-

Posts

205 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Craigar

-

The smog guy also showed me that the black rubber tube on the bottom of the Evap canister doesn't connect to anything - it's just dangling.. and I can't figure out where it should go , but he says that sub system tests OK so he can ignore it..? Thanks again Craig Edit 1 hour later : This post says it's a dangler i.e. goes nowhere - except maybe in the hole in the frame, and I see a hole on the frame I could stick it in .. so I'll stuff it in.. https://www.ultimatesubaru.org/forum/topic/36898-quickeasy-charcoal-canister-question/#comment-297552

-

Thank You SuspiciousPizza for the update that it is also used in a California SPFI EA82 Yea this sensor isn't listed - or any egt sensor - for an EA82 (at least not at RockAuto or Fleabay, google search) nor do I see it in any of the exploded intake manifold views.. but it looks about identical to this one https://www.rockauto.com/en/catalog/subaru,1994,impreza,1.8l+h4,1268861,exhaust+&+emission,exhaust+gas+temperature+(egt)+sensor,17051

-

Do these fail often? I R & R it when replacing intake manifold gaskets and it had a fair amount of carbon buildup so I gently scraped off most of it and I don't have a "check engine light" problem, and this car has passed smog 3 times so far. It runs good and seems to be getting OK mileage, has about 155K miles no smoke or steam coming out of exhaust, plugs look good also. This image is from a 1994 Impreza but seems to have same exact motor i.e. 1.8L H4 it goes in the threaded hole to the left of this brass stand off (passenger side of intake manifold) Thanks Craig

-

EA82 replacing manifold gaskets

Craigar replied to Craigar's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Got it all back together, driving it for a few weeks and runs maybe even better than before - sounds much better without the worn out water pump rattling - , no leaks! BUT didn't pass CA smog (engine light is off when motor is running) and was 2 degrees to advanced so reset it and ran a bottle of " CRC Emissions System Cleaner" .. double your money back... in a half tank of gas so going to try to pass test again. Thanks everybody for the support -

Thank you! The bolts didn't break probably cause they're hardened or tempered, they have a #7 on the top of the bolts. Yea first I'm going to hit the bolts and threads with a wire wheel but probably use a die on this particularly bad rusted one - the rest didn't look as bad - 3 of them came out easily. Will see Started a new topic for doing the gaskets and hopefully getting it back together without putting some of the spaghetti back in the wrong holes.. https://www.ultimatesubaru.org/forum/topic/186408-ea82-replacing-manifold-gaskets

-

after getting the bolts out (serious slow torture on the rusted encrusted ones https://www.ultimatesubaru.org/forum/topic/186067-any-new-ideas-for-the-old-intake-manifold-stuck-bolt-problem ) then had to clean up the surfaces - the right side was so pitted I ended up taking it down with a medium diamond hone. The first and second image are from just scraping it with a sharp putty knife and carefully filing with a old "cross hatch" file - not happy.. so I worked it for about 3 minutes total with this medium diamond hone. Walla! did the same to the bottom of the manifold - but only removed what lines, pipes,sm0g stuff, etc. I needed to in order to lift it up only a few inches, so I had to use my selfie camera and it doesn't focus (kinda like my eyes now ) as I'm hoding the cell phone camera facing up .. kinda like holding a minature yoga pose Here's a couple of images using a "dental mirror" showing the ends of the manifold's water galley, I think I need to clean it up more BUT it was getting too cold and the wind and fog were rolling in.. .. and before I stuffed the sock in the intake port I looked down into it and I see a pile of "oxide crystals" so I'm going to make sure that intake valve is closed and try to get a skinny rubber hose attached to a vacuum cleaner down past it and knock most of it lose with a chopstick .. if yea all think that's a good idea?

-

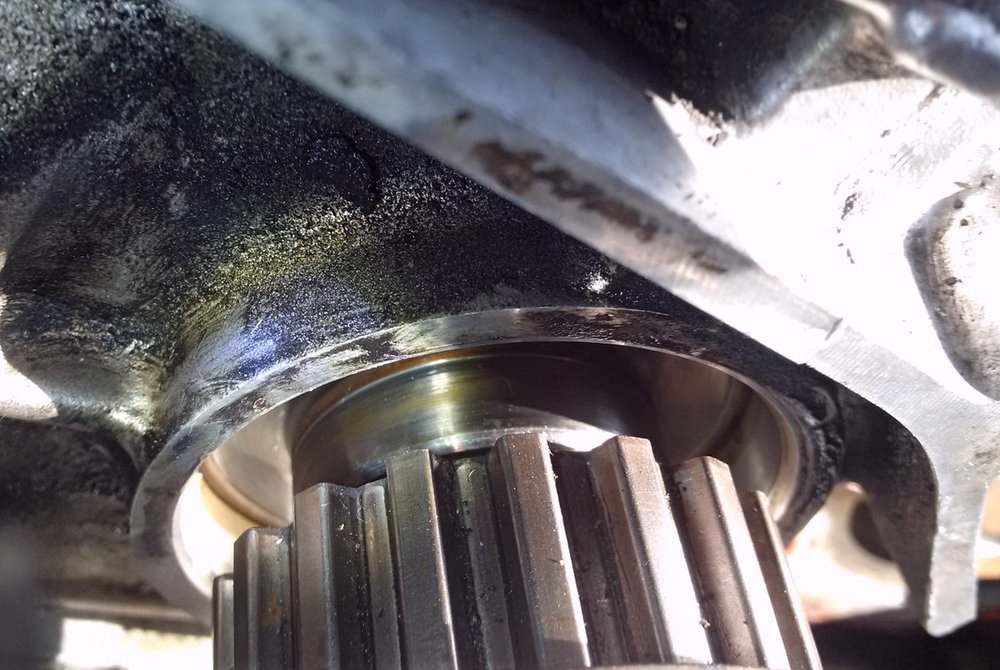

Got em all out without breaking any - I don't think Ive stripped the holes either but haven't cleaned it up yet. For this really tough bolt I decided to use a "paint stripper" heat gun on high for about 15 minutes and it still wouldn't budge so drilled a 2nd hole down closer to the threads, earlier had drilled a hole about in the middle of the column to get the penetrating oil down into the crud in the bottom inch of the column also. After drilling this second hole and then using a lot of penetrating oil, then heat, I had progress had to heat up down by the head for at least 10 minutes with paint stripper heat gun, that's why my aluminum shield has turned golden brown .. I tried a M.A.P. torch but it was to scary and causing way to much smoke for my comfort.. and wiggled back and forth tell I could get about 1/4 turn, came back next day tried it cold no t so much movement so heated it up again and kept working it back and forth - but not going as far in as out.. then add more sauce.. do it again and eventually.. Here's the bolt right after I got it out - I used a lot of B'laster penetration oil, and couldn't get it moving with the 3/8" impact gun - had to really push and pull on this ratchet - really hoping the bolt wouldn't break,, kind of amazed it didn't

-

.. and about a week ago I sprayed em with my 20 year spray can of Liquid Wrench, - which I discovered 3 days ago had lost all it's pressure probably cause I unknowingly banged the head on it, probably shutting the hood.. So I bought a new spray can of B'laster and sprayed and soaked it a few more days - no cigar So here's the specs of a very nice portable 3/8" torque wrench I just bought from Home Depot on sale for $140 with battery and charger Lightweight Design. Heavyweight Performance. Pair with MAX Output batteries for maximum power Industry’s most compact Powerful Brushless Motor delivers 250 ft./lbs. of breakaway torque 3 speeds + auto-tightening mode provides adjustable power and speed Auto-tightening auto-stops when fastening to prevent over tightening bolts Auto-tightening in reverse, delivers full breakaway torque, then stops when the bolt is loose Tri-Beam LED enhances visibility and provides even distribution of light Compatible with RIDGID’s AC13B04N Impact Wrench protective boot (sold separately) 100% Compatible: Works with all RIDGID 18V Batteries, Tools, and Chargers Lifetime Service Agreement with registration within 90 days Includes: R872071 18V SubCompact Brushless 4-Mode 3/8 in. Impact Wrench, R87002 2.0 Ah battery, charger, belt hook with screw, and tool bag RIDGID: Build for a Lifetime 18V SubCompact Brushless Cordless 3/8 in. Impact Wrench Kit with 2.0 Ah Battery, Charger, and Bag and it didn't seem to move any of em at full torque, even trying in both directions.. So I cleaned the oil + road dirt mix off the passenger side intake manifold area (to lessen the chance of a bon fire) and only M.A.P. torched it for about 3 minutes total cause I've never done it before and was getting smoke and embers and nervous and cold and it was now dark outside where I'm working on it and the crappy harbor freight "free head lamp" was turning off all on it's own way to much - even after messing with it a lot.... and "amazing to me " got the bolt loose closest to the windshield loose! BUT it didn't want to go "looser" and "tighter" back and forth ( CCW and CW ) only looser so went about 2 turns and going to give it chance to soak more over night. - and the head wasn't really very hot, maybe 110 F. Progress, not perfection ... One down, two to go Grrrr ,, I mean "patience..."

-

Well I didn't even think about a rethread kit but you say that making me think it's inevitable so when and if I gracefully get these bolts out it'll probably need to be rethreaded with maybe some bigger threads or you got to put in like a helicoil and for heating it up with a torch should I use a map torch or a propane torch, any preferences? Thanks

-

I was gone for about 2 months and I finally got back to working on this car and ended up drilling a small hole on the outside corner of the manifold where the bolt goes down to try to get penetrating fluid or blaster down in there and then went and got myself a modern 225 foot pound max rigid torque wrench gun and I haven't broke any of the 3 bolts loose yet, so I guess I gotta go get me M.A.P. Torch, thanks for the good suggestions.

-

Drilled through stuck intake bolt... and head bolt.

Craigar replied to Corvid's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Thank You! The little plate under this particular bolt can move so the head isn't stuck at least not to the top of the landing (don't know about passenger side yet) and I also thought of the "drill a hole for the spray lube straw into the corrosion cavity" sounds like a really good option! I started a new topic here https://www.ultimatesubaru.org/forum/topic/186067-any-new-ideas-for-the-old-intake-manifold-stuck-bolt-problem/ -

93 Loyale EA82 SPFI Whilst replacing my water pump etc. I discovered another problem - the right side (by alternator) intake manifold is leaking coolant, which I suspected for a few years.. and the back long bolt is stuck / frozen - and so are the 2 long ones on the passenger/left side also... I soaked their heads and around the gasket (where we need really need it but probably can't get past the gasket) with liquid wrench and have to take care of other business so it will be a month before I can get back to it. Read through lots of good ideas for stuck bolts BUT these long intake manifold bolts have the head of the bolt more than an inch and a half from the stuck threads going into the head so I don't think many of those ideas will work. I'm thinking a 6 point impact socket, impact wrench and maybe first drilling a small hole into the manifold close to the base of the bolt, about a quarter inch above the head that I can load up with some fancy "nut buster" sauce, I have liquid wrench from 20 years ago but maybe their is something a lot better now? Here's some good ones https://www.ultimatesubaru.org/forum/topic/44039-what-are-my-options-with-this-stuck-bolt/#comment-354824

-

Drilled through stuck intake bolt... and head bolt.

Craigar replied to Corvid's topic in Old Gen.: 80's GL/DL/XT/Loyales...

93 Loyale SPFI.. the back long bolt driver side intake manifold bolt is stuck / frozen - and so are the 2 long ones on the passenger/left side also... I havn't broke them off ( yet ) .. any easy way out? thanks all Craig -

Water Pump has me confused...

Craigar replied to 92_rugby_subie's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Well before I had to go on a "work furlough" to the east coast, I discovered another problem - the right side (by alternator) intake manifold is leaking coolant, which I suspected for a few years.. and the back long bolt is stuck / frozen - and so are the 2 long ones on the passenger/left side also... I soaked them with liquid wrench before I went to the airport. -

Water Pump has me confused...

Craigar replied to 92_rugby_subie's topic in Old Gen.: 80's GL/DL/XT/Loyales...

finished the shimming, added more images https://www.ultimatesubaru.org/forum/topic/185922-shimming-water-pump-pulley-to-align-with-crankshaft-pulley-only-need-3-5-mm/ time will tell - but don't have time to be able put everything else back together and test drive for at least 3 weeks -

Steptoe's, since my problem is neither the stock water pump height OR my timing belt cogs/sprockets incorrectly stacked or flipped I'm staring a new topic hopefully to help others with this different kind of a problem (and help my patience and sanity) and will paste in your good ideas.. I've painfully learned some more possible potential problems - but luckily not *the hard way* so far https://www.ultimatesubaru.org/forum/topic/185922-shimming-water-pump-pulley-to-align-with-crankshaft-pulley-only-need-3-5-mm/ Thanks Craig

-

That would have been good - before I installed & put all the rough stuff back together - 4mm would have probably been OK with a standard length shaft BUT it's a little "shakey" to go out 5mm with a stock length shaft cause the centering hole in the pulley won't be on the shaft, it will just be catching the tapered section right before the top/cut off of the shaft.. so I shimmed mine with 2 different washers to get a "safe" max height and want to make sure I get enough threads on the hub's studs, used one of each on all 4 studs - and used a micrometer to get all the heights the same - there is a LOT of variance in the thickness of washers even though they all came from their same packages. I put the larger one against the backside of the pulley , which is completely flat and th smaller on against the water pump hub, and got 3.6mm or .140" additional height and I think it will be OK, but not "perfect" in this image I lined up the (top) power steering center ridge with the (middle) crankshaft pulley center ridge , and we can see the water pump pulley center ridge (bottom) is still slightly offset. time will tell - but probably won't have time to be able put everything else back together and test drive for at least 3 weeks - unless my schedule changes again...

-

Water Pump has me confused...

Craigar replied to 92_rugby_subie's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Steptoe's, since my problem is not the stock water pump height I'm staring a new topic hopefully to help others with this kind of a problem (and help my patience and sanity) and will paste in your good ideas.. I've painfully learned more - but luckily not *the hard way* so far https://www.ultimatesubaru.org/forum/topic/185922-shimming-water-pump-pulley-to-align-with-crankshaft-pulley-only-need-3-5-mm/ Thanks Craig -

looks like 5mm would be optimal increase in water pump pulley height to be correctly aligned with crankshaft pulley BUT I'm going to go a little less - like 4mm so the pulley will still be secured by being (just barely) on the tip of the main 5/8" shaft of the water pump - at 5mm it's kind of loose cause it's is tapered by the top of the shaft .. and also the stock studs end up being too short at 5mm - (even with them turned forward in the hub) so 4mm height extension is my safest compromise I think. Here's the problem with water pump pulley on the bottom, crank on the top Of course I wish somehow I could have moved the crank pulley back BUT it only has barely 2mm clearance from the timing belt covers!..and I have my timing belt cogs on the crankshaft stacked in the correct order, so that's not causing this problem.. so I really need about 114mm hub / deck height - 4mm taller than the stock "tall" version, which is 110mm .. sounds like an easy simple job, right? .. as long and it stays together and the pulley doesn't wobble.. this solution by Steptoe's photos from Australia would probably be the best. https://www.ultimatesubaru.org/forum/topic/142209-water-pump-has-me-confused/page/2/#comment-1457136 but I'm hoping a "stack of 3 of these washers on each stud.." will suffice, cause I don't have easy access to any good metal shop tools and would at least want a good drill press and vice. https://www.homedepot.com/p/Everbilt-10-Stainless-Steel-Flat-Washer-50-Pack-800032/204276382 I found #10 washers at Homedepot that should work with a stack of 3 on each stud, going to blue loctite the studs & nuts. 1/2" O.D. x 7/32" I.D. x .049 thickness 304 Stainless steel - I just need to make the hole a little bigger and a stack of 3 of them is 3.81mm probably a safe compromise.. I'll add some pictures tomorrow if time permits and maybe Ill have the car back up and running in a couple of days - and hopefully the fan and the pulley stay happily attached.. will see.. If it starts coming apart then maybe try some 2" O.D x 1/2" i.d "fender washers" that could work if I open up the center hole to 5/8" and drill 4 holes for the studs - and I'd use 4 or 5 of the and it would be way more work and probably overkill.

-

neither did I - one "definitive marking" is the one closest to the engine has a "dot/punch mark" at 5.30 o'clock that you can kind of see in these fuzzy images. The rear cog is on the left, the 2nd picture is the pair flipped over showing the backside ... and the front cog his another notch /slot 180 degrees from the woodruff keyway. Gratefuly we can see both notches on mine (in my 1st image) so I must have them stacked in the correct order.. https://www.ultimatesubaru.org/forum/topic/66578-crankshaft-timing-belt-sprockets-the-truth/page/2/#comment-543849 Here are good images of the one closest to the engine, that has a "dot/punch mark" at 5.30 o'clock https://www.ultimatesubaru.org/forum/topic/139522-would-you-reuse-this-crankshaft-sprocket-ea82/ I found #10 washers at Homedepot that should work with a stack of 4 or 5 on each stud, going to blue loctite the studs & nuts. Also found some 2" O.D x 1/2" i.d "fender washers" that could work if I open up the center hole to 5/8" and drill 4 holes for the studs - and I'd use 4 or 5 of the and it would be way more work and probably overkill. Thanks Craig

-

I measured (again tonight) this water pump and it is 110mm hub height, as stated @ Rock Auto. so it's not what my problem is, Also discovered tonight that the crank pulley is maybe only 2mm away from the timing belt cover so I can't move it back/closer to the crank.. So possibly the best solution would be to pull/move this hub 5mm higher/forward (then it would have 115mm hub height) for it's pulley to align with the crank pulley ... or I could use washers but I would think it might be better to fabricate a spacer disk out aluminum - or buy one - I'd think someone may have made some for all the poor guys who installed a 105mm that really needed a 110MM? and to "lighten the load" on the bearings I wish I could find a "flex fan without a clutch, and I know many guys say dump the mechanical fan but I like good simple "fall back" systems in case/when the electric one fails.. Thanks Craig

-

Thank You! I think I got my crankshaft timing belt sprocket(s) in backwards, WRONG - they're OK ** after lots more research it seems I must have my timing belt sprockets/cogs stacked in the correct order, so that's not causing this problem. ** https://www.ultimatesubaru.org/forum/topic/66578-crankshaft-timing-belt-sprockets-the-truth/page/3/#comment-552982 my cog/sprocket with the dot at 5.30 o'clock is not visible because it's the one closest to the crank i.e. they're correct. it really seemed that my crankshaft timing belt sprockets were sticking out too far - but all the other images and videos seem to look the same as mine.. Craig

-

So maybe my crankshaft timing belt sprockets and pulley are sitting too far forward or something weird - or maybe it's been this way ever since I bought the car in 2016 - OR I messed something up and flipped a crankshaft sprocket when I did the timing belts & water pump in 2018. My crankshaft pulley is pressing right up against the timing belt sprocket and is held on with one big bolt (no washer) torqued to 140 ft/lbs. Also my timing belt sprocket on the crankshaft does seem to be sticking out bout this far (5-6mm) from the end of the crankshaft - although that seems the same as what I see in other postings and vids. ** after lots more research it seems I must have my timing belt sprockets/cogs stacked in the correct order, so that's not causing this problem. ** https://www.ultimatesubaru.org/forum/topic/66578-crankshaft-timing-belt-sprockets-the-truth/page/3/#comment-552982 Here are good images of the one closest to the engine, that has a "dot/punch mark" at 5.30 o'clock https://www.ultimatesubaru.org/forum/topic/139522-would-you-reuse-this-crankshaft-sprocket-ea82/ my cog/sprocket with the dot at 5.30 o'clock is not visible beacuse it's the one closest to the engine i.e. they're correct. this is when I was doing the timing belts in 2019, the crankshaft timing belt sprockets are circled in orange - and this is how they were when I started timing belt/water pump replacement in 2019. it looks like they are sticking out about 5mm beyond the end of the crank? Does that look right? other images and videos I've looked do seem the same Backside of crankshaft pulley 20240809 what got me Here's the misaligned pulleys ( unless Subaru INTENDED it to be this way? I doubt it ) **** EDIT 8/16/2024 2am I measured this water pump and it is 110mm hub height, as stated @ Rock Auto. *** so it's not what's causing this problem. *** Here's another great "zen art of Subaru maintenance" showing him pulling of these sprockets/gears.. both his "protection disks" are facing the crank, just like mine. https://youtu.be/QCnmC2gZahs?t=231 At first I was thinking that the pulley on the water pump I'm replacing is sitting about 5mm to far back compared to my crankshaft pulley - and it seems like I bought the correct 110mm hub height water pump as I explained in this post - in fact a solution would be to pull/move this hub 5mm higher/forward for the it's pulley to align with the crank pulley (then it would have 115mm hub height) Also discovered tonight that the crank pulley is maybe only 2mm away from the timing belt cover so I can't move it back/closer to the crank Thank You all Craig