-

Posts

23391 -

Joined

-

Last visited

-

Days Won

440

Content Type

Profiles

Forums

Gallery

Store

Everything posted by GeneralDisorder

-

EA82 "Hail Mary" pass repair

GeneralDisorder replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

If you hone a Subaru engine you will accomplish nothing and will cause more wear as the rings have to polish the bores back down. Period. End of discussion. I haven't honed an engine for rering over a decade. None of them use any significant amount of oil. I've seen plenty of honed engines that do though. GD -

Who knows? Could be the o-rings between the block halves, could be a blockage somewhere like inside the rocker assembly or the head. But are you really going to pull down a 1.8 to fix this? Replace the oil pump discharge o-ring. If that doesn't fix it throw the engine in the scrap and get a 2.2 for it. GD

-

Get it warmed up and check the resistance through the solenoid at the bulkhead harness connection. Usually around 35 ohms. If that checks out you will have to check the wiring back to the TCU. If it doesn't you will have to pull the solenoid out and check it as well as checking the transmission sub-harness for high resistance or shorts. The "Subaru" shop you took it to obviously is isn't much of a specialist if they can't fix a pre-05 Duty-C failure. GD

-

Learn to use the dipstick. Regularly - such as every time you fill it with gas. Ignore the light - it's there for morons that can't remember to use the dipstick. I don't see that it has been all that unreliable for you. Subaru gave you a new short block and you have done some wheel bearings and hatch struts. That's NOT significant cost of ownership for 140k. $550 to pull off the upper oil pan is not that much at the typical $130 / hour dealer rates. A few hours of labor, cleaning, and resealing. Being an intermittent issue though there is no guarantee it's a problem with the sensor. It might be, and if it is it's probably related to the short block replacement. Only testing will tell. I can tell you that your expectations of repair costs, cost of ownership, and modern vehicle overall reliability are too high. It sounds like its time to saddle up with a new car payment and have that warranty security blanket. Or learn to do some troubleshooting and repair on your own. GD

-

1988 XT6 FOR SALE

GeneralDisorder replied to RICK TRADER's topic in Old Gen.: 80's GL/DL/XT/Loyales...

You should probably post pictures, pricing, and put it in the classifieds section. But also understand that a non-running, broken suspension, cracked interior, faded paint XT6 is basically a parts car and is worth virtually nothing. You can't hardly give those cars away anymore. You can't get any parts to maintain them or repair them. You aren't likely to get more than a few hundred $ for it. Regardless of how much you LOVE IT!!! GD -

High mileage rated tires are made from hard rubber compounds and necessarily have poor traction because of it. It's a bit at odds with owning an AWD vehicle in a way. If you want great tire life and poor traction just get a prius. Otherwise I suggest you not worry so much about the rated treadwear. GD

-

Pretty normal. Depends on when you took the reading. A high reading MAF at idle is indicative of it being dirty. Negative idle trims and positive cruise trims are typical of dirty MAF and/or dirty air filter. GD

- 1 reply

-

- 1

-

-

EA82 "Hail Mary" pass repair

GeneralDisorder replied to rickyhils's topic in Old Gen.: 80's GL/DL/XT/Loyales...

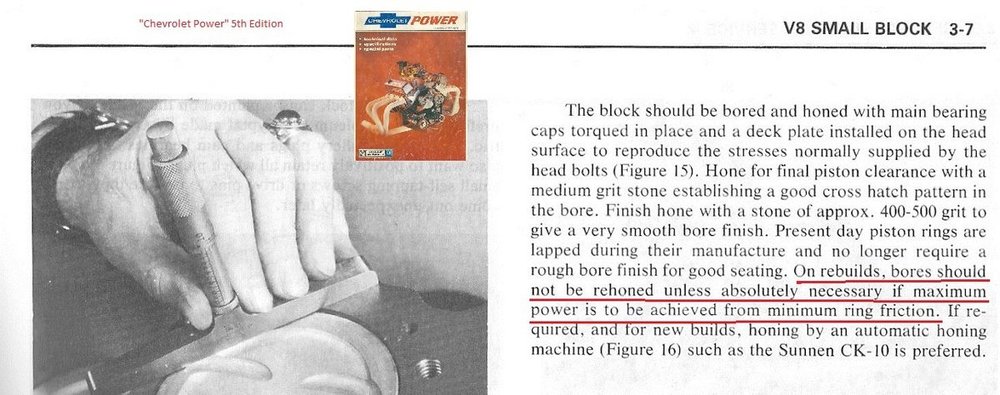

Reposted from a discussion on this very subject over on one of the Small Block Chevy forums I frequent. The attachment is from Chevrolet Power 5th edition published in 1984. Claiming you come from 'Merica school where they hone everything is simply ignorant of modern (well - if you consider 1984 "modern") best practices...... Yeah I've seen all the literature for and against. Half of that is perpetuated "common sense" that was made obsolete by improved ring manufacturing nearly 40 years ago. It does still apply to some very old designs, and to chrome rings, etc. It is not a one-size-fits-all situation though, and modern fuel injected engines don't typically wear out the bores like carbs did. My Vortec cylinders looked excellent at 177k miles. Better than that LT1 pictured even. Also the ring manufacturers publish the honing criterion for machinists that are final honing to size after a rebore. So they need to publish the proper grit and required surface finish. That Wiseco article is perpetuating bull$hit. They aren't even a ring manufacturer. They make pistons. Which gives them some cred but not entirely enough IMO. Also it's mostly in reference to bikes which I have no experience with but the previous article I posted specifically was talking about then with exact opposite recommendation...... funny. The Hastings one lists a single grit - which I highly doubt would be suitable for all rings, of all thicknesses, in all applications - cast iron, chrome, and plasma-moly. There are a lot of variables..... also 220 seems impossibly rough honestly. That will tear the hell out of the rings. I bet they will seat alright - right before they overheat and lose their tension. I guess the old school THICK rings would probably survive. My guess would be with a loss of compression and a reduced lifespan. My experience - especially with modern thin ring packs used on aftermarket pistons - is that honing (dingle ball, rough finish style) will produce too rough of a finish, does not control cross hatch angle, and does not address taper, out of round, ring ridges, etc.... leading to ring overheating and subsequent loss of ring tension. This leads to massive oil consumption and is then blamed on the rings "not seating". Which is exactly the opposite of what happened. They seated too much. If you hone a cylinder with too much taper from ring wear the rings will flutter from the rapid expansion and contraction required by the tapered bore. So that's a waste of time. The reality is that normal cast iron rings are EXTREMELY soft and will easily seat on a bore that is suitable for running. If there's not enough taper or out of round to require a bore job, then normal cast iron rings will seat almost immediately. Thats from Chevrolet Power back in the 80's. As you can see they recommend a rigid hone in an automatic machine, and a surface finish of 500 grit. VERY fine. And not to do it at all if you can help it. Also important to note the quote here: "Present day piston rings are lapped during their manufacture and no longer require a rough bore finish for good seating". I really believe that the manufacturers are just telling people what they want to hear because they know no back-yard re-builder is going to believe them if they tell them the truth. I used to work on industrial equipment and for a period of time after changing to sealed bearings Baldor electric motors pulled the Zerk fittings out of all their standard duty motors. This led to such a high call volume at their tech support center they put the damn fittings back, with the instructions that they only put in 1-2 pumps of grease annually. The grease went into an antechamber next to the bearing - which was sealed and could not accept grease anyway. They did this SOLELY to stop the tech support calls. So no one is going to convince me that manufacturers always have the "right" answers to these questions. They have the answers that produce the best customer satisfaction - be they right or wrong. Honestly - if it worked I would do it. It's not as if it's difficult or expensive (dingle balls hones are cheap in the scheme of things) - even to have the machine shop power hone them..... But I have had to fix too many botched "rebuilds" by other shops and give customers the "bad news" about their oil consumption on their recent rebuild too many times. Several of my direct competitors like to dingle-ball their rebuilds and they burn oil like no other. I actually had one of these shops tell a customer who called to inquire if his recent rebuild was "honed or not" (he was very unhappy with his 1 quart every 500 mile rebuild) that they could do an oil change for him and that they have special oil that it "won't burn". WTF does that even mean? GD -

Just get a reman short block from Subaru - 3 yr/ 36k warranty. About $2250. Don't even bother with used engines. The pricing on used engines and the warranty on the reman's make used engines a poor choice. Read about the main journal clearances that I posted above - you really want to put in a 150k engine? GD

-

It's just a matter of finding the right buyer. The hagglers - especially the really pushy ones - are usually in the game as car dealers and are trying to get a deal they can flip for a quick buck. That's not really your target buyer. KBB and the like are generally in-bed with the insurance companies and they don't in any way represent the market value on Subaru's. Even the banks around here will loan 150% of blue book because they know their customers can't even buy a car at the KBB valuation. GD

-

I don't really do any NA engines, though I have in the past. Mostly 25D's. I don't recall doing any 2.2's or 1.8's...... mostly because it's not economically viable when they are $400 used. The 25D's I have done the mains were way out of spec. Anything over 2 thou and they are toast IMO. As far as the failure mode - understand I am NOT saying the main bearings are failing. They have excessive oil clearance and the rod bearings are ENTIRELY fed off the mains. If the mains are squirting oil out like a garden hose then you won't have any rod bearing oil pressure and you lose the rod bearings - you ALSO lose the piston cooling effect of proper oil delivery to the rods which slings oil into the cylinders and keeps the rings from coking. All of this, to one extent or another, is related to excessive main journal clearances. At operating temp a journal with a clearance of 0.001" is going to be 0.002" - which is exactly where you want to be. If the cold clearances starts at 0.002", then at operating temp you are looking at a clearance of 0.003-4" as the aluminium expands more than the crank. This is WAY too much for the narrow Subaru rod bearings to get proper oil pressure. GD

-

Yes - the lower the power, the longer this process takes. Larger oil pumps don't seem to make any difference because it's not a lack of oil in the bearings, it's the design of the crank and the forces being applied to it due to cylinder pressure. The crankshaft has some amount of deflection - even being forged there are too many journals in too tight of a space. This has several effects - for one the journal width and therefore the ability of the journal to spread the load over a large surface area is compromised, also the lack of material between the journals and the counter-weights makes the crank really.... "floppy" - like a wet napkin. So that over time the natural deflection in the crankshaft deforms the aluminium of the case through repeated hydraulic loading of the main journal webbing. I have had occasion to tear down a few low mileage '09-'14 WRX short blocks. The one's that are now part of the class-action suit due to premature rod bearing failure. One in particular came from a 2014 WRX with 24,000 miles on the clock. The car was essentially stock. It had intake, exhaust, and an Access Port running a stage 2 off the shelf map from COBB. Was not driven particularly hard. I tore down the short block and measured the journals with a mic and a bore gauge. Now mind you - the specs are 0.0004" to 0.0012". All three of the center journals were over 0.002" which is WAY out of spec. Keep in mind while considering these specs that this is COLD assembly clearance. Which will effectively double at operation temp because the aluminium block expands at twice the rate of the steel crank. The really insidious part of this is that if you go by Subaru's factory service manual, this is NOT REPAIRABLE. If it measures out of spec the whole engine block goes in the dumpster. Now - in my world we can "fix" it with a line hone. But it will happen again and you can only line hone the case ONE time - after that you have problems with oil pump fitment. The service life is directly proportional to the specific power output and how often full power is used. Obviously if you drive like grandma all the time this will never occur. But most of us don't buy/build 300 AWHP cars to not use it. We generally give people a rough sliding scale - there is no way to know what the service life will be because it depends on usage and mileage is a very poor indicator of WOT full power usage. So if I build you an STI with say... ~500 AWHP I will make it clear that you can expect 30-40k miles from such an engine. Or two to three race seasons if you are lucky. It is also interesting to note that Subaru offers Reman engines - but ONLY for the NA models that make about 165 crank HP. This is because the turbo engine blocks aren't rebuildable without a line hone, which is not a procedure that Subaru recognizes is possible. They KNOW this. Why else would they not offer reman blocks for these cars (there is clearly an enormous demand - in fact they are offering re-manufactured turbochargers now), and why else would the diesel boxer have the main bearing webs replaced with steel inserts? These engines were designed in the mid-80's. They were designed with a maximum displacement of 2.2 liters, and a maximum HP of 275 on the EJ20 turbo. Everything that has come after that has been pushing the envelope of the engineering to it's max. The fix is simple - but I doubt we will ever see it. Cast the block from iron. Problem solved. *edit* - I re-read your post and yes a larger oil pump can help offset the larger clearances. Also thicker oil. On loose engines (and by that I mean we build them with close to the max factory main journal clearance - I usually aim for *exactly* 0.001" when cold) we run 15w50 race oil and 11mm STi oil pumps. On some clapped-out 250-300k EJ25 I would probably run SAE 50 or 60 in it and put on a 12mm pump. Honestly I would. The clearances are usually ENORMOUS on the mains. I've measured high mileage 25D blocks and seen over 0.003" on the center mains. GD

-

We really don't see a significant difference in 05+ engines. Actually the 00 to 05 engines with the 7mm and 9mm oil pumps have more problems. The AVLS pressure switches are only $24 and insignificant labor to replace. The 05+ engines use the STi rings - they DO NOT tolerate non-synthetic oil and poor maintenance. Give them what they want and they are fine. All the Subaru EJ engines back to 90 suffer from eventual rod bearing oil pressure loss due to increased main bearing clearances. This is a function of the block being made of piss-poor cast aluminium that's soft like Parmesan cheese. The main bearing bores in the block oval out and the excessive clearances drop the rod bearing oil pressure. The harder they are run, and the more specific power they are asked to make, the sooner this occurs. One only has to look at the design of the Subaru diesel engine to see that Subaru knows this very well. In these special blocks the main bearing bore's are cut out and replaced with steel or iron inserts to spread the crankshaft load. The design is honestly terrible for longevity. And people wonder why I drive Chevy Small Block's. 1950's tech. Cast Iron. With modern oil technology - virtually indestructible. Subaru engines are like religion - quickest way to become an Atheist is to read the bible. Likewise - tear-down and build Subaru engines for a decade and shine wears off. GD