nvu

Members-

Posts

352 -

Joined

-

Last visited

-

Days Won

13

Content Type

Profiles

Forums

Gallery

Store

Everything posted by nvu

-

Ball joints and endlinks you can full torque since they can swivel independently. The bushing bolts should be fully torqued with the suspension loaded. You can get away with padding wood under the knuckle and raising it with floor jack just until it starts lifting the car. Figure out how to do this without having to climb under the car. The biggest nut for the rear bushing will be a pain to torque on car. There's no clearance to fit a socket and torque wrench on there. You can use a special offset socket. Or finger tighten, put it on car and load suspension with floor jack. Mark the position of the bushing relative to control arm. Take everything off and full torque.

-

$1200 is kinda steep for a bearing job. These newer style cartridge bearings are easier to DIY since you don't need a press. Probably your biggest sticking point is loosening/tightening the axle nut. Look up some videos and decide if you can do it yourself, it's quite possible. It's probably about $200 in tools. After that you can do a practice swap with any el cheapo $50 bearings, then go oem $150 bearings later. You'd still come in under $1200.

-

At this point I'm guessing and throwing out ideas since changing the maf made some improvement. Check the connector and wiring itself to the maf. It might not apply here, on my turbo ej25 the fuel trims would drift too rich or lean over the years, I've always attributed that to dirty or failing maf and replaced a couple, it fixed the problem. Randomly on one of the refresh builds, I broke the tab on the connector and it wouldn't lock. Ordered a connector and found that one of the wires felt very stiff, it was the heater power for the maf. I chased it maybe 1ft into the loom until it got flexible like the rest of the wires. Then ordered a premade made pigtail and spliced it in. Haven't needed to replace any maf's since. Then again the loom ran near the turbo area of the bay.

-

No, smooth limp mode mainly points to electrical. Well you ruled out most mechanical issues. So fuel pump, injectors, spark, are in good shape. It doesn't rule out vacuum leaks though, in limp mode the car runs super rich and masks any leaks. It's mainly sensor and electrical issues now. It's not exactly the maf though. Unplugging the maf forces the ecu into limp mode, it ignores most sensors at this point. If you really want to make sure, you'd need to throw your maf into another car or borrow one from a working car.

-

Could your ecu still run in limp mode with the maf unplugged? Just as a sanity check, drive the car and warm it up until it does the stumbling in idle. Turn off the engine, unplug the maf, start it up again. It should be in limp mode and running rich, but should be idling smooth. If it's still rough, that could point to basic things like injectors, vacuum leaks, spark.

-

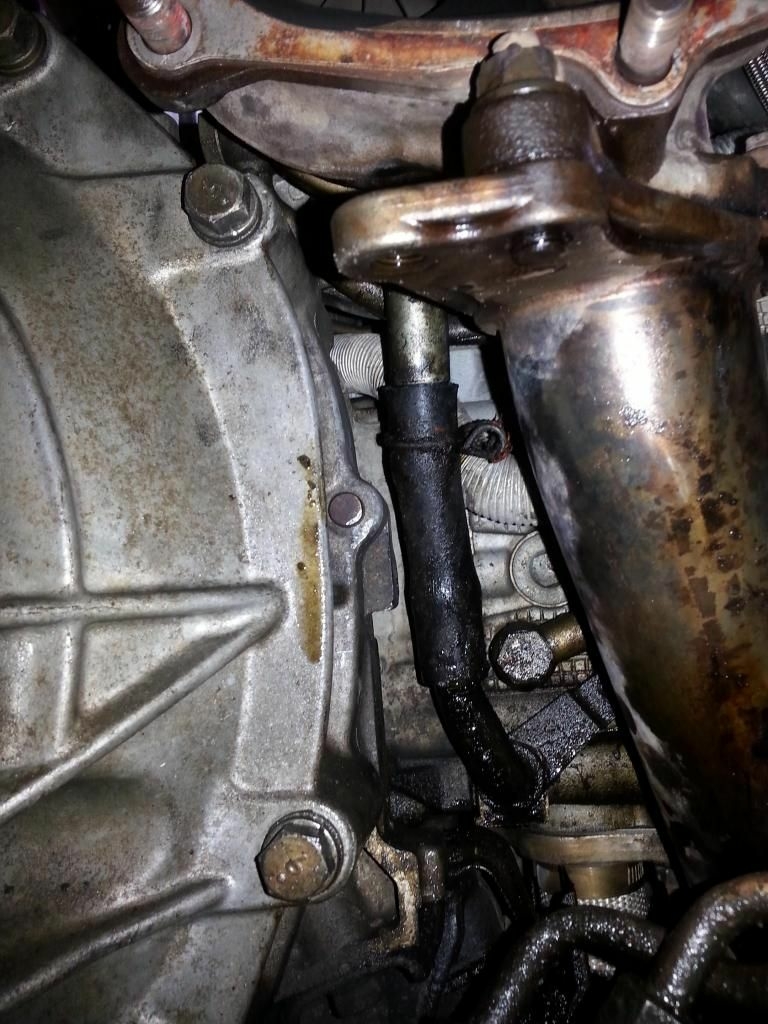

Not exactly that bolt, but similar issue. I've had bolts seize to the bushing collar. Depending on how accessible they are, my main go to is hammering at them with a beefy socket extension. I have a used impact extension just for punching things loose. The black ones that don't shatter, chrome ones do. They're also easy to grind to whatever shape needed. If you already have the replacement lateral link, you could cut out the old link with an angle grinder.

-

Are you talking about the stub axles? It's a tossup, some are spring clipped and you can just yank them off. Some are circlipped, no other way than opening the trans. The old one's broken anyways, cant hurt trying to yank them out. Put the cups and roll pin back on, pry at them and see if they pop out.

-

They look like wave spring washers maybe? https://duckduckgo.com/?q=wave+spring+washers&iax=images&ia=images

-

is the car in your posession? sounds like gaskets weren't done right from your story. you just need to confirm. no need to flush, start the car with engine cold. leave the radiator cap open and top off with plain water. idle it for 15-20mins, topping off with water until it's warm and the fans kick on. if you're seeing bubbles everytime you rev it, thats pretty much headgaskets. if not, it might be cracked radiator or leaking hose joints, because you mentioned steam. either way, if there's no bubbles, put the cap on and drive around, soon as the needle inches up, pull over and check if the reservoir is bubbling. any bubbles by now is headgaskets.

-

probably a good idea to install an oil gauge at this point. it's a non turbo so you probably have plenty of room to tap into the rear oil gallery plug. search for oil pressure sender gauges. i prefer the metal can looking ones with no plastic connectors that melt when placed near a turbo. don't ask how i know. it doesnt have to be routed inside. the gauge could live in the engine bay for diagnostic, taped to the hood, or unplugged if not needed.

-

Motor mount issue

nvu replied to lichen's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Is the mount still not in the hole? Had something similar happen before. The bolts didnt line up with the crossmember holes. I think I removed the dogbone and put a ratchet strap on there to pull the entire engine back towards the firewall. Then slowly lower it while prying things into place scrap wood sticks. Like lower it so it barely presses the metal, then pry it until it slots in the hole. No ideas on the whining noises.