nelstomlinson

Members-

Posts

180 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Gallery

Store

Everything posted by nelstomlinson

-

The car started right up in the shop, with coolant temp at +50F. It doesn't start at all now with coolant temp 30F cooler: it cranks, coughs a little, but never catches. This is really getting irritating. When I get the '02 running I'll probably just park this one for a while. I really hate fussing with spark engines that don't run right.

-

The engine is back together, and we've dug the car out of the snowbank and gotten it into the shop to thaw out. We'll try to get it installed and tested tomorrow. What sort of oil do y'all recommend for the break in period? I'm figuring some cheap, non-synthetic 5W-30 for 500 miles, then an oil change with more dino oil and give it about 2000 miles before switching to synthetic.

-

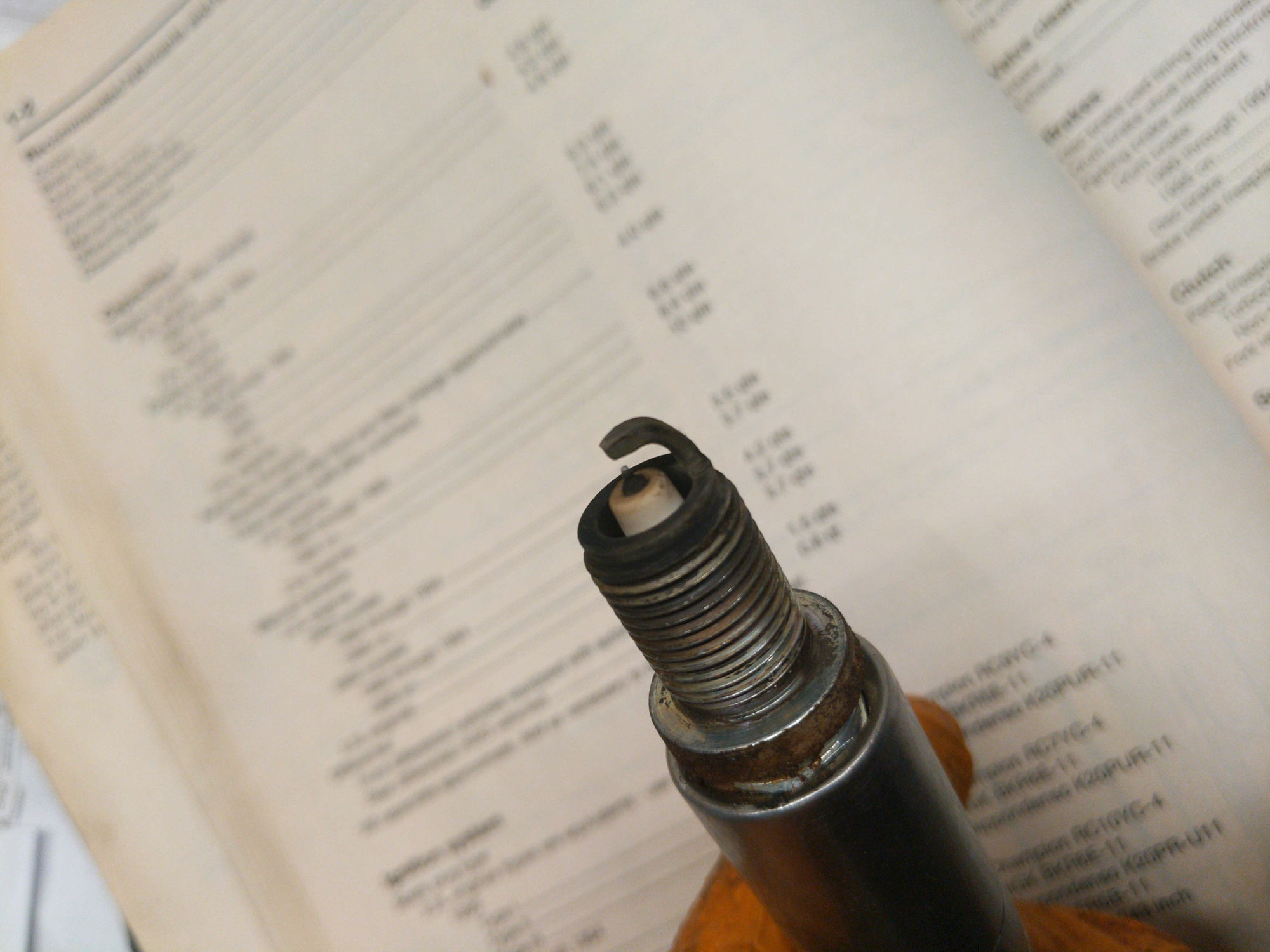

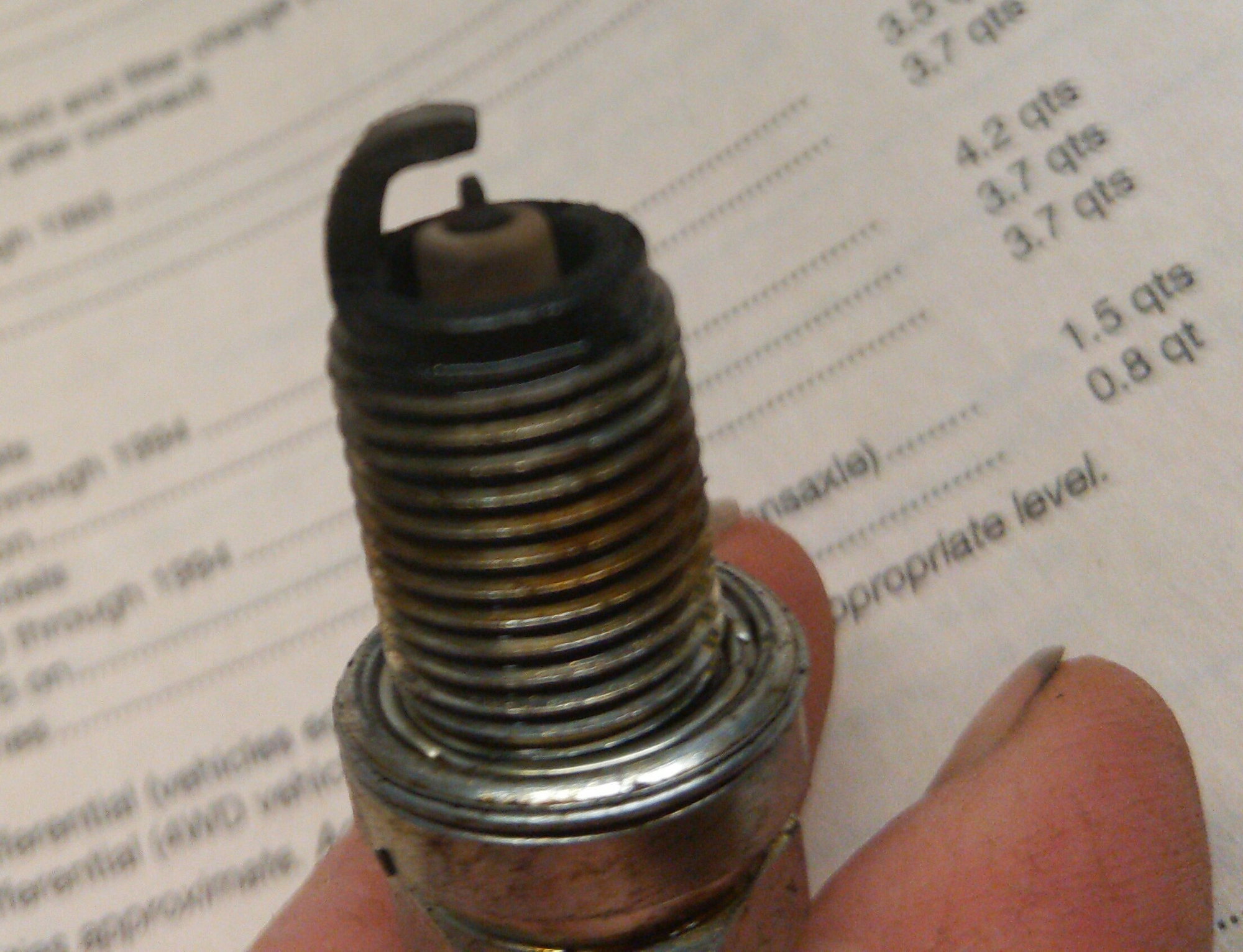

I changed the plugs, and it's starting a lot easier: crank-crank-roar! instead of cranking for 10+ seconds. The plugs looked OK, and the gap was still barely in spec. I changed'em anyway, and it started quick and easy for the first time in a week or so. Cylinder 2 plug was a little more discolored than the other three, but none of them look like there's serious trouble.

-

I'm not sure when we last filled up, we don't really track that. It's possible it's bad gas, I suppose I'll have to check the maintenance log in the car about the plugs and wires - from memory they're probably a couple years old, under 10k miles, but I might be thinking about the other '96. It's hard to remember what I did to which when, which is why I keep a little log book in the glove box of each rig. Thanks for the link, that's helpful. This kind of thing is why I hate spark ignition. My diesels don't have these flaky problems.

-

My '96 Legacy recently began starting hard, have to crank for 10+ seconds before it starts to fire. Once it's running, it runs great. Fuel mileage has been about 24-ish on the highway, down a little from what I expect, but this is winter with a lot of idling and bad road conditions. About the same time this started, the CEL came on. Code reader says it's P1100, interwebs say that's intermittent MAF error. I unplugged and wiggled and re-plugged the MAF connector, cleared the codes, and drove it a while. The code still hasn't come back, but the hard starting remains. The battery is in fair shape, and the starter spins the engine as quickly as ever, per my ear. While I drove around, I looked at some of the data on the scan tool. When I first started it, the engine coolant temp was 25F. That's probably about right. It quickly warmed to 180F, again about right. I noticed steady readings from the MAF of 0.01 at idle up to 0.11 or so accelerating up a hill at full throttle. Spark advance about 20 degrees at idle, up to around 40 when accelerating. I can't see any signs of any problems, but I really don't know what to look for on these spark ignition engines. I'm not sure what else to try, but I think I better fix this before I burn up a starter. Any ideas?

-

Absolutely top off the lube in the differential! I'm pretty sure the reason one of my '96s is now two wheel drive is that I neglected the leak in its rear differential, and it eventually ran dry and the gear box self-destructed. It's easy to top off if you can jack up the rear end a little, and replacing the differential is way harder.

-

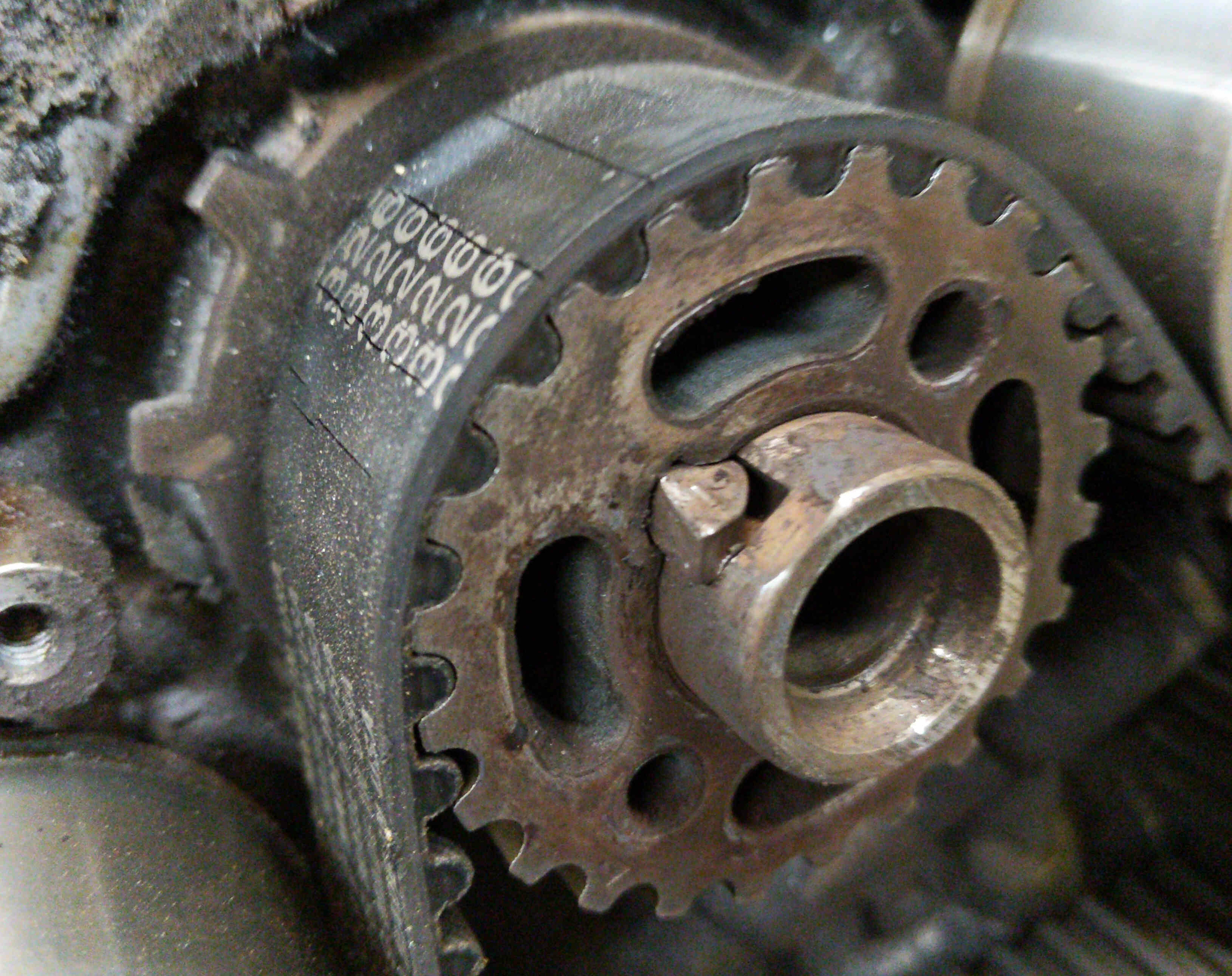

The tabs on the back are the least of the worries, that damaged keyway is way beyond usable. Don't know if it's clear in this pic, but the keyway is wallered out to the point that it will slop enough to feel on the new crank nose. I think maybe the damage was caused by the crank nose bolt being loose?

-

The crank nose pulley and harmonic balancer are both pretty well ruined. The pic shows the crank nose pulley, with the woodruff key turned sideways. The key is chewed up, and it wallered out the keyways in the crank, pulley and balancer. Where do I find a new pulley? What part name or number do I search for?

-

I'm hearing it's hit -40 in Fairbanks finally. We're getting wind and almost -30F. The cold came very late this year, and we've gotten more snow than we wanted. Probably going to have to wait a while for the Chinook to hit us, daytime highs slated to be well below zero as far as the weatherguessers can guess.

-

Thanks for all the help. I'm going with the Subaru #11044AA642 head gaskets, and I'll try the enginetech set for the rest. It claims to have MLS head gaskets too, but I'd rather not take a chance on that. Bad intake or valve cover gaskets are a smaller problem than a bad head gasket. I'm planning to take the heads up to the machine shop in Fairbanks next time I go up there, hopefully after the temps get back a little closer to zero.

-

I'm finally getting around to installing the new short block I got for my '02 Legacy, and I just realized that the short block did NOT come with the necessary gaskets.Rock Auto has ITM and Enginteck kits for ~$90, and AJUSA for ~$250. Are any of those likely to be adequate? What's a good source for good stuff? Ideally I'd like to get head gaskets that will last.

-

It has been popping out of 4th. We put it back together with a new friction disk, he's back on the road for now. We'll try fixing that issue another time, when I don't have a stack of things to do in the shop. Will our '99 Legacy tranny work in the '96? Next spring we have to drag that into the shop and strip parts off it, anyway. That car had the DOHC engine, and not a lot of miles on it. The transmission is probably fine.

-

Looks like we have to pull the transmission, take off the two back sections, split it, then we can pull the input shaft and get the bearings off? Have to get the preload right as we put it together? I've got way too many projects, don't have near enough time. We could pull the tranny and roll the car out of the shop and take the tranny north next week or so. I'll see what my son wants to do.

-

Or, we could wait for spring so we can get at the '99 with the manual transmission to swap in. I'm thinking now that if the next flex plate lasts 6 months, we'll have time to make the swap before the next breakdown. We'll call the gearbox shop up in Fairbanks for a quote on rebuilding the tranny, too.