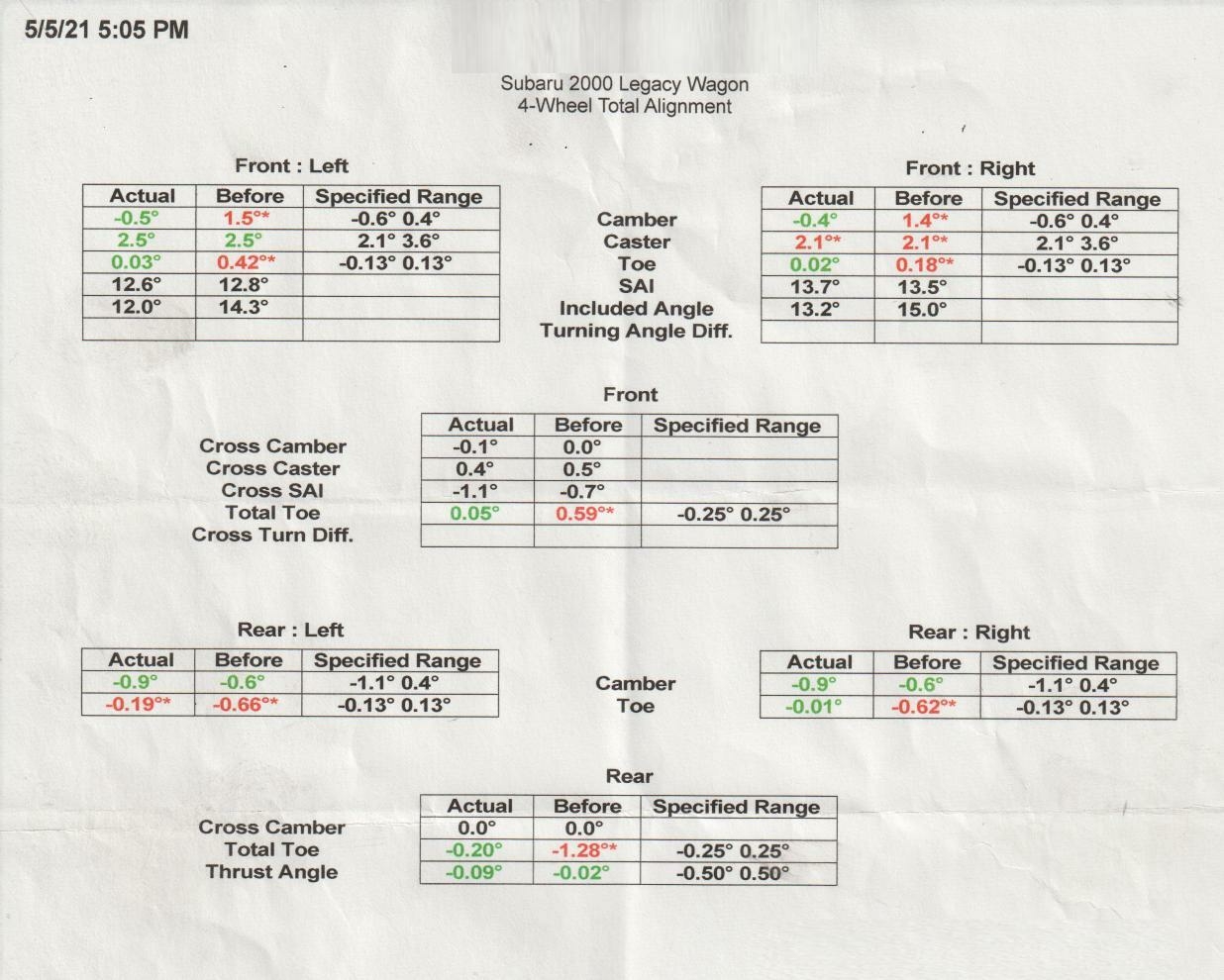

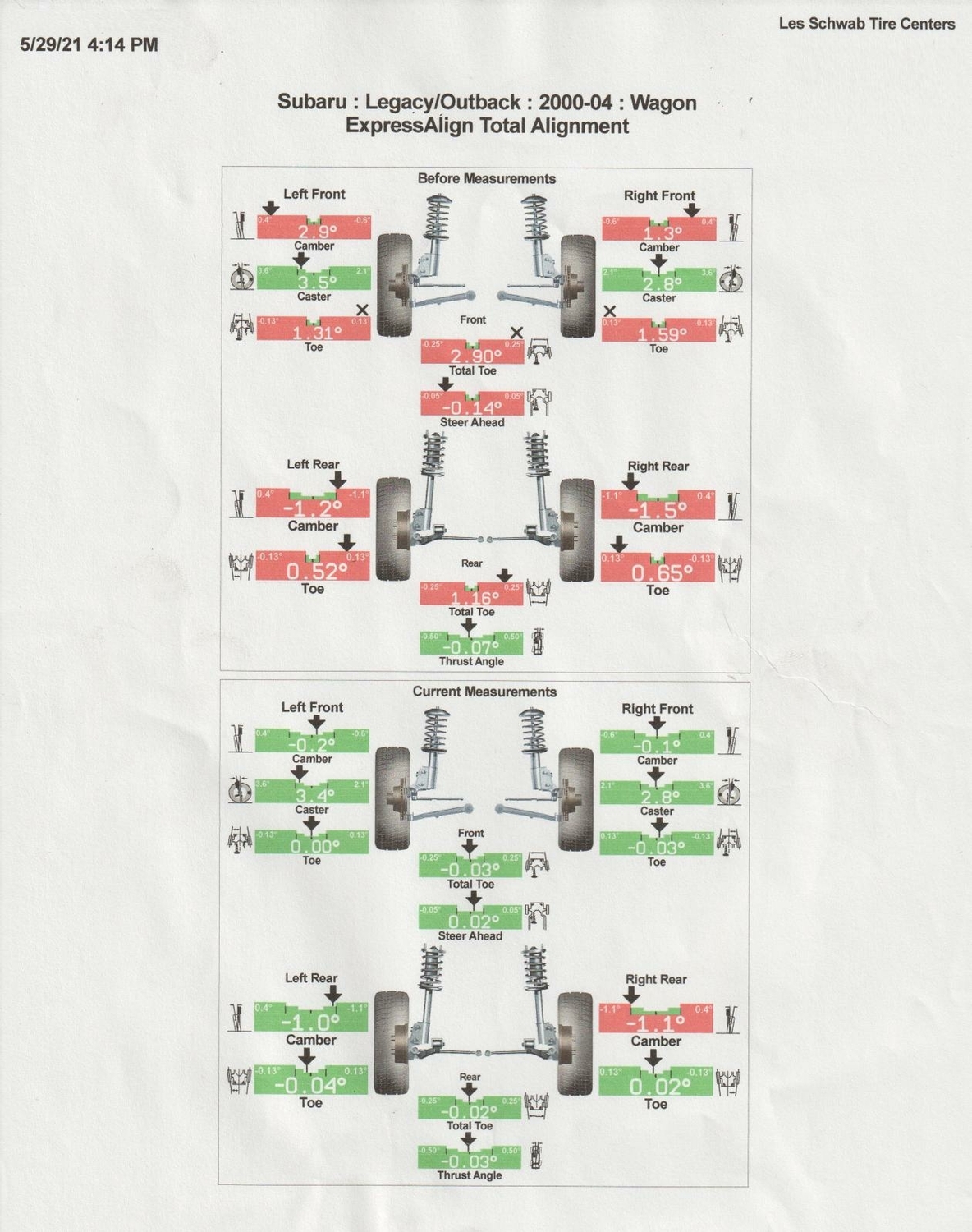

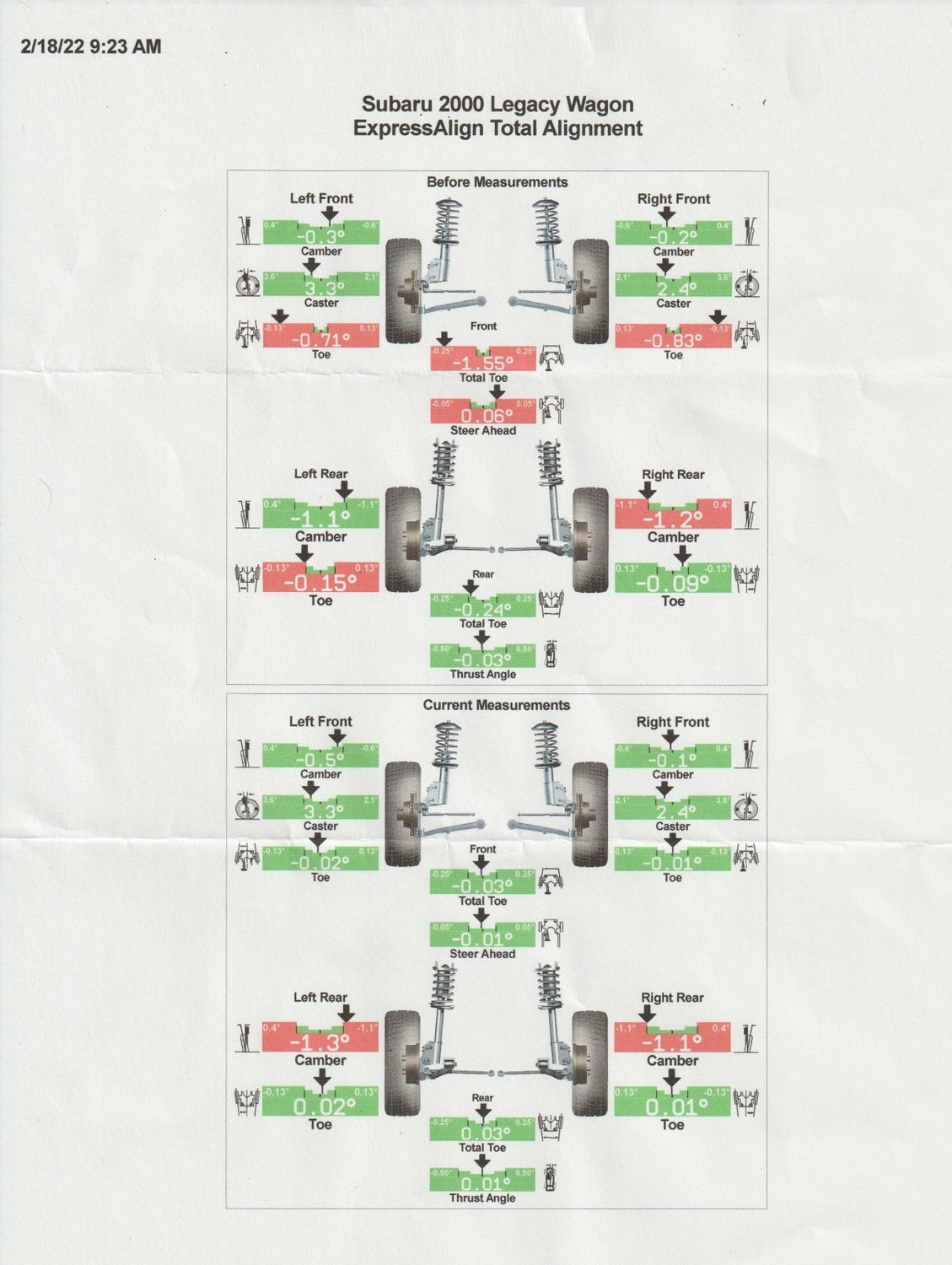

2000 Subaru Legacy L Wagon 2.5 M/T. In May of last year I did a bunch of work to my Legacy. Among other things, I installed Monroe Quick Struts for a Subaru Outback which I documented in a previous post. I also replaced my tires with Goodyear Ultra Grip Winter radials and had the alignment done. The car would pull to the right slightly so I took it back to Les Schwab to have the alignment re-checked. They tried to redo it but it ended up pulling to right even WORSE once they readjusted it. Said there was nothing they could due because of non-adjustable parameters (the camber?). So I lived with it. Please note that I had no noticeable pull to the right and Pirelli tires on my car prior to this, which wore evenly and lasted me 4+ years even with all the old, worn suspension parts still in the car. Come this year, I noticed my front left tire tread is worn unevenly and is toast. Now I have to replace my front axle tires at the very least. Fortunately the tread on the rear axle looks great so I'm hoping to just redo the front with the exact same model of tire and avoid torque binding issues. Had to shell out almost twice what I originally paid for those Winter radials because Goodyear no longer makes them in size 205/60R15, which is a pain. In order to try to eliminate clunking noises and the pull to the right, I previously replaced the following suspension parts just before and shortly after the strut conversion: 2x Rear Lower Control Arms with installed Inner Bushing (MOOG RK643085) 2 Rear Forward Lateral Arms (Dorman 524-197) Front Right Lower Control Arm (Dorman 526-972) (Includes Pressed-In and Transverse Link Bushings; bushings on the front left arm looked good so I left it alone) 2x Outer Bushing for the Rear Lower Control Arm Bushings (20254AE02A) 2x Inner Bushings for the Rear Upper Control Arms (20254AE020) 2x Outer Bushings for the Rear Upper Control Arms (20254AE040) 2x Front Stabilizer Bar End Links (Moog K80693) After discovering the uneven tread wear on the front left tire, I had Les Schwab check it again. They found bad differential bushings, worn trailing arm bushings, and play in the front left tie rods, so I replaced these additional parts: Inner Tie Rod on Left Side (Moog EV473) Outer Tie Rod on Right Side (Moog ES3712) Full Set of Differential Bushings (Energy Suspension 19.1105G) - Fun sawzalling out the old ones! 2x Trailing Arm Bushings (Moog K202056) - These were a lot of work! The drag to the right is still there, and I now have vibration at high speeds. The senior alignment tech says this is because the bad tie rod could have been masking vibration caused by the uneven tire tread. So now I'm replacing those tires. I'm also going to replace that front left lower control arm and associated bushings out of an abundance of caution (Dorman 526-972). However I expect at the very least for the drag to the right to still be there, since it was there originally when I had brand new tires and they couldn't figure out how to fix it. Here's my alignments: First in May of 2021, second attempt in May of 2021, and third alignment after additional suspension parts replacement, February 2022: https://imgur.com/a/tYP8gyz So two questions for you guys: 1) The technician said the camber on the front axle is non-adjustable, which is why they weren't able to bring it into spec. Is that true? If so, is there anything I can do about it? 2) Is there anything about the conversion from Legacy to Outback struts that could have caused the drag to the right and subsequent uneven tread wear? Should I have used subframe spacers or some other part to avoid alignment issues? Any input is much appreciated. Thank you!

-

Just investigated the issue further, and it appears to have been my aftermarket Duralast clutch master cylinder. Sprayed some lithium grease inside the protective boot and the noise changed completely. The click is 95% gone but there is a bit of squeaking now (probably from the aerosol solvent). Total garbage part despite having a "lifetime warranty". Got it because one or both of the cylinders went bad after a clutch replacement job and I was in a tight spot without a working vehicle or many options. I'll probably end up replacing it if it continues just because it's so damn annoying. Pierced a small hole in that boot so the solvent can dissipate overnight and I'll see how it behaves in the morning. Just investigated the issue further, and it appears to have been my aftermarket Duralast clutch master cylinder. Sprayed some lithium grease inside the protective boot and the noise changed completely. The click is 95% gone but there is a bit of squeaking now (probably from the aerosol solvent). Total garbage part despite having a "lifetime warranty". Got it because one or both of the cylinders went bad after a clutch replacement job and I was in a tight spot without a working vehicle or many options. I'll probably end up replacing it if it continues just because it's so damn annoying. Pierced a small hole in that boot so the solvent can dissipate overnight and I'll see how it behaves in the morning. UPDATE: Issue is 100% resolved. The lithium grease spray inside the boot of the clutch master cylinder did the trick. No more clicking, and the squeaking subsided with the evaporation of the spray solvent. I've seen this issue posted on other Subaru forums and for other types of vehicles. Just a heads up that this appears to be the fix. I'd recommend using a hooked mini pick to temporarily stick a foreign object like a chopstick between the cylinder boot and shaft to allow a gap so the solvent can evaporate overnight. I only pierced the boot because I got frustrated laying upside down in the footwell for so long.

- 1 reply

-

- 1

-

-

So my clutch pedal has started to click, usually when depressed but it can sometimes happen when released as well. It can happen pretty much anywhere in the pedal stroke. It is definitely coming from the footwell area. I've tried to lubricate all the moving parts, to no avail. The click can be felt through the clutch pedal when it happens, indicating some sort of mechanical issue with the pedal mechanism itself. I searched around for answers and suggestions in various places have ranged from an unseated spring to a worn connector pin between the master cylinder and pedal. Couldn't find anything about it on this forum. Has anyone else encountered this problem, or found a solution?

-

Could be! My problem is too much negative toe, meaning the front of the tire points away from the centerline of the vehicle too much The lower control arm in that picture (the one with the visible adjustment bolt) might be bent in a way that makes it too short to bring the front of the tire towards the centerline. This could be due to the previous impact. I am tempted to remove that control arm and hit it with a sledge hammer or 45lb weight plate while it is sitting on the ground to make it a bit longer. That could solve my issue. I'll measure it before and after to see if it gets any results.

-

My Subaru actually got T-boned a few years back on the left side directly on the rear axle by some dumbass turning left without looking. It wasn't a huge impact but it was enough to shove my car sideways and definitely threw off the alignment. That could explain why the left side is having issues while the right side is not, although I can't speak to the exact mechanism. Slight warpage of the frame or subframe, perhaps? I'm actually pretty sure that I replaced the bushings on that lower control arm last winter when I was trying to eliminate suspension noise, but I will double check. I might have just replaced one but not the other. Looks like replacing bushings would be a good bit cheaper than adjustable control arms. I'll investigate that option further if the bushing option doesn't pan out. A shame there isnt simply a slightly larger adjustment bolt, it's so damn close. I'll keep my fingers crossed that it's a bushing once again.

-

So after a lot of research and consideration, I found and went with the EXEDY 15801 Stage 1 racing clutch kit off RockAuto. It's a step up from the EXEDY KSB04 OEM Replacement Clutch Kit. Still an organic clutch disc but higher quality materials for better performance. The one issue with this kit is it only comes with a standard bearing. My previous M-PACT clutch kit came with a standard throwout bearing and an oversize bearing with a repair sleeve to deal with the common transmission quill damage issue. I did notice some wear marks on the aluminum quill, which is why I used the oversize bearing and repair sleeve 18 months ago when I last did this job. I also noticed that the original throwout bearing retaining wire had become detached on one side; not sure if that's caused by quill wear on just something that can happen on an old Subie clutch. So here is my final question on this subject for you guys; do you think I should use the old oversize throwout bearing with repair sleeve, or use the new bearing without the repair sleeve? The wear marks on the spindle were noticeable but not deep enough to be alarming. I actually had to consider whether or not to use the standard size bearing when I was last looking at it. I'm not super interested in buying a new oversize bearing, in part because my clutch has actually started to slip consistently during hard acceleration. I expect it to fail completely sometime within the next week or two, so I want to get this job done ASAP. My options are reuse an 18 month old bearing with about 24k miles on it, or use a new bearing without the repair sleeve on a mildly worn quill. What would you guys choose?

-

So it turns out the reason they couldn't get the rear left toe into spec is because they've maxed out the adjustment on the cam bolt. The tech said I will either need to get an enlarged aftermarket cam bolt or an adjustable lower control arm. He described this kind of control arm as being adjustable in the same way as a tie rod end, with a section that is threaded. Does anyone have any familiarity with aftermarket parts like these to fix alignment specs? I've tried looking a bit but so far no dice.

-

Just today I replaced the front passenger side transverse link bushing on my 2000 Legacy, which was completely blown (pictured below). The tech at Les Schwab identified it as the reason my wagon was still pulling to the right after a recent alignment. Putting one of the bolts back was a major pain in the rump roast because I may have partially cross-threaded it on my first attempt to reinstall it, and I ended up having to drive it in the rest of the way using an electric impact wrench. In the past 18 months I've replaced my clutch components, the clutch master and slave cylinder, the head gaskets (blown), half a dozen suspension bushings, two control arms, all four struts, the catalytic converters, the fuel pump and relay, the starter and relay, the spark plugs, and the tires. Things seem to really to go to crap on a Subie after 20 years. I like my old Legacy but I won't be buying a Subie older than 12 years in the future, I don't care how cheap it is. The cost is in the upkeep not the purchase price. As a guy who has to do all his repairs on the street, I specifically loathe undercar work. I have to do my clutch AGAIN this weekend because I burnt out the 18-month-old one driving it hard and overloaded. That entails screwing some plywood to a 2x6 board so I can compensate for the decline of the street gutter and have a level surface to operate the transmission jack. Never thought I'd get tired of working on my car. Hot damn.

-

Sounds about right guys. I'm probably just overthinking it, or being overly cautious. If the manufacturer didn't include a heat shield or the attachments for the original one, then it probably means it's not necessary. And I could do without any more new mystery sounds on my vehicle, so I'll just scrap them.

-

So I recently replaced the blown-out cat on my 2000 Legacy with a high quality one from Bosal. However, I noticed the new catalytic converter bodies are shaped differently from the old catalytic converter bodies; they are round and cylinder shaped rather than an oblong, flattened shape like 1 of the 2 OEM cat bodies. For this reason, and also because I was short on time, I didn't even attempt to transfer the OEM cat heat shield components to the new cat. I have, however, removed them from the old cat and kept them just in case. I wanted to ask folks here if they think I should try fitting the old cat heat shield components to the new cat. The old cat had extended flanges and holes in those flanges to allow for installation of the heat shield components. The new Bosal cat doesn't have those at all, but I could probably get it to fit with a bit of bending and maybe some slightly longer bolts. It wouldn't be a perfect fit but it would be more than nothing. I know temperature affects how efficiently the cat works, but maybe Bosal just designed their cats such that the extra heat shielding isn't necessary? Not seeing any advisement from the manufacturer regarding this issue. Photos of old uninstalled cat (heat shields already removed) and new installed cat attached.

-

Thanks for the help Texan. That info helped me get the job done besides being worried that I was missing something. I used the scissor jack like you recommended, although I positioned it at a different location (pictured) and also used a jack from the bottom. After getting the rear struts in, I tested them by standing on the back bumper and jumping up and down. They didn't bottom out like I was fearing they would, which gave me a lot of relief. After that, the front struts went in without any jacks or substantial effort on my part. The biggest remaining issue was the alignment, especially on the front axle where camber was so excessive that you could see the tilt in the tire. The real test for me was getting the alignment done. I was worried that they would come back and tell me they couldn't do it because larger struts were preventing them from making proper adjustments. However they were able to perform the alignment without issue, apparently. There's a couple values in my alignment datasheet (attached) which were out of spec, and I might call them tomorrow to ask about that, but everything seems good so far. Possibly a tiny bit of wobble in the steering wheel around 45ish miles an hour, and it might drag a tiny bit to the right, but it doesn't seem noticeably different from before I changed my tires a month ago and is otherwise a complete success. I even had time to install the new cat while I was at it yesterday evening, which shouldn't be scraping the ground so much with the extra 2-3 inches I've gained. It seems to be more than just the height difference between the old and new struts, possibly because Outback struts are stiffer but also because I went with Monroe quick struts which are reportedly stiffer than the OEM style KYBs. With this lift, the winter tires, the countless dents and missing trim strips, I think my Subaru might officially be a trashwagon. Well, I might need a brush guard to make it official, but it definitely is on the way! I've attached additional photos so you can see the results. Confirmed: You can straight swap the struts on a 2000 Legacy with Outback struts and no additional parts, and I am guessing that is true for the entire 2000-2004 generation. I'll let you know if I develop any problems down the road. If anyone can offer an opinion on the slightly imperfect results of the alignment, I'm all ears.