-

Posts

72 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Store

Everything posted by joomanburning

-

I’ll look into the Launch. As far as what and why I want to monitor- the whole car, and I was hoping I could find an answer to my 99 Legacy’s problems. My problems started when the GF left the 99 Legacy in D and shut it off. Went for a walk around the lake. Couldn’t re-start it, obviously, because it was in D and then had a couple (?) people try to jump her unsuccessfully. Somewhere between when she ‘parked’ and when I get there she puts it into P, because when I arrived, it was in P. I jumped her with my truck right away, first try. She drives home, 100 miles through two pretty serious mountain passes (we’re in AK) and drives the car for a couple weeks, more passes and hundreds of miles, but there’s this new hesitation, a blip mostly noticeable at idle and sometimes near shifting when hard on it uphill etc. Since incident, gear selector (4EAT) doesn’t have the same click when I push the button to move it and the ignition tumbler won’t go to “lock”. Problems started in with hesitation and got worse a couple weeks after this incident, quickly progressed to intermittent flat throttle under load, eventually falling into rough running and idle. It would start and run great after it sat overnight for a few days but issues would start all over again after a few miles. Now it’s tough to start and falls right to the shitty idle. It falls flat on its face and dies when you try to drive it. Exhaust hits hard, thump thump thump. Mileage unknown, Speedo intermittent since well before I owned, but showing 150k. 30th Anniv, 2.2. Idles and revving like it’s missing, whole block has a consistent shake, no codes besides a high input limit from the fuel gauge. It has NEW- oem front o2, fuel pump, excellent fuel pressure on engine side, fuel filter, battery, oem MAF, oem coil (spark visually confirmed at coil and plug gaps), oem IACV. PCV is perfect, recommended NGK plugs, new fuel filler neck, TPS checks out with multimeter, NGK wires, alternator, cats are good, good compression (181-185 across all 4, all plugs out and COLD, because I’m afraid of running it too long idling like it is). Good vacuum. I haven’t pulled the timing cover yet because the compression was so good. I replaced the timing system ~3 years ago with a Gates kit. Thinking of shotgunning the camshaft sensor, maybe the crank sensor while I’m at it even though I’m doubting either of those? Found a spare ECU for next to nothing I’ll try too if needed but before that I was hoping perhaps to solve it with a more advanced approach. I mean, I almost took it to a shop… god forbid. I’ve wiggled every wire harness I can find, I’ve tested the fuel, I’ve checked the returns. I’m stumped. Also would like the software for the new addition- Bought 08 GT Limited as all this was happening because, well I wanted a Legacy GT. I want to be able to interact with this car. I’m new to this side of things, I’ve always just used a multimeter and logic and done pretty well. I’ve been fixing my own vehicles for 20 years, but they were all from last century. This 08 (I know, that was 14 years ago, feels like yesterday) is a different beast and I’m absolutely interested in looking at the car through some better software available. I understand the risk associated, will do (due?) my diligence and take advantage of whatever resources available. so… Is FreeSSM still viable? What if not? Com Cable recommendations? sorry for delayed reply, working my rump roast off up here

-

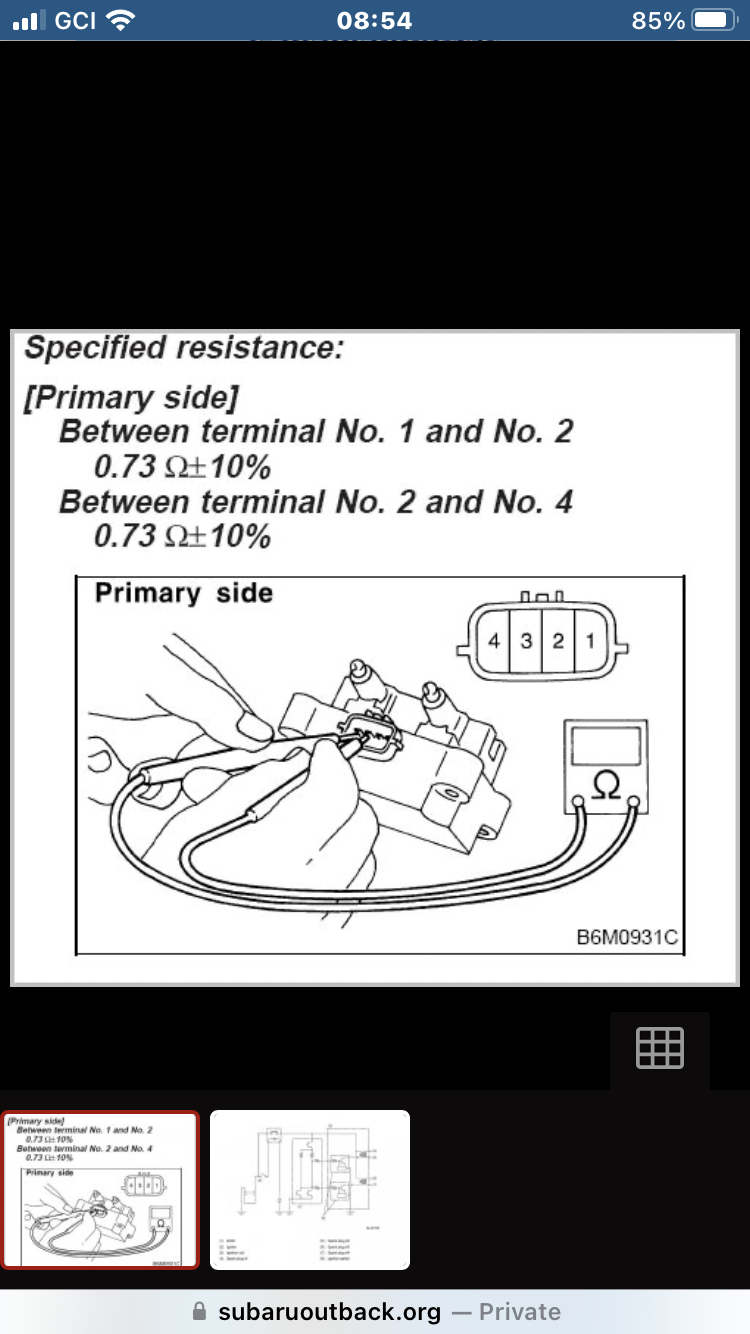

I only went to the other terminals because I got a new multimeter and was curious. I started with what was in the diagram and then proceeded to probe around out of curiosity. The image above specifies 0.73ohm, and I am getting 80ohms across the above pins and NOTHING else. Compression checks out across all cylinders. All between 183-189. Plug on cylinder 2 was soaked in fuel…couple this with the lightning storm that came off the end of the lead when unplugged and the fact that the engine doesn’t run any worse when I pull that particular lead off and I want to believe it’s not the coil but maybe it’s just not pushing the required voltage and amperage anymore edit- prove to probe

-

No codes. Just rough idle and lack of power. Sometimes it runs fine, for a bit. Then rough idle and no power. Now when I unplug cylinder 2 when running rough the boot end is shooting sparks everywhere but the engine doesn’t change. If I unplug 1,3 or 4 it bogs down. I swapped plugs, NGK copper. NGK wires. The coil is an OEM coil. I’ve changed the fuel pump, fuel filter, plugs, wires, alternator, cleaned IACV, MAF, ran down the vacuum lines. Have strong fuel pressure on engine side of filter. Strong smell of gas in exhaust when it runs rough. Have O2 sensor and new IACV on the way but I feel like this isn’t it, car has unknown miles so these parts don’t hurt my feelings too bad that I’m shotgunning parts at it. Checking compression on #2 next.

-

Testing 4 pin coil on 1999 Legacy L 30th Anniv, 2.2. Using the pin number assignments in the photo, on the 4 pin primary the ONLY resistance I can pick up is 80ohm between pins 1&3 and 3&4. On the secondary I am reading a hair over 10k. These are a far cry from any spec I’m seeing in any service manual. No visible damage, smells or otherwise. Is this coil junk?

-

1999 Lego L, 30th Anniv., 2.2, Auto. Mileage unk, but high. Love this car. So, gf decides to park car to take pretty pictures of Alaska fall colors, leaves the car in drive, shuts it off. She gets back in after photo time. Car won’t start. (It’s in drive.) Calls me, I am an hour away and start to drive, don’t even occur to me that the car could’ve been left in drive. In the interim a UPS truck stops and attempts a jump, no luck. Not sure if it was in P or D when the jump is attempted, but I have my suspicions. How many times she hit the key with it in drive, I have no idea. At some point the car gets put into park before I arrive, I can only deduce that happens after the UPS truck makes its attempt because when I get there, it’s in P, I jump it, runs fine….. HOWEVER- Now, the ignition tumbler refuses to go to LOCK and the gear selector button feels finicky, like it’s not properly engaging- it selects and stays in each gear just fine- but it doesn’t feel the same as it used to. I have a feeling these two are related to whatever happened while I was on my way to the scene… like the key was in the wrong spot when she was messing about the gear selector or vice-a-versa? Correct me if I’m wrong, but isn’t there communication between the gear selector and the tumbler? Any and all help appreciated, I do ALL my own work, but I have no idea where to begin here, and I’m not finding related threads!!!

-

99’ LEGO, 30th. 2.2. Auto. 150k. Stock. New factory front o2 (replaced because I had it laying around not because of issue) new knock sensor. New coil, NGK plugs and wires. New fuel filter. OUT OF NOWHERE—Intermittent- Car bogs, dangerously so, anywhere outside the first and last 1/8 of throttle range. If I have the car mid throttle- BOG. As I let back out and get in that first 1/8 again it will downshift and surge with life. Rusty filler neck that throws EVaP code and leaks when filling, sometimes. Never runs bad when CEL illuminated. Never throws CEL when it runs rough. This is the 3rd Subaru I’ve had with this issue. Solved those with o2 sensors. The other two didn’t have holes in either of the filler necks, but each had EVAP ghosts.

-

0:03. You can hear my pen moving and hit something almost immediately upon video start, sorry. 0:03 tach drops below 2k and I bump the throttle +2k and it makes the noise. Sometimes under the right, consistent load- it’s near continuous. Arrhythmic in nature, not hitting every revolution type thing, but close. Like a TBI 350 pinging! If I’m going uphill and feather it +/- 2000RPM I can get it to make the noise almost every throttle blip which is what got me thinking belts and pulleys....it’s metallic but there’s almost a ‘tweet’ with the noise that the camera doesn’t so much pick up. Ive since removed the A/C belt to rule out those pulleys, checked over fascia for loose parts, checked/secured all heat shields again, checked all flywheel bolts through access port, went over brakes and bearings, tie rods, CV shafts (bad exterior boot on DF, but doesn’t make any clicking noises at full lock). Motor mounts look good. Tranny mount looks good. U joints are all tight, support bearing looks/feels good. Fluids good in rear diff, gearbox and trans. No chunks, ATF passes white paper and smell tests, proper trans filter. I can’t reproduce the sound in park, or in drive with brakes held, or on jack stands in any capacity. I’m lost! Seems to be getting a bit worse but slowly. Lots of miles in Chugach mountains daily here, so I hear it a lot and my sanity is waning. A ‘ride-along’ with a Subaru tech here on the last frontier is 2 months out, I don’t trust those guys any farther than I can throw my 60” pipe wrench, anyway. NGK wires and wouldn’t dare use anything else. Edit- Clarity

-

99 Legacy. EJ22. Auto. @ 2000 rpm +/-, I have a rattle that only comes when driving, lower in the RPM range with light throttle that sounds a lot like a 350 Chevrolet when the timing set is too hot. Recently replaced plugs (yes, NGK 2756), coil, wires front O2 sensor, timing assembly. New calipers both front. Owned like 5 1999’s, have mostly rebuilt them all, never heard this sound before. Driver front CV shaft both boots are bad and throwing grease, but doesn’t make noise when wheel is at full lock and moving forwards or back, left or right. Ball joints and tie rods are tight. Can’t find a loose beat shield. Driveshaft seems in great shape. Wheel bearings are smooth. No CEL. Even swapped good knock sensor for another good knock sensor. Idler pulley for compressor belt is smooth and silent as are the others. I’ve taken the timing cover off twice now since the job to see if the problem is in any of that system but only find that all is operating smooth. Cannot recreate sound with parking brake and foot brake held with trans in 1, 2, 3, or D. Cannot recreate sound in park. It only happens when in motion. Only with light throttle or when I let off and come back on throttle easy....also more pronounced on incline. Car goes to full throttle smooth and comes down smooth to idle. Starts good. Going to try decarbonizing via sea foam today.... CV shaft is out a few days as I’m in Alaska. Ideas? I can’t find any videos of spark knock in a Subaru but I can’t imagine it’s muxg different. Can the CV joint cause this kind of sound? If so it’s a new sound to me. Thanks for lookin

-

Definitely replace the throw out bearing clips and pivot retention spring (aka mousetrap spring). They're like $5 from the dealer. You might go ahead and replace the clutch fork too, for they are known to break. Mine did a few weeks ago at 195k. Rendered car inoperable. The motor has to come all the way out for it too, so do it now. As stated above-if you can feel even a little groove on the smooth part of the transmission snout, order a sleeve. My snout was a little worn so I installed the sleeve. World of difference- no more chatter when taking off from a stop, and the clutch is butter smooth. Note- the snout repair sleeve REQUIRES a matching oversized bearing -- every kit I've found offering a sleeve, offers the oversized bearing to go with it. One such sleeve kit- http://www.pdmusa.com/ Note 2---People (especially the tuner nuts at NASIOC) will steer you away from AMS clutch kits- but they come with a nicely machined sleeve (with set screws!!) and quality oversized bearing to match for 1/3 of the cost. I've had nothing but good luck with these kits. But if you can go the OEM/Exedy route- do it. Sandwich bags labeled with sharpie save my a** every time. Be prepared to get creative and buy swivel sockets for the bell housing bolts.

- 20 replies

-

- Clutch Slipping

- clutch

-

(and 2 more)

Tagged with:

-

As far as bearings go- To have a shop do it, bearings alone will run you $200 each, thats on the low end. If you're interested in spinning the wrenches yourself, the wheel bearings can be done in just about any driveway- Harbor Freight also sells a "Front Wheel Bearing Adapter Kit" for $90 that makes the bearing job pretty painless. I WANTED to do all four after I used it. Snap-On and the other big timers sell them too, but you know the drill. If you so decide, spray everything with penetrating lubricant, especially the lateral link bolts (look it up ), well before you intend to tear into it, especially if you're in the rust belt. Even if you're not wanting to do it yourself, you're asking questions, so I assume you want to learn----find some of the DIY wheelbearing threads on this very forum, so you'll have a good idea what you could be paying a mechanic to do. At $100+/hr.

-

+1 to wheel bearing. You can put the car on 4 jack stands, put it in gear and listen to the backside of each hub (as close to the bearing as possible) through a mechanics stethoscope. ($5-10 at Harbor Freight) FAIR WARNING- This method requires that you will be under the car with the drivetrain in motion. Obvious hazards. If you have a friend present, you could have them rotate the tires by hand as you listen. MUCH safer. Even if it isn't the bearing, listen to the hubs, differentials and any other stationary surface associated with the drivetrain. When drivetrain is in motion the stethoscope will likely point you to the problem area, if you've got your ears on.