nelstomlinson

Members-

Posts

180 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Gallery

Store

Everything posted by nelstomlinson

-

1 Lucky, not sure what happened. The engine was put in by a flaky mechanic I bought the car from, and I'm not at all sure he was competent. I wouldn't rule out him just putting it in wrong. The crank seal and other cam seal were looking good, so if there was high pressure, it wasn't bad in those places.

-

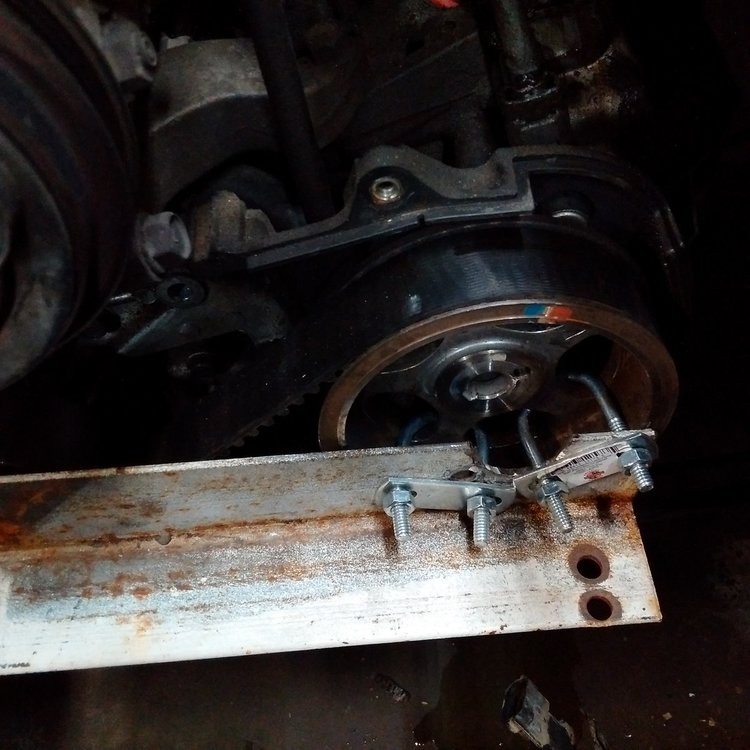

One of my '96 Legacies was trickling oil from the front of the engine. We opened it up, and saw it was time to change the timing belt. The oil was obviously coming from the driver side cam seal, so we went to pop off the cam pulley, and the bolt wouldn't budge. We tried the rattle wrench, we tried heat and oil and the rattle wrench, we bought a new, compact 1/2" drive rattle wrench to rattle harder. That thing was STUCK. We finally put u-bolts around two spokes of the pulley, and fastened them to a 2 foot piece of angle iron to hold the cam and pulley still. Then we put a pipe on the breaker bar, and hammered on the pipe while we heaved on it. It broke loose without breaking anything! The bolt had just a dark shadow of corrosion on the bottom 3/8" or so. The bolt on the other cam was bright all the way down, and rattled out easily. We put them both back in with a bit of blue loctite. Blue loctite will come loose without heat, and it seals the threads to prevent corrosion. Once the pulley came off, we could see why the oil had been streaming out: the cam seal had come out of its recess, and was probably 1/8" clear of the head, spinning freely on the cam! The other cam seal and the crank seal both looked very good, so we left them alone, and just put a new seal on the driver side cam. I'll add a couple of pictures later.

-

Like the title says, '96 Legacy with 2.2L, the plastic radiator started coming apart. Found a leak in the upper radiator hose, pulled the hose off to replace it, and found a ring inside the hose! I looked at the neck the hose clamped to, and found that the ring was the outer half of the neck. Got a new radiator from Napa, and all is well again for now. Hope this one lasts 26 years like the last one. Picture of the busted bit attached.

-

General Disorder, do you have a link? If I were to put in a junkyard connector, I'd have two wads of butt joints, so I might as well just skip the whole connector thing and put in one wad of butt joints. If I can get a new connector I can do it cleaner, and it would be worth getting a new connector if I can get one. It definitely doesn't need to be a duplicate of the original.

-

It's a '96 Legacy Outback. The connector that connects the window and door lock wiring from the body to the doors is badly damaged by corrosion. We're going to have to either put in a big wad of butt splices, or get replacement connectors. Is there a source for replacement connectors? One side of the connector is labelled D1 in the factory manual schematic, can't remember the other right now, but we'll need both. They are really damaged by corrosion: pins broke off when we pulled them apart, and there is no saving them.

-

Since it was a male I talked to the second time, I knew it wasn't the same female I talked to the first time. It took the first one about 2 seconds to find nothing, but the dude who actually tried spent about 2 minutes navigating through the computer and cross-referencing part numbers to find the part and make the sale. I don't think the first one tried at all. No idea whether she doesn't care because she's female, or because she has some real malfunction, but she definitely doesn't care.

-

I called the Fairbanks dealer again, and this time I talked to a man instead of a girl. He was able to find both new and reman short blocks. The reman cost about $25 more, and included the oil pan and water pump, so I went with that. Now I just need to get a quote from the shop to install it, and decide whether I'm going to give up the time or the money.

-

1 Lucky, JDM would mean shipping from Seattle, and that's expensive. If I can get something in state, that's going to be way cheaper. The dealer will get a container of freight every month or two and that whole container costs him about $5 grand for freight, but for me to get one pallet is going to cost close to one grand. There is a 2001 Forester for parts on craigslist up in Fairbanks. If I can get that guy to respond, I'll be set.

-

Thanks, Forester2002. So I'm looking for an EJ251 engine? From the Infogalactic page: Usage: Impreza 2.5RS, 2.5TS 00-02 (US) Impreza Outback Sport 00-02, 04 (US) Forester 00-04 (US) Legacy 00-01 (US, 4EAT) Legacy 02-04 (US) Outback 00-01 (US, 4EAT) Outback 02-04 (US) Baja 03-05 (US) I should be able to get a 2.5L engine from any of those and drop it right in, right? Any subtle issues to look out for?

-

Took this to the mechanic. He found that the bolt that secures the timing belt pulley on the crank had come loose and the pulley had wallered out the keyway, so the pulley was drifting 20 or 30 degrees. He was able to get the pulley back to the correct position and tightened the bolt. It's running great, so far so good. I talked with the machine shop I usually use, and he's telling me that the crank can't be repaired, and he recommends getting a short block from the dealer if the mechanic's fix doesn't hold. Thanks for the info on the ECU, Rampage.

-

Rampage, knock sensor wouldn't cause timing to go to -10 degrees on acceleration, would it? Anyway, the engine has never once died, it just makes no power at all, until suddenly the spark advance jumps into positive territory and away we go. I had a spare aft oxy sensor on the shelf, so I threw that in last night. Zero change, so that wasn't it. The front oxy sensor was changed out a couple months ago by a mechanic who solved an earlier proble. What controls spark advance on this machine?

-

2002 legacy outback, automatic transmission. It hesitates when I step on the gas, sometimes for several seconds. When the engine is cold, it may not move at all for up to a minute. When I look at live data, I notice that spark advance is negative 8 to negative 15 when it's hesitating, maybe +15 at idle, +30 to +40 when accellerating normally. The throttle position sensor is reading normally, even when the spark is retarded. Manifold pressure runs around 5ish psi at idle, rises when I open the throttle. What in the world could cause the spark advance to go the wrong way intermittantly? What other data should I look at?

-

I ran out of time, took this to a local mechanic. He found that the heater on the front oxy sensor was defective, and replaced it. That was definitely a problem, but not the only problem. The car now starts fine when cold. Still getting intermittent misfire errors, but since it's running better, I still don't have time to chase them down. I'll update this once I make some progress.

-

Lucky and Montana, those are both good ideas. I'm back to work through Thursday, will try to get back onto this project in the evenings. The spring thaw is starting soon, and we've had to start canning the food that was frozen outside all winter, so as usual, everything is demanding attention at once. Spring thaw is at least a nice problem to have.

-

Brus, yes, I turned them in until I got some resistance, then about another 1/2 turn. Threads must be pretty clean down there, because they went easy until the washer contacted the head. Montana tom, I'm starting to think that it's fuel not ignition. On NASIOC I found a little list of causes of misfires that included things like fuel injectors, a bad-ish knock sensor and a dirty MAF. That last one is easy enough that I'll try it after work. Is there a way to check fuel injectors without special tools? Edited to add that I have a 2001 Impreza with a blown head gasket that I'm robbing parts from. It ran pretty well before the head gasket went. I could rob injectors from it?

-

This is in my 2002 Legacy four-banger. The short of it is that I've changed the plugs (new NKG, gapped at 0.044), new plug wires (NKG again), and swapped in a coil from a car that didn't have this particular error, and still I have a consistent po303 and po304. When this started, I had misfires on all four cylinders. I checked the plugs, and they looked awful, so I put in new plugs. All was well for a day or so, then the problem came back. I swapped in a coil from a 2001 Impreza which was a good runner until its head gasket went. All was well for a day or so, then the problem came back. Then the new wires arrived from Rock Auto, so I put them in. All was well for a day or so, then the problem came back, but now it's only cylinders three and four that are misfiring. I'm starting to think I have some non-ignition problem which might be intermittent. What should I try next?