-

Posts

2375 -

Joined

-

Last visited

-

Days Won

56

Content Type

Profiles

Forums

Gallery

Store

Posts posted by pontoontodd

-

-

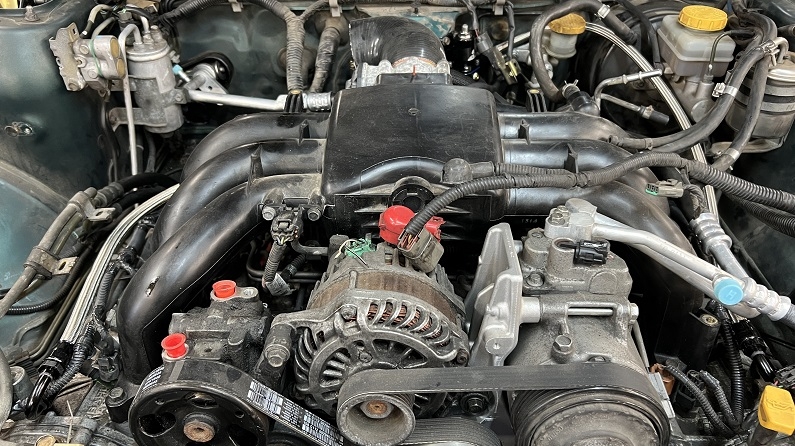

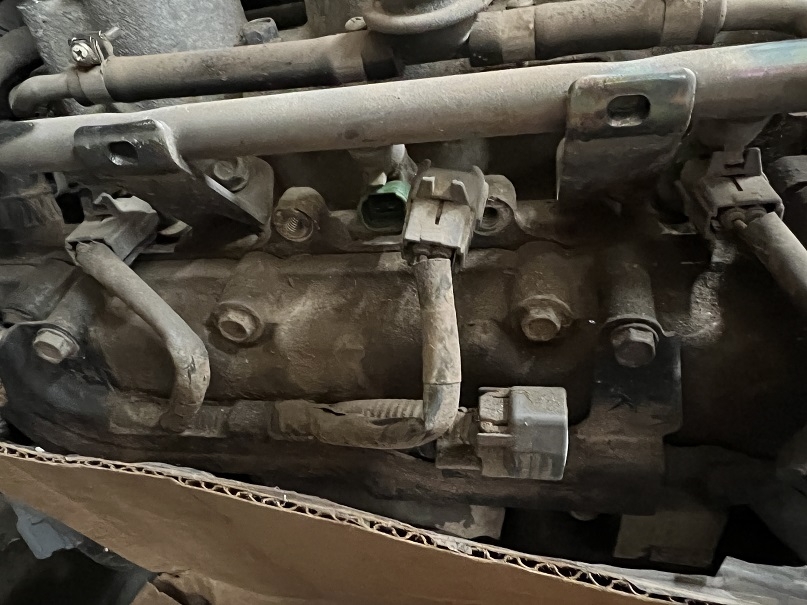

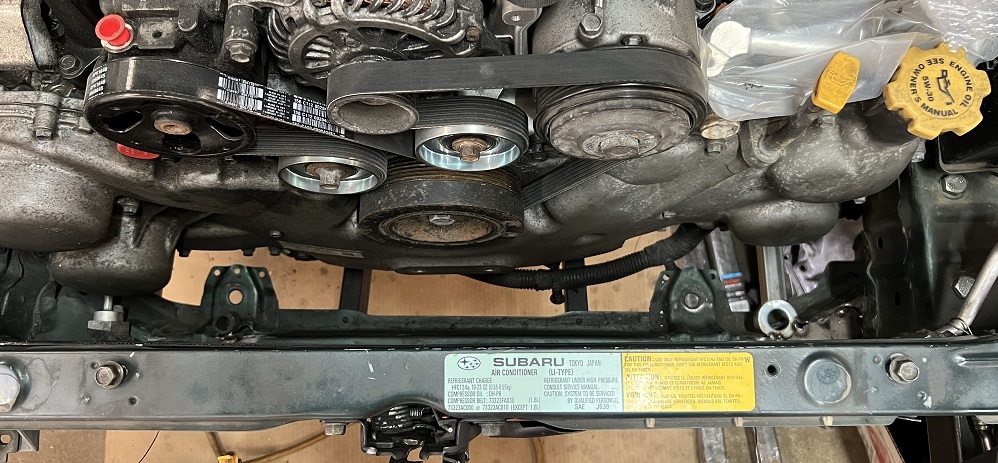

Mostly unrelated but B and I stopped by C's shop. Standard EJ25 with a rod sticking out. Has another one with rod knock, in his dreams he will eventually make one good engine out of two.

The main reason we were there was to remove and disassemble a CVT out of a 2014 Outback. C bought the car pretty cheap knowing the transmission was bad and since he's cheap he wants to try to fix the trans rather than just replacing it. It still ran and drove but made horrible noises. Car has 208k miles on it but has minimal rust. Previous owner supposedly pulled his 18' pontoon boat in and out of the water with it regularly, which may not have been a good idea. Once we removed all the bellhousing bolts, the transmission wasn't too hard to remove.

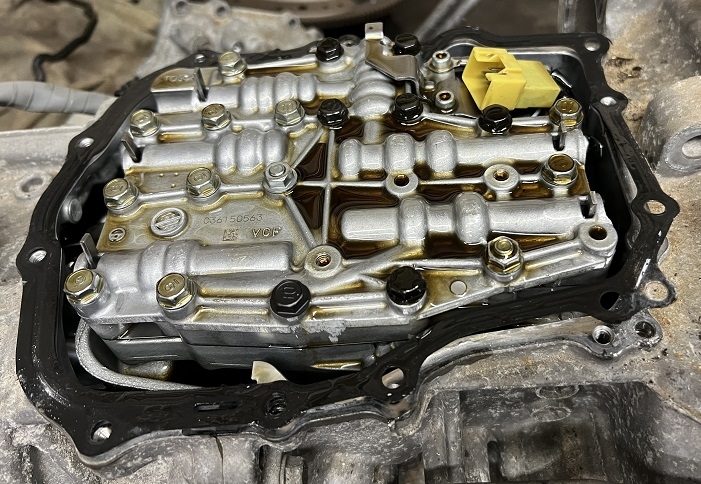

We first tried unbolting the front/bellhousing from the trans but that didn't seem to work. Then we unbolted the top cover and removed this valve body which also didn't accomplish much.

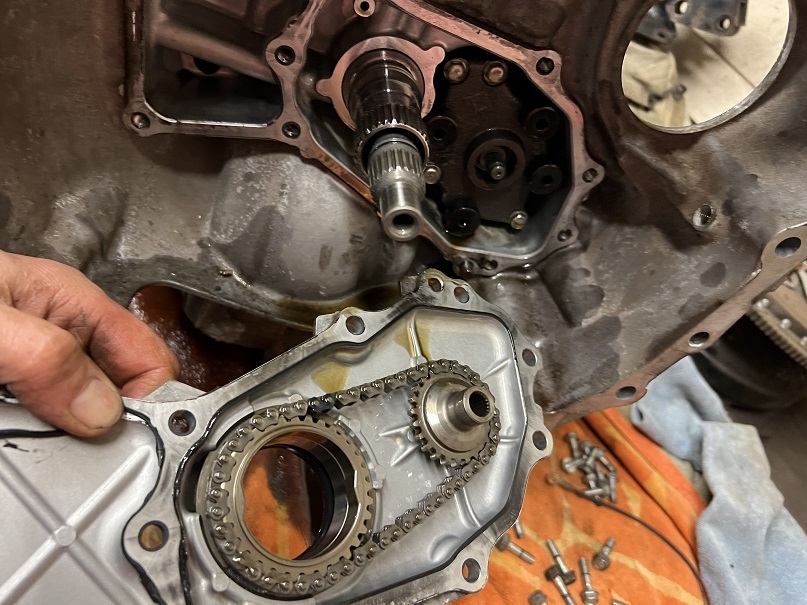

Figured it was a long shot but removed this front cover and oil pump, also no real progress.

These screws are pretty crazy though.

Took the tailhousing off, standard Subaru auto trans clutch pack for the rear drive. Didn't really look at it at the time but seems feasible that some kind of planetary low range might be possible.

Took the pan and filter off and some kind of splash/windage tray.

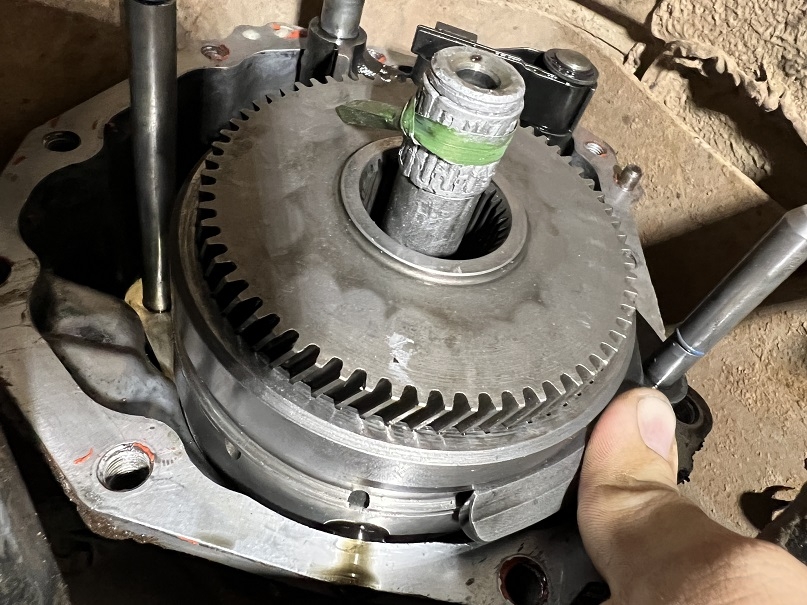

Then we were able to split the case. Transmission is pretty simple really. Sheaves still look very smooth. Some burs/wear on the top edge of the pulley on the left, I'm guessing that's what was causing the intermittent nails on the chalkboard noise C told us about.

Pretty sure we found the root of the problem.

This used to be spherical.

C plans on replacing that bearing, a sensor we broke during disassembly, and putting it back in the car.

-

1

1

-

-

B and I finished the remaining fab and paint on the skidplates and bumpers. Round tube bumper is for the rear of B's Forester, everything else is for my Impreza. Dropped it all off at paint today. Didn't listen to slammo and travelvw and asked the paint shop to match the gold color on the bottom part of the body for the front bumper and skidplate. Everything else will be black.

-

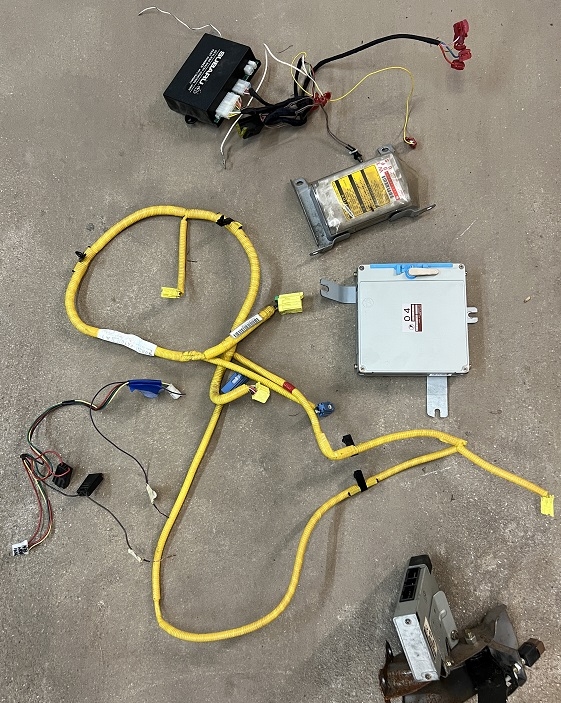

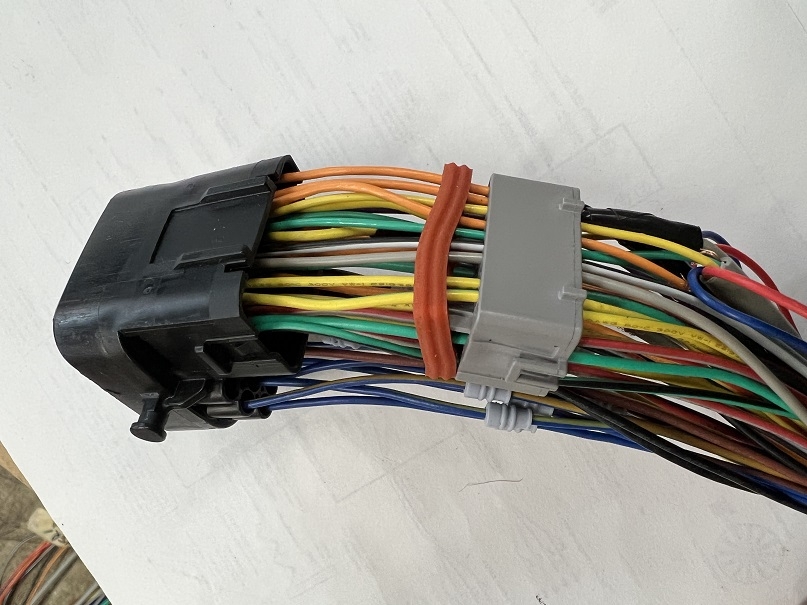

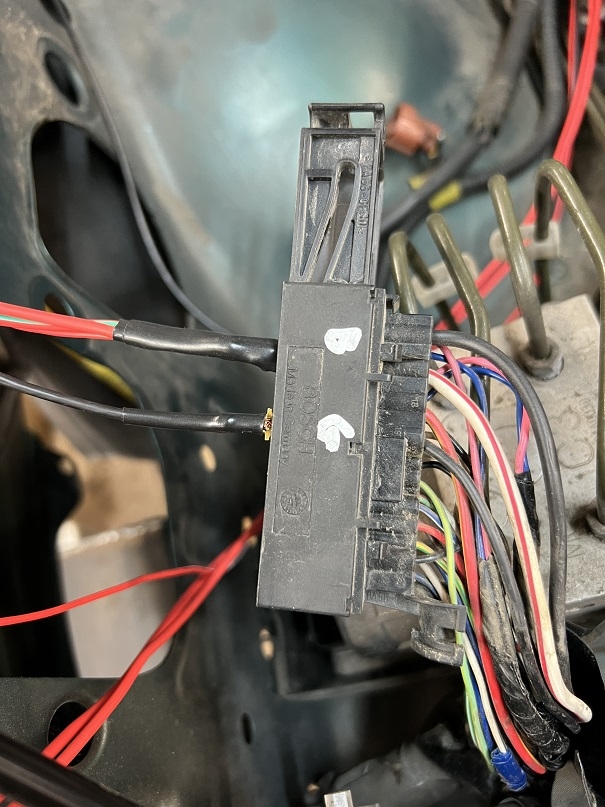

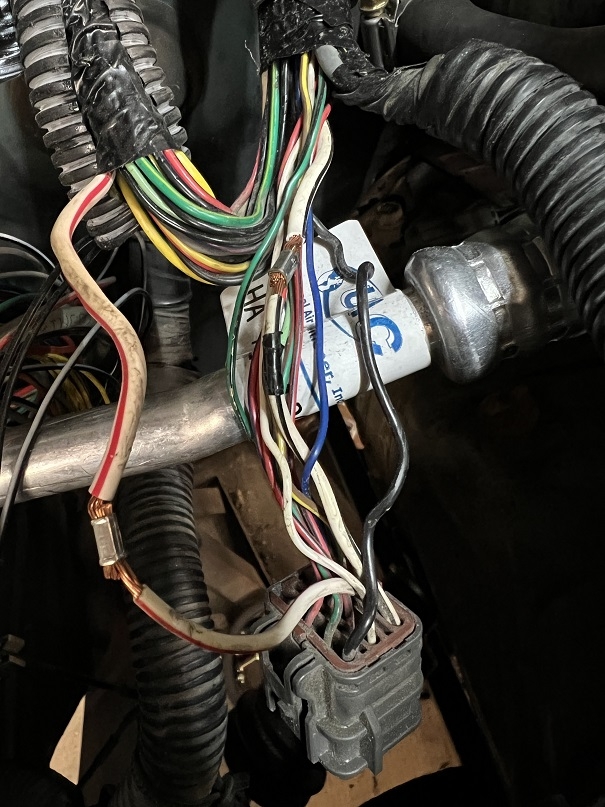

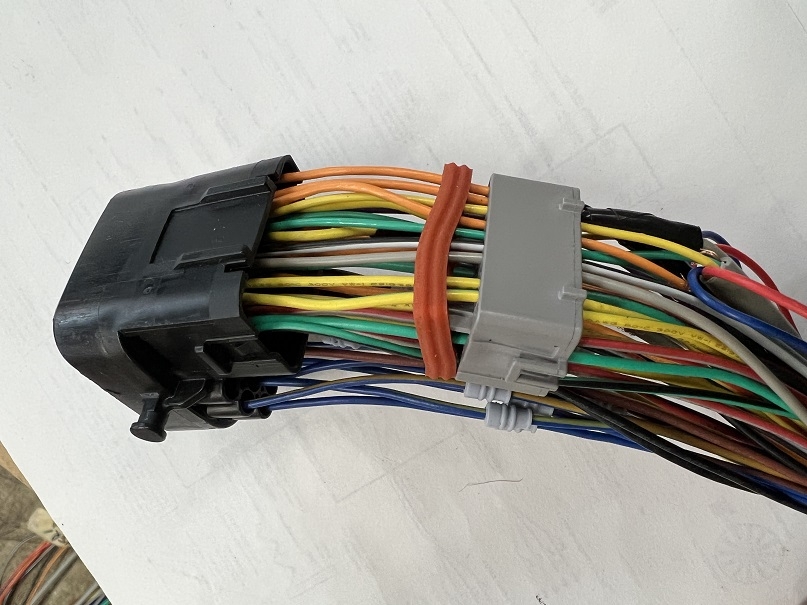

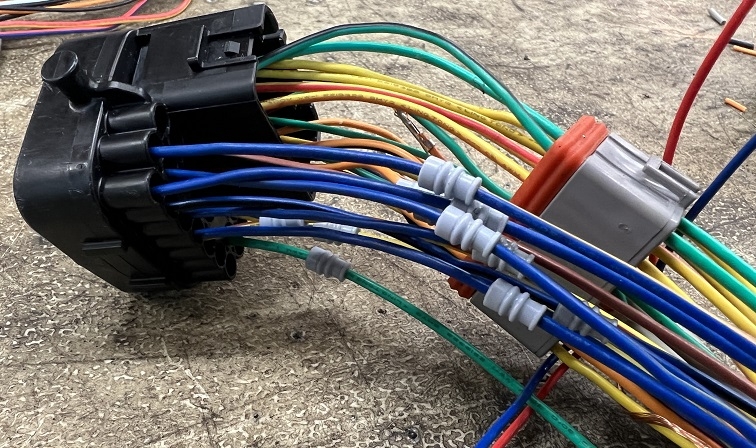

Most of the wiring and modules we removed. Keyless entry, airbags, TCU, ECU, aftermarket cruise wiring.

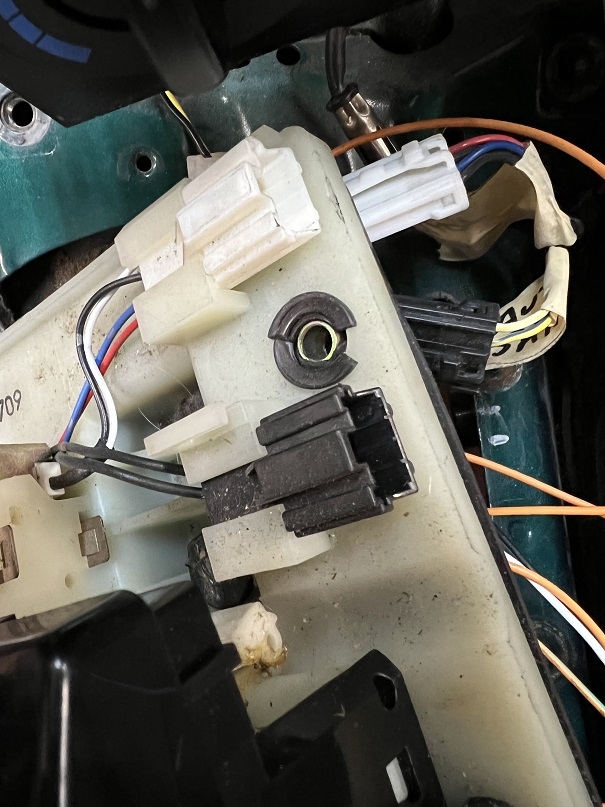

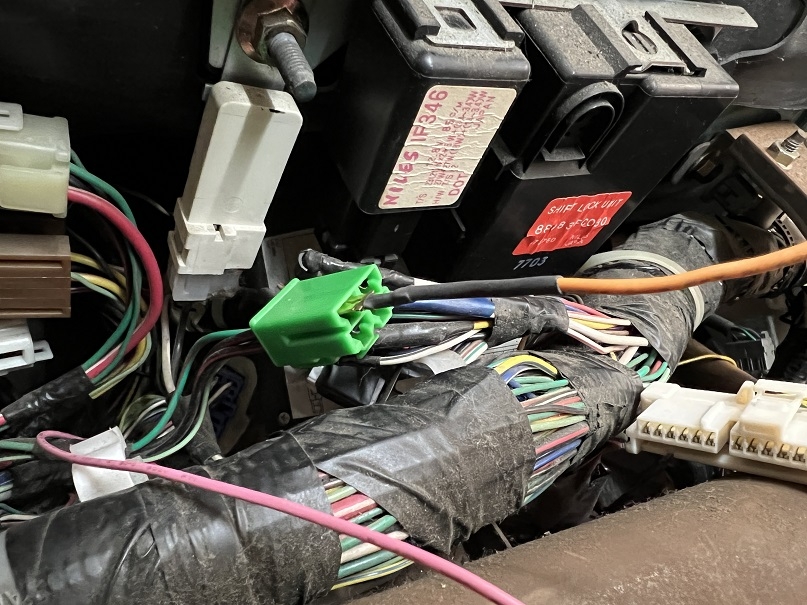

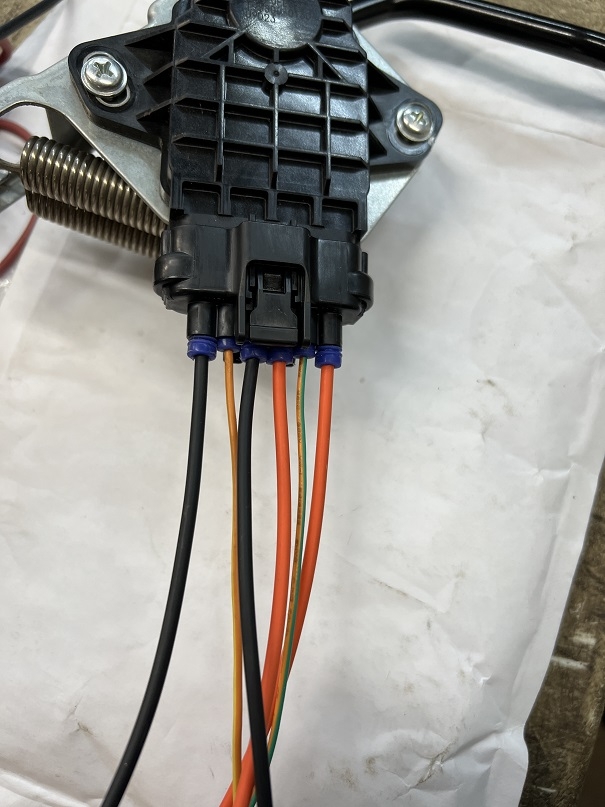

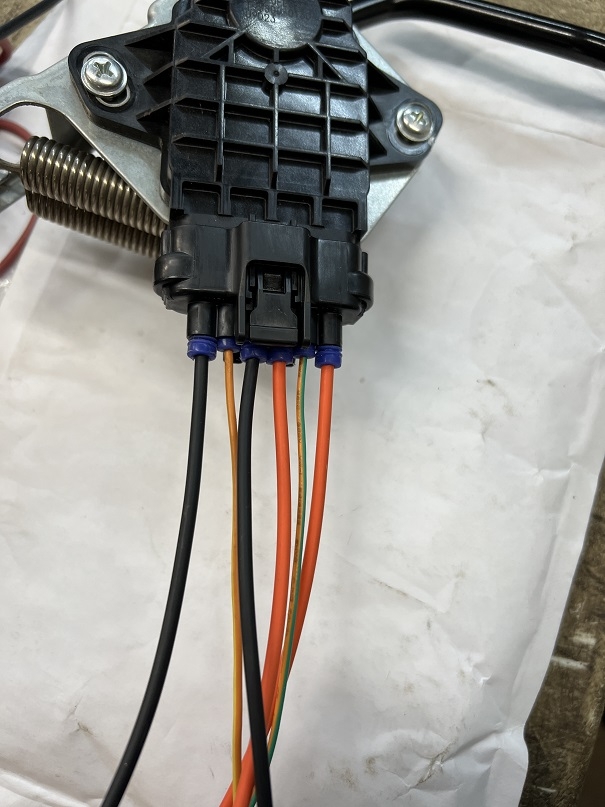

At first we couldn't remove the ignition key from the lock cylinder even in the off position. If you plug the shifter (big white thing) in to that white wire plug and have it in park, then you can remove the key.

Those blue and red wires go the park position sensor.

The two black wires below that go to the lock cylinder seem to be the culprit.

If you unplug them at this connector under the steering column you can take the key out normally. Then you don't have to deal with the park position sensor. The black connector with two white wires is the other side of the connector.

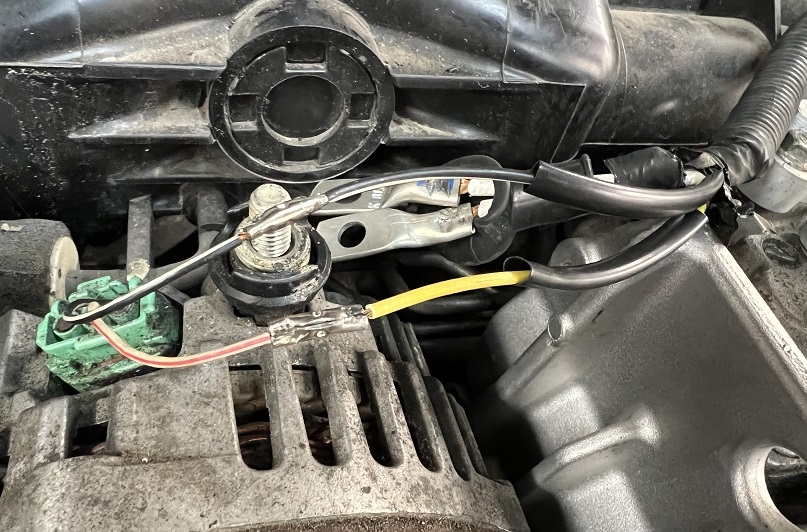

Alternator wiring. The two big white wires go to the large post. Then the black/white wire is the same on both cars so I spliced those. Spliced the other one. I did order a wire plug for this so I can get rid of the splices.

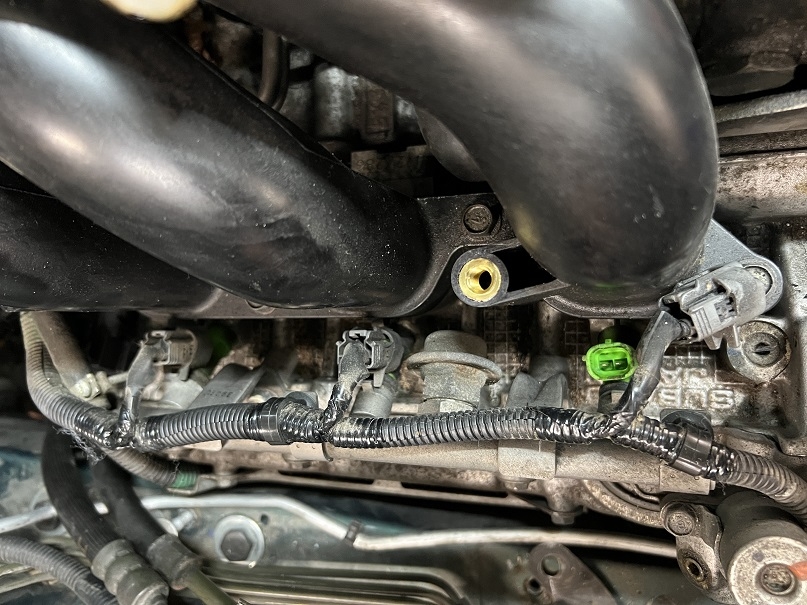

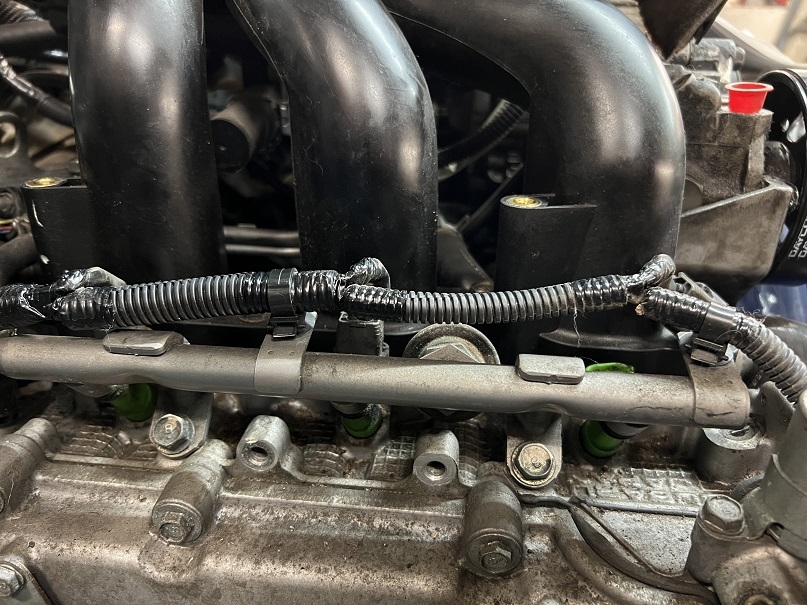

Spliced a wire off the EZ36 coolant temp sensor to the dash but that caused the Haltech and dash to read low. Thought about running an output from the Haltech to the temp gauge, maybe I will eventually but I installed an EZ30 coolant temp sensor. Same threads, has three pins instead of two. In the EZ30(D) cars, one pin (2) goes to the ECU, the other one goes to the gauge. I was hoping this would make the sensor read more accurately on the Haltech (I think it reads about 20F higher than actual) since that's what the base map was set up for but it seems to read the same as the 2 pin sensor. I ran this purple wire from pin 3 under the intake in some small loom.

Put a spade connection near the engine harness plug.

Unfortunately this didn't accomplish much. Seems to read the same as the EZ36 sensor on the Haltech. Gauge fairly quickly goes beyond H as soon as the engine starts warming up. For reference, the 2001 EZ30(D) sensor reads:

4.6kohms 30F

2.7kohms 60F

190 ohms 212F (not sure how accurate this is)

The 98 Impreza gauge reads:

100 ohms (to ground) H

120 ohms 2/3

150 ohms top of C

180 ohms bottom of C

After some trial and error I spliced a 100 ohm resistor between the gauge and sensor and now the gauge and needle is in the middle at operating temp (200-210F on the Haltech). This was without the ground for the temp and fuel gauges grounded (see below, pin 16 of the 16 pin EJ connector). After we grounded that, I removed the 100 ohm resistor and the temp gauge is functional. Seems to read low though, at normal operating temp (200-210F according to the Haltech but probably a little lower than that) the temp gauge only reads about 1/3. As long as it's consistent it should be good.

Here we have the wires for the instrument cluster.

connector a/i10

pin 1&3 speedometer (not working yet, see below)

pin 8 R/W check engine light (from Haltech)

pin 9 G/W oil pressure switch (from engine)

pin 10 G tachometer (from Haltech)

connector c/i11

pin 3 Y/G auto trans oil temp (spliced to EZ36 oil level switch, see below)

pin 11 W/G coolant temperature (see above)

-

1

1

-

-

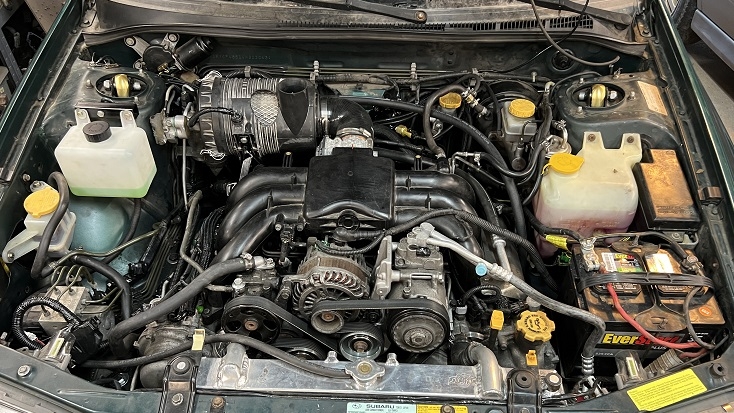

B finished welding the rear brumper yesterday.

We also finally got the EZ36 running in the Impreza. Seemed to be running on all six, the only leak we noticed was one of the injectors so I should get new o rings for those. Cranked it for a while to get some oil circulation and maybe pressure. Even without the fuel pump running it started to fire when we plugged in the ECU. Fired right up with some fuel pressure, responds to throttle pedal. Only ran it for 5-10 seconds a few times. Still needs a lot of little things but a bit of a relief to hear it run.

I'm going to try to put all the details of the engine swap on this thread:

Will probably start copying some of the relevant info from this thread into there and use this thread for our usual fabrication, repairs, and trip reports. Thought it might be handy for future reference to have all the engine swap info in one place.

-

3

3

-

-

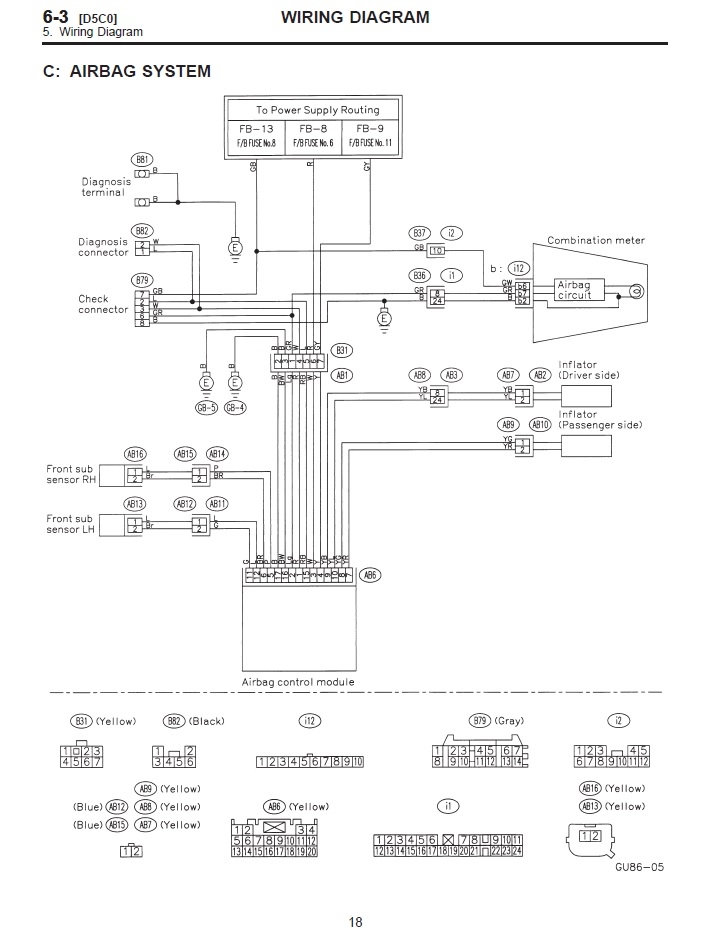

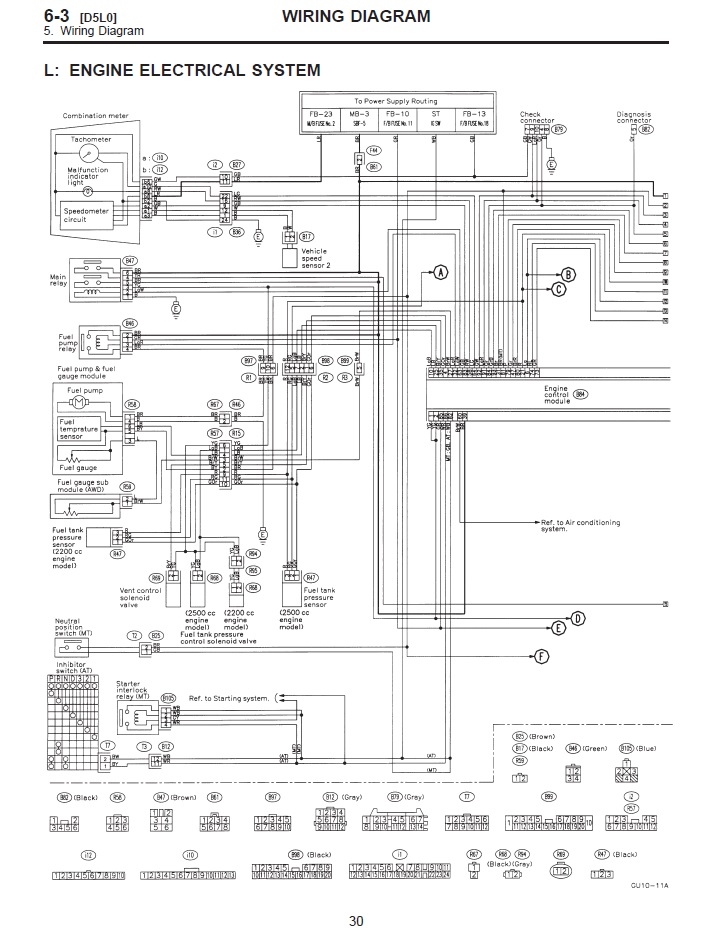

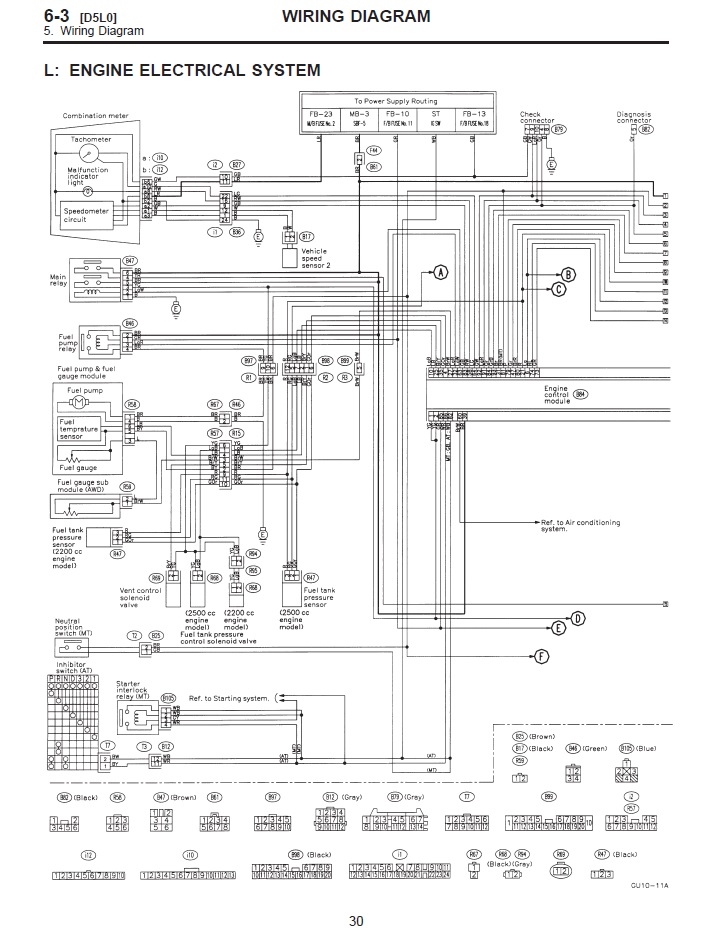

Download the FSM from jdmfsm.info, most of the following is from that.

Pinned out connector to EZ36

Some Impreza specific wiring:

Was looking for a good source of 12VDC with the ignition on that's not shared by any other fuses. Since we removed the airbags, computer, and wiring, it was convenient to tap into the airbag harness connector near the dead pedal. Ran the pink wire from pin 13 of the Haltech to that.

Pin 6 connector B31 red wire as seen below:

Almost spliced into the B/R wire running to the fuel pump by the passenger footwell but decided to tap into the connector that normally goes to the fuel pump relay (white thing on the left side of the picture). Ran the orange/blue wire from the Haltech fuse box there.

Pin 4 of B46 black/red wire as shown below:

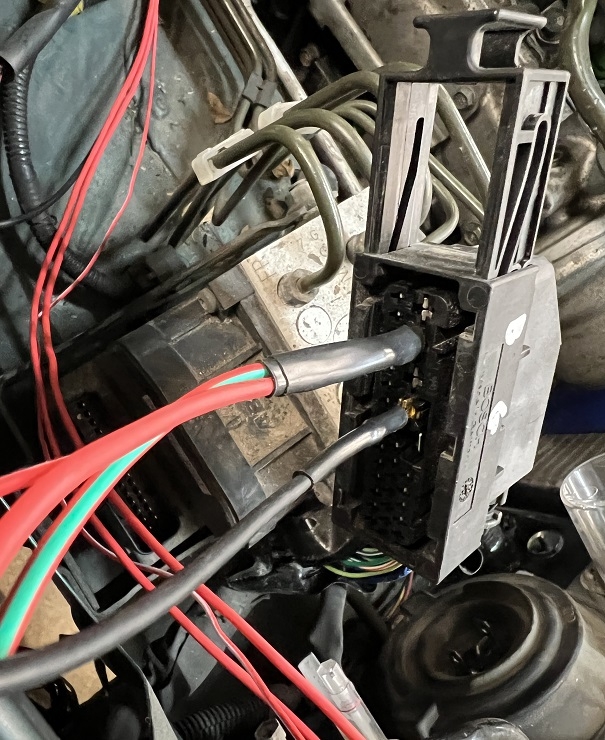

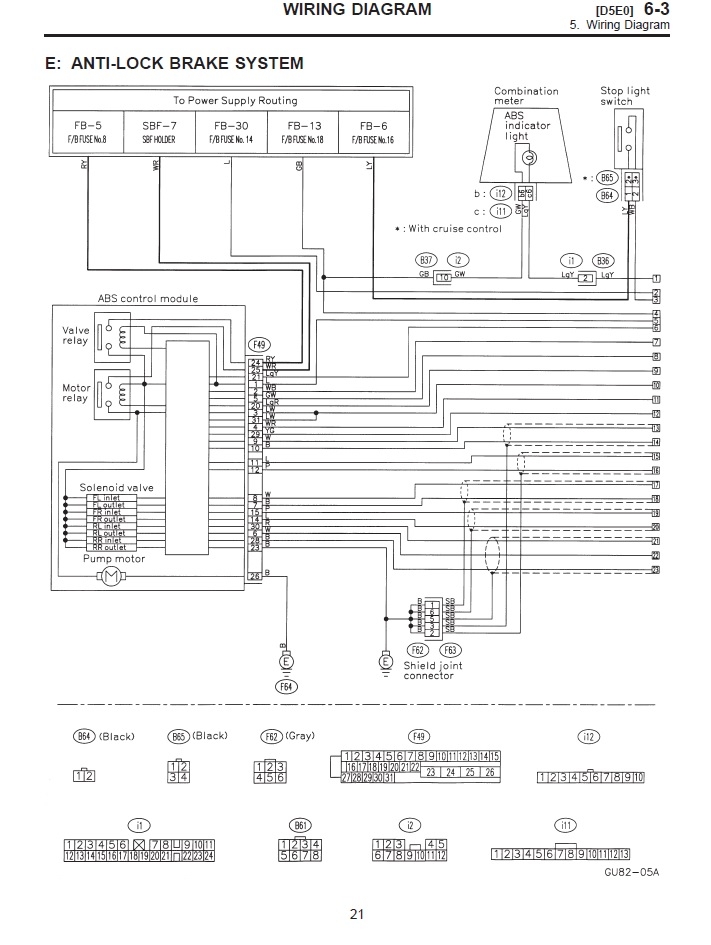

Also wanted a dedicated but fused battery voltage source so tapped into the ABS connector since that will no longer be functional. Goes through the main 80A fuse and a 50A fuse in the main fuse box and then over to the ABS module (W/R wire marked B). Plugged the red, red/white, and red/green wires for the Haltech fuse box in to that.

Used a large ground wire there too (black wire marked G), ran the black ground wire from pins 10 and 11 of the Haltech to that.

Pins 23 (black) and 25 (white/red) of F49 as seen below:

Simplest way I could figure to do the starter circuit was to splice these two wires (large W/R and W/B) that originally went to the shifter on the auto trans. Cut them on the large side of the factory splices and spliced them together.

Large white/red and white/black wires of B12 as shown below:

For some reason we had to unplug the stock ECU for this all to work properly but we were obviously going to do that regardless.

I plan on adding more detail to the above and other wiring as I have time.

-

1

1

-

-

As noted above this is for an STI accelerator pedal, I think the pinouts on the Legacy/Outback and possibly the one shown on the Haltech site are different so definitely verify that.

Most of that was figured out from the basemap I got, Haltech's site and instructions (their color coded wiring diagrams are great) and the FSMs.

One minor hurdle we had was the Haltech EZ30 basemap being set up for a PWM pump (I think), had to switch that to the B/Y wire so it would actually turn on the fuel pump. Fuel pump seems to run continuously with ignition on even if the engine isn't running, haven't looked to see if or how that can be changed yet.

Also had to adjust the pot position on the accelerator pedal to keep from getting an error at full throttle. Simple, just two phillips screws.

Also have to calibrate the accelerator pedal and DBW throttle, also simple, just follow prompts on the screen.

-

1

1

-

-

Going the other way, wire colors to the ECU connector for reference.

2013 EZ36 pinout color (car) B21 54 pin color (engine side) GY/L 1 Lg knock sensor 2 (signal) GY 2 GR intake cam pos sensor RH (signal?) Y 3 W crank position sensor Also 14 GY/G 4 LR knock sensor 1 (signal) G 5 Lg intake&exhaust cam pos sensor LH&RH (ground?) B/W 6 YG throttle control, MAP, coolant & oil temp sensor, knock sensor 1&2 (ground) IGN GY/R 7 L exhaust oil flow control solenoid valve RH 8 B Or EGR control solenoid valve Y/B 9 RY ignition coil 1 Y/G 10 WL ignition coil 4 11 RG purge control solenoid valve (signal?) gauge V 12 BrW coolant temp sensor (signal) Y 13 G intake cam pos sensor LH (signal?) G 14 B crank position sensor Also 3 GY/BR 15 BY exhaust cam pos sensor RH (signal?) 16 W oil level switch switched to ground G/R 17 L Or exhaust oil flow control solenoid valve RH 18 PB power steering oil pressure switch switched to ground 19 BL EGR control solenoid valve Y/R 20 YG ignition coil 2 IGN GY/R 21 L intake oil flow control solenoid valve RH G 22 R intake oil flow control solenoid valve RH Y 23 YB MAP (signal?) O/R 24 Or throttle control signal? O/B 25 W throttle control signal? GY/B 26 G exhaust cam pos sensor LH (signal?) gauge 27 L engine oil temp sensor (signal) O 28 LY throttle control, MAP (power?) 29 YR EGR control solenoid valve 30 Y EGR control solenoid valve Y/O 31 GW ignition coil 3 IGN GY/R 32 GY intake oil flow control solenoid valve LH G/B 33 RY intake oil flow control solenoid valve LH B/W 34 BP ground for ECU? B/W 35 LR ground for ECU? B/W 36 WR ground for ECU? (coil ground?) B/W 37 LR ground for ECU? BR/R 38 BW throttle control BR/B 39 BL throttle control B/W 40 BP ground for ECU? 41 IGN GY/R 42 R exhaust oil flow control solenoid valve LH G/BR 43 RW exhaust oil flow control solenoid valve LH Y/L 44 BY ignition coil 6 gauge cluster 45 G Or oil pressure switch switched to ground L/Y 46 GW fuel injector 6 L/O 47 Br fuel injector 5 R/L HTFB 48 YL intake&exhaust cam pos sensor LH&RH, fuel injectors 1-6, purge control solenoid valve (power?) R/Y HTFB 49 LB ignition coil 1-6 (power – ignition relay?) Y/BR 50 BL ignition coil 5 L/R 51 RG fuel injector 4 L/BR 52 G Or fuel injector 3 L/B 53 LR fuel injector 2 L 54 Lg fuel injector 1 HTFB = Haltech fusebox STI accelerator pedal pinout (left to right looking at harness connector) O 1 sub 5V+ O/G 2 sub signal (analog) O 3 main 5V+ B/W 4 main ground O/Y 5 main signal (analog) B/W 6 sub ground -

1

1

-

-

I used the Haltech fusebox kit which has four fuses and relays for ECU, injectors, ignition, and fuel pump.

Chart of wires from the Haltech and which pins on the engine connector and throttle pedal I ran them to.

Main connector 34 pin (Elite 2500) looking into connector on ECU 1-9 left to right top row EZ36 ECU Haltech Wire Colour Connection EVAP 1 V/BR DPO 2 Pedal 5 2 O/Y AVI 4 9 3 Y/B IGN 1 20 4 Y/R IGN 2 31 5 Y/O IGN 3 10 6 Y/G IGN 4 50 7 Y/BR IGN 5 44 8 Y/L IGN 6 28, pedal 1&3 9 O +5V DC GND 10 B BATTERY GROUND GND 11 B BATTERY GROUND - 12 O/W +8V DC IGN 13 P 12V IGNITION INPUT AC request 14 W AVI 10 ( TPS ) 23 15 Y AVI 9 ( MAP ) 25 16 O/B AVI 2 24 17 O/R AVI 3 tach 18 V/B DPO 1 54 19 L INJ 1 53 20 L/B INJ 2 52 21 L/BR INJ 3 51 22 L/R INJ 4 AC clutch relay 23 V/R DPO 3 Haltech relays 24 B/Y DPO 5 ( FUEL PUMP TRIGGER) Haltech relays 25 B/R DPO 6 ( ECR OUT) Haltech relays 26 R/L ECU INJECTOR POWER INPUT

(REQUIRED CONNECTION FOR ECU TO OPERATE)47 27 L/O INJ 5 46 28 L/Y INJ 6 29 L/G INJ 7 30 L/V INJ 8 IN2 22 31 G STEPPER 1 P1 / DPO IN1 (LH) 33 32 G/B STEPPER 1 P2 / DPO EX1 43 33 G/BR STEPPER 1 P3 / DPO EX2 17 34 G/R STEPPER 1 P4 / DPO Main connector 26 pin (Elite 2500) looking into connector on ECU 1-7 left to right top row EZ36 ECU Haltech Wire Colour Connection 3 1 Y (SHD) CRANK (TRIGGER) ( + ) Inangle1 (LH) 13 2 Y (SHD) CAM (HOME) ( + ) 3 GY AVI 7 (AIR TEMP) 12 4 V AVI 8 (COOLANT TEMP) 14 5 G (SHD) CRANK (TRIGGER) ( - ) 5 6 G (SHD) CAM (HOME) ( - ) 7 GY/R (SHD) SPI 4 Inangle2 2 8 GY (SHD) SPI 1 Exangle1 26 9 GY/B (SHD) SPI 2 Exangle2 15 10 GY/BR (SHD) SPI 3 IGN 11 R/W +13.8V ECU SUPPLY (ECU POWER) 12 GY/O (SHD) AVI 6 (O2 INPUT 1) 13 GY/Y (SHD) AVI 1 (O2 INPUT 2 ) 6,34,35,36,37,40 14 B/W SIGNAL GROUND Pedal 4 15 B/W SIGNAL GROUND Pedal 6 16 B/W SIGNAL GROUND CEL 17 Y/V IGN 7 18 Y/GY IGN 8 FAN relay 19 V/O DPO 4 Pedal 2 20 O/G AVI 5 4 21 GY/G KNOCK 1 1 22 GY/L KNOCK 2 CAN O2 23 W CAN H CAN O2 24 L CAN L 39 25 BR/B DBW 1 / DPO 38 26 BR/R DBW 2 / DPO -

1

1

-

-

I'm going to try to make this guide as comprehensive as I can for setting up an EZ36 with a Haltech Elite 2500. Haltech does have some good wiring instructions on their website for the EZ30 but the EZ36 is significantly different. I also had someone share with me a base map for EZ36 but it's for the older (ESP) version of the Haltech software, so I will try to post that once I get it working well, probably after some dyno tuning too. Will also include specific wiring for putting this in a first gen Impreza (specifically 98 GF in my case, the older first gens definitely have different wiring in the instrument cluster if nothing else).

-

2

2

-

-

Mounted regulator, assembled and installed fuel lines.

I think I have the engine harness plug pinned out well enough to get the engine running.

Pinned out the connector for the DBW pedal. Which doesn't look like it will directly bolt in place of the Impreza gas pedal, will have to figure out something there.

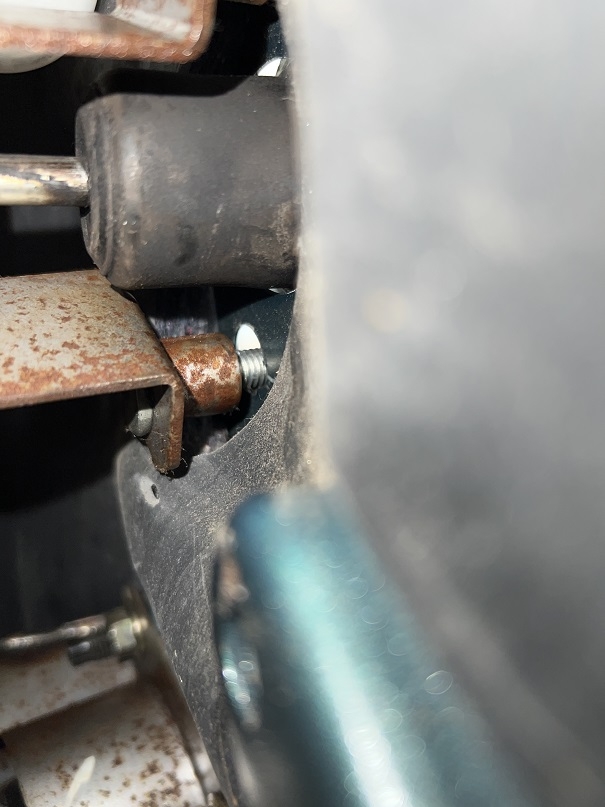

The rear brumper for the Forester just needs to be welded and painted. And yes that's road salt.

Made tubes running forward from the bottom of the bumper to the swaybar brackets. Made the one on the right side easily removable, should protect the carbon canister.

-

1

1

-

-

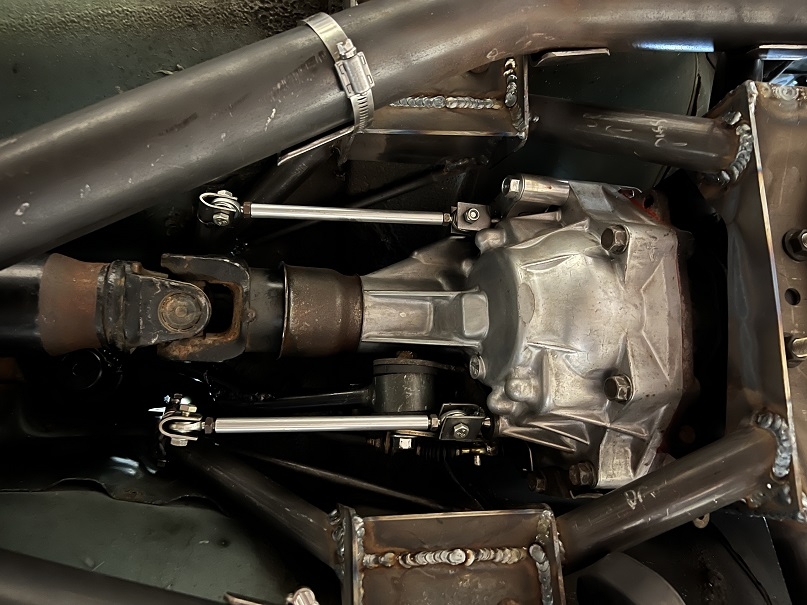

Been making some progress on the Impreza too. Shifter was interfering with one of the low range shifters (I think lock/unlock) so B welded in a different tube and cut the stock one.

Welded in a front receiver for winch or jack under the front bumper.

Hangers for rear muffler. Should probably brace those a little better.

Fit the middle 2.5 x .095 4130 exhaust section and tacked in a V band clamp.

Welded main portion of the exhaust.

STI pedals basically fit but seemed a little off. We tightened it down and seems OK.

Got a lot of the wiring done. Engine harness connector mostly pinned out from the Haltech, need to add a few powers and grounds.

Pretty sure I figured out the gauge wires (oil press light, temp gauge, tach), main ignition switch wires, and fuel pump power wire running to the back. Getting fairly close to running I think.

Haltech recommended running a pressure regulator and return line rather than trying to control fuel pressure with the pump. The EZ30 does have a pressure regulator on the end of one of the fuel rails but the rails and injectors are completely different than the EZ36.

EZ36 supposedly has higher flowing injectors.

Apparently most people either buy billet rails (which cost money and would also require AN feed lines or adapters) or just drill and tap the stock rails. I drilled and tapped them 1/2-20 and chamfered them for O ring boss AN fittings.

Have all the fittings, line, and regulator, just need to put it together.

-

B and I are finally back to spending more time on our Subarus.

Replaced the tie rods and rack boots in the white Outback and set the front toe. It's been running well. Definitely has some ghost walk on slippery surfaces but feels very stable on clean pavement. I think at least one of the trailing arm bushings is pretty sloppy.

Did some work on B's Foresters including some tie rods and rack boots. Revalved all of his shocks and replaced the fluid in most of them. Went back to basics, I think we'd kind of gone down a blind path the last few years. He says it rides better and is less noisy on the street including a small jump. We now have significantly different valving in his car, Z's FXT, and my Impreza but the same size tires and springs and similar weight and wheelbase so we're curious to see how they compare off pavement. Would like to get the long travel struts tuned better this year. We also got a good start on a rear bumper for B's Forester to match his front bumper. We'd already bent a template out of conduit so we made two copies of that out of 1.5x.095" 4130. Longitudinal body mounts are 1.25" receiver tubes spaced up with 3/4" square tubing. Figured we had to use something to mount to the body and it gives us two more solid jack/recovery points. A little hard to see in the pictures but the stock bumper and hitch are just bolted in from the bottom. We drilled all the holes all the way through and ran long bolts all the way through the body.

Mock up of the two bent tubes. Lateral square tubes are also 1.25" receivers. B wants a 2" receiver on center and can then just use a 1.25" reducer to fit our winch, hitch, etc. Need to shorten that up and add some diagonal braces. Will also miter vertical tubes on the ends, probably add a few more short vertical tubes too.

Needs some tweaking but this is where we left off with that project. Another good day on that and we should be able to get it ready for paint.

Been doing some "reverse shopping" as my brother calls it. Went through my mostly bald and leaky mud tire inventory and took the worst seven to the tire shop to get disassembled. Had a few that didn't leak and had some tread on them but were worn funny (every other block worn down, blocks worn at a taper, super noisy, tire in foreground is a perfect example).

-

UP trip video from 2022

-

1

1

-

-

M finally decided the old Impreza wasn't worth fixing. Compression had gotten so low the car would roll in gear with the engine off. In a way this is the one that started all of our Subaru off pavement adventures after I hit a deer over a decade ago. A little disappointing it didn't hit 300,000 miles. Certainly the most entertainment per dollar of any car I've ever owned.

inside of the gas tank:

Some of the parts we scavenged. The main things I wanted were the wheels (and tires), shifter/console (although most of that doesn't fit my '98), and the front axles and knuckles. The knuckles had been upgraded to the bolt on wheel bearing style and it had the big front wheel drive style axles. We considered removing the transmission (since it's the older style 5MT with the top inspection plate) and a few other things but had to draw the line somewhere.

That left us with the question of how to make it roll. The simplest/cheapest idea I could come up with was to weld a tube to the bottom of the control arms (they're kinda rusty and I already have a few pairs of good stock ones).

Then I welded some short pieces of tubing inside some space savers to act as hubs. These weren't centered or anything but it was just for getting the car out of the garage and on the flatbed.

"hubs" were retained by tack welds.

Gave us some hot Carolina squat action. Don't worry we kept the chrome lug nuts and only used a couple old rusty lug nuts per wheel to put some crappy tires on the back.

M specifically told the tow company they should come with a flat bed but they didn't. He insisted the guy look at how poorly the "front axle" was attached but the guy was unconcerned. Put the front end on a dolly and dragged it out of town. Frightening.

A day or two later when I unloaded the parts the one taillight still had plenty of blinker fluid in it.

Have made some progress on the green Impreza too. Will try to post a few pictures sometime. Unfortunately I've been busy with other things. Mainly buying a building to move my machine tools into. In the long run that should be great but it's kept me from finishing the Impreza.

-

2

2

-

-

Some last minute rust repair before the last trip I forgot to post. Black Outback's muffler is quite rusty and started leaking. This is after hitting it with the wire wheel, a big chunk of it evaporated.

Welded on a patch.

High temp paint.

Maybe a waste of time but did make the exhaust significantly quieter.

On to the Impreza. Most of the fab work is done. Bumper and skids about as welded as they can get on the car. Made mounts for the stock turn signals (without those they blink fast). They'll be mostly behind a sheet metal panel below the bumper. B made fan mounts, only have one right now but you can see the tabs for both sides. Headlights and a few other things I just set in place for pictures.

Made mounts for light bars just under the headlights. B figured out radiator mounting a while back.

Obtained the right section of harness for the PS, alt, and AC compressor.

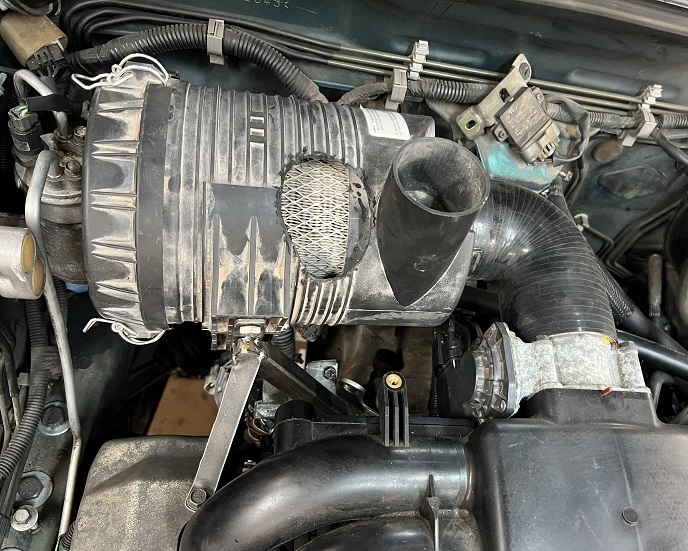

B mounted the airbox a while back, I popped another hole in it. Might epoxy a tube on that eventually, still need to cut a hole in the hood scoop blockoff panel for those.

I had the exhaust mostly laid out and then B reminded me about the gas tank guard. Pressed a divot in the skinny muffler to fit that.

Probably won't restrict flow too much. Also made the ends out of round but phased 90 from the middle (you can kind of see in picture below).

Skinny muffler in place.

If/when I fab a rear bumper I can raise the big muffler an inch or two.

Front portion of exhaust is basically done. Going to add a flange/gasket where this will meet up with the skinny muffler. If anyone has a recommendation on a 2.5" flange/gasket I'm all ears.

Have to remove the various crossmembers/skids/bumper for finish welding and paint.

Still need to find power steering lines and reservoir (2015ish H6 Outback) if anyone has a line on those.

Also need to swap in DBW gas pedal and manual brake/clutch pedals and clutch hydraulics.

Most of what's left is wiring. I think I have that mostly figured out. Might mount the Haltech where the passenger air bag was and make that panel easily removable.

-

2

2

-

-

20 hours ago, travelvw said:

Bummer about the low range, that helical gear looks roached! Get that thing sorted; I want one that can handle even more thrust force and a similar driving style. Whenever you get to disassembling and rebuilding it, I am curious to find out if there are any additional parts with excessive wear, or if it is just that one gear.

I think it's time to focus on the first gen, right? You should be proud of the years of use and abuse you got out of the black Outback.

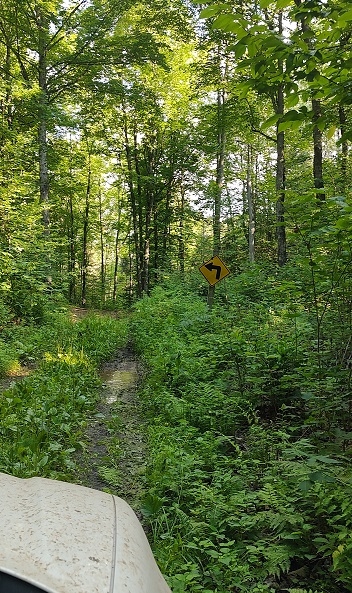

Gorgeous up there.

KReally need to make straight cut low ranges over the winter. The plus side is that the low range was still working fine all weekend just making a ton of noise.

Yes, trying to get the Impreza going, then part out the black Outback.

-

1

1

-

-

11 hours ago, el_freddo said:

I love these epic updates! Kudos doing the gearbox work out bush! Was it difficult to keep it clean from the dust?

That black outback is definitely looking pretty cactus! Over here in Oz that would’ve been condemned a loooong time ago!!

Cheers

Bennie

I'm not going to say it stayed extremely clean (we tried) but there wasn't really any dust to worry about. Dirt falling off the bottom of the car, yes.

If not for the cage we would have parted the black Outback out a long time ago. Or so I keep saying.

-

1

1

-

-

Went to the UP the last weekend of July with three Subarus and five people. B wasn't able to join us. Before the trip I was checking my notes and realized there was a crack in one of the rear uprights of the black outback so I welded that.

The rear tires on the white Outback were almost completely bald so I put some less bald tires on it.

I had looked before we went and saw a large area of public land east of Sagola we hadn't explored. There were several fire towers and the ELF (extremely low frequency transmitter) in the area too. Didn't expect much of those but gave us something to roughly wander towards. Fire towers turned out to not exist or be on private property which is about what I expected. When we went to where the ELF was originally marked on my GPS we couldn't find anything. Later Z looked it up and we did make it there but it's some kind of secure gov't facility so we didn't get to see anything.

On the way up I was driving the black Outback when suddenly I looked down and the coolant temp gauge was pegged. It had been right where it normally is for hours so I figured it might be the sender or gauge or something. Pulled into a shady spot in a parking lot. Realized it was the same hose that had rotted out on us out west and replaced it with a spare I had. The oil leak there keeps eating those hoses. Left that skidplate off for the time being figuring we'd just reinstall it at camp.

Crossed into Michigan and started wandering off pavement. Z got his Forester high centered and stuck on a stump (between engine skid and trans crossmember). Lifted it off with the high lift and threw some wood under the tire.

This part of the UP was rockier than most of the UP but not like the Keeweenaw.

Trying to follow a powerline grade Z got his Forester stuck in some soft mud.

Good reminder that any time you see even a slight trickle of flowing water up there the ground is probably going to be super soft. At this point I realized I'd left my brand new speed strap and folding recovery ramps at home. Then we broke my 2” speed strap, it's seen a lot of abuse but I was still a little surprised. Z had a tow strap and with a combo of that and my marginal speed straps we were able to get his car out. One of those situations where we tried about ten iterations of straps thinking each one would work, might have been just as fast to winch or jack him out of there. Went the other way on that powerline grade which had some good rock ledges and climbs but didn't go very far before going off into the woods. Before one fairly big drop we decided we should put the one skidplate back on the black Outback so we did that while V cooked the burgers since it was supper time. Maybe the first time we've cooked supper before getting to camp.

Saw a (juvenile?) porcupine standing in the road, got a few good pictures of it before it walked off into the brush.

Late in the day the black Outback started making some fairly high frequency drivetrain noises proportional to wheel speed like a gear in the transmission was rubbing on something. M was driving and I played with the shifters and then it went away. Found a FS campground and stayed the night there.

The next morning we did a little more trail riding but the transmission noise was back.

It was making enough noise even in neutral that we didn't think flat towing it would be a good idea. We discussed a few options and decided the best would be to try to fix it. I have been carrying a stock DCCD so plan B was to install that and plug the shifter holes. We went back to the campsite we'd stayed at the night before since it was decent, close to toilets, and there had been no one else in the whole campground. Of course during the day two other campers showed up and occupied the spots on either side of us. Disassembly went fairly smoothly but time consuming. Realized we'd need gear oil so Z and V drove to town to get that and some groceries so V could cook us some fajitas since we knew he'd have plenty of time. The main problem seemed to be thrust forces (from the helical gears I assume) wore out one of the snapring groove lands to the point that one of the snaprings was just floating around in the middle of the low range. We just removed the snapring, the part it'd been holding on was already galled/peened in place. M and I tried about ten times to put the low range back in the trans and then put the cover on with no success. Finally we put the low range in the cover and put the whole thing on and it went right together.

One trick we used was to tie the split needle bearing on the front output shaft on with a blade of grass since it would instantly dispose of itself, before that those bearings kept falling out of place during assembly even though we'd greased them. As it turned out the grass fell out during assembly but did its job.

Then we put everything else back on and I took it on a test drive around the campground before dark. Seemed to work fine but still a little noisy. Camped again in the same spot we had on Friday night, something else I don't think we've ever done before.

Sunday we had a solid day of trail riding with no major issues.

Found a stunt area, unplugged a culvert that'd been dammed up by beavers, then Z got properly stuck in the mud in a clearcut area. Probably over 100' from the nearest fairly solid ground. Set up the winch and swapped the Anderson connector from the white car on to his battery. Winched off of several different stumps with the snatch block and eventually got him on to solid ground. Good reminder that having a winch you can put on either end of any car is far superior to having it permanently mounted to one end of one car. He was then able to drive through the clearcut along the trail back to where we were parked. The whole thing took under two hours with surprised us.

I got the black Outback stuck after turning around and trying to climb up a steep bank. A backed the white Ouback back to where we were. By then I remembered I had a proper elastic snatch strap and soft shackles so we used those. They hit much softer than the speed straps. I couldn't really even feel when it hit even though A was taking a 10-20' run at it. He eventually pulled me up the little bank. Somehow the rear bumper cover of the white Outback had come off so we cobbled that back on and continued.

Monday morning while we were following the black Outback it seemed like the rear camber on it would be both tilted to left, then both straight. Eventually A decided to pull over because it was steering itself. The subframe had pulled out of the remains of the unibody on both sides. We also had brackets connecting it to the skidframe which had mostly ripped off. We sort of straightened out the brackets and hose clamped them back on and ratchet strapped the subframe up into place.

(We were able to ratchet strap the subframe back up to the body, not shown)

A managed to navigate us down a fairly long and almost entirely off pavement route south. Got to an abandoned railroad track.

Had to restrap the rear subframe a couple more times. The last time A came up with the idea of strapping the subframe to the skidframe laterally which helped a lot.

Black outback is probably finally and properly totaled. Needs a trans rebuild, radiator, coolant hose, rear diff is no longer limited slip, rear axles and wheel bearings are ticking time bombs, and most importantly needs some serious body/frame repair for the rear subframe. In the meantime it is still driveable if I need to drive it around town some. Really need to get the Impreza running. Will try to post an update on that soon.

-

4

4

-

-

Wife and I have been doing a lot of kayaking day trips, mostly in northern and central IL. Took a weekend trip a couple weeks ago and found some interesting trails. Had to control myself as we had no tools or spare parts and were traveling in one car.

-

Video from our trip to Missouri last year.

Have made some progress on the Impreza too, will post an update on that fairly soon.

-

1

1

-

-

Finally got video edited and posted from our Kentucky trip last year.

-

9 hours ago, travelvw said:

Love the addition of the hi/lo shift levers over the cables. Looks like you are about finished mocking up the rear suspension. The entire skid plate frame looks well executed. Everything I'm seeing is an improvement over the Outback... man, you are taking this car to the next level!

K

Thanks K.

I would have done levers instead of cables on the Outback but I kept thinking it'd be totalled by now. Should be much easier shifting.

Yeah rear suspension is just about ready to weld and paint.

Skid plate does hang a little lower than most of our other cars in order to protect the headers, hopefully that won't be too much of an issue.

I think the biggest improvement over the black Outback will be the 1000#ish weight reduction.

-

Hard to tell from the pictures but this is after some massaging and trimming we did to get the condenser farther forward, maybe 1/2-3/4"?

One of the little things we did was to bend the bracket/line on the driver's side (LF) of the condenser to give us a little more room for the radiator.

One issue was this corner of the radiator support had a big radius/gusset to it so B notched that out and patched it back in. I have some grommets that will fit that washer for the radiator mount posts. Other side we've got a tube tacked in with a piece of hose for the post. Bottom of radiator will probably also be padded with rubber and will rest on radiator support.

Radiator is for a 99-05 Mazda Miata and fits without any trimming or modifications. About a half dozen companies make thicker core aluminum radiators for those cars, this one has a 42mm thick core. Just narrow enough that it sits alongside the passenger side (LF) cam phasers. Unfortunately I think I should find/make some 90 degree bent water necks for the top tank. I might be able to get a hose with a tight enough bend to clear the PS pulley but I want to get one welded on the other side anyhow.

While I'm at it I'll probably put a 1.5" water neck in the bottom and at a more downward angle for more clearance to the timing cover. Again, this one would probably work as is but it's smaller than stock (1 3/8"?) and the hose would be very close to the timing cover.

-

1

1

-

-

Box for rear trailing arms is still very close to the wheel. Might even rub just from the weld bead sticking out when finished if I just welded them as is.

I plan on tweaking those for a little more clearance before welding.

Shortened up the links on the driver's side by 1/8". While I was at it I refit the tube to the bottoms of the bushing sleeves rather than centered for some shock clearance. Not ideal structurally in tension/compression but that's almost certainly not how they'll fail.

With the shorter links the inner CV still has a little room before it bottoms out at full droop.

We also put a tire on and stuffed it up as high as it'd go with the jack and I still think rolling the fender and removing the rear bumper cover will be enough.

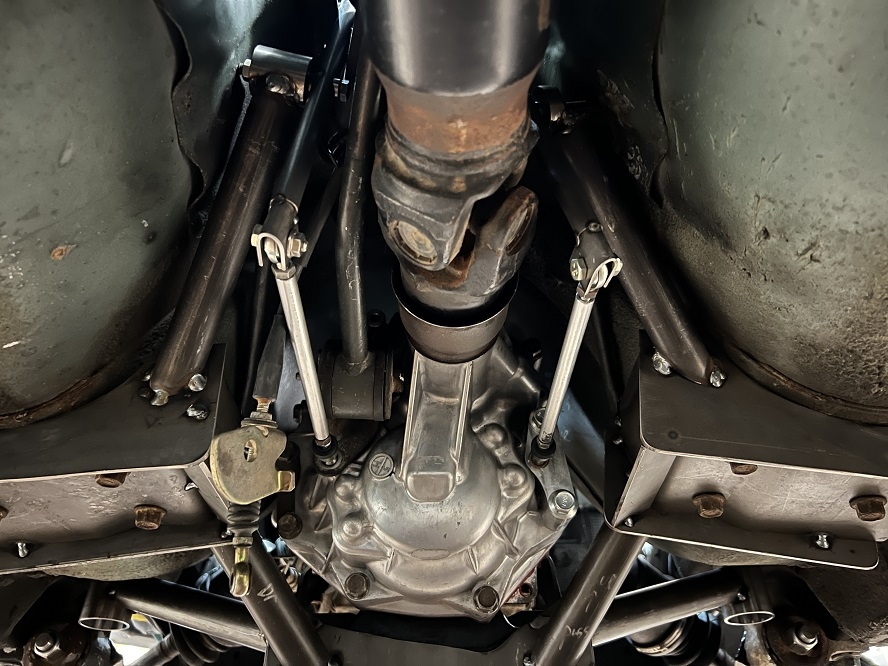

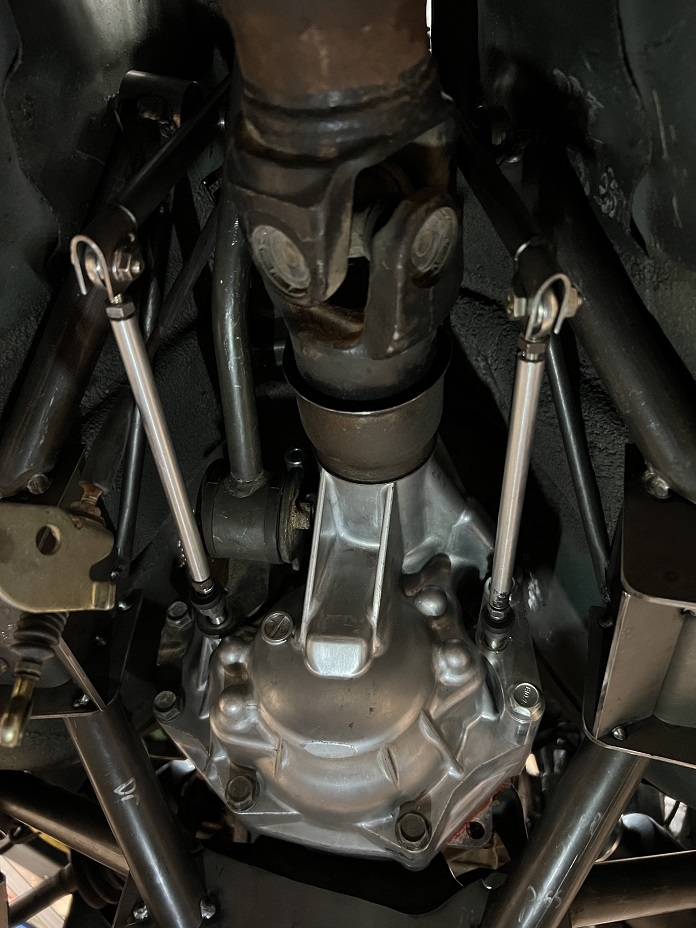

High/low and lock/unlock shift levers/linkage tacked up:

Seems like most of the compliance is in the trans mount so it should be stiff enough. There is an alarming amount of slop in those in line ball joints though, I need to find some better version of those or replace them with rod ends. B was able to shift high/low and lock/unlock while I turned the driveshaft. High/low is pretty easy, lock/unlock takes considerably more effort and turning. This is the same experience as in the Outback with the cables but is definitely easier with the levers. They have about a 2:1 mechanical advantage and you can actually push or pull hard with one hand.

Plan on bending the right side lever to the right. Plan on just poking holes in that rubber boot for them to pass through, they don't move much at that level.

B did say the left lever (hi/lo, requires more travel) does get close to the dash in low but that can be adjusted.

-

1

1

-

long travel Outbacks or making Subarus faster and more reliable offroad

in Off Road

Posted · Edited by pontoontodd

B and I made more progress on the Impreza too. Got the headers welded. Seems like getting them ceramic coated would cost $350+ so I'm just going to skip that. They are stainless and as B pointed out, they'll probably fail due to mechanical damage rather than corrosion.

Did some welding on other portions of the exhaust. Should have tacked more things together before removing all the tube work underneath the car.

Sprayed the welds with a little high temp paint, most of it is already aluminized.

While we were at C's shop he gave me a radiator and fans that had the right plugs I need so I spliced those in to my fans. Note the polarity is reversed since we're using them as pushers. Will put more detail on that in the swap thread.

Painted the mounts and bolted the fans in. Spliced wires from Haltech to where they went to stock ECU to switch on the relays.

Siliconed a grommet for an air temp sensor in the air box. Definitely not pretty but wanted to get something in place.

Wired in the connector.

Made a couple of tabs, welded them on the bumper and painted them. Drilled a couple holes in the bumper beam.

The Outbacks have hoods on them so the light only shines down but they have a different wire connector. The Impreza lights don't have hoods so I painted all but the bottom of them. Need to fab a rear bumper for this thing sometime but this seemed like the simplest and cleanest solution for now. Open to suggestion on how to do this when I fab a rear bumper. Planning on 2x4" steel tube like the front sticking out at least a few inches beyond the hatch. On my old Impreza I just screwed the plate and some aftermarket license plate light to the hatch but I'm not keen on doing that to this car.