Rampage

Members-

Posts

683 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Rampage

-

Remove the master cylinder from the booster and see if there is brake fluid on the back side, it should be dry. Get plugs to fit the brake line holes in the master cylinder. Remove the lines, put the plugs in and see if you get a pedal back. Sometimes you can see the fluid churn inside the reservoir when the pedal is pushed if the piston seals are bad.

-

I just found this. Copper-nickel is shown as the most reliable material by far. Users of copper-nickel brake tubing in addition to Volvo include world-class vehicle manufacturers like Rolls Royce, Lotus, Aston Martin, Porsche and, most recently, Audi. Copper-nickel is also used in military, fire fighting and other heavy vehicles. And this. https://www.amazon.com/s?k=copper+nickel+brake+line&i=automotive&crid=1H4REOPR8WG37&sprefix=copper+nickel+brake+line%2Cautomotive%2C355&ref=nb_sb_ss_i_2_24

-

I get it at Fisher - Federated Auto Parts where I retired from. (they still give me the employee discount) I'm sure other auto parts stores would carry it, because I've seen it under different brand names. Find a mechanic that can get it for you at a discount. It comes in a roll. I normally reuse the old connectors depending on rust. It is great for double and bubble flares. If I need new connectors I buy the shortest (6 or 8 inch) steel line that comes with two connectors on it, because it is cheaper than buying the two connectors alone.

-

Copper-Nickle Alloy is all I use anymore. It is on our 93 Ranger, 96 Voyager, 95 and 97 RHD Legacy's the one that goes over the fuel tank. It will not expand with normal brake pressures and if you take a piece of it and bend it like 90 degrees back and forth until it breaks (it takes a while) it will not kink shut. You can wrap it around a screwdriver handle to make a coil.

-

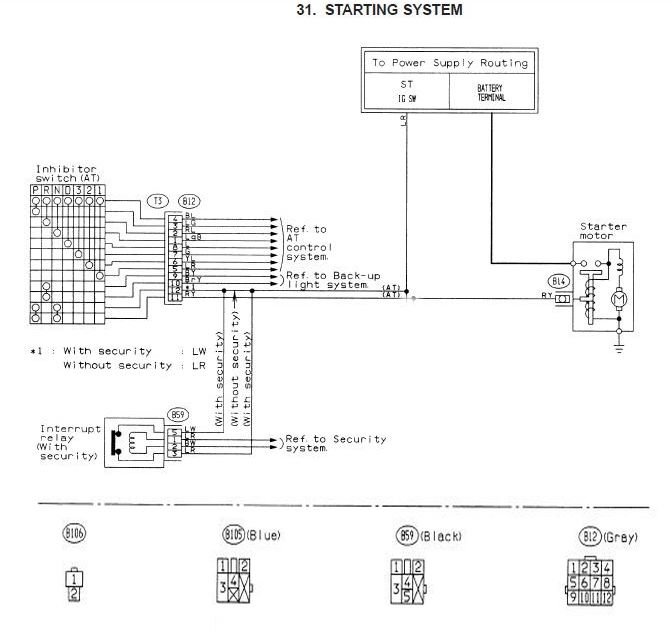

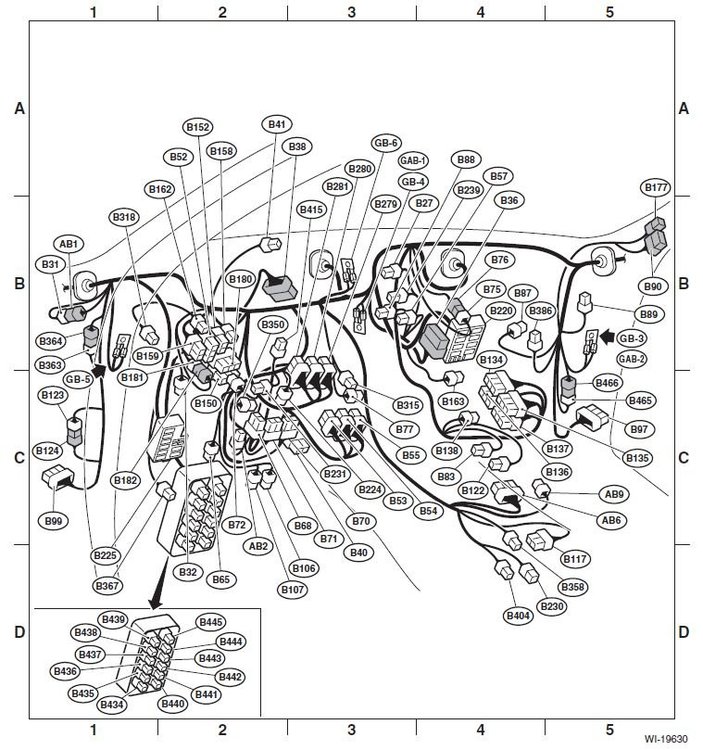

This will give you an idea of the route the voltage takes to get to the starter. Battery, Fusible Link, SBF 45 amp, connector, Ignition switch connector battery in (it will be good to this point) and starter out, connector in and out for the inhibitor switch, and finally the starter. The connector for the inhibitor switch is on top of the bell housing. In the diagram you'll see Pin 12 in and Pin 11 out to the starter. I removed the wires for standard tranny. Also note that "only" if it has security system it will have a relay.

-

Yes they can, but usually they will be intermittent first. I took the ignition switch out of our 97 when it acted up 2 years ago and was surprised to see the wires are "soldered" to the contacts on the switch. On two of them the solder had started to melt. The melting solder usually happens if the solder starts to crack and it has a smaller connection point, or the contacts inside the switch are dirty and the contact point is smaller and will get hot.

-

The problem can be as Mike104 said, or if you have anti-theft in could be a relay or something else. Had the same problem on 2 of our 95s and our 97 Legacy RHD with automatics. Most of the time they would start but some times the starter would not work. I added a Push Button to the starter circuit. Now my wife just turns the key on and hits the button if it don't start with the key. Very important on the mail route. Beside the steering wheel are 4 rectangles, two on the left and two on the right. One or two may be populated with push on - push off switches like for fog lights or something. Drop the steering wheel down with the release lever. Take out the 4 screws holding the bezel in front of the gauges and you will have access to the back side of it. Pop out the right rectangle and drill a hole (I think it is a 1/2 inch) in it to accommodate the push button switch. The one I used (20 or 30 AMP) is available at most auto parts stores. The button is silver. It fits tight. I only had to trim out a little plastic for it to fit. Mount it with the terminals facing to the right. You can tap into an empty spot on the fuse panel that is hot only with Ignition ON. Use a 1/4 inch male spade crimp connector. Hook that wire to one of the terminals on the switch. From the other terminal run a wire through a rubber plug in the firewall and over to the starter. At the starter solenoid connection I did this. Get a male spade connector and an insulated female spade connector and a 4 inch piece of wire. Crimp the short wire and the wire from the push button switch in the male connector. Crimp the insulated female connector on the other end of the short wire. Unplug the wire from the starter solenoid and plug it onto the male connector and then plug the female connector onto the starter solenoid. Now if the key does not start the engine, just hit the push button. Keep in mind that it will start no matter where the shifter is...…… Most people are in the habit of having it in park.

-

I would have done the relay first because the MAF sensor and fuel injectors do not work correctly without the proper voltage. One down. Just the other day I had to replace the new MAF bought in August on our 97. One from the junk yard fixed it. I did some research on your previous codes. Mass Air Flow sensor or No. 4 Injector or the wire to it, or maybe MAF and injector. P0204 Cylinder 4 Injector Circuit Malfunction. This code means the ECM detects a problem in the injector or its wiring, or in the injector circuit for cylinder 4. P3100 Ignition System Or Misfire Fuel Rail/System Pressure - Too High Cold Start Injector Malfunction may also be triggered by faults earlier down the line. For example, a dirty MAF sensor might be causing the car to overcompensate in its fuel-trim adjustments. As a result, oxygen sensors are likely to report fuel mixture problems. P0104 This code means that there is an intermittent or erratic fault detected in the Mass Air Flow (MAF) sensor or circuit. The ECM detects that the actual MAF sensor frequency signal is not performing within the normal expected range of the calculated MAF value. P2000 NOx Trap Efficiency Below Threshold (Bank1) This code usually indicates a faulty oxygen sensor(s). However, in some instances it can also be used for a faulty catalytic converter as well, since the O2 sensors are located on the exhaust system along with the cat. converter(s). You should check your O2 sensors before replacing the catalytic converter.

-

Go to Google and type in car radio bulbs. I haven't had to replace bulbs in a Subaru radio yet, but I have in other brands. If replacing the incandescent bulbs, you will want the same size bulb for it to fit and work correctly. I have bought them with and without the base from our local electronics store. If you are lucky, maybe the ford ones are the same. I have also used fingernail polish for a tint. One thing the guy in the video did not mention is that an led will not tolerate much heat from the soldering iron. Too much heat and they will not work for long or not at all. No more than 600 degree iron. My Weller station has replaceable tips at 600, 700, 800 degrees. The 600 degree tip is long and skinny so it is not real hot at the tip.

-

Motor swap

Rampage replied to Zoltan's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Wow zero compression. It could be a broken valve spring not closing a valve, or a cracked valve missing a chunk , or a hole in the piston, or head gasket. Bad rings would still make a little compression. Pull the valve cover and have a look. I remove all the spark plugs, pull the plug to the coil and use the starter to crank it about three pumps on the gauge. -

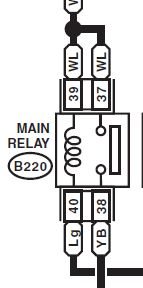

OK---this is weird. The Service Manual says that relay is the Main Relay. I went to the following site and they call it Seat Heater Relay. It has the same picture that I posted????? If your relay looks like the first one in both of the following links, it should be right because the pin layout is different on other relays. Subaru Parts Warehouse in Branford Ct. https://estore.subarupartswarehouse.com/a/Subaru_2009_Forester-25L-4AT-X-Limited/_52016_6023761/ELECTRICAL-PARTS-BODY-RELAY/S12-835-02.html https://www.subarupartsforyou.com/search?search_str=relay

-

I'm not sure what year they started putting the Ignitor inside the Coil pack, but I think it is on yours. Our 95 and 97 have the Ignitor mounted on the center of the firewall. You have to set your ohm meter to the Diode setting and it will only read in one direction. Reversing the probes it will read open. The Ignitor has high current transistors in it that fire the coil so the ECU doesn't have to handle the load of the coil or the feedback pulse. When you are checking the input of the coil you are checking the Base (input) of the transistors and bias resistors, NOT the primary winding of the coil like on the old ones. With a little ingenuity they can be tested, but that doesn't mean it will work properly on the engine. You did the best thing by replacing it.

-

The stuff that is in there is probably Stop Leak for Power Steering. It is supposed to condition the seals, but more than likely the seals are too far gone for it to work. I have tried it on our 97 RHD Legacy and the rack seals still leak. I bought the kit to rebuild it (some day). If you go back to Dexron type ATF fluid, It may leak a little faster or not. But, you won't know unless you try it.

-

I tried a new aftermarket front axle in our 95 RHD and the outer joint was so tight it jerked the steering wheel a quarter turn as it rotated, so it is on my scrap pile. Reman axles go about 2 years until the boot splits and the joint gets dirt in it. Wheel bearings should be Subaru, or like you did, get a complete knuckle from a yard. Aftermarket wheel bearings with a new hub only lasted about 5 days in our 95. The Subaru bearing I put in about 5 years ago is still going strong. When you change the bushings on the control arms, you are supposed to have the weight of the vehicle on the wheels when you tighten the bolt on the front bushing and the nut on the rear bushing. I pull the car onto ramps to tighten them.

-

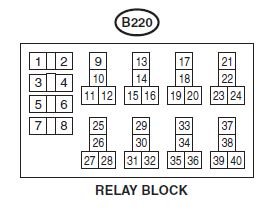

All that wiring harness in the photo is behind the dash. The holder for the relay looks like it would be behind the glovebox right below a wire that goes through the firewall. I don't know if it is mounted to the firewall or on a bracket. These two pics say the Main Relay is located in the upper righthand corner of the relay block. In the wiring harness above it shows the 4 fuses on the bottom of the block.

-

I found this article on pros and cons of full synthetic motor oil interesting because of the rollers on the rocker arms in our EJ22s. Does the following problem happen because of the extra pressure of dual valve springs and cam lift and duration? And, will this problem happen to a stock engine and if it does, does it really matter? https://www.carsdirect.com/car-repair/common-problems-associated-with-fully-synthetic-oil Problems with racecar type engines using roller lifters. Because of the less friction with the use of synthetic oil, these rollers actually slide instead of the rollers turning as designed.