-

Posts

857 -

Joined

-

Last visited

-

Days Won

26

Content Type

Profiles

Forums

Gallery

Store

Everything posted by jonathan909

-

Yeah, I've always assumed it was a dodgy commutator when it did the intermittent-a-little-worse-when-cold thing - you're actually spinning a roulette wheel and instead of red+black it's landing on start and no-start, then the temperature just adds a dollop of chaos. So I replace it with a boneyard pull and don't wongleflute ("wongleflute"? What I really meant was "kerfspluddle".) around with rebuilding.

-

Sure, it could be the keyswitch. A (mechanical) switch is a switch is a switch, and the contacts can go bad like any other. Actually, I was a little surprised that you did the starter rebuild rather than just replacing it, since (iIrc) you indicated you have a nearby pick+pull yard. I've experienced exactly that rest/temperature sensitivity in starters, and I solved it with replacement, not a rebuild. As for the security system, I should be the one to answer that, since (as I mentioned in the other thread) I kinda went overboard a couple of years ago in an effort to understand the Alpine remote entry system used from '98-'04 (or whatever it was). The security module is a second little black box that communicates with the remote entry module. I built a jig for testing and messing with them (both parts), but to be honest didn't play much with the security module, since I don't care about it - I was mainly interested in being able to reliably program the remote entry system (that is, to register the fobs to it), and there's been a long-standing question of why that programming stops working in these old cars. To disable the security module (if you have one) you just unplug it. It's usually found under the hand brake trim. But that doesn't answer the relay question, and I honestly don't remember that part. Will have to consult the drawings. This is where the question comes full circle - my conclusion on the fob programming problem was that it stems from wear in the keyswitch. But that's just a point of interest. My guess is that your starter is just being a persistent PITA.

-

Finally took the '01 Forester out for a proper spin, first since the bearings+rings job. I haven't fully characterized it yet, but it was pretty damn cranky. Idle-hunting, stalling, surgy when accelerating at low speed and revs, etc. Finally popped the "too rich" error - along with 3 misfires, which are clearly the effect of the former. Fwiw, the dash temperature reading was normal. Now, I get that this is a closed-loop control system, and I'm pretty good with those - I just need a back-of-the-napkin sketch of what the relevant inputs and outputs are, and a little on the nature of the transfer function. Can anyone direct me to something reasonable and succinct and understandable to the slightly dense reader? Worth mentioning that it was running fine before the teardown and nothing was replaced other than some bad pieces of metal, so it wouldn't surprise me at all for the odd slightly crappy connector/connection to be implicated.

-

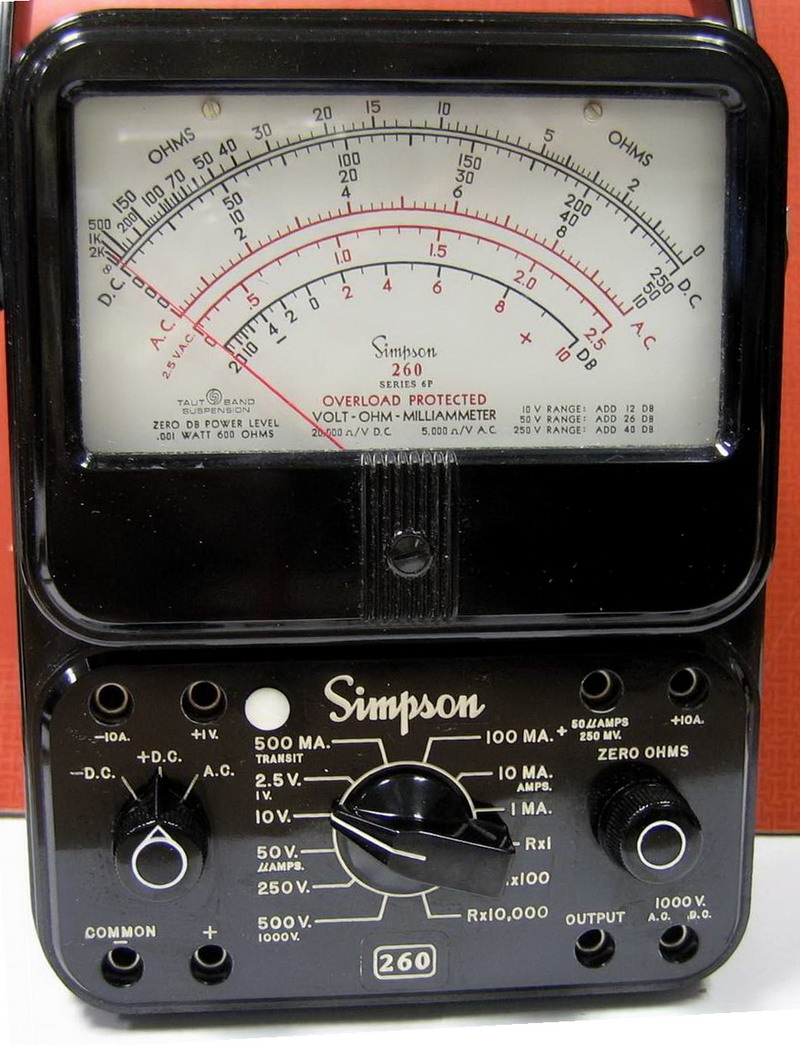

They built a lot of variations on this one - I think some had mirrored scales, but probably the same meter movement. Right about the needle movement - that's what I've been alluding to in this thread. Even regular, low frequency (think 1Hz or less) periodic functions, whether sine, square, triangle, sawtooth. With an analog meter you see immediately what's happening. Digital: Just a lot of wild numbers bouncing around. Of course, lots of DVMs have the little bargraph down below to help, but it's not the same. A few years back I banged together a little CO2 controller for grow rooms - modern CO2 sensor with an analog output fed into an AVR to run the CO2 generator, room ventilation, etc. On the first pass I put a digital display on it for the ppm reading, but then built a second rev with a nice big analog meter instead, kinda just for fun. I tell you, even I was surprised at not only how much faster and easier to read it was, but also at its retro/sexy/cool vibe.

-

Dude, exactly. Up here, though, it was more often a Simpson 260 - though I'm kind of stunned to see the prices associated with these things now. A few years back I bought a crate of 'em for twenty bucks through a rather odd surplus->thrift store channel. This is the type of meter I'd recommend to our friend here, because you can really see what's going on. Even for hardcore electronics pros, what you get on a DVM can sometimes be very confusing. And autoranging.... Don't get me started on autoranging...

-

Yeah, probes are a whole thing. For many years my preferred probes have been the extendable needle point probes made by Huntron: https://www.jensentools.com/huntron-98-0078-mp10-microprobes/p/447me109 Fluke used to sell them as well, but not anymore, afaIk, which is a shame. They may have replaced them with a version of their own. Huntron's stuff (at least, their early products like the "Tracker") was bogus, attempts to bring troubleshooting to people who don't understand what they're doing. Yet another friend a long time back called it "the new charlatanism". But those probes were and are brilliant, only one of their features being that because they're so slim, you can easily handle them exactly like chopsticks. The only thing that's not perfect about them is that they're relatively fragile - they're not made of a flexible/resilient plastic like most probes, and if you step on one it's a goner. I've never actually fired anyone for allowing one to sit on the ground, but I have issued "the only warning you will get for this" a few times.

-

Sure. I've never noticed it myself, but I guess you can get some inductive (like a transformer) and capacitive coupling between the two wires, and how much would depend on how long the run is. But you probably wouldn't be able to measure much between the two because there'd be little phase difference.

-

Oh - and after all that, if you STILL have doubts about my knowing what I'm talking about, next time you're in the neighborhood of New Kensington - about 3 hours from you, according to google maps - you can pay a visit to a working computer museum another friend of mine runs there (and I'm talking about big vintage iron - mostly DEC - not little crap like VIC-20s), and I'm sure he can straighten you out. PM me for the location details.

-

I don't want to beat this to death, but you should understand that you're trying to give basic electricity lessons to an EE who's been in the field for more than 40 years. You might get a little sense of my background if you search some of my old postings, particularly the thread about figuring out why it's so hard to get the Alpine remote lock fobs to sync with old cars (I went a little crazy with that one, to the amusement of some here). To your points: You don't have to be naked to not be carrying any static charge. As soon as you touch the car you're bleeding it off. And you'd be amazed at how little dielectric strength (that's "insulating power" to you) most shoes offer, whether you're handling a defective power tool or getting struck by lightning. As for your second lesson, please donate your DVM to someone in need, because it's just confusing you unnecessarily. You should instead be using an old-school analog-movement VOM, because it'll give you nice, solid, accurate readings for all the things that matter in the car (short of digital communication channels e.g. between the ECU and TCU, for which you need oscilloscopes, logic/protocol analyzers, etc.), and you won't have the DVM's dancing digits making you believe that things you saw once in a youtube instructional video matter when they don't. In closing, I don't like to brag, but you're kind of needling me into it. This picture is of the discharge electrode of a Tesla coil (built by a good friend of mine in the Bay Area). The electrode is 2 meters in diameter, and on top of the coil's secondary, 10 meters in the air. I am standing inside the electrode (not just for fun, either, though there was a lot of that - I was up there taking measurements), and together we are at a potential of approximately 1.5 megavolts. If anyone ever asks whether Faraday cages really work, this is what you show them. Now, since I've shown you that I'm reasonably well acquainted with both big volts at high frequencies and little volts at DC, was there anything else you think I need a little brushing up on?

-

Yeah, that's pretty much what I expect - except that it's not a "simulated" load. With a live circuit either it's a load or it's not. If you're doing a computer simulation, you can simulate a load along with the rest of the circuit's behaviour. But if you've got a real system and are trying to measure it with a real meter, it's going to have to be a real load. The problem I have with the lack of information on this thing is that the details matter - without knowing the switchable load's resistance or power rating, it's difficult (impossible, really) to know how the system is going to behave - or how easily the load itself can be burned out. So without some further data, I'd file this under "sketchy".

-

That's not really how things work in these situations. Nobody is going to confuse a little noise with a legitimate DC reading. Also, this has nothing to do with "static" charge or stray RF. You're grounded quite enough for this not to be the case at all, and your skin resistance lowers the impedance of the circuit in question enough to make any of the tiny effects you're describing disappear. Besides, the measurements of interest are DC volts, not the AC microvolts or millivolts that may be riding on it. What you're describing are non-issues when taking readings in a car. If you want to talk about an RF test bench, that's another matter altogether.

-

Can you give me the Cole's Notes version? I started looking at the youtube vids on this probe and the first thing I got was some knucklehead complaining that there are always gonna be haters, whaddayagonnado? Lots of "users" blabbering on about it without actually getting to the point. Manufacturer's web site isn't much more informative. I mean, I don't need a half hour video. If you can't describe it in two minutes or less, you don't understand it. Is this just about adding a pushbutton and a resistor to the probe to (effectively) lower the meter's input impedance?

-

Fwiw... when I hit the self-serve yards I carry a big open-top tool satchel. Every nut, bolt, and other fastener that I remove in the course of getting to the part I want just habitually gets pitched into it - other small bits like fuses as well. They don't (try to) charge for that stuff - it wouldn't be worth their time grubbing around in a customer's tools over such little weight. Over time I've accumulated buckets of spare hardware exactly for occasions like this.

-

That is, if the trick works. With my last order I couldn't avoid it being broken into three shipments, two from Rock and one shipped directly from Enginetech. Still, even with all that shipping factored in, it totaled a fraction of what I would have paid here. And don't dismiss the wreckers - you can get an awful lot of perfectly serviceable stuff for next to nothing that might be cost-prohibitive new. I'm partial to the self-serve yards, as we have three in the city, two of them pick+pull. They're based in CA, but it looks like you're a couple of hours from their nearest location (near Salinas).

-

RockAuto Customer Service <service@rockauto.com> But again, I challenge you to pose a question they're capable of answering. When you look at their prices you'll understand why they're a zero-service company - they exist to move product at volume at the lowest possible price, and that's all. I'm not dissing them at all - they're my first stop for most parts. There are exceptions, one being specific components (e.g. the timing parts often discussed here) where you need to be picky about manufacturer for reasons of quality; another being that there are cases (e.g. brake rotors) in which the weight causes shipping cost to negate the savings over local purchase. Otherwise, fill your boots.

-

Since nobody has put up their hand to say it does, I'd guess it doesn't. Obviously, having some empty tubing in there will reduce the volume of coolant it can hold/cool, but I doubt it's enough to matter. The only thing I'd be worried about (since I only own Legacy/Outback wagons) is whether the GT version is a different height, but it sounds like you're on it.

-

"RockAuto" and "tech support" are two combinations of letters that are not permitted to occur in the same sentence. They have taken unhelpfulness to previously undiscovered heights. If you don't see it on the screen in front of you, they don't have an answer either. How bad can they be? I was curious what they'd sell a crankshaft (reground by Enginetech) for - it's listed, but as there's no stock there's no price shown. I asked what the last price they sold them at was, just so I'd have a ballpark number, not a quote. It took about six increasingly-insistent emails to get past their probably-autoresponders, and when I finally got to a human, the answer was, "I am truly sorry but this is not information that we have available or are at liberty to provide."

-

Looking at the photos of the suspension frame (thank you, these are really helpful), it's clear why those bushings aren't listed as a separate part - they're moulded into the frame, with the inner sleeve moulded into the rubber. So it's all or nothing with this assembly - a bushing tears away inside or out and the whole thing's getting replaced. With the big washer between the bolt head and the underside of the bushing, it's a Chinese puzzle. Can't grab the sleeve to try to hold it still while turning out the bolt because the washer's in the way. Can't remove the washer because...