-

Posts

23391 -

Joined

-

Last visited

-

Days Won

440

Content Type

Profiles

Forums

Gallery

Store

Everything posted by GeneralDisorder

-

Drain the front diff. I think you probably lost the front differential on the transmission. The speedo drives from the front pinion and the only way that's going to spin freely without driving the wheels is if you lost the teeth on the ring and pinion. I've seen plenty of duty-c failures and never have they resulted in this behavior. Also duty-c and clutch pack failures on 99+ transmissions are rare. I've seen plenty of fragged front diff R&P's though. GD

-

Before you go an blow up this engine/turbo - check the turbo for shaft play and PLEASE re-route the oil feed to the turbo from the engine block main oil gallery. The 05/06 LGT platform cars (OBXT being one) have major problems with turbocharger failures due to the lack of proper turbo oil feed. The stock setup is shared with the right bank AVCS oil feed and there are three 0.040" orifices in the turbo feed banjo's besides the banjo bolt oil screen filters (remove ALL of the these). Delete the factory turbo oil feed and re-route with a single 0.040" orifice (the turbo CHRA banjo bolt itself). These also suffer from ring-land failure and oil pickup tube cracking so those should be addressed and the turbo inlet should be replaced with silicone. Also the TMIC's are plastic and the tanks blow off. We have a saying around the shop - "Friends don't let friends by Legacy GT's". Because they are a total $hit-show. The 5EAT's often have electrical gremlins too. Which is a whore to fix usually. GD

-

You set the crank to the timing belt installation mark - it is not TDC. The installation mark leaves all pistons at 50% travel. All marks are at 12 o-clock. Install the tensioner and the upper right smooth idler. Install the belt. Install the cogged idler - orientation of the cogged idler is irrelevant. Install the lower right idler (smooth with lip). Pull pin Rotate engine two revolutions and recheck cam/crank alignment marks are still at 12 Done. GD

-

I just told you - I haven't found any that work well with Subaru's. Launch is ok but you need to spend several hundred dollars for a decent one. What do you think you will be able to do with it? The problem you are currently having will not be solved with a scan tool. What is it you want to do with the scan tool exactly? GD

-

None of them work all that well for Subaru's. The support is poor from and even my Snap-On Zues that cost $14,500 retail price has a hard time with Subaru. Bi-directional control support is terrible, and I highly doubt that any of them other than the dealer Select Monitor can help with forcing the ECU to run the P0455/P0456 code test. And none of them tell you code setting criteria - for that you need a service manual database subscription or access to Subaru's technet. GD

-

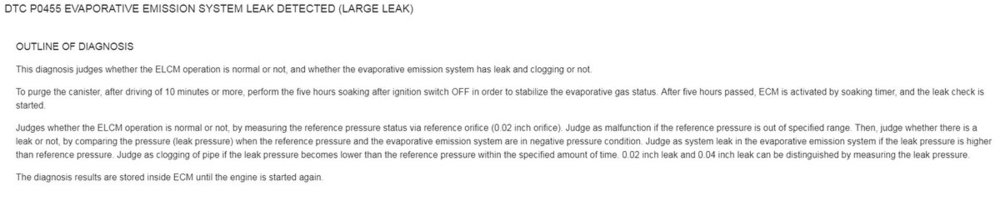

The 11 Forester has an ELCM (Evaporative Leak Check Module) that is only activated 5 hours AFTER a drive cycle (yes the car must not be driven for 5 hour for the ECU to run this test). So you must first perform a drive cycle (there are time, temperature, speed, and other constraints attached for it to be a valid "drive cycle") and THEN wait 5 hours for the ECU to perform the P0455/P0456 test. Please see attached image of code setting criteria - an excerpt from the service manual that your "mechanic" did not even bother to consult. FIND A NEW MECHANIC! GD

-

He did not do adequate testing. He does not understand the cruise and traction disable features and he does not understand that many of these codes require complete drive cycles and often MULTIPLE drive cycles. If he has access to proper repair information like ShopKey, Mitchell, Alldata, etc he could lookup code setting criteria and stop guessing with your time and money. He's a hack. Find a real mechanic. GD

-

The light is there for a reason. Find a different mechanic that has the knowledge and ability to properly diagnose the P0456 code. They need to lookup code setting criteria for 456 and finding the leak will almost certainly involve running a smoke test. The light does not come on for no reason. The flashing cruise and traction lights are present for any Check Engine light as a driver alert feature. They mean nothing other than you have a (P0456, or any other) code stored. GD

-

Yes and no. Depends what hat I'm wearing at my performance shop. Most of the time I'm management, and sometimes I'm the janitor. My most important role is as the shop's lead diagnostic technician. Occasionally I get to open up my $14,000 Snap-On tool box and *just* be a mechanic - usually on weekends when no one is bothering me and I'm usually spending that time working on personal vehicles or projects - none of which are Subaru's other than the wife's Outback. This is our website: http://superiorsoobie.com/ Does that answer your question? GD

-

You're not a mechanic. Subaru is no different than any other brand. Better than some in some ways, worse in others. Your massive sample data set of two whole vehicles, while breathtaking in it's sheer scale, is unfortunately insufficient for making these judgements. You think Subaru is bad? Try Nissan - go find a 1990 300ZX Twin Turbo and see if you can find..... anything. Or Ford - try doing a head gasket on a 6-point-uh-oh! Stop asking silly questions. Your code most likely has nothing to do with the charcoal canister anyway. You need to perform a smoke test and It's highly doubtful you have a smoke machine or know how to use it. The problem will end up being corrosion related would be my guess - very unlikely to be hose. Take the car to a mechanic and let them be the judge of how hard it is to get at things. GD

-

I don't recall a complaint like that. Probably going to have to monitor live data through the event and see if you can spot an abnormality. You should probably look over the live data anyway. Something might show as abnormal even during normal operation. I just had an 08 Imp come in for stalling and low idle. No check engine lights. Symptoms for two months. Been to several other shops. Live data showed +25 to +30 long term fuel trims. Traced it to a bad aftermarket PCV valve installed by a shop during a "tune up". Why it didn't throw a P0171 is beyond me, but it didn't. Just stalled and low idled for two months. Drove the guy nuts. He drove an hour to see me. Went home happy. GD

-

Oh yeah. We have both. I haven't had to fire many customers (or employees for that matter) but it has happened. I once packed a customer's dissasembled turbo engine into the back of his Forester and told him to F*ck right off my property. That guy took it to another shop I know, they performed the improper repair that he asked me to perform (which I refused to do) and a few months later that engine blew up and he was back in there blaming them for screwing it up and threatening legal action. GD

-

When you're dealing with customers driving late model modified STi's you can't take that risk. The clientele that's looking to save $200 on a timing belt job don't usually even bring their car here - I have enough trouble with people that get overly sensitive about watching the DAM on their access port and call me immediately if it drops down to 0.9 I get it. I work on some vehicles like that. Used to work on a lot more but rising overhead and now being a mainstream shop that charges very near industry average hourly rate.... it's not how I want to be percieved by my customers. When we go in there we replace all wear items. And the tensioner is a wear item. They can and do fail. It's the same reason I use a $750 Snap-On digital torque wrench.... perception. People expect a higher level of work from us, just as they expect to see me and my tech's using tools they don't have at home. If the customer is budget limited I have financing available, or sometimes if it's a real basket case or the customer is just down on their luck I will put in some lightly used parts to help them out. We do this type of stuff for people. We highly advise against it and they are warned up front that it's a temporary fix. But for the general public that intends to maintain their car on the Subaru reccomended interval... well the price is (currently) $950 for the typical SOHC timing belt job and they should have known they needed to budget for this long in advance. It's not a repair. It's scheduled maintenance. GD

-

Our experience is that the tensioner piston may not make it to the 2nd belt interval even if it's visually ok. We always replace 100% of the timing components. The Aisin pumps always come with the metal gasket. Sometimes the NPW one's do also. We stock the factory ones in case. Sometimes we can't get an Aisin pump and have to use NPW. GD