-

Posts

2375 -

Joined

-

Last visited

-

Days Won

56

Content Type

Profiles

Forums

Gallery

Store

Posts posted by pontoontodd

-

-

3 hours ago, el_freddo said:

Looks awesome, great craftsmanship there!

Are those front control arms reinforced stock units or completely custom built from scratch? They look impressive!

Cheers

Bennie

built from scratch, see post 85 and the next few afterwards

-

On 2/28/2023 at 6:56 AM, travelvw said:

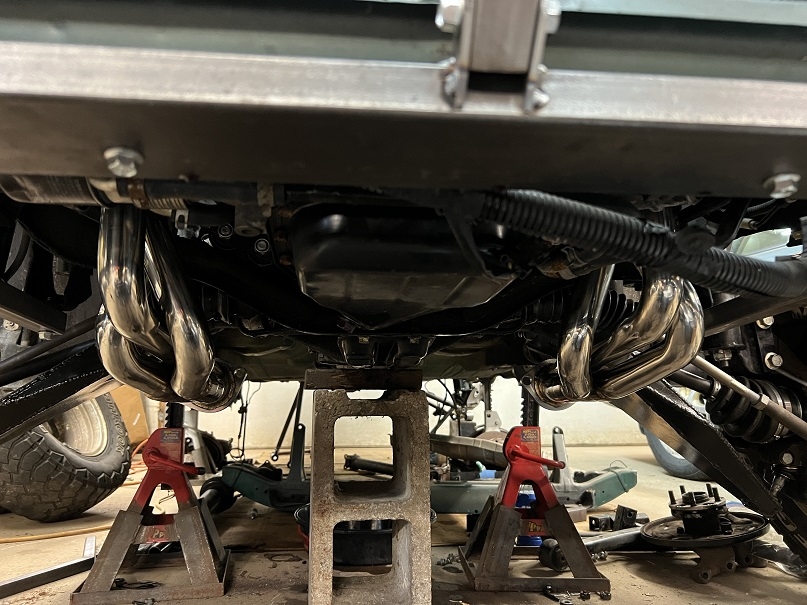

The first gen is coming right along. Lets see the final install of L/R billet knuckles and chromoly trailing arms. Headers look close enough to the rack boots, I'd make heat shields or wrap the ends.

K

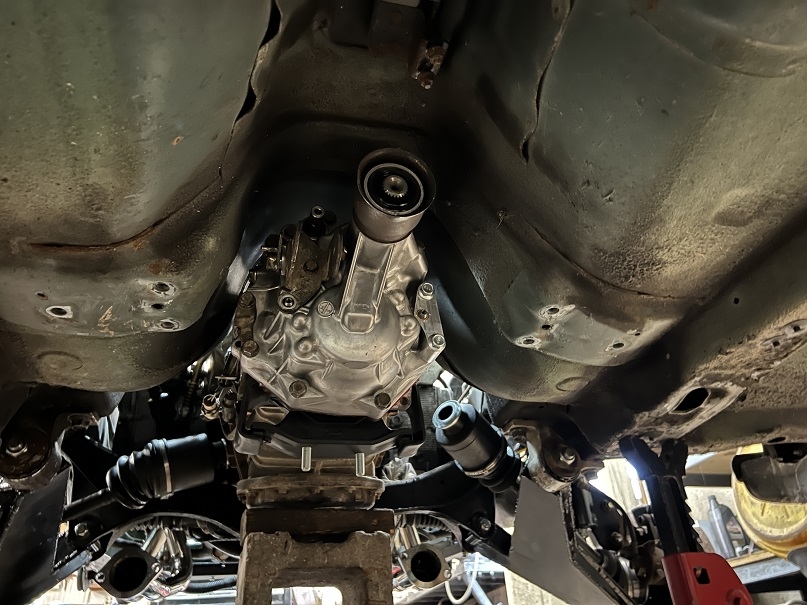

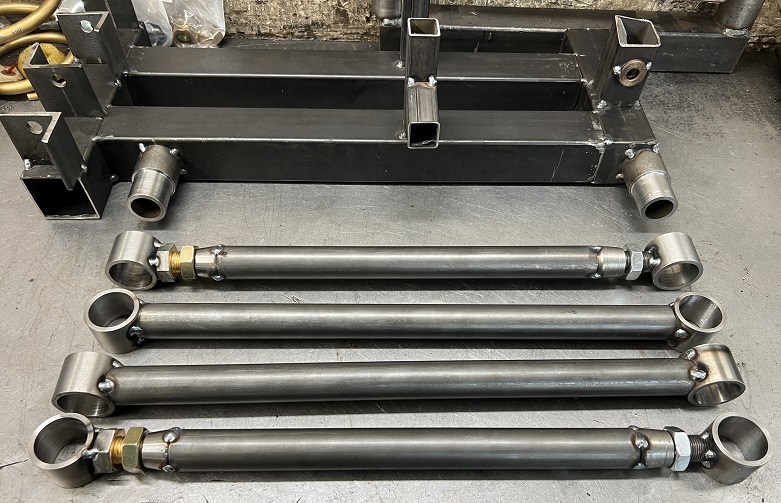

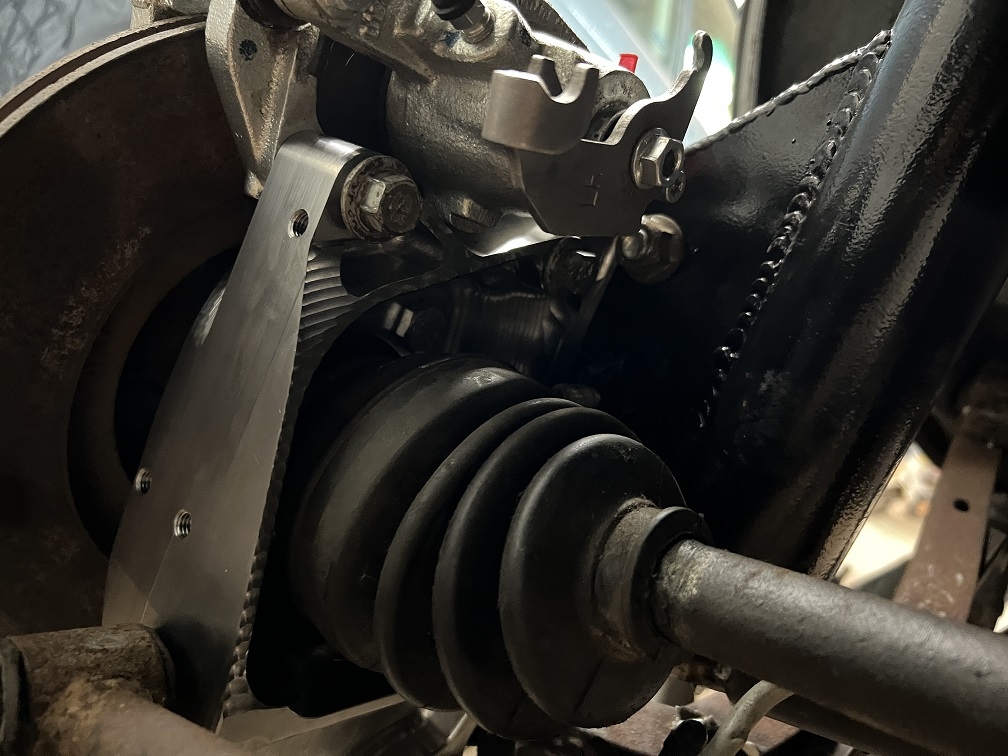

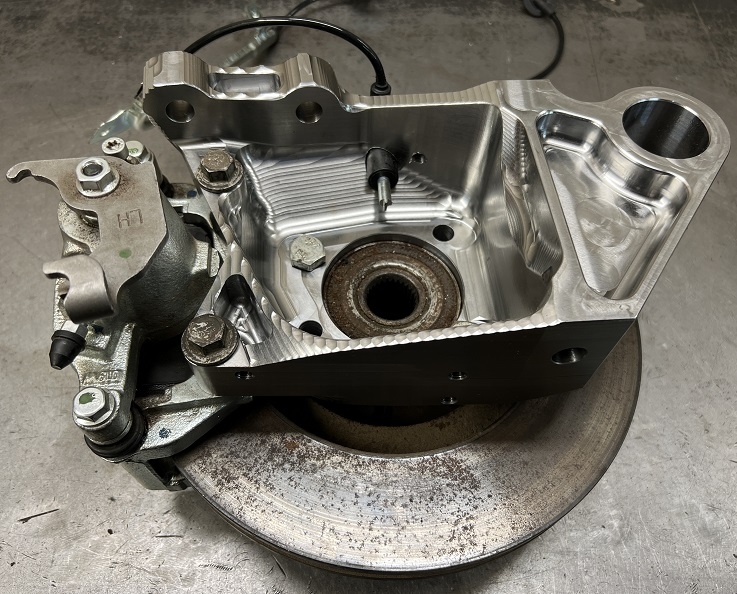

Here you go, rear suspension fully mocked up with fabricated links, front axles, and billet knuckles with bolt on wheel bearings. Might shorten the lateral links a bit but have to check. Should work as is.

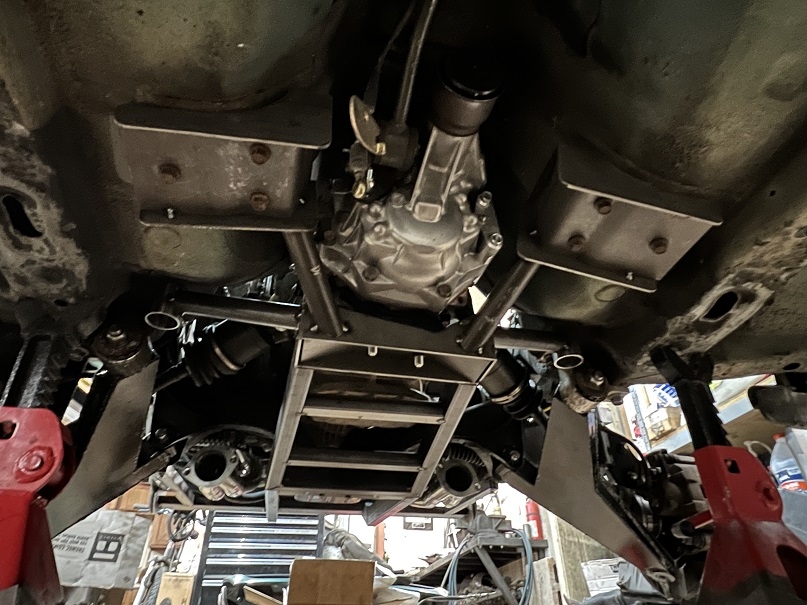

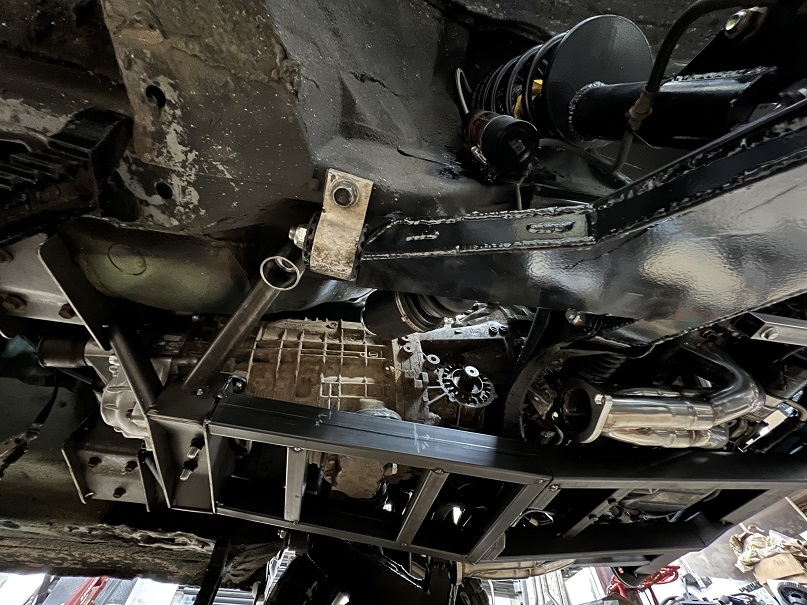

B and I got the engine and trans skids/mounts mostly fit and tacked up. Trans mount bracket, wanted it to protect the studs.

Brackets bolted on in stock crossmember location need to be gusseted/trimmed.

It hangs down a little farther than I'd like but is only about 1/4" lower than the headers and I didn't want those to be the lowest point. Should be a bit stronger than most of our engine/trans skids. Needs a few lateral tubes in front of oil pan and headers. And obviously some sheet/plate.

-

1

1

-

-

43 minutes ago, el_freddo said:

Hey Todd, this website could help with finding parts to the size you need. A mate got me on to it as we look for alternative parts on our MY Brumby/Brat utes…

That exhaust looks MINT! So shiny, but I bet not for long once offroad! Shame the three pipe done sit horizontally flat beside each other for maximum clearance. If you went that way it would probably be easier to fab up your own headers for that setup!

Cheers

Bennie

Wow! That's perhaps the greatest website I've ever seen. It's like going back fifteen years when the internet was useful. Thanks a million for the tip!

Probably getting the headers ceramic coated but yeah I hope they won't stay clean and shiny long. Not that anyone will see them. Someone else online suggested what you just did with the pipes side by side, would definitely be the way to go but I just don't have time to make everything from scratch. Otherwise I'd finally build a two seat buggy.

-

Video from our trip to OK, TX, and NM with slammo.

-

1

1

-

-

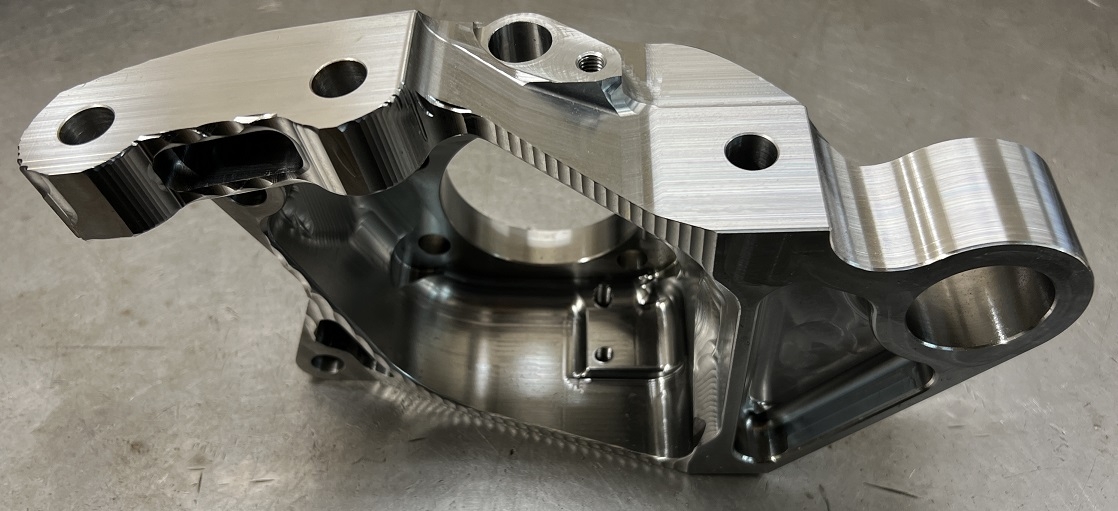

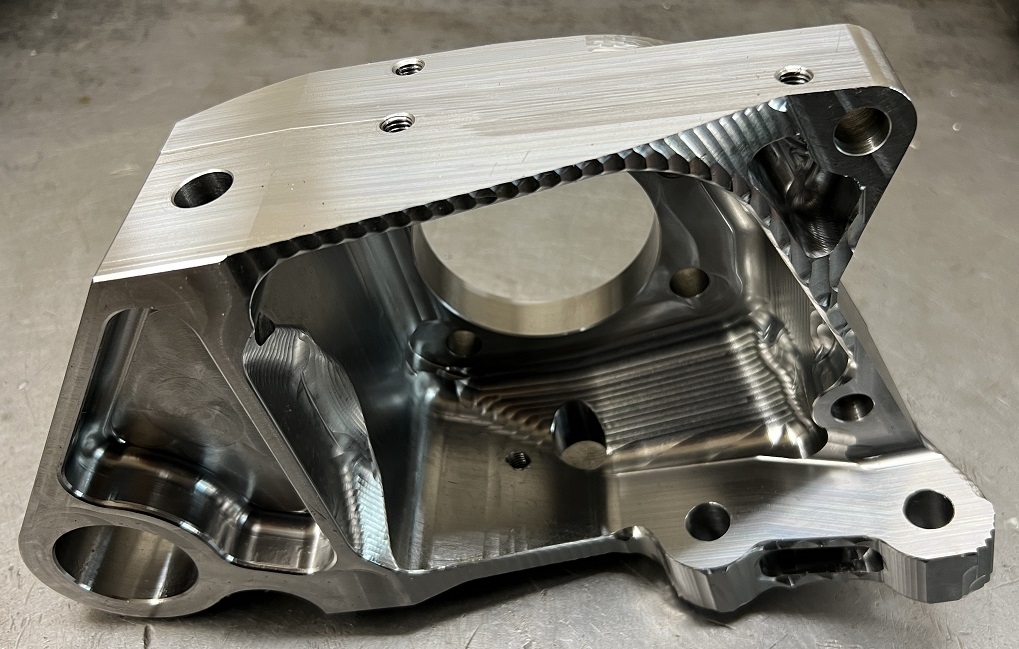

Got the right rear billet knuckle finished.

I made a couple of legit trailing arms using sleeves Z turned up. Sleeves are about 50% thicker than OEM and made out of chromoly so hopefully they will stay round unlike the used one in the background.

So I think we can now fully mock up the rear suspension.

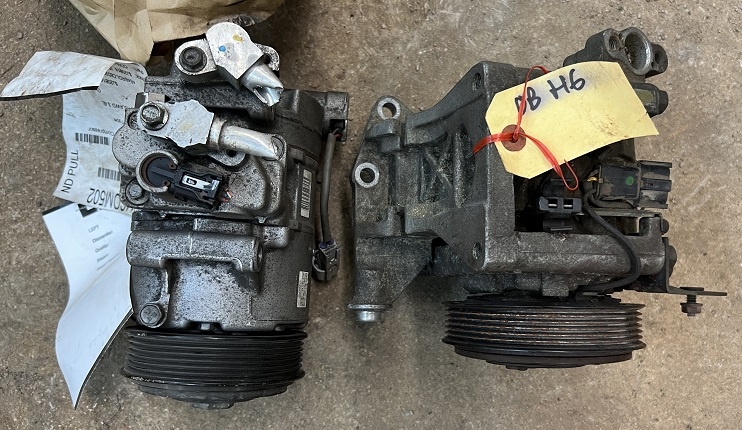

I finally got brackets and bolts for the AC compressor so B got the accessories and belt on.

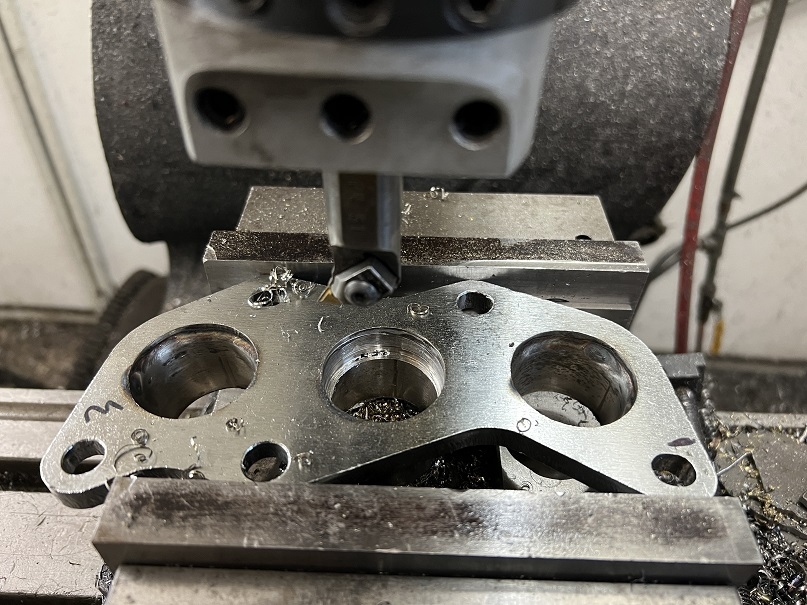

We wanted to shorten the primary tubes on the headers for more ground clearance. They slide in bores in the flange and are welded inside. First step B cut them off about 1" from the flange. Then I bored them out on the Bridgeport. After that it was easy to knock the rest of the tube off and B ground the welds a bit. Then we were able to pry/hammer the tubes back in the flanges and tack welded them on. Passenger side one was pretty good but we wound up angling the drivers side tubes toward the center of the car for more clearance to the crossmember. We'll probably cut off the flange on that one and extend it for more clearance but they're about as far up as I feel comfortable with. I want some clearance to the crossmember and rack boots.

B also removed the auto shifter and put in the STI shifter but we need a rear pivot bushing. On the plus side it looks like we should have a decent amount of room for the hi/low and lock/unlock shifters in front of the stock shifter and room for a steering brake (two handle?) next to the parking brake.

It appears that a 99-2005 Miata radiator should fit beside the passenger side cam phasers so I plan on getting one of those. One nice thing is that there are at least a half dozen companies making thicker core all aluminum radiators for those Miatas. I think I'm going to go with the CSR. Main reason for wanting aluminum tanks is then I can get a second inlet welded in the top tank.

-

2

2

-

-

Finally getting some video editing done, more to come in the next few weeks.

-

13 hours ago, el_freddo said:

That billet knuckle!! It would be sick to make a billet EA swing arm with the EJ bearing setup to make rear disc swaps easier, then we could legally (in Oz) and easily upgrade the tyre size to the same as the forester without major complicated engineering testing we require over here.

But that would be Uber expensive to make up, hence why it’s not done.

Keep the good work coming! You have this going in no time!

Cheers

Bennie

Thanks Bennie, from where I sit we have a lot of work ahead of us to get the Impreza running but I'm looking forward to driving it.Finally got video from our 2021 Vegas to Reno finish edited and posted on Youtube.Six minute version:Thirteen minute version:-

2

2

-

1

1

-

-

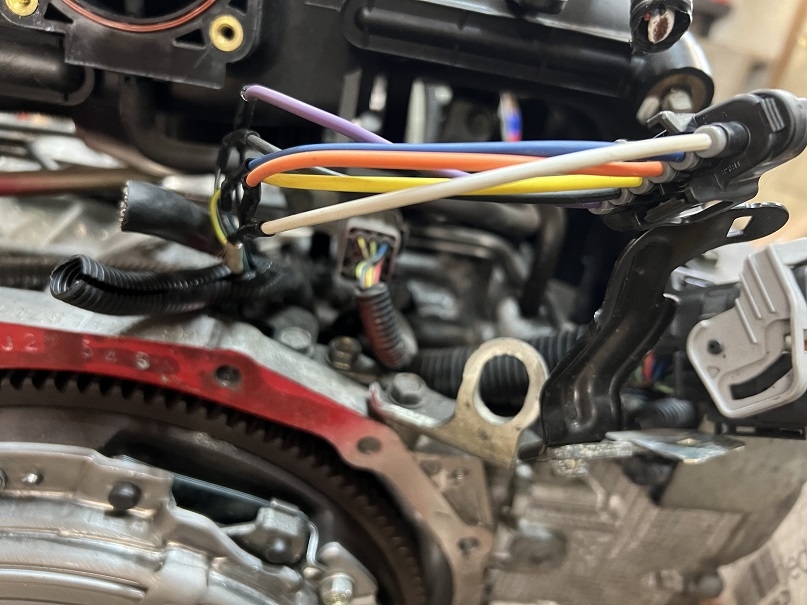

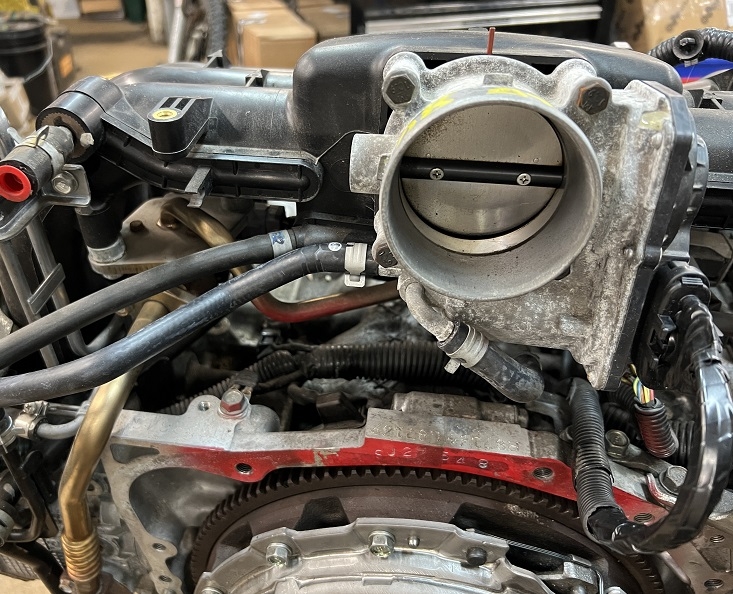

Wired in a connector for DBW TB and installed that.

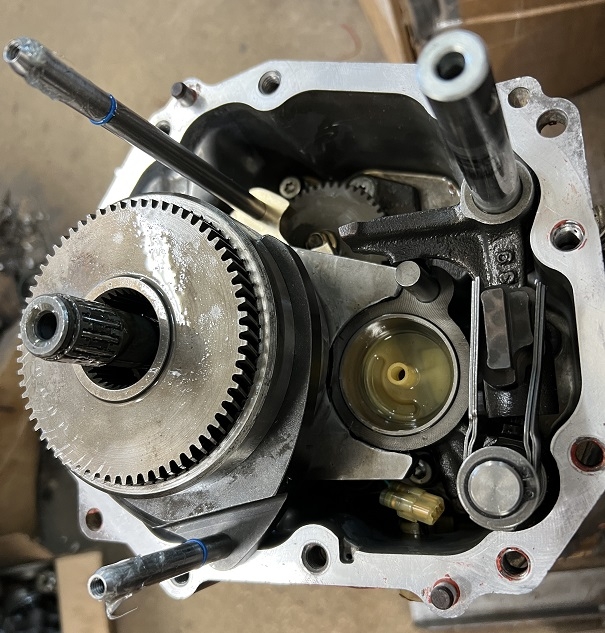

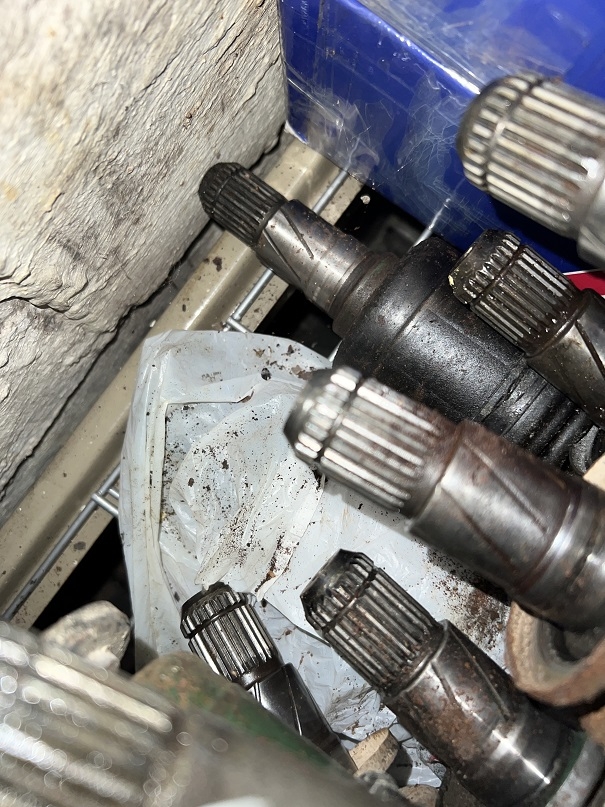

Installed low range in my other good 6MT for the Impreza.

EZ30"D" radiator on left, EJ22 radiator from 98 Impreza on right.

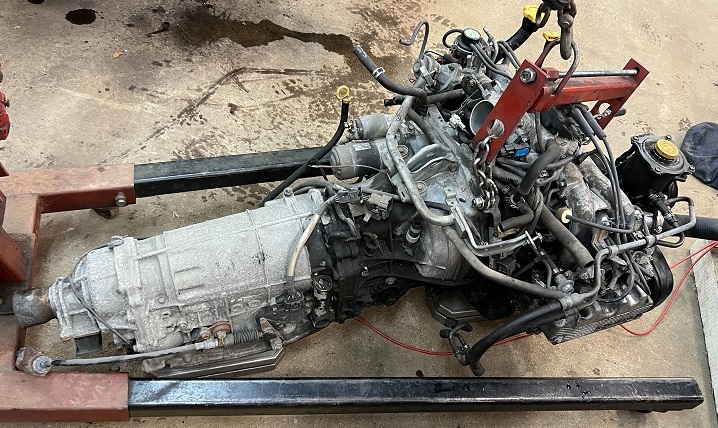

EJ22 and 4EAT from 98 Impreza.

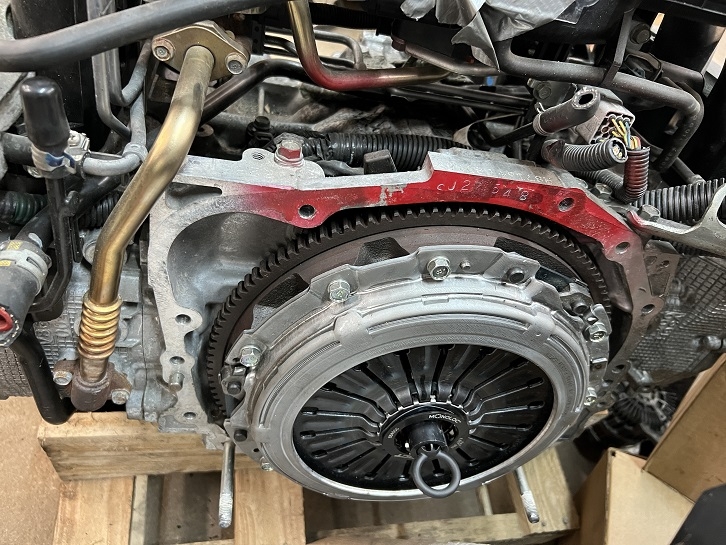

EZ36 and 6MT in 98 Impreza.

Biggest issue seems to be radiator clearance. I've seen at least one person put this engine in this car with AC and a ~2" thick radiator but the lower passenger side cam phaser was basically rubbing on their radiator. Seems to be the same for me, which wouldn't be good for off road use. Going to shop around for some narrower radiators, should be a decent fit if we can just avoid those cam phasers.

Not a lot of room in front, stock condenser wouldn't fit in front of radiator support due to headlights, would be a tight fit for condenser and fans between that and front bumper anyhow. Yes at this stage it wouldn't be too difficult to shift the bumper forward a bit but it already sticks out pretty far.

On the plus side, should be a pretty straight shot for a skid from the radiator support to the front crossmember, might have to drop it down a bit for the oil pan but the timing covers are pretty high up. Headers need to be shortened vertically and probably at least the driver's side extended to put the flange in a better spot. They're not bolted up 100% so might look a little off.

Plenty of room in trans tunnel.

Z turned up some trailing arm sleeves for the front pivot. He also did some test fitting on the R180 to female front axle diff stubs. I have the RR billet knuckle almost done.

So we're closer to getting that whole package figured out.

While we were doing a bunch of this disassembly and assembly we weighed a bunch of things:

11# 98 Impreza EJ22 alternator

14# 2013 Outback EZ36 alternator

466# 98 Impreza EJ22 engine and 4EAT w/ PS pump, engine mounts, starter, engine oil

362# 2013 Outback EZ36 engine w/ flywheel, clutch, PS pump, engine mounts

198# 2007 STI 6MT

127# 5MT

So the EZ36 & 6MT is only about 100# heavier than the EJ22 & 4EAT.

-

22 hours ago, docmidBratt said:

So update after todays work

The cam and crank triggers are the the same between both bg5 and sf5.

Have power going to coil pack

Have checked coil pack and tested it. working fine.

Cranks over easy but still no spark.

Got good earths, added a few more to make sure.

checked all plugs

Bit off a loss now.

Didn't check igniter, don't no what im looking for ha ha ha

Yea i only have iphone on a prepay system do not connected to net to post pics from track

but my wife made a instagram account and put something on it but i dont no what

But next time i'll get some shots and a flick or 2

Thanks doc

Do you have some kind of OBDII scan tool / app? Might tell you something, at a minimum whether the ECU is coming on. Is it getting fuel?

-

Still need a few parts before we put the engine and trans in. B replaced some of the coolant hoses and put the Kein engine mounts on.

I put the used H6 radiator in. Bottom lines up perfect, need to move the top mounts but that'll be easy. It'll be tight with the EZ36 even with no fans.

Modified the trailing arm fixture to also fixture longer lateral links. Tacked up a set. Waiting on Whiteline bushings so we can easily test fit these. Much easier to swap in and out than the stock bushings.

B's driveshaft has been vibrating occasionally. He thought it was the center support bearing. He filled the old one out of his green Forester with urethane and then swapped it out. As he was doing that he noticed the front u-joint on his driveshaft was extremely worn, probably missing all the needles in two cups.

Good thing he replaced it but the one he just put in vibrates over 55mph. Didn't get marked when it got disassembled so we'll probably try clocking it 180.

TT called today and told me the writing on the rear diff of the red Impreza was just his way of telling me when he'd replaced the fluid. So that five bolt diff is probably stock. Maybe the one bolt diffs were a base model automatic thing?

-

1

1

-

-

21 hours ago, docmidBratt said:

How's it going

We have had the brumby at the track a couple of times now with mixed results.

Since the change to the sf5 engine out of my forester no engine problems other then running on gate. (6 psi)

And the handling need some work. but got a plan for that.

Hooked up boost control solenoid and got boost jumping up around to 5000 the solid 10 psi. Got a fix for that.

But seems really slow for a turbo 2.0.

Down the back straight its only getting to 165kph which i would expect it the be 180kph with say 190hp?

My honda with a b16b does 185kph with 185hp. There's not push into your seat.

So the handling we are going to run a stiffer front spring and toe in the back a little to force it to turn in better

as I can feel the back wanting to brake loose.

Now the problem is we decided to swap out the 1996 sf5 300000km block that through a sparkplug out the head

for the 1996 bg5 200000km block which is in way better condition.

Swap everything over, blocked up unused holes, wiring etc.

Problem is it won't start.

Now my guess is that the crank and maybe cam triggers are different?

Any ideas

Thanks doc

Glad you're getting it out and using it. I'm sure we'd all love to see more pictures of it in action.

I don't know much about Subaru turbo engines so I'm no help there.

With equal power I wouldn't be surprised if the Honda is faster on the straights, it's probably lighter and has less air and drivetrain drag right?

-

Originally put this together for a friend, then realized it might be helpful to others wanting to do an STI swap. Basically everything you'd need to upgrade the drivetrain. Prices are roughly what I've paid in the last few months in US dollars. Yes you can use an automatic driveshaft and swap the flange from R160 to R180 but the STI driveshaft has significantly bigger u joints. If you find the right swap kit you can probably get a cheaper total price but I already had the trans. That's what I did in my black Outback, for instance just used the stock clutch and flywheel and only replaced the disc and release bearing. Can also buy a lot of these things from the dealer but they're more expensive. Conversely some of it you can buy on rockauto etc for close to used prices but I'd rather have factory parts for most of this.

$2500 trans used 2006+ to fit our planetary low range

$200 driveshaft used - get one same wheelbase as the car you're putting it in, 2007 STI seems to fit first gen Impreza perfect, got a newer one that fit my Legacy Outback.

$715 diff used 2006+

$150 shifter used -2013? at some point they made the shifter longer I've been told

$150 flywheel used but resurfaced

$10 flywheel bolts (800610740)

$8 flywheel pilot bearing (816212020)

$12 flywheel dust cover (30216AA070) IMO required for off pavement use

$6 pressure plate bolts (800508310)

$450 clutch/pressure plate/release bearing Exedy FJK1000 from Rock Auto, looks like rallysportdirect is cheaper but not in stock

$92 ACT monoloc from IAG - definitely optional

$70 clutch slave used

$10 clutch line 37250FE052

$23 clutch hose 37251FE030

$2 clutch hose banjo bolt 112925161

$2 clutch hose crush washers 114130151

$104 Trans mount 6MT 41022FE010

$75 starter usedProbably not required but in order to run female front axles you need:

$96 front axle stubs 4EAT 38415AA070

$5 front axle stub seals RF806730031

$5 front axle stub seals LF806730032

$2 snaprings for front axle stubs 805329010Also since my car is an auto I needed:

$35 clutch master used

$75 STI pedals used (I think any Subaru manual trans pedals would work, looks like even Forester pedals would bolt in)Finally, you need one of the following:

STI CV axles (rear at least), knuckles/hubs, brakes - can't fit 15s and are a larger wheel bolt pattern

Slammo says "04 STi rear knuckles let you stay 5x100 and use stock 04 STi rear axles with an R180, and you can fit the WRX 2-pot calipers without adapters, but you have to use special rotors since the STi parking brake drum is a bigger diameter" but those 04 STI rear knuckles are rare.

Suberdave's conversion races - maybe these would work OK on a lighter car if driven carefully but then what's the point? Definitely the cheapest route but at least moves the weak link to the axle which can be replaced in the field in a reasonable amount of time.

Billet rear knuckles and R180 to front CV axle stubs - probably cheaper than STI knuckles, hubs, and brakes, and I think the best solution for reasons already discussed.

-

2

2

-

1

1

-

-

On 1/18/2023 at 3:51 AM, el_freddo said:

I hang out for these updates!!

With the above, are you saying the one bolt came before the five bolt R160? Or is there and early and later version of the two diffs (that I don’t know about)?

Asking as the five bolt came before the one bolt. I know the 1980 brumby/BRAT models run with the five bolt diff and you could bolt one any five bolt r160 into the back of them.

The one bolt I believe appeared mid to late naughties, but I think the five bolt is still to be found in those years as well depending on which vehicle model you look at - I could be wrong though!

Cheers

Bennie

Excellent question, I don't know.

The EA vintage Subarus had bolt in drive stubs, right? We used many of those in our buggy. I'm almost positive those were five bolt so maybe you're right. Can't remember what my Loyale had in it.

I think all the EJ Subarus we've had have had the five bolt R160. Since this one bolt R160 is out of one of the oldest EJ Subarus I've ever had and it's clearly smaller and lighter I just assumed it was an older design and the five bolt was an upgrade. FWIW my red Impreza has a five bolt but also has junkyard markings on it so it's definitely not stock. Not sure what kind my 96 Impreza had in it, never had to take it out.

-

1

1

-

-

Haven't accomplished a lot in the last couple weeks, been sick and busy with other things. Still need to get the throttle body sorted at a minimum before we put the engine in. Will hopefully have engine mounts this week.

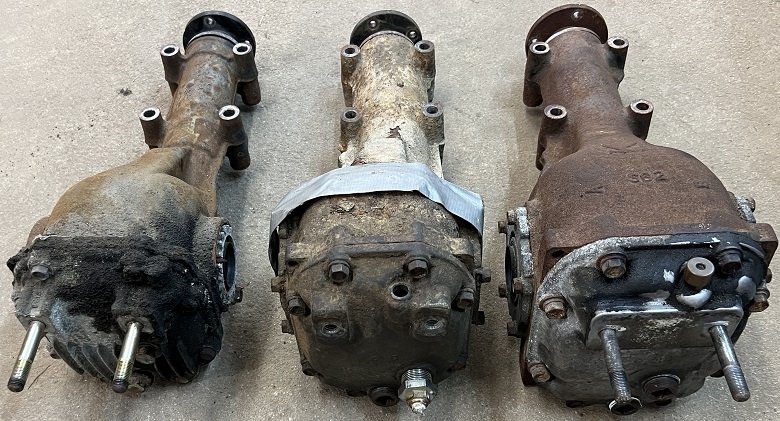

Biggest thing we accomplished was swapping in the R180. Left to right, "one bolt" (earlier) R160, "five bolt" (later) R160, R180. Some studs and plugs swapped over.

Definitely one good reason Subaru has a Lego reputation. After swapping over those studs the R180 bolts right in.

Weights are 37# (1 bolt R160), 47# (5 bolt R160), 57# R180. 5 bolt R160 is definitely a 4.11 open diff, I assume the 1 bolt is open also but probably 3.7 or 3.9. I was shocked how much weight difference there was between the R160s.

Had to trim one of the little diff mount brackets so it would sit flush on the R180.

While we had this out I cut the tuned mass damper (?) off.

Surprisingly only weighs 1#, seems heavier. Thinking by adding 20# of rear diff we've ruined whatever NVH tuning that was supposed to accomplish.

STI driveshaft appears it will just bolt in. Looks to be a little on the short side, anyone know if the splined part towards the rear is supposed to telescope? There's definitely splines under the rubber cover but we couldn't get it to budge.

Looks like we need to make the rear lateral links a little longer than what we'd mocked up for the R160 but I think then they'd work with either diff. Still need to machine the RR billet knuckle, started programming that the other day.

B and I also worked on putting a planetary low range in my other STI 6MT. He swapped over the various reverse lockout parts, etc. Unfortunately the rear output shaft has about .008" (.2mm) endplay so I need to get a thicker shim and swap that out.

-

2

2

-

-

On 1/7/2023 at 9:46 AM, slammo said:

OK, I didn't see those lower "gussets" at first but I like the idea. Should be plenty of room there since I'm not running a turbo. I really want to minimize the welding on this body as I think that's going to make it rust faster but will definitely take a look at mine and see what we can do. Also reminds me it might be a good idea to do a strut tower brace that attaches to the pitch stop mount. But maybe that's why the wiper arm on my black Outback keeps scraping the windshield when we beat on it?

-

1

1

-

1

1

-

-

On 1/5/2023 at 7:13 AM, el_freddo said:

That swing arm fabrication is awesome! Very neat and look like it’ll more than do the job!

And wow, that salt is NUTS! I’m glad that in Australia it’s illegal to salt roads in our alpine area, it’s a small area that’s also in a very sensitive environment so salt is a no-go. Our Alpine area is not home to millions of ppl commuting etc either, it’s utilised for recreation skiing. Some Australians don’t even realise it snows I this country!

I’m lucky to have worked at lived at Hotham Heights for two seasons. My favourite thing to was drive on snow packed roads - it’ll be something I may never get to experience again.

On the EZ, weird they’d sell it as a complete engine without the throttle body! There’s a massive array of drive by wire throttle bodies available out there these days. I’d probably pick one that you know will be on the market for a long time that’s easily available.

As for the plugs, got a self serve parts yard over your way to grab your own? Other option is to re-plug the engine loom to match an aftermarket ECU setup if you go down that path.

Cheers

Bennie

6 hours ago, travelvw said:Love it! I can't believe you bought headers; car is going to sound good, too. How about doing those head gaskets now while it's out of the car instead of later when it's in the car?

Looks like these cars need more bracing for the front a-pillar; same place that repeatedly cracked on the Outback? Does B's Forester have any bracing up front like a WRX?

K

That salt picture is definitely a worst case scenario but yeah it's bad.

I'm not too surprised they pulled the throttle body off, if you're replacing a blown up engine the one on it could probably be swapped over. More pissed that they cut the wiring rather than unplugging that one connector. I'd like to have as few splices as possible.

Know of any throttle bodies in particular that fit and are better in some way?

I can get the main car side harness plug here, they just listed it:

https://www.corsa-technic.com/item.php?item_id=1783

Headers weren't super expensive. Supposedly +20ft-lbs through most of the RPM range. Engine as expected didn't come with enough exhaust to work with so I was going to have to buy/make something either way.

I'm going to hope for the best again on the head gaskets. Yes 90% of the EZ30s we've bought have needed them but those engines are twice as old as this one. Also it's quite a job.

It's too bad there's nothing solid under the top of the fender to bolt to, I've seen braces that bolt in there but it seems like that part of the body is super flimsy. B's Forester does not have a U brace, that would probably help a ton. For this car I'm planning on bracing the front crossmember to the trans crossmember like I did on the black Outback.

-

1

1

-

-

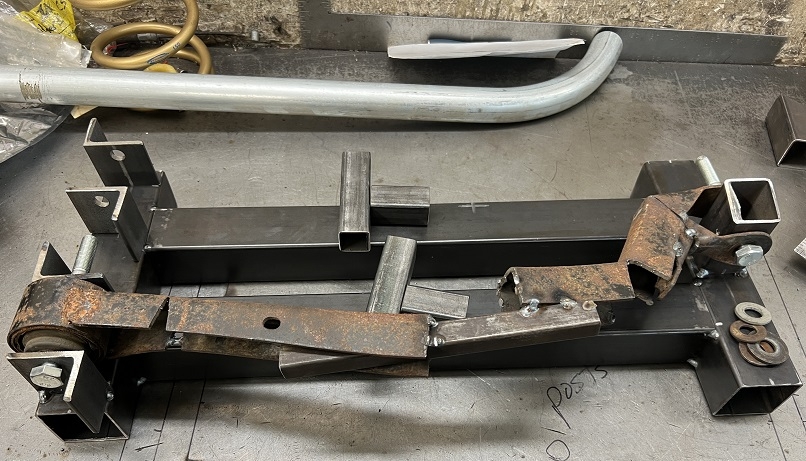

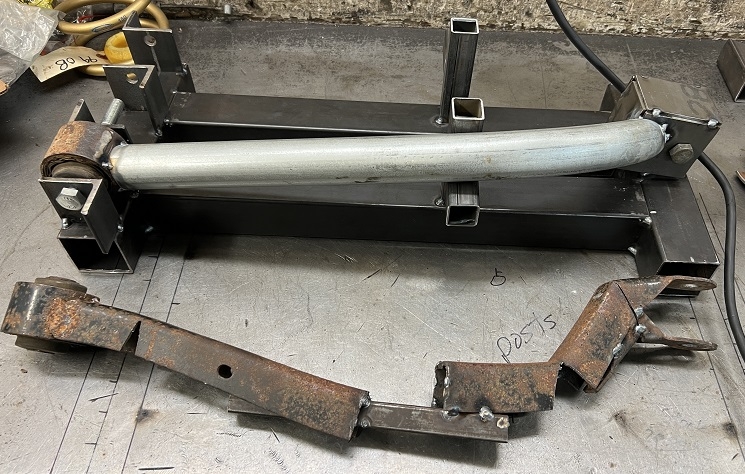

Made a jig and more sano mockup trailing arm.

Just used a piece of conduit we'd bent with B's tubing bender. For the actual trailing arms I plan to use 1.5 x .120" 4130 and also turn the sleeve for the front bushing on the lathe.

Incredibly bad picture of it installed.

Initially hit the knuckle and lateral link at full droop.

Hit the wheel near full bump.

Modified the box clevis on the rear end for clearance.

So we've got a good plan on those now.

Side note for those of you living in foreign countries or states. This is what our roads and parking lots look like in the winter time. That's salt, not frost.

Picked up an EZ36 last week.

Kinda wished I'd tried harder to find one that's more complete though. Junkyards of course normally sell them without accessories, so I bought those separate. But that means I don't have the brackets for them. Had a bracket that worked for the PS pump but the AC compressor is much different. EZ36 on left, EZ30D on right.

Need to find a plug and pins to fit this.

I got a resurfaced STI flywheel and Exedy clutch kit and B assembled all that and chased the threads in the block. You can see here where the junkyard cut the wires and coolant hose to the throttle body (I assume). They probably did this when they removed the throttle body, didn't even think about them stealing that, now I need to get one of those. Have heard of people using non Subaru. Plan on drive by wire but open to suggestion if there's something better than Subaru since I have to buy one either way.

Got a trans mount, still need to install low range in the 6MT. Got a driveshaft and R180. Have engine mounts on order. Got some shiny headers from Australia, last set they had, hopefully we can make them work.

-

1

1

-

1

1

-

-

Finally got back to video editing. Had almost run out of hard drive space and also spare time. Video from our tip to the UP June 2021:

https://www.youtube.com/watch?v=OUrIVHmtNPc

Since we've been taking less video the last few years, this one's pretty short. Also it's a lot less often we get out and stop to get video of jumps, whoops, hillclimbs, etc. In those cases we usually just enjoy it and keep going these days. But when we're stuck there's usually plenty of people standing around to document the process of getting unstuck.

Already have two more from 2021 basically edited down and have started on our last trip of 2021. So I should be posting a lot of videos this winter.

-

1

1

-

-

12 hours ago, slammo said:

From what little I can find the one bolt design is also known as VA type and was used in early Imprezas. The five bolt design is also known as T type and supposedly uses bigger internals. The rear diff in my red Impreza does have a date of Dec 2021 on it in paint marker, presumably from a junkyard. So someone probably put a later diff and axles in it fairly recently.

That semi posterior trailing arm mockup does hit the wheel at full bump. First step was just figuring out how long we want it and how much dogleg (in each direction). Next step will be a closer to production mockup using some conduit bends.

-

B did some work on the blue Forester. It's been getting water on the passenger floorboards for a while now after (but not immediately during) rain or a trip to the car wash. He cleaned out a couple drains near the blower motor, couldn't find anything obvious. It seems to be leaking behind the rubber/foam on the firewall so it's hard to tell exactly where it's coming from. Probably not the source of the leak but he also noticed the area in front of the passenger door hinges was mostly cracked.

He cleaned off the paint around the cracks.

I didn't get any pictures since I was working on my rear suspension but he got it all welded up and painted and put the fender back on.

He also replaced the tie rod and wheel bearing on that corner, they were both a little sloppy.

First issue I ran into trying to mock up the front CV axles in the rear for the billet knuckle was that the rear axles in this thing seem different than any other EJ Subaru rear axles I've run into. This is the rear diff in the green Impreza:

All of our other R160s look like this, including the one in my red Impreza which is a year older:

Green Impreza axle on left, "normal" EJ rear axle on right. I think the splines are the same, obviously the snapring groove is totally different, also the spiral cut bearing diameter from the green Impreza is smaller.

Just made sure I wasn't going crazy and took a look at some of my rear axle collection, they're all like the one on the right in the picture above.

Long story short I turned up a dummy stub for mockup instead of using one of the ones we'd made. Ultimately it doesn't matter since I'm not going to use this diff but surprised me a little. Need to swap the R180 in (finally got one) and put those stubs in to see how that works out.

Mocked up some new links with the billet knuckle. Surprisingly it doesn't seem like the trailing arm should be much longer, just needs a big dog leg at the rear end to clear the wheel. Need to mock that up better with some round tube bends. This is with the Impreza trailing arm bracket and no spacer. Lateral links need to be a little over an inch longer as expected. Surprisingly the tire doesn't rub the wheel well much worse than it did before. Camber is zero at ride height in the middle of the adjustment as best I can tell.

Caliper bolt and strut nut are close to each other but can be removed and installed independently.

Hard to tell in this picture but decent clearance even with the "big" front axle installed. Boot needs a strap but there's plenty of room for it.

-

1

1

-

-

15 hours ago, el_freddo said:

Sweet work on that billet hub! Ditch the bearing to help reduce unsprung weight!

Seriously, you could make a set of aluminium billet hubs and carry the steel billet hubs as back up if one cracks out bush. Best R&D there is.

Cheers

Bennie

That would improve our sprung/unsprung weight ratio! Think I'll just stick with steel and not worry about it. Considering a wheel and tire assembly weighs 50#, 5-10# here or there isn't going to make a huge difference.

10 hours ago, Numbchux said:Well, I've used an Impreza pedal box on a Forester.....

I did some googling for the ones I was thinking of, which have a little dam on the front edge, but I found many other designs. Our GC rally car had a JDM aluminum hood, but just stock OBS/RS vents (I don't remember if was had the plates under them or not) and scoop. But we also had a big aluminum radiator, FMIC, and didn't really ever have any cooling issues.

Good to know, B measured the Forester pedal box and seems like it will bolt right into the Impreza.

Not too worried about overheating either but I am tempted to unblock the hood vents when it gets hot out to see if it makes any difference.

-

1

1

-

-

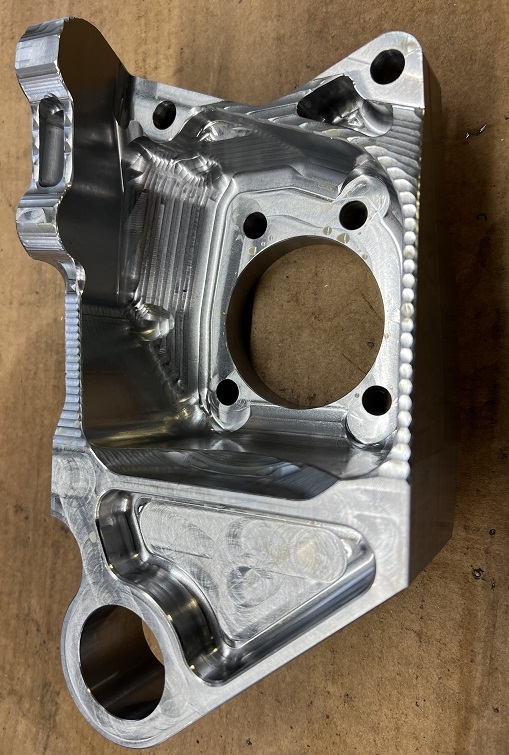

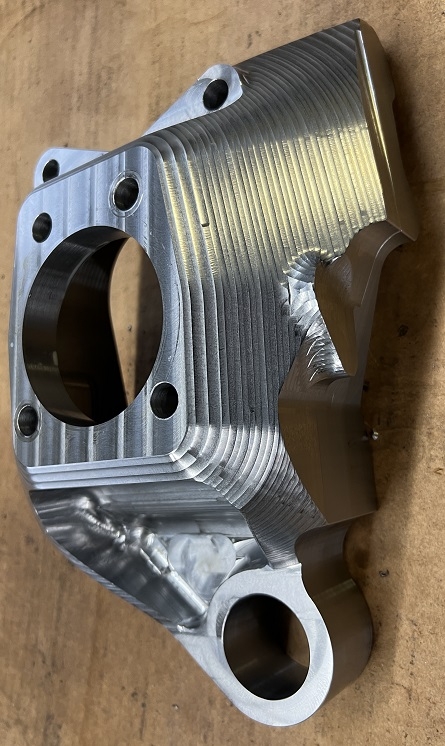

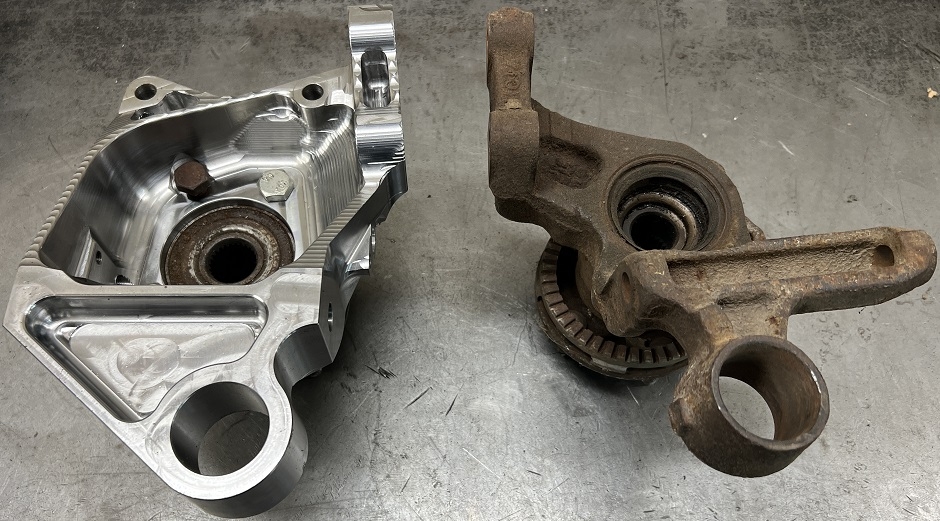

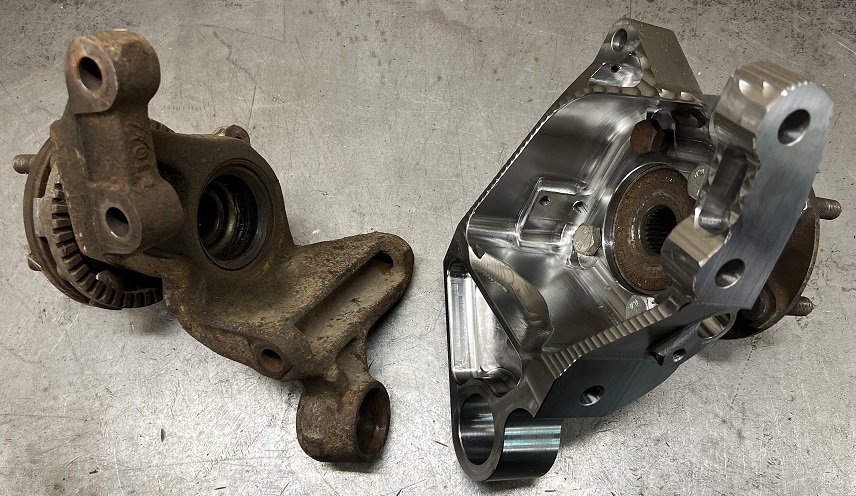

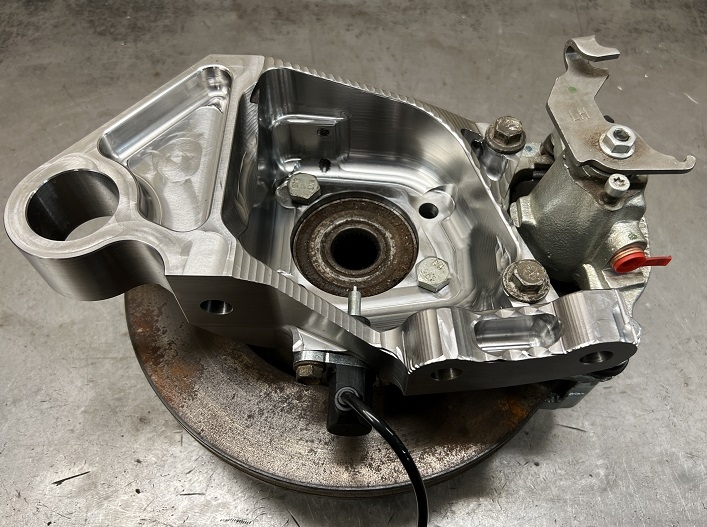

Billet knuckle vs stock knuckle

Stock knuckle with wheel bearing weighs 14#.

Billet knuckle with wheel bearing weighs 19#.

Bare billet knuckle weighs 13#.

We kinda knew this up front but after seeing them in person compared to the stock knuckles, aluminum would almost certainly be strong enough with this boxed design. Would require steel sleeves for the strut bolts and long bolt but the machining would go a lot faster.

The brakes will probably be heavier than stock and CV axle will definitely be heavier but I think a ~10# unsprung weight increase per rear corner will be worth it.

-

3

3

-

-

58 minutes ago, slammo said:

It'd look better with the stock plastic bumper.

As you know I'm putting it that low to fit light bars and get more air to the radiator.

-

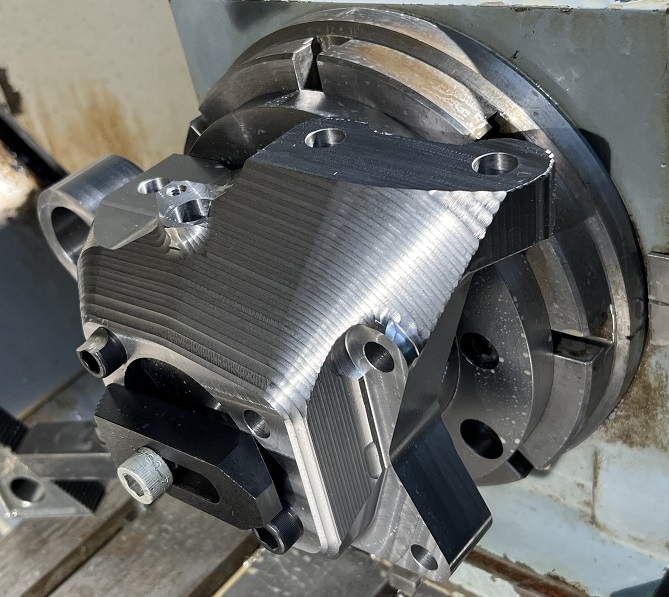

Finished machining the first billet knuckle. No major problems, went as well as I could have hoped.

With caliper, wheel bearing, disc, and ABS sensor bolted on.

Edit: Just noticed I first started designing these almost two years ago now. We 3D printed the first prototypes over 20 months ago. Didn't realize they've been in the works that long. Thanks again to slammo for helping with a cleaner more compact design.

Some pictures of the bumper, most of the fitting is done now. Ran out of 1" square tubing so we stopped here. Got the tow bar mounts done, barely visible under the main beam. Ran some tubes from the radiator support back to the swaybar mounts, barely visible. Ordered some 1.25" receiver tubing but they sent 2". Even says 1.25" on the shrink wrap but it's definitely not. So we'll still have to add those, planning on having one in the center and one on each side like we did the white Outback. Waiting until we get the EZ36 in to make the engine skid.

Might be getting engine, driveshaft, and diff this week. Might order a Haltech today.

-

1

1

-

long travel Outbacks or making Subarus faster and more reliable offroad

in Off Road

Posted · Edited by pontoontodd

Checking rear suspension travel, interferences, and axle lengths.

At full bump the RR inner CV is almost extended all the way, balls are pretty close to the big snapring.

Over a half inch from being bottomed out at full droop.

LR is a little over 1/4" from being bottomed out at full droop.

LR at full bump still has a lot of travel before it's fully extended.

So I'll probably shorten the lateral links 1/16 or 1/8".

Bottom of shock shaft hits lateral link at full droop, will probably bend lateral links to give a little clearance.

This got me thinking about how we could get more travel. The shocks still have some to spare. Springs get close to coil bind and we've actually broken a couple of them so we don't want to work those any harder. Could potentially mount the springs in line with the strut bodies like most the aftermarket does but we seemed to have a lot of friction when we did that. With these axles there's quite a bit of room in both directions before they're the limiting factor. Wheel well is already going to need some rolling at a minimum so more bump travel would require either serious body surgery or more subframe lift.

Really just need to tune what we have.