nvu

Members-

Posts

354 -

Joined

-

Last visited

-

Days Won

13

Content Type

Profiles

Forums

Gallery

Store

Everything posted by nvu

-

The damper rarely fails, on a 2010 I doubt it's the culprit. You could get away with removing it completely and bridging the lines. You're describing the fuel pressure regulator, it's near the injectors and has a third port that goes to a vacuum hose. Unplug the vacuum hose while the engine is running. It should not have fuel coming out. Fuel pressure probably doesn't hold overnight, but it should hold for a couple minutes right after key off.

-

I got mine at an importer, it's from a jdm forester but not sure if turbo. I could affirm that 5th gear revs high like he's seeing. But again to the OP, the fixes are fairly involved. The 5th gear set parts were ~$200 from the dealer when I did mine around 2012. Labor might be more than that. It's working, drive it.

-

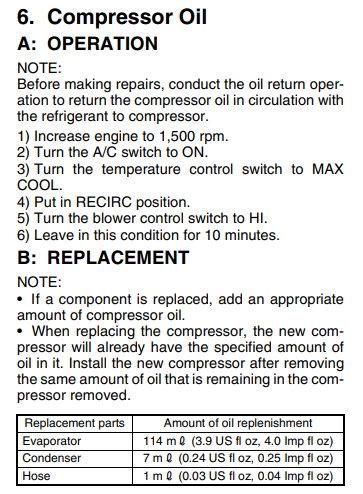

How much oil is in a new compressor for 02-07 era imprezas? The car is an 03 impreza. The system hasn't been working so I couldn't cycle the compressor. Almost everything except the hard lines have been replaced: -condenser/drier -evaporator -TXV -soft hoses -compressor Dumping out the old oil in the compressor, there's barely any and it's thick black. I've gotten a used compressor. Dumping the oil out of that one there's a lot more of it, but clear. Looking at the service manual doesn't show how much oil to add to the compressor.

-

The one behind the crankshaft never wears out, it can be reused. You'll see the cogged idler next to the water pump. All the idlers lose grease eventually, they'll probably fail eventually. You could probably limp it home if it was any smooth idler. Failure of the cogged idler usually skips timing or snaps the belt entirely. Take your time and gather the right parts. The timing belt almost never fails on these engines, and with lower revving sohc it's likely your idlers are still in good shape when 110,000 rolls around.

-

https://parts.subaru.com/a/Subaru_2009_Legacy-25L-4AT-4WD-Limited/_54102_6024341/EXHAUST-EXHAUST-COVER-06MY-/B13-440-10.html There's a gasket 3" away from the rear o2 sensor. 44184. It doesn't look like the older donut style that tends to leak though. I tried https://www.google.com/search?q=subaru+2009+legacy+p0420, only thing that sounds plausible is cleaning the maf.

-

If it's not hard metal clacking chances are it might be a failing tensioner. Take the covers off again and do the prybar trick to test.

- 8 replies

-

- 1

-

-

- poor

- compression

-

(and 4 more)

Tagged with:

-

Maybe you had a bent pan. Subaru oil pans are fairly soft. You can get the lip surface flat again by placing on concrete face down and tapping around it with a scrap piece of wood and hammer. Most times it's the holes on the pan that gets dimpled, look closely at them, flatten those out and it should seal with minimal rtv again. Tighten to full specs, overtightening will just dimple them again. If the engine is out and on a stand it's even easier. Flip it upside-down, place pan on it, and tap the lip flat again. The pan is that soft. Similar idea in this video, I use scrap wood instead of a metal chisel.

-

Ultra grey works best with flat surfaces. Full torque if both mating surfaces are machined. Case halves, oil pump to block, cam carriers, etc... The finger tight, allow set time, then full tight is for imperfect surfaces like stamped oil pans and covers. I don't do it, just torque it down and let it set.