-

Posts

27 -

Joined

-

Last visited

-

Days Won

3

Silverbull3t last won the day on January 19 2025

Silverbull3t had the most liked content!

Profile Information

-

Location

Adelaide, Down under

-

Occupation

Fitter/turner

-

Biography

1981 wagon with all the good bits!

-

Vehicles

1981 wagon, 1984 Brumby, 2004 Liberty

Recent Profile Visitors

Silverbull3t's Achievements

Member (2/11)

16

Reputation

-

My 81' wagon EJ20 swap project

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Sure thing! Brief run-down: My parents bought this car new in 1981, been in the family ever since. It was handed down to my brother and then me, both our first cars. I drove it for a couple years then took it off the road more than 10 years ago for a full bare shell restoration with upgrades. Been back on the road close to 4 years. It's now got a 2" lift kit + 27" tires, touring wagon dash/center console, power steer/air con/power windows, entirely new wiring loom designed and made by me, L series 5 spd, air adjustable rear shocks, 5ch sound system with sat-nav. The list could go on...I'm constantly working at improving and upgrading things. The front suspension will be next as its way too stiff. New gearbox coming soon etc. Here's from a recent camping/fishing trip with the 4WD club It's my daily driver and gets pushed into service for vaious jobs... Right after I got the new 15" wheels -

My 81' wagon EJ20 swap project

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

And maybe I've put this in the wrong section of the forum, sorry mods! If it's possible to move it then feel free to do so... -

My 81' wagon EJ20 swap project

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I think that just about covers everything! Only thing left to do was get it dyno tuned. This took 2 different attempts; the first time was plagued by fuel pressure and electrical gremlins. After this I made the hard fuel return line to get more flow back to the tank. Also when I made the new engine loom that goes under the manifold. The 2nd visit was trouble-free and I got a whopping 60kW at the front wheels or 80hp Still this is plenty enough to light up the 27" tires and have the open front diff torque steer the car if I floor it from a stop. The gearing in the 3.7 ratio L series 5 speed is all wrong for 27" tires. I'm waiting on a 3.9 ratio gearbox rebuild which should make it nicer to drive I think. This will be going into an EJ gearbox casing so I can do-away with the adapter plate and use a full EJ flywheel and clutch. This is still in progress. In any case it drives much better now and uses less fuel than the EA81 twin carb. Highway cruising is a breeze, I can stay in 5th gear for most hills. And the absolute best part and one of the reasons I did this whole swap; no more oil leaks on the driveway! Fire away with any questions you might have. -

My 81' wagon EJ20 swap project

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Other bits and pieces; the pitch stopper rod needed a custom bracket made for the engine and I modified the old EA rod to suit. The radiator I got the outlets modified in the usual way. I'm using 2 x 10" SPAL radiator fans on the engine side plus a tiny 6" or so fan on the front side just to help the A/C a bit. For the power steering I used the EJ pump, modified 1 hard line so I could use my old EA hoses and custom mounted a later model remote reservoir next to the manifold. The A/C was a big PITA to get the hoses right since the place that did the engine rebuild put a different compressor on there. Which meant the hoses I had from the old EJ compressor no longer fitted. Went down a rabbit hole of finding out just how many differen compressors Subaru used on these engines (hint, a LOT of different ones) eventually found the right ones. Then I had the same place that did the radiator make some new rubber hoses to connect the EJ compressor to my EA A/C system. Don't have any photos of this part. For the exhaust system I got an off the shelf stainless UEL header for an Impreza for $600 and made an adapter piece with a catalytic converter to join to the rest of my DIY exhaust system. Theres a wideband sensor for the Haltech right before the cat. The exhaust uses V band clamps throughout, makes servicing so so much easier. -

My 81' wagon EJ20 swap project

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The engine wiring was the next biggest job after the fuel system. I don't have a large hole + grommet on both sides of my firewall e.g. under the wiper motor like later model cars have. So I decided to enlarge the hole that the choke cable used to run through and got a new grommet to run the Haltech wiring through there. The loom is actually quite thin and was able to fit through this hole, not many wires are needed to run the engine. I used the standard EJ engine harness connectors on the bellhousing. After chasing electrical gremlins with the decrepit old EJ engine harness, I re-made that from scratch too using all brand new plug and pin kits for the OEM connectors from iWire (in the USA!) and high temp TXL wire. Used Raychem heat shrink mostly with some braided sleeving and Hellermann Tyton cloth loom tape (good stuff!) The manifold got a clean up too, and new injectors as the old ones were hopelessly gummed up with old varnish. -

My 81' wagon EJ20 swap project

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

For the coolant temp and oil sensors I used the old EA sensors to keep my 6 gauge dash working properly. I put a sensor adapter in-line with the heater hoses for the old coolant temp sender. The oil pressure guage sender I got an adapter made so I could thread it into one of the oil gallery plug holes on top of the engine block, under the throttle body. The old EJ 3 wire coolant temp sensor was binned in favor of a bosch 2 wire sensor that the Haltech could use threaded into the same hole in the coolant crossover pipe. The heater tap below is a highly modified London taxi heater tap. It was too much work and does not work 100% right, would not recommend this swap. -

My 81' wagon EJ20 swap project

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The fuel system was the biggest headache of the whole swap and took the most time. I wanted to use an in-tank fuel pump for a few reasons. I also wanted to increase my tank capacity from the puny 45L I had. Since I have a 2" lift kit I figured I could increase the tank height by 2" which would allow me to use a weld-in fuel pump kit from Raceworks. So I miraculously came across a 1980 model wagon at the aforementioned wrecking yard which had the same 45L tank as my old one. It was more rust than car but the fuel tank was salvageable. Long story short I cut both the tanks in "half" and welded the top from one onto the bottom of the other but 50mm or 2" taller. So I only had one weld seam going around instead of 2 had I welded in a 2" strip. The weld-in fuel pump kit also had some difficulties as you can see in the photos. It all worked out in the end and doesn't leak. Another big headache was the fuel return line since my did not have one. I ended up making one from aluminium hard line to run inside the car next to the factory supply line. This worked out quite well in the end. I made a couple of spacer blocks to space the fuel tank down 2". The filler neck worked fine as the rubber elbow had enough length in it. -

My 81' wagon EJ20 swap project

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

This engine had the 6 wire stepper motor IACV which my ECU could not handle. So I went to the local wrecker and got an earlier throttle body that had the 3 wire servo IACV. Cleaned it up and got everything moving nice. I believe the middle sensor was MAP which I didn't need so blanked off that port. My engine adapter plate has threaded holes at the top so I didn't need to make the adapter bolts (that use elongated holes in the adapter plate) I got my EA81 flywheel professionally machined on the bolt pattern to bolt it to the EJ crank. Used my old clutch which is L series. Just needed to elongate the engine mount holes in the engine crossmember and it dropped straight in. -

Silverbull3t started following My 81' wagon EJ20 swap project

-

Hi all Been a little while since I visited this forum, don't hold it against me! Thought I might show the process I went through to EJ swap my 81' wagon. It's not a detailed step-by-step instructions, but maybe the photos etc could give a bit of inspiration to anybody else contemplating or in the process of doing a similar conversion. This was done over the course of a year (!) wasn't meant to take that long but there were unforseen hurdles. It's been back on the road for 9 months now and has done plenty of miles in that time. A cross country trip and a few camping trips with many more to come. Planning to do a camping trip every month this year, that's my new-years resolution! Anyway the "old" engine was the venerable EA81S twin carburettor engine. This had around 30,000 k's on it (<19,000 miles) since it was rebuilt. It was fun and sounded great but just made too little power for how much fuel it consumed. I also wanted something more modern. The new engine was an EJ20 from an early 2000's Forester that I bought for $250 a number of years ago. I had no donor car, no ECU, no dash wiring or any of that. I decided it was too hard to source all of that stuff and I don't have room to store a parts car so, I went the custom ECU option with a Haltech Elite 750. This made the wiring job so much simpler in my mind. I had other reasons for going this way as well, too many to go into here. This was my EJ after I got back from rebuild by a very reputable local place. It was "blueprinted" as they say, new bearings and everything you'd expect of a rebuild. They didn't touch the intake manifold though as I discovered later.

-

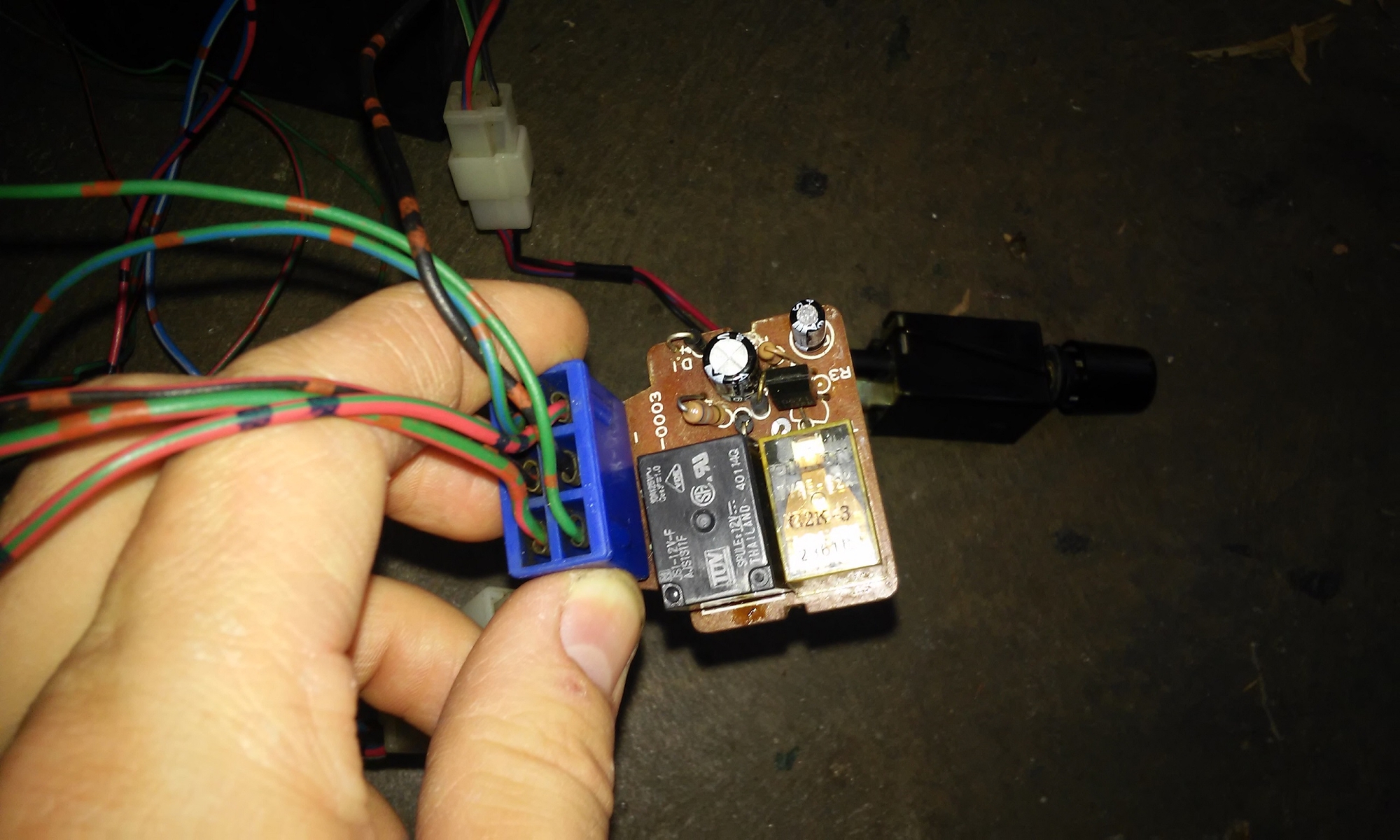

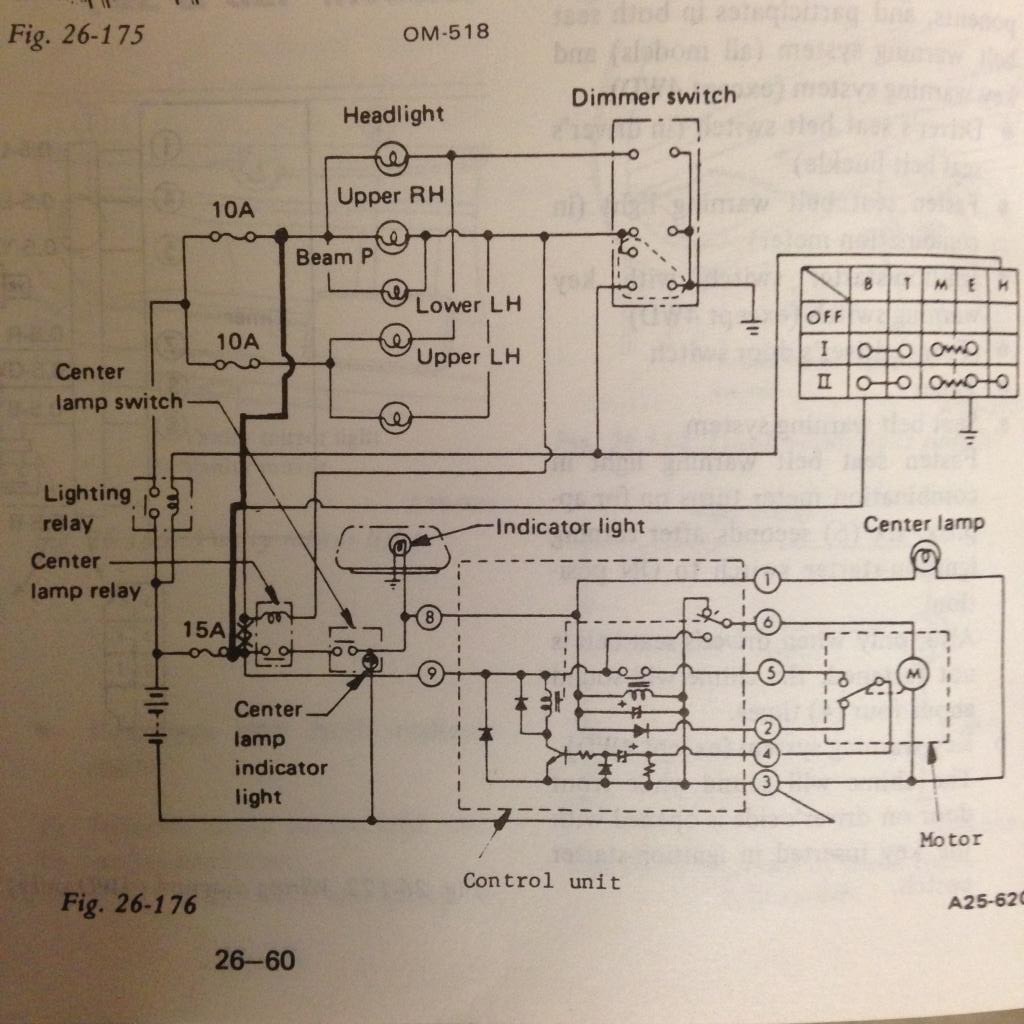

Cyclops light issues

Silverbull3t replied to bratfien82's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Is yours still operated from the factory control box? If so here is a schematic diagram of what's inside. I think most people throw this away completely and run it off a DPDT toggle switch. Mine had a problem which required me to replace one of the relays inside and one of the electrolytic capacitors. I can't remember what the problem was exactly, it was a while ago, 2016 Need to be handy with the soldering iron for this option. The relay on the left of the image below. I ordered one from an online supplier like Mouser or RS components IIRC. It turned out to be too big but I made it work anyway. Still working to this day.- 1 reply

-

- 1

-

-

Driveline angles 81' wagon

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The new bearing caps have the C clip grooves in them. The original yoke has a flat area on the inside faces which I cleaned up with a hand file, the C clip sits up against this face on the inside of the joint, 4 places. -

Driveline angles 81' wagon

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Thanks for the suggestions Bennie, let's see if I can address them all And yes I've been driving around with the rear half of the shaft out up until I got those new uni joints in the post. The vibe is gone with that out of the picture. Guess I can keep it in the back of the car when I'm en route to a destination then install it for the 4WDing part - broken/worn engine or gearbox mounts They were all brand new when I installed them, I did check the gearbox mounts at least withtin the last 6 months and they are fine/intact. Engine mounts, I will check. - modified gearbox mounts aren’t sitting true/have changed driveline angles They're the stock MY/Brumby mounts, bolted onto the L series brackets if I remember right which I filed the holes out oval shaped where they bolt to the sides of the gearbox. This is what Steve Rising sun (certified old subie guru) told me to do. Using the standard MY X-member. I never was 100% happy with this setup though. - rear output shaft bearings are toast in the gearbox, but this is usually accompanied with a leaking rear output shaft seal too (been there done that) I do suspect this gearbox (and diff for that matter) are trash, you could be onto something. The rear main seal isn't leaking though. (selector shaft seal is, dripping) There is another un-related weird low frequency wobble even in 2WD with the tailshaft removed, happens when I let off the throttle at around 80km/h or so. A bent internal shaft in the gearbox has crossed my mind. Amazingly that wobble went away with the tailshaft installed I'll be glad to get that new 3.9 box in there to compare. Does this vibration come on strong/quickly straight up when you start driving or does it work itself up to the vibration at set cruise speeds? It's weird is all I can say. Today I could feel it at 60km/h, then at 80 it was less severe but definitely still there. At 100 it is like a butt massage, get's worse from there. 3rd, 4th, 5th gear it seems pretty uniform. As for engine health, I should hope it's not that but it's not out of the question I suppose. Been meaning to do a compression test on it, it just feels too gutless (big wheels don't help) Maybe I didn't break the engine in properly? But it doesn't burn a drop of oil. Spark plugs I replaced a few months ago, old ones looked clean, good combustion signs. Can't understand that either, how it could be not running rich with the amount of fuel those twin carbies drink It might even be slightly lean as it pops/crackles on deceleration. -

Driveline angles 81' wagon

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

azdave, couldn't tell you why they went to two piece shafts except maybe because they could use smaller diameter tube, less chance the shaft could "whip" at high speeds perhaps. Well I knew it was too good to be true. The vibe is back Had 5 days of smooth driving to get my hopes up. It came back the day after I got back from that camping trip, as bad as the single piece shaft was when it bit the dust. I figured the second hand shaft uni joints were cactus (they were) so I got some greasable unis to replace them with, turned the staked joints into C-clip joints yesterday and today on all 3 joints. It is a bit better now but still definitely there, feels exactly the same as it did the first time I got this car on the road with the rear axles in it and that cursed single piece shaft. A low rumble at 100km/h / 60mph, will get worse as the speed increases. Right back to square one. Guessing it will gradually get worse over the next 18 months like it did the first time as the uni joints wear prematurely. And with this development I officially give up. The combination of this gearbox and diff in this car for some reason has un-solvable driveline angle problems. There will be a vibration always that can't be fixed, just have to live with it. I honestly don't know what I've done wrong that's so different to everyone else that's done a 5 speed swap. Unless they all have vibes too just people don't notice it? I dunno I currently have a 3.9 ratio 5 speed and rear diff at a local place being rebuilt. Going to get them to install it too because I don't have the facilities to do a gearbox swap at home. Might ask them to investigate the driveline angles while they're at it, get a second opinion, maybe they can suggest something to fix it. That won't be any time soon, but should be some time this year. There's an EJ20 swap on the cards too -

Driveline angles 81' wagon

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yes I was going to get a diff to swap in to see if it made any difference...except the only one in the wreckers yard was a 3.9 ratio! Ended up taking the gearbox home with me as well. Both will be professionally rebuilt then go into the wagon. Been a while since I updated this thread because I haven't done anything on it until now...the weekend before I'm due to go away on a 4WD trip next long weekend which I took an extra day off work for and everything. I've been driving the car with the rear axles removed for ages cos I got sick of the vibe and was at a dead end re fixing it. Well last weekend I had to replace the rear wheel bearings (not enough grease in them, they were howling) and decided to put the axles back in while I was there. Tried to get it up to highway speed that same day but couldn't because of heavy traffic. I got it up to highway speed about mid day yesterday and well...I thought the car was going to rattle to pieces. The vibe was worse than ever, so bad I couldn't see anything in the mirrors because they were shaking so much, high frequency vibration. So, I kinda freaked out because there was a 8+ hour road trip only a few days away... Ended up going back to the yard I got the g/box + diff from and taking the 2 piece tailshaft from that L series as well. Had to cut through a 10mm bolt with a hacksaw blade to get it out since the center bearing mount had spun the captive nut. And so my weekend went, yesterday and today frantically creating a center bearing mount for the 2-piece using what I had laying around. Was grinding till about 7:30 last night and I was back into it 7:30 this morning, got to test drive it about 6PM tonight (have to get to work tomorrow too, no stress!) well and truly tired and fed up. If it didn't work I probably would have cried. Instead I almost cried tears of joy because...the vibration is gone! Completely! 100% fixed. Couldn't quite believe it myself, have been fighting this issue for so long, 18 months probably. Amazing what a deadline will do in regards to motivation! Ended up going the crossmember style mount. It was made from 2" square by 1/8" wall tube and some 3/16" flat bar reinforcing. It's many times stronger than the floor it's bolted to. Not really happy with the strength of the floor. When I've got more time I'll make up a strap out of flat bar that hugs the tunnel on the interior and join the two mounting nuts together. At the moment I welded the nuts to some large square bits of 3/16" plate to spread the load a bit. -

Driveline angles 81' wagon

Silverbull3t replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I rang the tailshaft shop during the week, a double-cardan joint is a no-go apparently, too much work to adapt things they don't want to do it So after I clocked off on Friday at work I jumped on the lathe and knocked out 4 spacer blocks for the torsion tube/rear subframe, 10mm shorter than the ones that were in there. They are a bit small (largest scrap round bar I could find) but I figure they were a quick temporary thing to test my hypothesis, if it works out then I will go to some more effort and make something a bit bigger. It was an easy job to get them in, just did one side at a time. I measured the angle of the pinion drive flange before and after, the difference is about 1 to 1.2 degrees. Lets say the operating angle of the rear uni is now 2.4 to 2.6 degrees. This is with a 5mm shim underneath the moustache bar lift blocks as well, so 15mm difference front to back, 0.6 inches roughly. The ride height in the rear is now 10mm lower as well, rear tyres are 10mm closer to the body, which is annoying but I don't think I can put 15mm shim under the moustache bar only or the diff would hang lower than stock! Went for a quick drive, no rear axles in place so I drove it in high range. The vibration seems to be gone or at least not noticable with no axles in. What is noticeable however is the howling and whirring noises coming from the rear diff when I'm on the throttle...I think this diff is junk Or at least the bearings in it are toast. Couldn't pick it out amongst all the other noises and vibrations before I started this journey. I'll have to get it or another one rebuilt to swap in. There is also the low frequency wobble that happens in 2WD that I wrongly attributed to the tailshaft before, only now it occurs to me I never got a wheel alignment done on this car It doesn't crab sideways or scrub the tyres so I never put it on the priority list, perhaps that was a mistake So one step forward two steps back...