nvu

Members-

Posts

383 -

Joined

-

Last visited

-

Days Won

15

Content Type

Profiles

Forums

Gallery

Store

Everything posted by nvu

-

Maybe you had a bent pan. Subaru oil pans are fairly soft. You can get the lip surface flat again by placing on concrete face down and tapping around it with a scrap piece of wood and hammer. Most times it's the holes on the pan that gets dimpled, look closely at them, flatten those out and it should seal with minimal rtv again. Tighten to full specs, overtightening will just dimple them again. If the engine is out and on a stand it's even easier. Flip it upside-down, place pan on it, and tap the lip flat again. The pan is that soft. Similar idea in this video, I use scrap wood instead of a metal chisel.

-

Ultra grey works best with flat surfaces. Full torque if both mating surfaces are machined. Case halves, oil pump to block, cam carriers, etc... The finger tight, allow set time, then full tight is for imperfect surfaces like stamped oil pans and covers. I don't do it, just torque it down and let it set.

-

i've had good results welding plastic bits back together with a plastic soldering iron. picked up one at harbor freight, it has a triangle tip and seems to lower heat point than standard soldering irons. I've fixed door cards, headlight tabs, window switch panels, etc... it took some time fiddling with techniques until you get to feel on how to melt plastic just enough to weld and not too much that it becomes brittle. if you get the hfreight kit, the black strips they supply is hot glue and not plastic. you'll have to get a separate plastic rod welding pack or just use whatever spare plastic bits you have as welding material. i've found the black abs plastic from old dell lcd monitor covers to be really good for this.

-

looks like you already have the bracket, oops it's missing a bottom bracket for the compressor. for the tensioner, you could skip it all together and get a stretch belt directly from the crank to the compressor. here's a diagram, it's 73611 https://parts.subaru.com/a/Subaru_1998_Impreza-22L-MT-4WD-Outback-Wagon/_54104_6022881/COMPRESSOR/G10-732-02.html

-

Looks like you have a pull style clutch. It's the same bearing for all 5mt pull style transmissions. Here's the part, use the crossreference to find it elsewhere, should be no more than $50 last time I got one. https://parts.subaru.com/p/Subaru_2002_Impreza-205-5MT-4WD-WRX-Wagon/BEARING-CLUTCH-RELEASE/49239161/30502AA130.html

-

It's water getting past the rubber boots and collecting in the hole. Just pull the plug wires and look at the clamp inside them. Might as well pull the plugs and inspect while you're there. Might be a good idea to blast the holes with compressor air before taking out the spark plugs. I found a picture, see the wavy areas where the plug wires are. Water likes to collect up there and eventually makes it inside the hole.

-

Sender port is the simplest for a temporary install if you want to diagnose the problem. You could remove the alternator belt and swing it out of the way. The car could run for an hour before batteries get low. It's likely just the sender, the engine would already make bad noises if it were actually low pressure while driving. With the engine warmed and real pressure gauge attached, rev it a bit and see if the pressure stays good.

-

Intermittent blower

nvu replied to Arty's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Not sure on 99's, I had a similar issue on an 03 and it did turn out to be the relay. For the 03 it was next to the fuse box on the drivers side, had to remove lower dash to access it. It was a cylindrical relay. -

ign relay

nvu replied to subpoop's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

remove the lower dash, should be only Philips screws, unhook some switches attached to the plastic panel. then if needed you can also unhook the fuse box from the frame, it's only some 10mm bolts/nuts. no need to unhook anything, but should give plenty of room -

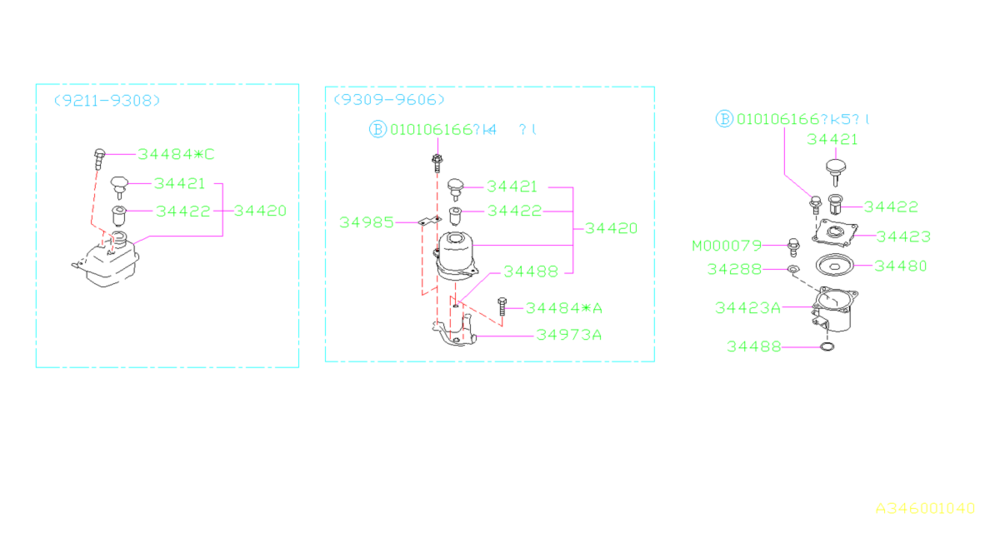

you have the version where the 2 bolts are external to the tank. i don't think it needs any washers. middle one. the one i have the bolts are internal to the tank, directly touching the fluid. the washers go inside between the bolt and the internal tank bottom. right one. rtv wouldn't hurt, just give it a day to set. it really shouldn't need any to seal. thinking that bottom plate is tweaked, check that it's flat and square. If the crush washers helped, maybe the bolts are too long and not original. Here's the link to the pic https://parts.subaru.com/a/Subaru_1996_Impreza-Outback-Wagon-22L-MT-4WD/_54100_6028409/POWER-STEERING-SYSTEM/G10-346-02.html

-

are you using the ratcheting sleeve compressor? place the piston face up on a flat surface, place the compressor over it and lightly tension it down making sure everything remains square. pick both up and put it them on the block, tap it so the skirt protrudes into the block and the rings are around the last tension band. lightly tap around the top of the compressor and tension a bit more. make sure it's squared and centered. the piston should slot in with moderate tapping.

-

Outback tyres

nvu replied to pitscars's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Center diff takes the brunt of the mismatch. In a safe place, drive in figure 8's and see if there are any odd noises under the car. Center diff failures are usually a binding/release feeling, then quick knocking sounds, then catastrophic failures that could lock all 4 wheels. It's probably safe if there are no noises or binding. -

For composite gaskets it wouldn't do much as they fail the rubber/graphite breaking down and eventually coming apart. Moving the thermostat to the top has the risk of it never opening if there's a pocket of air big enough to dry it out.