Rampage

Members-

Posts

683 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Rampage

-

Surtrack/Trakmotive must be making a better product now than they were about 4 years ago. That is the brand of the one I threw on my trash pile because as it rotated forward, the steering wheel would turn about a quarter turn in the direction of which ever side it was on, right or left. I did swap it side to side. I had been using Cardone reman axles on the front and after 2 - 3 years the outer boot would split.

-

Pretty much what you said. You could check the pump pressure and see what it is. A friend of mine that has a transmission shop will check the pressure on some vehicles while driving it. Check the plug on the tranny harness for corrosion on the pins. Here is a good article on that code. https://www.700r4transmissionhq.com/p0741-subaru-forester/

-

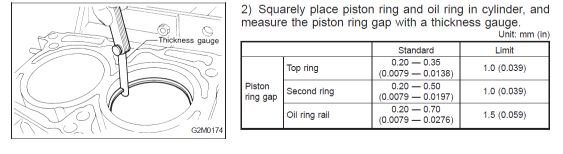

Don't know unless you measure. If the crank journals look good, then more than likely they are, but you should use plastigauge with a new bearing to see what the oil clearance is. Compare that to the what is in the FSM. See picture for ring end gap. The pic is for an EJ22. See what the end gap should be for yours in the FSM. The rings wear and so do the cylinders. Knurling is cutting a diamond shape into the outside of the piston with sharp wheels to give it a slightly larger diameter to prevent piston slap. It depends on how much the cylinders and pistons are worn, if the pistons need this or not. The wheel is like the cutting wheel in a tubing cutter. When it cuts into the metal it causes the metal on each side of the wheel to raise up.

-

Get one new compression ring and check the end gap of the ring at different depths of each cylinder. If the gap is beyond the limit in the FSM you would have to see what is available. Also you would have to have each piston knurled to make up the extra space. Back in the early 60's I had the tool to do that. For the bearings they make plastigauge to determine the tolerance for oil. You would also need one new bearing to check it with. Or see what you have with the old bearings. Without doing that you don't know, so it is hit or miss.

-

Limited lifetime warranty is for material and workmanship. Meaning it should be in good shape and fit and work, when you get it out of the box. If you damage it, they don't have to replace it. But, I have seen things like that get replaced. It depends on where you got it and what kind of mood the counter guy or gal is in. Most aftermarket auto parts stores are owned by a corporation and they handle such a large volume of parts through their many warehouses that the returned (new) defects go into a dumpster because it is cheaper for them not having to handle those parts. (so I was told) Some manufacturers do want their parts returned so they can see what is wrong, others don't care.

-

MAF cleaner works as long as dirt or a bug is the problem. It worked on my 93 Ranger 4.0. I did my Ranger on a Monday morning and would you believe it, during that same week at work, 5 guys asked me about the same low power problem. The cleaner fixed 4 of them. We got to sell 4 cans of cleaner and 1 MAF sensor. I have not had as much good luck with cleaning it on our Subaru though. Sometimes the engine works a little better, but I usually have to replace them. Get two from a yard and put one in a zip lock bag for later if needed, or an expensive new one with a good Warranty.

-

Yes, and you would have had to add several gallons of fluid to the reservoir. Plugging the brake line out puts of the master cylinder and pushing the pedal will tell if it is capable of working. If it goes to the floor, then the seals on the pistons are shot. Auto Parts Stores have what they call a bleeder kit consisting of four plastic plugs. A lot of times they come with a new or reman master cylinder.

-

I have seen two different outside diameter torque converters on a TZ102A, 4EAT. Maybe the larger diameter is for the 2.5. I remember the bolt hole pattern was a larger diameter because it did not fit our EJ22 flex plate. I just looked at the smaller diameter torque converter and the starter ring gear is in the way of drilling from the backside.

-

Not if the tolerances are within specs. Back in the 60's I used the compression rings from a flathead V8 in my 47 Harley. I had to grind some off the ends to get the proper spacing on the end gap on the rings. Take the compression rings off each of the pistons and put one into each cylinder and measure the end gap at different depths in the cylinder. That will show the amount of wear on both the used cylinder and the used ring. If the end gap is within specs, you will have good compression. Ideally, you should have a new ring to check the cylinder for wear. I never had to look and see if the FSM has the ring end gap measurement.

-

I'll have to look that up. Resistor to lower the voltage and a cap to smooth out the ripple. Once our cars went over 270k both threw the P0420 code. Looking at the waveforms the downstream o2 sensor looked almost identical to the upstream. Sparkplug non-foulers fixed both on them. They are on YouTube too. I read an article that said the coating wears off the honeycomb over time and there is nothing left to work on the exhaust.