Rampage

Members-

Posts

683 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Rampage

-

Kind of sounds like carrier or pinion bearings in the rear diff. If the carrier bearing (on the pinion side) wears it will allow the ring gear to move into the pinion gear. That could cause a roaring sound. If the ring and pinion are loose, you get a whining noise. If really tight, the drag would cause tread wear. With the rear wheels on the ground or locked, how much play is there in turning the driveshaft and does it turn freely? Get all four wheels in the air and run it in gear. Applying the brakes will put a load on the rear diff. Does it make that noise? I used to run cheater slicks on the street with the cars I drag raced. No sway or fishtailing on dry roads. They were nasty on wet roads. Rear end was all over the place. Excessive toe in or out will cause swaying and tread wear, but it did not cause a roaring sound. Been there before.

-

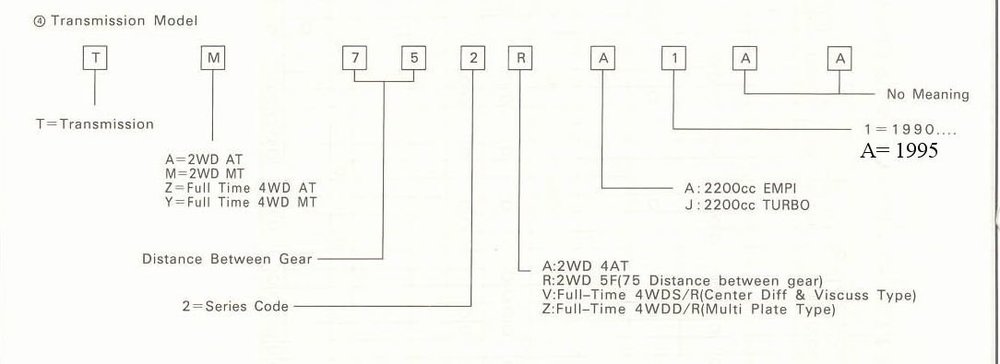

Take a look at the chart on this page. Scroll down to the bottom for XT. It shows a TX number like yours, but where you have a "6" they show a "G" and it is a 3 speed. https://web.archive.org/web/20080801230226/http://prosubaru.com/tech/transid.htm

-

I don't know what the TX is. I have only worked with the TZ 4EAT trannys. I'll have to do some research. Hopefully someone else will know. I looked up your 87 on Car-Part.com and they show one listing in Gettysburg for an 88 XT Turbo AWD 4 speed auto trans. But, they did not list any numbers.

-

Our 95 Legacy 4EAT originally had TZ102ZAA**. The 10 is the gear ratio, ours is 4,11. What number do you have?

-

Quick check for a worn or loose wheel bearing. At the top of the tire, one hand on the tread with fingers down on the inner sidewall, other hand, palm on the outer sidewall near the tread. Push in and pull out until the car moves. If you hear a clunk that is the bad bearing. That worked many times for me. Then I jack that corner up to see how much it really moves.

-

Look on the top of the bellhousing above the starter for a long sticker with 10 digits starting with TZ******** . On the other side are there 2 connectors, a 12 pin and 16 pin? You can also download some of the pdf files from that site and look at the pictures of the tranny.

-

If it is a 4EAT it will have a lock up torque converter. Torque converter lock up is most noticeable when warmed up, in 4th gear above 40 mph. With a steady throttle on a level road you will see an engine RPM drop when it happens. You may or may not "feel" it, because it can happen fast or slow. When in lock up, it you slightly increase the throttle you will not see an RPM increase. When not in lock up, you will see an RPM increase. From the 4EAT manual. The 4EAT Transmission is a 4 speed, microprocessor-controlled transmission that was first introduced in 1987.5 Subaru models. It features a lock-up torque converter which locks up in all forward gears except 1st. It has been offered in FWD or Full Time AWD configurations. Duty Solenoid “B” is located on the lower valve body next to the ATF temperature sensor. It operates the lock-up clutch (inside the torque converter) in 3 modes: “ON,” “OFF,” and a gradual “ON/OFF” control of the lock-up clutch during gear shifting in order to reduce shift shock. If duty solenoid “B” fails, the torque converter lock-up will not occur. You can find several 4EAT Phase I transmission manuals here. For the connector wiring you need the FSM. http://jdmfsm.info/Auto/Japan/Subaru/--Articles--/--Transmission--/

-

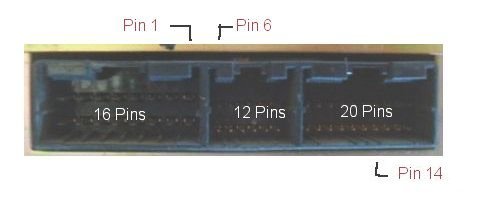

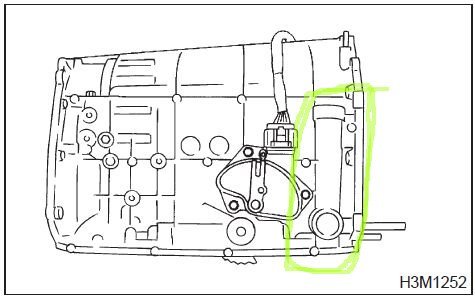

Good. 12 volts on that fuse indicates the power out of the ign. switch is good. I didn't want you to change the TCU and find out later you need a switch. If you want to check the pins at the TCU, these are the 3 to check for power. The wire color on Pins 1 and 6 is Yellow. Goes hot with ign. ON. Pin 14 is Yellow - Red stripe. Always hot. The image would be looking at the wires on the connectors plugged in. Notice the release tabs at the top of each one. Pin 1 is in the upper right corner of each one.

-

Coolant leak

Rampage replied to jonbfish's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

I had a cheap aftermarket pump leak at the shaft seals 2 days after installing it. Replaced it with a DAYCO and it was fine. If the shaft seals leak, it channeled to the rear of the pump behind the timing cover, so it won't get on the timing belt. I use high tack on one side to hold the paper gasket in place while mounting the pump. There is a piece of rubber used on the timing belt covers that can get in the way of mounting the pump. I pull it out. Maybe that got between the pump and the block and the pump is not seated on the block. -

GD nailed it. Old electronics will have problems. Electrolytic Capacitors (the ones that look like an aluminum can) will have a longer life span when their circuit is working. If they are left sitting for years (even new ones on the shelf) the electrolyte can dry out on some and they become useless and the circuit they are used in will not work like it should. I have bought a few of them. They puff up for two reasons. One least common reason is they develop a short internally between the two sheets of foil and get hot or heated by an external source. I have seen the electrolyte leak out onto the board and eat the copper traces. The other reason is, voltage above their rated voltage. If AC voltage higher than their rated voltage is applied to them or if the DC voltage is reversed, they will explode. I have seen solder joints that look perfect, but the solder is just laying on the copper trace not connected to it. Using a pick it will move. Also, broken joints that you can see a ring around the pin.

-

The ECU uses a map to adjust timing under different engine situations and uses knock signals from the knock sensor to retard the timing in order to stop the knocking. When a faulty knock sensor keeps sending signals to the ECU, the ECU will keep retarding the timing because it thinks the engine is knocking. To make our engine shut down, it must retard it quite a bit. I don't know if a retard limit was added on later models on not, but a new knock sensor fixed our 95.

-

Fuse 16 gets its power from the IGN Switch ON and START positions. Maybe, the Start position of the switch does not have a good connection to supply the voltage needed for the TCU. The IGN Switch gets it power from SBF 4. (Slow Blow Fuse 45 amp) Fuse 14 gets its power from SBF 5. (Slow Blow Fuse 45 amp) The wiring diagram shows lights you refer to are controlled by the TCU. So it would seem the TCU is not getting power or it is shutting down.

-

Wow, I didn't expect a reset would fix it. Cool. It would seem there is an intermittently poor connection between the transmission and TCU, since it went into "limp home mode". Or the TCU is beginning to fail. Could also be a wire. There are two fuses for the TCU, 14 and 16. Pull flip and reinsert them to improve their connection. Also remove and replace the connector on the TCU (behind the glove box on ours) and the 16 pin connector located above the bellhousing (TCU to transmission). May as well do the 12 pin connector too (inhibitor sw. and select lever). I would look for any corrosion or discoloration on the contacts of those connectors. If you want to spend some money, there is a product I use on RAM modules and cards in computers and sometimes on the car made by SMP - Standard SL5. It is a liquid for improving electrical connections on DC, AC and High Frequency connectors. It works, but is not cheap. Don't matter if you are sloppy with it, it will not conduct between adjacent contacts. Comment from a mech - It is perfect for resistance issues on SRS systems. Putting this product on the pins for the airbag connections under the seat of a jeep cleared the airbag light.

-

MAF sensor plugged in? Do you have one you can swap? Is the Knock Sensor plugged in? Remove it and see if the plastic is cracked. OE has it pointed towards "your" steering wheel. Some of the earlier blocks have a raised portion that will push up on the sensor and crack the plastic. I put ours in pointed the other direction. Fuel lines connected properly at the intake? The top one is supply from the fuel filter. Fuel filter ok? I would check fuel pressure connected between filter and engine. Ours is around 28 PSI. Does it drop when you open the throttle? If you momentarily pinch the return fuel line, it should jump up to around 80-90 PSI if the pump is good. When you swap intakes, you are also swapping Idle Air Control valve, Throttle Position sensor, Fuel injectors, fuel pressure regulator and ignition coil, unless you are swapping those parts. We have a 95 and 97 RHD Legacy Wagons. My wife is a Rural Carrier. All three are going to retire shortly. Rust is taking it's toll on the cars.

-

Do you have a multi meter if needed to check Volts and OHMS? If the head light switch is ok, the problem should be one of three things, a short somewhere in the wiring harness, contacts in the relay shorted (burned together) or the rocker switch is not opening. Those rocker switches rarely go bad. When most headlight switches go bad they normally will not turn the lights on. Power is fed to the Tail Illumination Relay and the rocker switch behind the steering wheel. (the two are basically connected in parallel) When the relay closes (using the headlight switch) or the rocker switch is flipped the parking lights go on. Try this first. The Tail Illumination Relay is located at the top center of the under dash fuse panel. There should be 3 relays there side by side. Remove the center relay, connect the battery and see if the lights are off. If the lights are off, then replace that relay with one of the relays right beside it. Did the lights stay off or come back on?

-

You can get the Factory Service Manual here. I have found some older FSMs that list part numbers. You would have to look at a Subaru web site to get part numbers. I looked at one and nothing was listed for the 4EAT transmission. Google "Subaru parts" and you will see subarupartsforyou subarupartswarehouse and a whole bunch more. If you get the lower plug out, a local auto parts store should have O-rings.

-

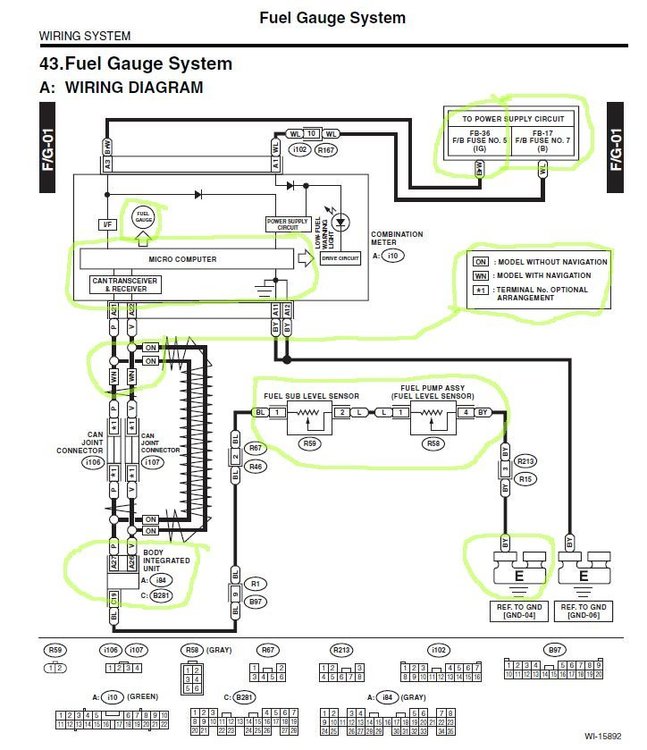

Yes the pump will run, it is a different circuit. There are two sending units. One on each side of the fuel tank. The FSM says to check both and the gauge and replace. You would have to remove them to check them. It does not mention the Body Integrated Unit shown in the diagram. The diagram shows a micro computer feeding the Fuel Gauge. I don't know if it is part of the gauge or the combination meter.

-

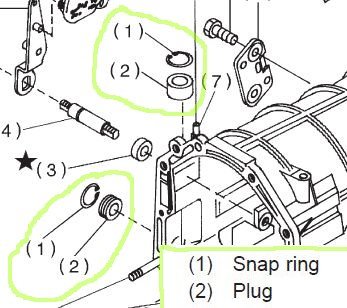

These pics should be what you are referring to. I never had to remove them. Snap ring and plug. It looks like the bottom one has an O-ring on it. I would try cleaning them, remove the snap ring, clean again, and use a small suction cup (maybe with a little oil on it). I don't know if tranny oil will run out of the bottom one or not.

-

Until you can check the valve clearance, replace a quart of engine oil with a quart of Lucas Motor Treatment and add "half" a can of Seafoam Motor Treatment to the gas tank(half to full). In the summer I use 10w30 in our EJ22s and 5w30 in the winter. The FSM recommends thicker oil in hot areas.

- 23 replies

-

- throttle position sensor

- adjust

-

(and 2 more)

Tagged with:

-

If the fuel pressure is going up during the stumble one or two things are happening. Lower than normal vacuum in the intake manifold that will affect the fuel pressure regulator. Less vacuum more fuel pressure. Could be any thing connected to the intake, including a sticky intake valve. Another oddball thing that happened to our 97 is, the pin for the roller (in the rocker arm) that rides on the cam lobe came out and the roller moved into the cup on the rocker arm and the exhaust valves on one cylinder did not opening completely to let out all the pressure from fuel detonation and then when the intake valves opened for the piston to pull in air and fuel, the excess pressure was pushed into the intake causing pressure instead of vacuum. The other thing could be that something is causing the ECM to cut back on the fuel injectors and not letting enough fuel into the cylinders. The coil could have a problem when it gets hot. The insulation could be breaking down. At higher RPMs you won't notice misfires like at lower RPMs. I would get one from a yard and see if it makes a difference. It would be a good idea to check the clearance on the valves. They may not be opening all the way since they are loud. Maybe the rockers are not getting enough oil and starting to wear. When checking compression I remove all the spark plugs. I write down the compression from 1 pump of the piston and then 3 pumps on each cylinder. My reasoning is when the engine is running, there is only 1 compression stroke in each firing cycle. Most testers have a check valve that keeps the pressure on the gauge and usually will show an increase with more pumps.

- 23 replies

-

- throttle position sensor

- adjust

-

(and 2 more)

Tagged with: