Rampage

Members-

Posts

683 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Rampage

-

Trying to repair/restore my new 1982 GL Wagon!

Rampage replied to Subastu's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yep, 90% of the list says Discontinued. But, what they do have will be OE. Some of the other Subaru sites don't go back near that far in years. -

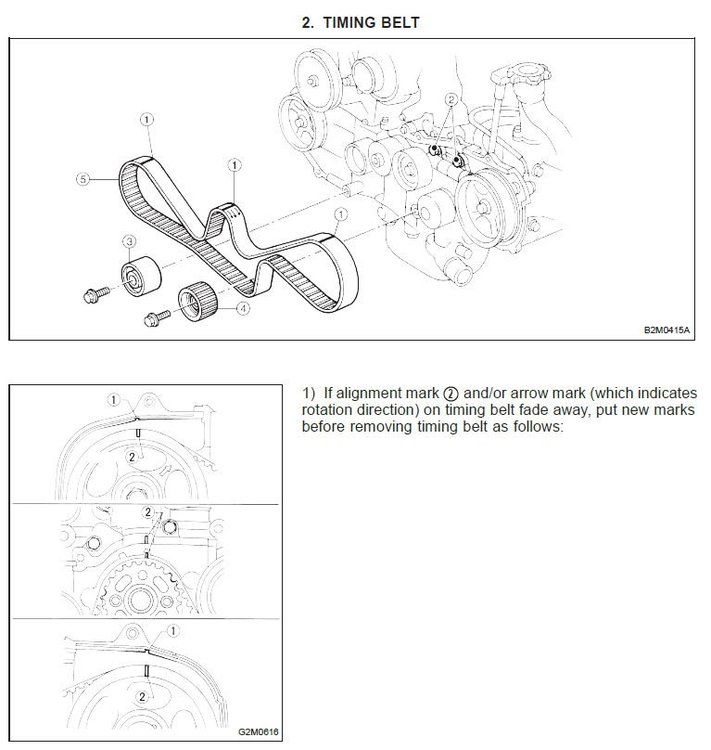

Remove the radiator hold down bracket. Remove the fans and overflow tank. The fan on your left I lower it out the bottom. Remove the left and right timing belt covers. 3 10mm bolts each. Turn the crank clockwise and watch for the mark on the front surface of the cam sprocket (on your left) to line up with the notch in the rear cover. Then look at the other cam sprocket and see if it lines up with its notch. Note: it may be a smidgen off, but not a whole tooth. Sometimes I have to go around a couple times before I can see the tiny mark. If the marks do not line up I can post a pdf on how to replace the belt or you can download the factory service manual.

-

Trying to repair/restore my new 1982 GL Wagon!

Rampage replied to Subastu's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Is the engine a 1.6 or 1.8? This site only goes back to 1984 which is a 1.8. https://www.subarupartsforyou.com/v-1984-subaru-gl--base--1-8l-h4-gas/engine--engine This site did not ask for engine size. I guess it is a 1.8 The list is on the left. https://www.partsgeek.com/catalog/1982/subaru/gl/engine_mechanical/intake_manifold_gasket.html?rp=intake_manifold_gasket_set On this site click on repair parts, then engine and it will ask 1.6 or 1.8. https://www.carid.com/1982-subaru-l-series-accessories/#spb_interioraccessories This one only lists a 1.8 https://www.rockauto.com/en/catalog/subaru,1982,gl,1.8l+h4,1268298,engine Good luck. -

Take the three screws out and see if the spring is ok. It is on the inside of the cap. Maybe the spring is distorted and got on the wrong side of the lever. While the cap is off, make sure the lever easily closes the choke plate. When it is cold you turn the cap until the choke closes. If it has notches on it go one more notch and tighten the screws. Other models had water pipes on that cap.

-

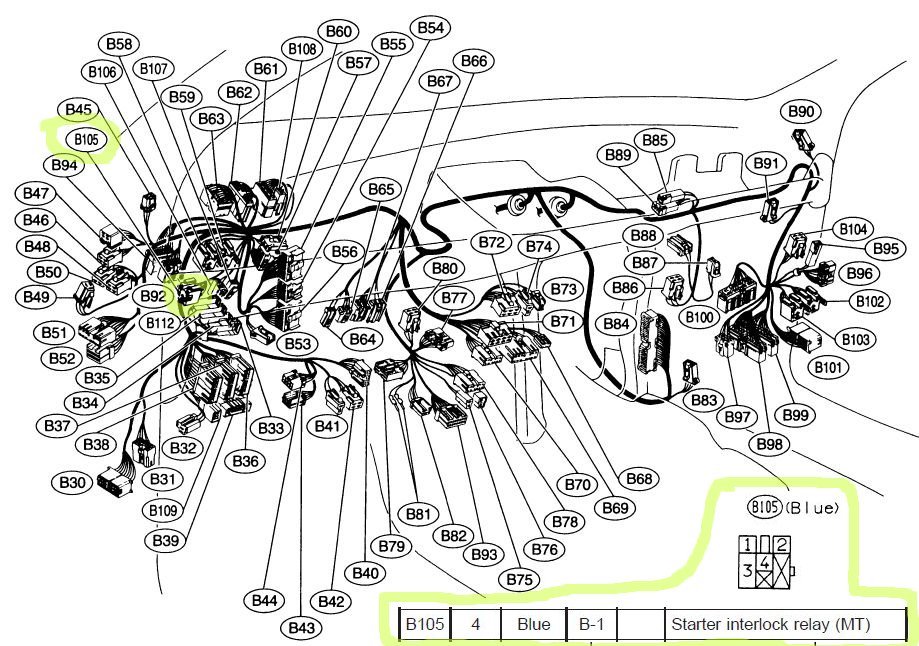

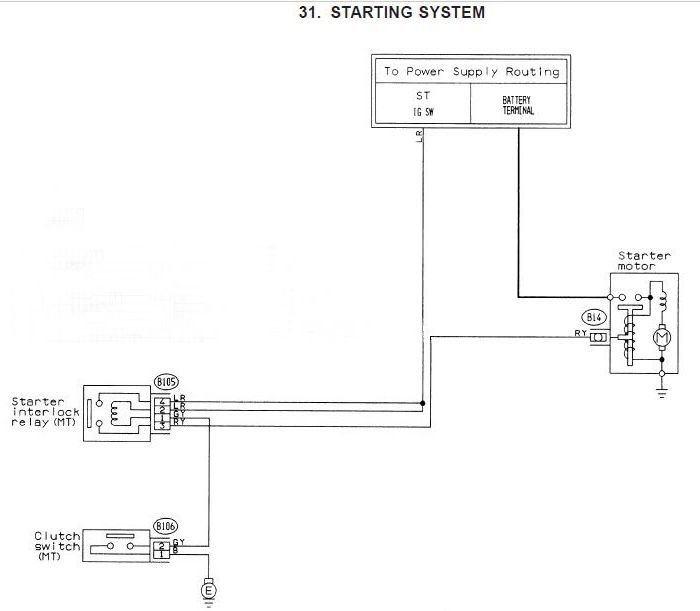

I'm guessing this 96 is LHD. If the chatter is coming from the upper left of the dash where the Starter Interlock Relay is located, it is probably a bad Clutch Switch not passing enough current causing the relay to chatter. Or a poor contact on the clutch switch connector, or the relay socket. Or a bad Start contact in the ignition switch. Temporarily, you can unplug the connector from the clutch switch and jumper the two together and see if it starts. Put it in neutral to try this. See photos. The relay socket is B105 and it is Blue. Hope this helps.

-

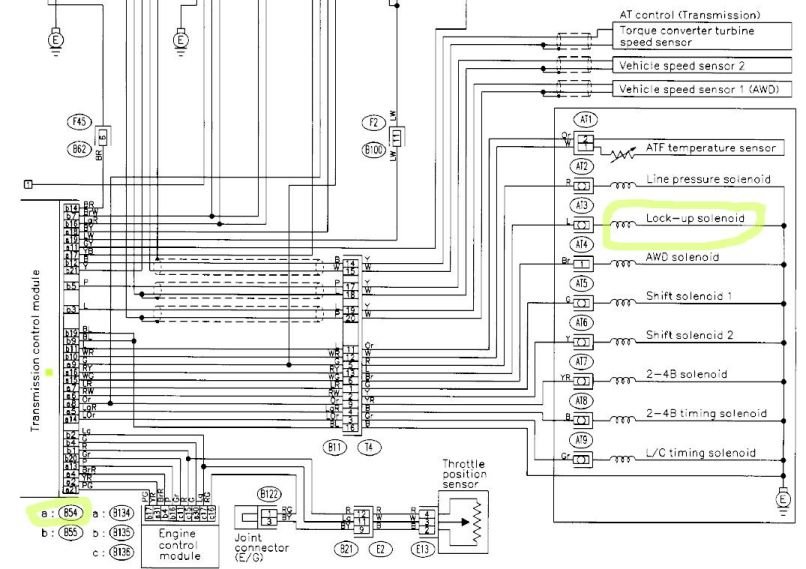

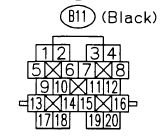

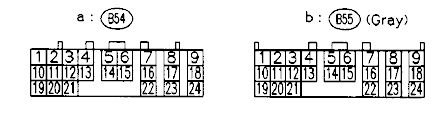

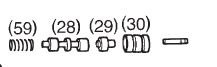

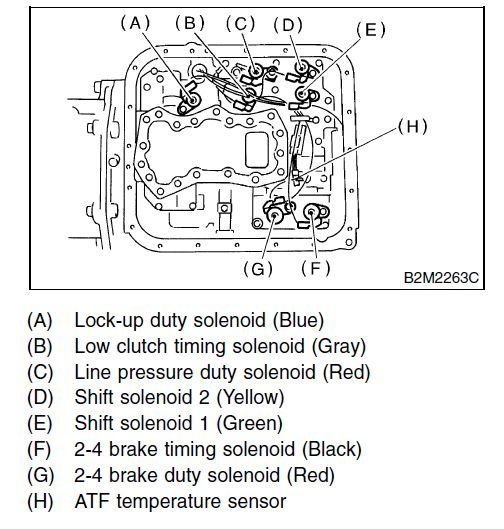

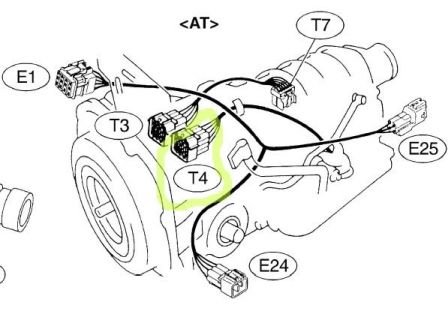

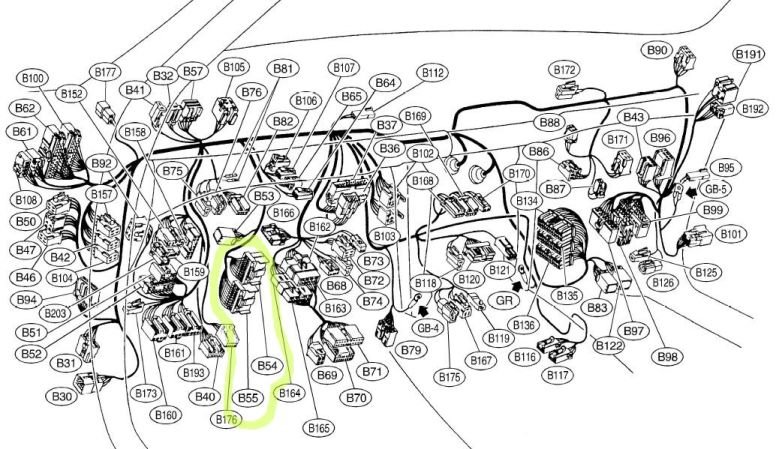

Now for the not fun part. Working under the dash can be nasty. In the images I posted, you will see one end of the Lockup Solenoid coil is grounded and the other end goes out on a Lavender colored wire to Socket T4 Pin 13. Plug B11 plugs into T4 and on Pin 13 the wire color changes to Red-yellow stripe then goes through the firewall to Plug B54 Pin 16 that connects to the TCU. T4 and B11 are located on top of the bellhousing. It is a 20 pin connector. The Harness diagram shows the TCU is located around the steering columb. There are 2 plugs in it, B54 and B55. I have seen older units that had TCU right on the label. You will tap into the Red-yellow stripe wire under the dash or under the hood with one of the bulb wires and the other wire on the bulb will go to ground. The bulb will light when when the TCU turns on the Lockup Solenoid and will go out when it is released. If the bulb goes out when you brake but it is still in lockup then the problem is in the tranny. If the bulb stays on when you brake then It is the TCU or maybe a sensor input. I know that most of the valves in the tranny have springs to return the valve piston when the solenoid releases. If the spring is weak or broken or there is sludg build up the piston will not move properly. One of the images is the valve and spring. The Lockup Solenoid valve routes pressure between two ports going to the torque converter - Lock-up apply pressure and Lock-up release pressure port. So, if the problem ends up being in the tranny, it could be the solenoid, valve, valve spring, a leak in the release port or the torque converter it's self. We'll see what the light says. You can save or print any or all of this info. I cropped and resized the images to make the file size smaller.

-

OK, I'll work on getting some info for you. Instead of stripping the insulation you can use a needle and pierce the insulation (lengthwise) of the wire and then tape it to hold it in place, or push it into the connector beside the wire, but that may not be a solid connection. See if you can find a cheap low wattage bulb and pigtail socket, or just get a 194 bulb and solder wires to the contacts on the bulb. The wire you will use can be thin. Even telephone (solid) wire will work to run the bulb. You can flatten the wire and solder it into the eye of the needle.

-

I don't think it will start because the ECM is in test mode, and I don't know if trying to start it would hurt the ECM or not. Maybe someone else knows. I would not put 12v on the IAC valve without looking at the factory service manual. Unplug the MAF sensor and see if it tries to start. I found another post where the MAF sensor caused the rough idle and stalling and that caused the code 24 to be set.

-

Are you ok with splicing a wire onto another wire and then hooking it to a light bulb socket (with a 2 wire pigtail) and hook the other wire to 12volts? Let me know. I can look through the Wiring Diagram and try to find the wire under the dash (or under the hood) that goes to the Lockup Solenoid and you will have an indicator showing weather or not the Transmission Control Unit is releasing the solenoid or not. If the TCU is not releasing it, then either it is bad, or receiving a flakey input from a sensor. If it is releasing, then the problem should be the solenoid or the torque converter.

-

Had the same kind of problem with one of our Legacys about 5-6 months ago. I was charging the A/C system and the engine stalled. Restarted and it stalled in 3-5 seconds. I ordered an off brand MAF Sensor online and it worked good for about 4 weeks then the engine started loosing power. I went to a local yard and grabbed two of them. Cleaned one of them with MAF Sensor Cleaner, put it on and the engine ran good like it used to. Any kind of dust or dirt or even a tiny bug on the filament can mess up the signals from the MAF Sensor. You could try the cleaner, but it will only fix it if dirt is the problem. One thing about "some" OBD1 systems, If you disconnect the battery to clear codes, when you start the engine the Engine Control Module will be expecting to see perfect signals from all new sensors. So, if the MAF Sensor is not up to par it could set the code almost right away. It did on my 93 Ranger 4.0. I cleaned the MAF Sensor and it was fine. Code 24 - Idle Air Control Valves seldom go bad. You could look at the contacts on the plug for corrosion. You could also try a cleaner on it.

-

The door locks work, it is the dome light delay he wants to get working. Talking about changes, my next project is to get our 97 door locks to work like our 95. Both are RHD. They use different Door Lock Timer Modules and switches. On the 95 (472k miles, she has put almost 400k on it delivering mail) when she opens the drivers door all the doors unlock and she can go around and get out packages. On the 97 opening the drivers door only unlocks that door and after finding the other doors still locked ******* she has to go back and hit the switch on the drivers door to unlock the other doors. A 400k mile habit is hard to break. That is one feature I wish they hadn't changed, especially on a mail car. The drivers door locks and unlocks all doors using the lever inside or the key outside.

-

When applying the brakes, the brake light switch sends voltage to the Transmission Control Module and it should release the lockup solenoid for the torque converter. Personally, I would drop the pan on the tranny. In side on the bottom of the pan is a doughnut shaped magnet. It can be removed and cleaned with paper towels. It is normal for it to have a light coating of metal powder on it from the wearing of clutches and bands. Its purpose is to keep that stuff from getting into the many bearings in the tranny. But if the crud is thick, then the clutches etc. have a lot of ware on them. I don't know automatics good enough to guess how much longer it has to live. But, I can say that I have gotten a used tranny from a yard with 100k miles on it and the crud was about a sixteenth of an inch, and the tranny went another 100k in our mail car. When you do the control arm bushings keep in mind that the vehicles weight must be on the wheels when you tighten the nuts for the front and rear bushings. Mount everything and then drive the front wheels onto ramps and then tighten them. If the vehicle is jacked up and the control arm is hanging down and you tighten the mounting bolt and nuts, the rubber in the bushings may not last a year. I learned that the hard way. When you have some time, read this page. I knew about two of their products that work wonders, but the Sperm Whale oil was a surprise. https://www.lubegard.com/technology/

-

Alternator replacement issues

Rampage replied to wysubey's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Cool. You got one that works. Thanks for letting us know. To play it safe, I would keep an eye on the voltage. 14.2v is ok, but also the limit for most vehicle electrical components. I have seen a few new ones at 14.6v. Think about this, a light bulb for an auto is rated at 12v and a certain wattage or Candle Power. Voltage times current = Wattage. But it is used at 13.8v or 14.2v and that shortens their life. That's one of the reasons you see so many newer vehicles with burned out headlights and parking lights. A 12 volt lead acid battery is supposed to be charged at a constant 14 volts and the current drop off as it charges. If the voltage is higher it will slowly eat away the lead plates and cook out the acid. I learned that from GE many years ago. -

The gates belt that I tried split from the front edge into the center of the belt, then split lengthwise about 3 inches then the rear half broke. I could see wear marks on the front edge of the first split. Like yours the rest looked fine. Never had a Dayco belt break, but the bearings in their kits only last a couple years.

-

More than likely it is the caliper bracket mounting bolts not tight or the caliper guide pins loose or worn. Check it out soon. You don't want the caliper popping up and lock the wheel from turning. That may not happen, but you know about murphy's law. Our 95 acts the same way on bumps. It is the hole in the caliper for the guide pins is worn and lets the caliper bounce up and down only a little, but it is noisy.

-

That stuff is really nice to work with. A few years ago I had to replace the brake line that goes between the floor and the gas tank on our 95 RHD. Being a right hand drive, the brake lines go to the rear on the right side of the wagon then through the floor under the rear seat. I ran that line across, under the rear seat to get to the other side of the car, through the rubber plug and to the left rear wheel. It was soo quick and easy to do.

-

The code P0851 means the Engine Control Module does not see a good ground from the inhibitor switch (neutral safety switch) mounted on the transmission. It should see a ground in Park and Neutral and an open in any other position. To verify this you can test it with an ohm meter. Unplug the "12" pin connector located on top of the bellhousing. First check pin 12 on the socket from the harness for a good ground. Then hook the ohm meter probes to pins 11 and 12. Move the shifter while watching the meter. It should read 0 or 1 ohm. If it reads higher or fluctuates replace the switch. There is an adjustment procedure when mounting the switch. In the picture you are looking at the face of the plug on the wire going to the switch. The other code may be because the engine is not cranking properly. Find out later once it is starting like it should.