1980ea71Brat

Members-

Posts

106 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Gallery

Store

Everything posted by 1980ea71Brat

-

I also had to replace the driver's side ball joint because I fucked it up when removing it. Nothing I could tried worked to remove it without destroying the boot, and it eventually had to be pickle forked apart. Was a waste of a perfectly good ball joint. Parts are hard to find for this car. I picked up some spare front calipers off a loyale, but finding rear calipers seems to be next to impossible. I have looked around on this site, and it looks like I might be able to adapt 1990-1993 honda accord rear disk brakes to it - another project for the future. For now, I literally just cleaned up the brakes and put it all back together. I usually splurge and buy all new parts but these brakes actually work, and I need to save cash at the moment.

-

I also rebuilt my drivers side axel, and by that I mean I replaced the inner boot. It had a small pin hole of a crack but that was enough to sling grease everywhere. Let me tell you what - this was the first time I had just replaced a boot, and although it wasn't overly difficult, it was a fun learning experience. I believe these to be the original axels, despite not being green. They have the exact ridges and 'cooling fins' as described in the factory manual, and I don't think that the replacements you can get these days have anything like that. So that increased the importance of replacing the boot to keep this one functioning.

-

Did I mention I am an expert at removing gauge clusters now? I think I have removed 10 or so between the Junkyard and my RX

-

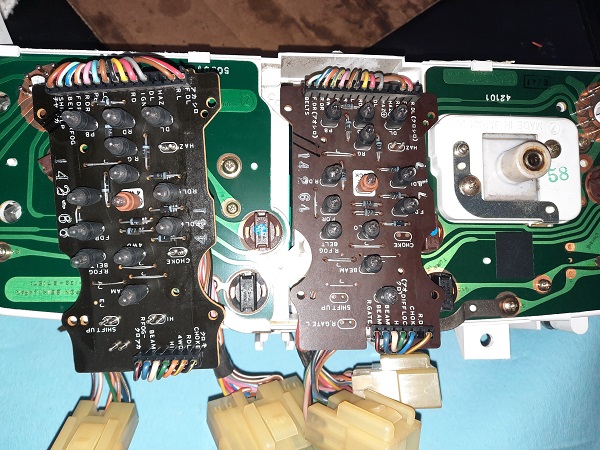

Aye - Thanks Bennie. Been looking forward to it. Its been a couple weeks so I wanted to throw up a few things that I have done/fixed. I solved my Diff lock problem. The reason why I swapped clusters was because the gas gauge in the old RX cluster wasn't working (I did all the diag that lead to that conclusion). But what I didn't know is that the center light configurations change over the years. So the center panel on the left is from a 93 Loyale, and the one on the right is from my RX. They look mostly the same, but they are not. I swapped these out and it looks like my Diff lock light is working correctly, and the hazards lights (these were previously only blinking one side). I also had to swap out the plastic center piece that I didnt picture here, but that made it so the lights lined up correctly. I probably could have just swapped out the gas gauge side in the RX cluster but this is ultimately what I ended up with. I also have several spare clusters and parts now for the future if anything breaks.

-

Welp. Cross the heater not working off the list. Like I suspected, the vacuum source I picked off the EJ22 was not sufficient the first time. Now I am tapping directly off the throttle body and the defroster vent works. I hear a clicking noise when I try to put it into center lock - but not sure if its working, the light isnt coming on. That could just be because the tach I swapped in doesn't have that circuit. So going to have to figure out a way to test that, and or eventually see if I can get the tach light to work. Honestly that was my biggest worry because I need defrost for the winters around here.

-

to "finish" off this project, or at least put it in a place where I just try to tackle one small probably a week, or every 2 weeks - I am putting on new tires: And getting an alignment. These are just RP18 West Lake stock tires. I have the original hub caps for the car, and I plan to just keep it original. No fancy lifts or 5 lug swaps. (for now). I am also getting the interior reupholstered. I am literally going to spend ~2000 for this to be turned new: Its all there. The original seats, front and back. Its going to cost me about 600 per seat, plus extra for bolster repair. I'm going to fix up the rear carpet as best I can (its in terrible shape) and I am going to apply sound deadening to the whole back. Once all that is finished (and after I replace the CV boot) I am in coast mode. 1 project every week or two. Feels good to get this car that far along. I have a rather unique collection of vehicles and am super happy this one got saved from the crushers. *Edit* And get a cat back exhaust. It's currently too loud. I'm not 18 anymore and 30 year old me appreciates an aggressive, great sounding car, without the ear piecing neighbor cursing loudness. Probably another $500 or so but worth it.

-

Appreciate it Bennie, you might be the only one reading this progress blog and I appreciate you lol. Once I am done, I might save this story for my daughter when she grows up. So at this point, I have driven the car maybe 20 miles and things are mostly working correctly. Not overheating, low oil pressure at idol, but that's okay. Used engine that I did absolutely nothing to before putting it into the RX. It won't be the permanent engine, just a place holder to get everything else around it sorted. Part of the motivation for this project was I had parts piling up for 3-4 years in the garage, and I had completely run out of space. Now that this is mostly finished, I can finally get rid of all my old EA82T parts in confidence and not have to worry so much about needing them. The garage is making a recovery. Issues I need to sort out with the swap still: - IAC P0505 Idle Air Control valve error code is my only engine code. The car seems to be running fine and idling fine, so I'm not sure how much time I am going to invest into fixing this - Center Diff lock not actuating. I believe part of my vacuum system has been compromised since I did the engine swap, I imagine this will take me a long time to sort at... if at all. Its actually pretty low priority at the moment. - Heating vents not working correctly. They are stick in the default position and wont go into defrost mode, I have check all the internal connections under the dash, so I have a vacuum problem under the hood (perhaps related to the center lock problem). - Passenger window doesn't roll down from switch (easy fix I have a spare mechanism for the switch). - Torn inner CV boot on the drivers side front axel. I have a replacement, need to get that fixed before it can go on a serious drive. - Brake signals/lights in general, not all the lights are working, probably due to burned out bulbs and I have to do a repair for the license plate lights, the original mounting point is one of the worse rust spots on the car. - Clutch does not seem to be adjusted correctly, it is very stiff on the disengagement and it engages near the top of the pedal. Not sure how I am going to fix that bit yet. Besides all those various items, I still have rust repair/ battery tray, and the torsion bar to cut and weld together. I am going to slowly be working on the above but I have hit the point in the project where things are going to slow down. I really wanted to get this 85% tackled before my daughter is born (due date is 9/5) and I feel as though I have accomplished that. I have three other car projects waiting, and now I can finally move and drive the RX around so I can swap in other projects as needed. Doesn't mean I wont fix those other items eventually, just going to take a lot longer from here on out. Oh and long term, if I keep the car (yeah might even sell it), I'd like to put a new EJ22 in it, maybe even turbo the N/A engine. We will see, that takes a lot of money.

-

Still got a ways to go on my check list for the weekend. Just finished up replacing the trans fluid tonight then called it for dinner. I have two more days off, I am hoping by Tuesday I will have the rest of the 'front' interior cleaned and installed, and go for a test drive.

-

Lastly, I got a little fancy with it and ordered some sound matting off of amazon for the hell of it. I have never used it before, and it was really cheap. I am probably going to order more when I get to the back of the car. And here's my last pick after 3 days straight of getting after it. I owe a lot to my wife for helping me out. We cleaned for hours and hours. The carpet actually smells nice finally, and all the dust from the vents have been Q-tipped and cleaned out. She helped out a ton with getting the dash back in. All the gauges are working how they are supposed to now too.

-

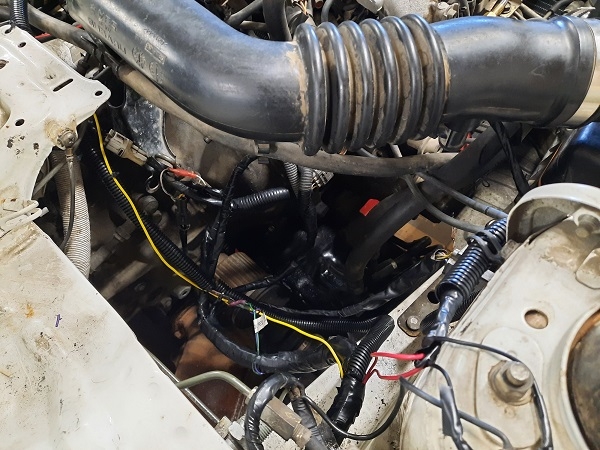

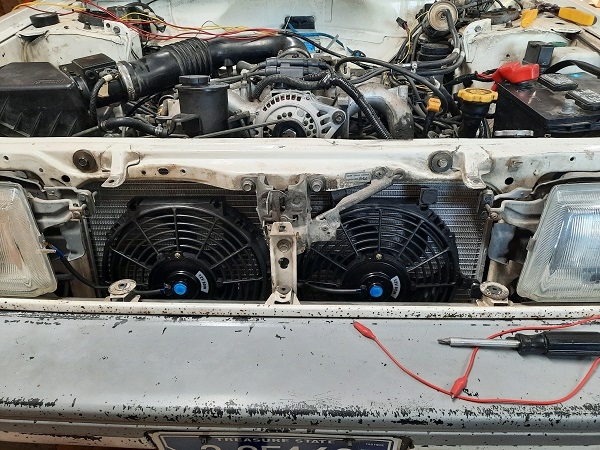

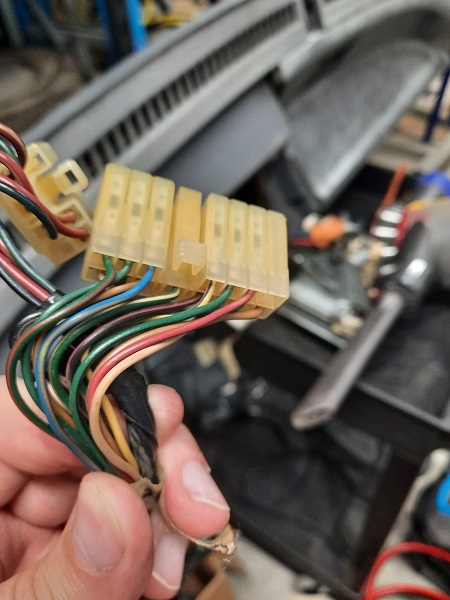

The hole is a little messy, I used a lot of oil to help the hole saw get through it. But once its cleaned up, it fits really nice. Here's where most of my wire sits out, including the fan wiring. Out of the way, I forgot to throw the starter wire into the power loom so it sticks out a bit lol. I was tired after ~8 hours of wiring. Here's the fans I went with. Not sure on the brand, but two 10' pushers off of amazon. $50 each was right for me. Wiring wasn't sorted yet at this point. Here's after I finished all of the endless splicing:

-

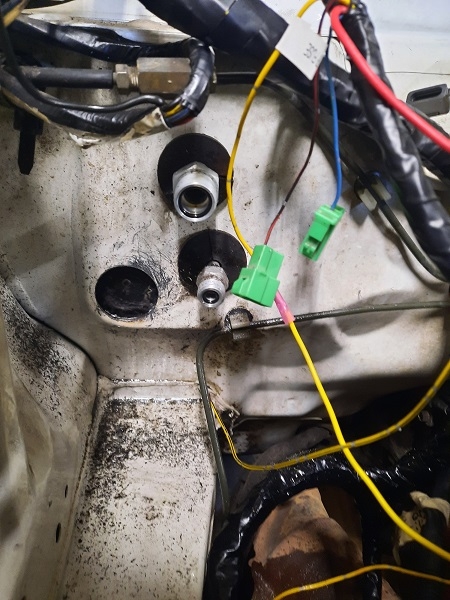

I ended up using the EA82T power steering lines, for some reason the EJ22 lines off the 96 were not going to line up correctly at all. Could be a US spec deal, or maybe its a different rack in the RX. The EA82T weren't perfect but with that little bit of fabrication it was mostly a straight shot. Not sure what you mean by guard, but the loom itself was pretty small. Here's a shot of what the hole looked like: After the loom was mostly installed: Here's my loom for the oil pressure, coolant temp, switched power, constant power, and tach. Extra fuses for the relays.

-

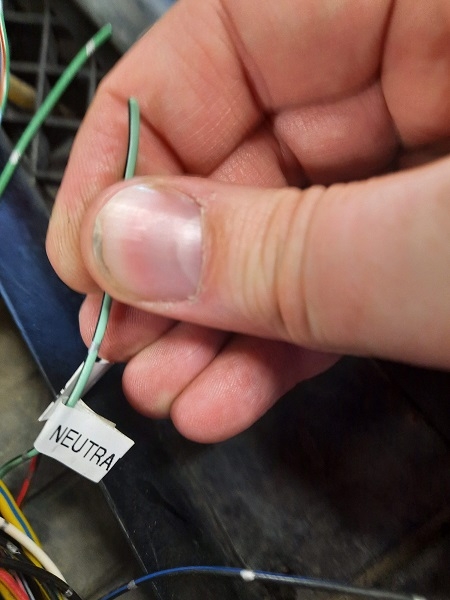

That's basically it for now. It took a while working with shops to get some of that stuff taken care of. This weekend my goals are: 1) Cut a factory looking hole in the fire wall. Relocate the ECU to the passenger foot well. 2) Finalize all wiring to the ECU. In a separate post, I have been trying to figure out the last of the wiring. As of me posting this now, I have 7 out of 8 wires sorted. I am not 100% on the neutral wire but I am just going to wing it for now, and correct it later if it poses a problem (I don't think it will). Surprisingly I am having trouble finding an exact pin out for my EA82T ECU. 3) Figure out how to do the check engine light... if I don't do that today I am going to proceed with the rest of wiring and worry about it later. Surprisingly, if you go about the way I am, almost none of the wires go to the gauge cluster. They can all be tapped elsewhere. I eventually want to go through and replace the bulbs with LEDs (maybe) so I might worry about the CEL later for when I do that. 4) Wire the radiator fans. THE FANS ARE COMING EARLY - I am supposed to get my 2 10" fans today from Fedex, and I bought some relays just incase they do. So I am going to mount the fans this weekend, test the relays, and finalize that part of the ECU wiring. 5) Hook up new heater hoses. (I did get the heater core tested and reinstalled, so this should be obvious...) 6) Reinstall the dash 7) Reinstall part of the interior 8) Replace transmission fluid Test drive. If I can get all that done this weekend, I will be stoked. My priorities after all of this will be new tires, alignment, possibly brakes, and reupholstery (hoping to saving the original RX material!!!). Later down the road, I need to weld in a new battery tray, and repair a couple of smaller rust spots. Then you know - save like 10k for a paint job (probably will never happen). Anyways, one thing a time. This weekend should be a banger.

-

6) Last item, but not really finished yet. I decided I am going to cut a hole in the fire wall. Yeah, I cringed when I first came up with the idea. But the fact is, this RX is not an original car. It has a few rust damaged spots that need to be repaired (pics on those later...) and its got an EJ22. The paint is in terrible shape, and the interior needs some reupholstering. I'm not going through the fender for a rather selfish reason... the body kit. On a normal EA81 or EA82 car, you don't have a body kit in the way of removing the fenders. On my car, I have to fully remove the front and side body kits in order to get the fender to separate correctly. I don't want to do that. I'm worried it won't look the same or be perfectly level if I have to reattach it myself. So hole in the fire wall it is. I looked around this is the spot I chose: I am going to put a 1.5 inch hole to the left of the A/C lines, and use a grommet to make it look factory. I am going to store the ECU in the foot well on the passenger side, just like the EJ22 was done originally. There looks to be enough room to hide the main power loom behind the blower tube to A/C tubing:

-

5) I fixed my door. If your door only opens from the outside latch, but not from the inside latch, the lever is out of adjustment. In the photo below, the lower of the two levers controls the action from the door handle. All I had to do was loosen the nut, pull it more taught, and retighten the nut. Plenty of room for adjustment there. I didn't get a picture of it, but I removed 80% of the old vapor barrier sealant and replaced it. The vapor barrier was in terrific shape, and I think I am the first person to have removed the door card. Using proper tools is extremely important to not breaking any tabs.

-

3) and 4) I got my power steering lines professionally shortened and I got my oil pressure sending unit plumbed for the 1987 oil pressure gauge. Each cost me about $50. I should mention the heater core cleaning and testing cost me about $70. Still all worth it in my opinion. The power steering lines aren't perfect, but good enough and now they are out of the way of the air box. I wanted to keep the original air box and stuff for now, maybe one day I will worry about changing it. I've never been much a believe in the 'cone filter' upgrades. *Most* intake systems are designed to be extremely efficient from the factory.

-

2) I removed the carpet and had the heater core pressure tested and flushed. They found nothing wrong with the heater core, and I learned that the unit is entire copper- no plastic tanks. I also had to replace the insulation that isolates the heater core in the box, stove threaded sealing material worked really well for this and has a heat rating well beyond what the heater core will see. I scrubbed and cleaned the carpets with an extractor in an attempt to remove any stains or residual smells. I also found a hidden pack of unopened cigarettes from the 1980's. So clearly this had been a smokers car at some point (no surprise since its from Montana).

-

Well I decided to update here the progress I made up to this weekend. Quite a few things have been crossed off the list. 1) I removed the dash, heater core, and blower motor. I cleaned everything and all the vents, there was quite a lot of dust and debris in the system and I really wanted to make sure I wasn't going to have any problems with the ventilations system. I mentioned at the start of this forum that the car was abandoned for 12 (? ish) years outside, and there has been some evidence of mice so I really wanted to make sure everything was clean for that reason.

-

EA82 to EJ22 Couple Wiring questions

1980ea71Brat replied to 1980ea71Brat's topic in Old Gen.: 80's GL/DL/XT/Loyales...

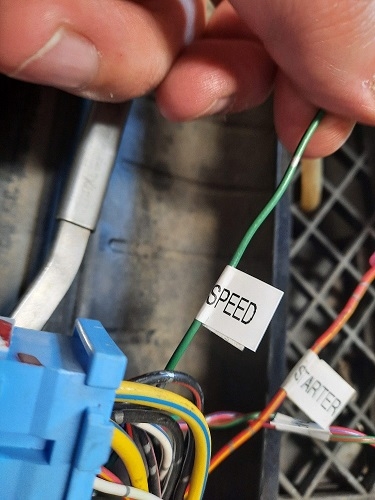

Thank you guys. This helps a lot, I will be in a great spot if I can get the wiring lined up before I reinstall the dash and get everything set up on the final stretch. I basically spend all my free time at work using google search with 'site:www.utilmatesubaru.org'. It seems to work a lot better than the search function, but its still not perfect. Bennie, I took your advice and followed the continuity until I found the Tach, oil pressure, and coolant temp signals inside the engine bay. That will make a clean set up with my power wires. Numbchux, thank you for the advice, my fans* should arrive next week so I will be wiring up the relays next weekend probably. I also located the VSS 'T' connection mentioned in other posts, and used a spare T connection to extend the wires to be more easily accessed. That just leaves me with three connections - Check Engine light, Neutral, and 'Starter' (Though I just wired this to the starter directly so I think its fine). I technically have the two A/C wires off the ECU as well, but that fell to the bottom of my priorities list. Hopefully I can figure out the Neutral and Check Engine light wiring tomorrow. -

EA82 to EJ22 Couple Wiring questions

1980ea71Brat replied to 1980ea71Brat's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The other wire that is close for the check engine light is the Green/Blue wire @ Black Combination Switch #11. Possibly just a typo from the manufacturer? That Blue wire off the clear combination switch is like blue/yellow or blue/white -

EA82 to EJ22 Couple Wiring questions

1980ea71Brat replied to 1980ea71Brat's topic in Old Gen.: 80's GL/DL/XT/Loyales...

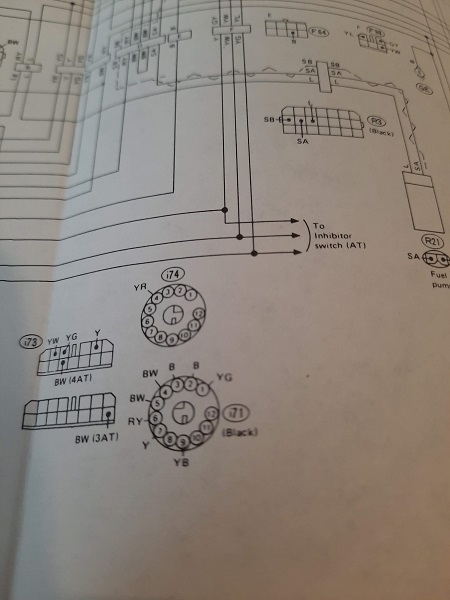

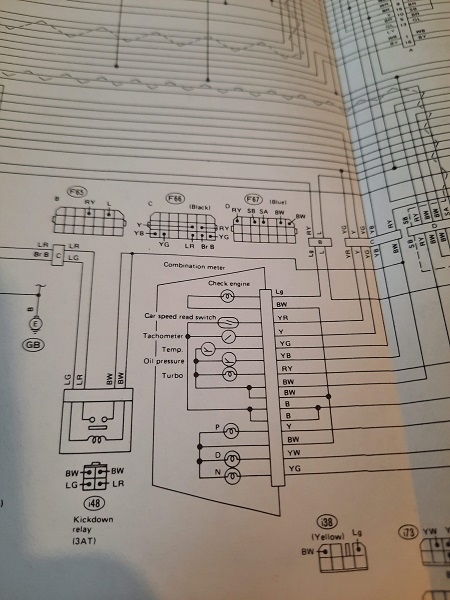

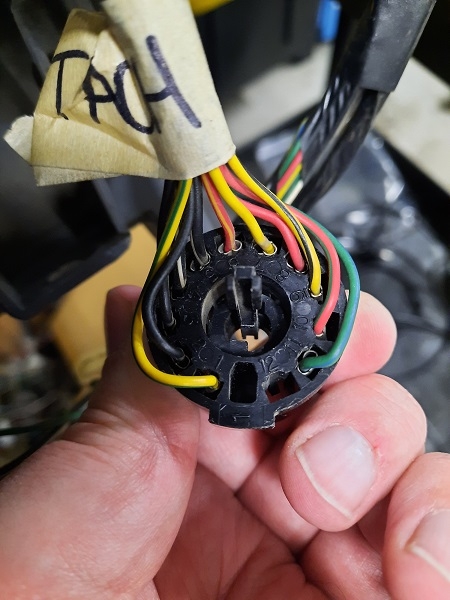

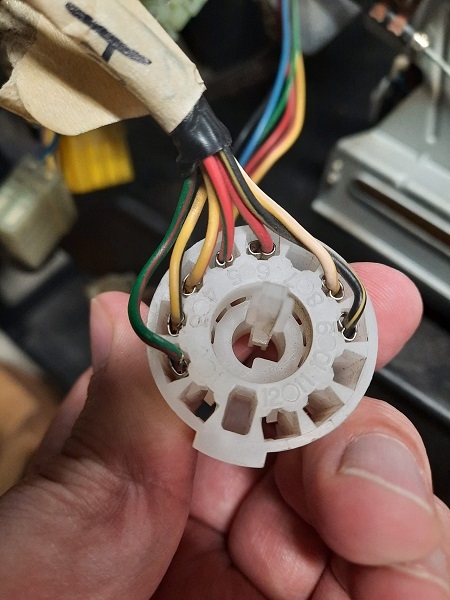

So according to the diagram - I am looking for: EJ22 Check Engine Light wire to Blue/Green (Combination Switch?) EJ22 Oil Pressure wire to Yellow/Black (Black Combination Switch #9) EJ22 Coolant Temperature wire to Yellow/Green (Black Combination Switch #1) EJ22 Tachometer Signal wire to Solid Yellow (Black Combination Switch #7) These should all be connected 'Going into' the combination switch to feed the corresponding signals to the Gauge Cluster. The last signal is the VSS signal (if I wanted it, sounds like not needed) which should be: Yellow/Red (White Combination Switch #4) to the 'Speed' Signal wire EJ22. This should be the only connection made 'leaving' the gauge cluster correct? *Edit* I guess this would actually be hooked up the same as all the others, the only difference is the signal is coming from the Yellow/Red wire instead of the other way around. All 5 connections should be made with a wire coming from the EJ22 into the combination switch. Does all that make sense? This only leaves me with my check engine light... the only Blue connector I see is on the 'Clear' Combination switch. Thoughts? -

EA82 to EJ22 Couple Wiring questions

1980ea71Brat replied to 1980ea71Brat's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I thought I had this mostly figured out. But I am hoping to get some more clarity. Here is what I am looking at: -

EA82 to EJ22 Couple Wiring questions

1980ea71Brat replied to 1980ea71Brat's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Thanks Bennie, its a slow and arduous process. If I can leave the 'speed' wire unplugged, any idea what it does when it has reference to vehicle speed? I didn't get a check engine light last time I ran the engine (besides the engine rad fan being unplugged) -

Hi all, I am hoping to wrap up a major step of my EJ22 swap this weekend and just had a couple questions that I was hoping someone could answer. I found some answers from the search but not exact for my situation. The donor car is a 1996 Subaru Legacy Outback 2.2L Harness was wrapped and prepared by SJR Receiving car is a 1987 Subaru RX I have already got the car to run and drive, I am just in the process of getting the gauge sorted and all the wiring routed in their final positions. 1) My speedometer is mechanical, Do I need this wire labeled 'Speed' and which 1987' wire am I looking to tap? 2) I have two wires labeled 'Rad Fan', are each of these a ground reference for the relay? As in, can I wire each to trigger two separate relays for two fans? 3) I have read on here that the Neutral wire is irrelevant for manual transmission cars, just wanted to confirm I leave this one alone. Any help is greatly appreciated. I have a 4.5 day weekend coming up and I am hoping to make some big progress on the project.

-

EA82 Steering wheel puller

1980ea71Brat replied to 1980ea71Brat's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yeah the lesson I have learned from this is that I should have just started with a puller. I tried heat, hammers and penetrating fluid. Bought a puller set for 27 bucks and should be here by the weekend. Thanks all for the input. -

Hey all - cross posting this for visibility. See link at the bottom for the full story. As you can see in the attached picture, I am in the process of removing the dash from my 1987 RX. I am struggling to get the steering wheel to separate though. If anyone knows the correct tool that will work for our application or of a technique that doesn't involve a hammer I would be super grateful. I have already slightly started to damage the nut and threads using the hammer method and have decided to reach out for help before going too far down that rabbit hole. Thanks for reading.