nvu

Members-

Posts

383 -

Joined

-

Last visited

-

Days Won

15

Content Type

Profiles

Forums

Gallery

Store

Everything posted by nvu

-

That pretty much confirms it's inside the trans. Though, when I had 2nd let go on one, it broke off an entire tooth on the small gear only make a light clicking noise, and lodged the tooth in the center section. Draining didn't find anything, only taking apart showed the issue. Though with how old yours is, it might also be loose bearings causing enough slop to make that constant noise

-

I vaguely recall sohc single port EJ22 is an oddball thing somewhere around 97 when they went from phase 1 to phase 2. Are the valve covers on the heads the old school ones that have "16 VALVES" imprinted on them? \ If it's an 99 ecu, it's probably not really meant for those heads, probably why performance is poor. Good and bad is ecu is fairly simple and doesn't care which block is in there. Swap in the 2000 block, it's what the 99' ecu wants over all. Or if your state emissions doesn't care, drop in an 97-98 ecu and it might fix everything; if the current block has good compression and no mechanical issues.

-

I don't think I've ever seen a car with front parking brakes so you should be fine on that aspect. Probably a good idea to remove any abs sensors from the hub beforehand to avoid damaging them. Also avoid overtightening them when installing. If you get both wheels off the ground, test the bearings. Hold onto the spring while turning the wheel by hand to feel any vibrations, they should feel similar on both sides. Unhook the sway bar links to get that extra clearance on lower control arms

-

Other things to check in addition to whats mentioned above... Check the pedal assembly under the dash. Those years can get cracks in the pedal bracket. Remove and check the pivot pin itself for wear. I've long since replaced mine with a hardened bolt, washers and locknut. Is 2006 the a push clutch? The stamped fork tends to crack overtime. Hard to check though. Pull clutch uses forged fork and has no issues.

-

If it's the old school manual air, check the pressure sensor. It's somewhere on the condenser high line. Short it and see. The temperature sensor is some feedback transistor, you can't short it to test. Unlikely as it only cuts out when the temp is too cold. Unlikely the AC switch itself is bad, you can bypass it and force AC on by turning to full defrost. No idea where to begin with the auto climate control, never had to deal with one.

-

If it's the single gauge one on the low side only. Yes it would read high, around 80-90psi when the system is off. Not much else to add about why it's not kicking on, but it's normal to see it high on a single gauge reading. Thinking it's more electrical than a system problem. Did you swap the relay with a similar one on the car yet?

-

Swap in the used pair, it's less hassle. But also measure the length of the front bushing on your car and confirm first. The swaybar mounting tab may be different too, make a note of it. Figure out if you want to get those Delphi bushings and build a spare set later. Also pray to the rust gods that the big bolts don't break the captive nuts in the frame when you try and remove them. If it's the original bushing on the car, chances are the nut inside is corroded, I'd recommend completely relieving pressure on the arm by removing the knuckle before breaking loose bushing bolts.

-

oh right, if it's 2.5 electric throttle. the tps is in there but not easily replaceable, you have to adjust the set screw for it and have an ecu data reader. though, i've never heard of a tps failing on those style of throttles. they either completely fail with the motor not working or make a terrible grinding noises if the gears are sheared. the tps part is pretty reliable

-

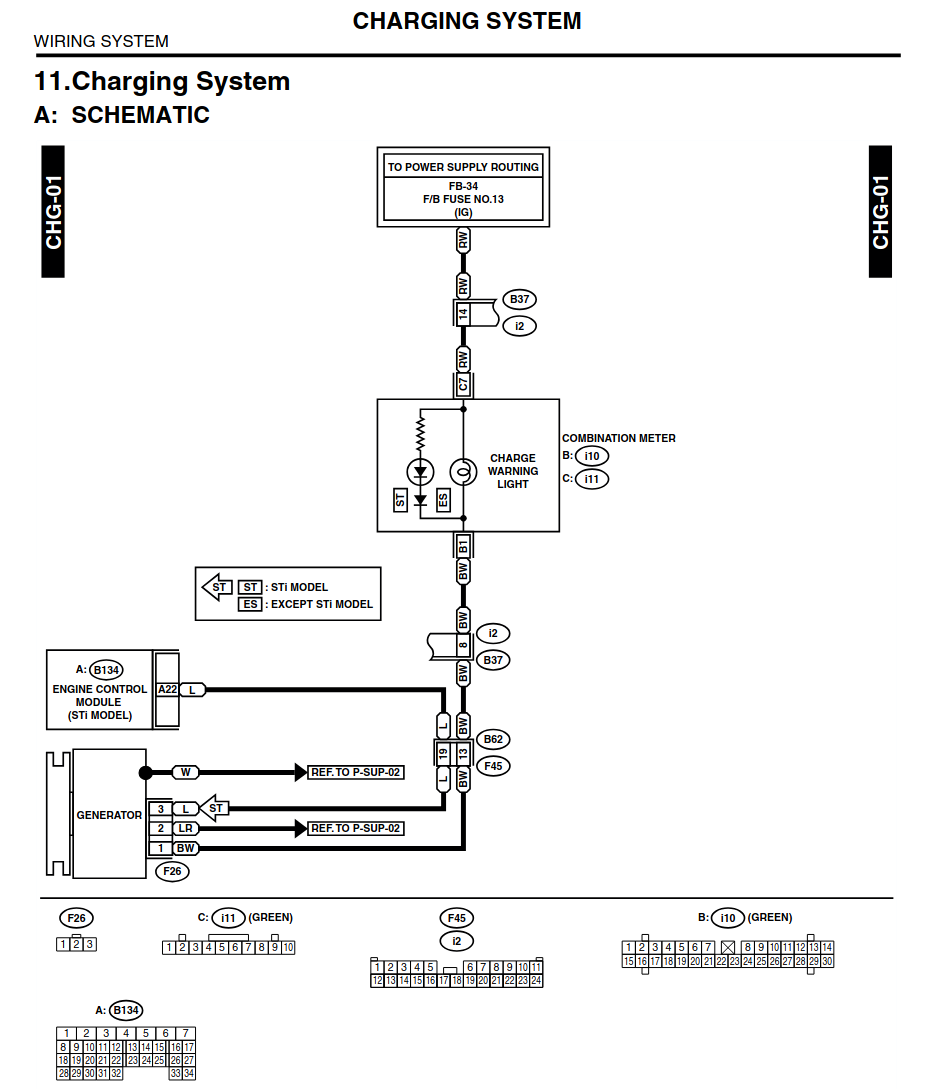

Odd, it should not kick off from charging at all for these models. There's no ecu control if it's 2 wire so no way to tell it to power off. Do you think there's a corroded wire in the harness causing intermittent charging? If you have a spare connector, dash lightbulb, and a switch, you could make a dongle from the alternator to the battery + and manually force the alternator on to test.

-

If there's air, theres a leak. Check the lines for wetness and under the clutch reservoir. Get a scredriver and depress the slave piston in so you can wiggle the clutch fork back and forth. It should only move in two directions. If it's flopping all over the place, somethings broken, bearing, fork, pivot pin.