Rampage

Members-

Posts

683 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Rampage

-

If there is a leak the fluid level will drop. If the fluid level does not drop, the master cylinder is bad. I have seen a few new and reman ones that were bad. This "could" have happened to the original master cylinder. During normal use the piston will only travel 1/4 to 1/2 of an inch and you have a full petal. The seals are working in that area for years. When initially pumping the brake pedal, if you push it to the floor the piston seals are moving into an area that could be rusty or coated with crud and that would mess up the seals. If they leak the fluid seeps past them and goes into the reservoir.

-

Did the piston return all the way when you bench bled it. Only other thing I can think of is to check the length of the push rod from the booster to the new master cylinder. If the piston in the master cylinder does not return far enough it can not take in fluid from the reservoir. Make sure the brake pedal comes up all the way.

-

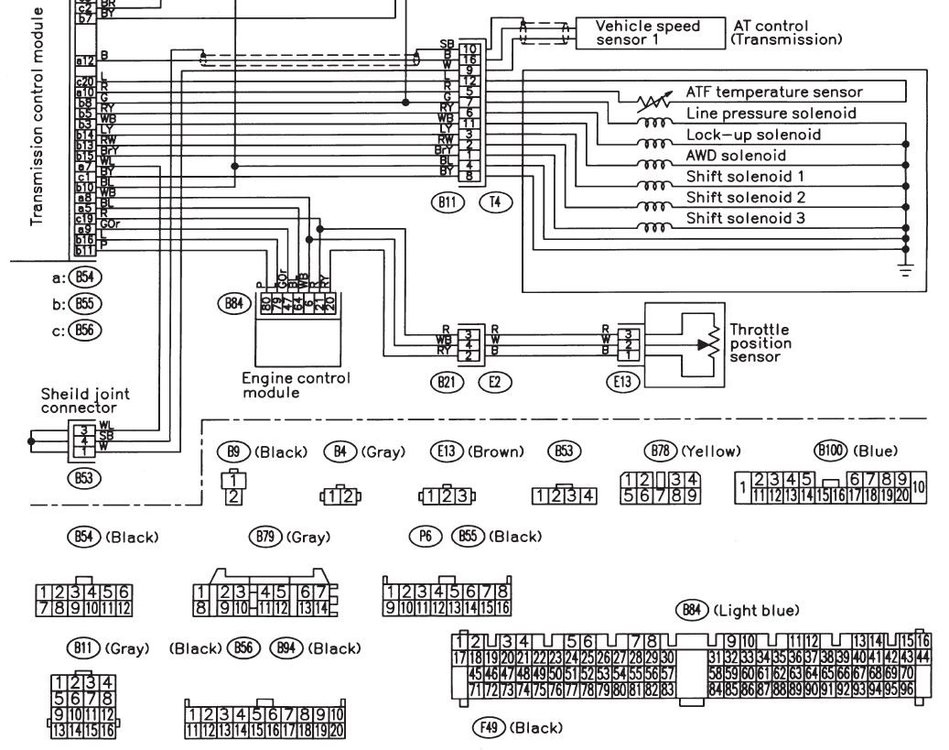

The wiring diagram has the info you want. On top of the bell housing are 2 big connectors a 12 pin and a 16 pin. You want the 16 pin connector B11. Connector B11 has a brown wire from the tranny into Pin 11 and a White wire with a black stripe coming out that goes to TCU Connector B55 Pin 3. Check the diagram to see what the connectors look like. The AWD solenoid is the Duty C solenoid.

-

O2 sensors 1996

Rampage replied to YOWZA's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

Great... It's a shame something so simple has to be so hard, but it's a great feeling when it's done. -

O2 sensors 1996

Rampage replied to YOWZA's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

On the floor, I put the bung into a pipe wrench facing up, slide a box wrench onto the sensor. Put a piece of wood under the wrench to make it set level. Get the wrench tight and tap it with a hammer. The shock will loosen it and then it usually turns off by hand. -

I spoke with the lady that does our taxes and she said that some time ago the gov passed a law that out of state sellers must do one of two things. Collect sales tax and submit it to the state of the buyer or report the sale to the gov and then it is up to the buyer to pay the tax. I actually got a letter from one seller telling me it was up to me to pay the sales tax to Pa.

-

I know the plug, our 95 RHD had it on the pump. Glad your pump is not a Carter, those skinny pumps only lasted 11 months in my wife's wagon. The car went through 3 of them warranty replacements until I found the larger diameter pump with the two studs for the wires. They last quite a few years in her car. I had changed the fuel tank, so it is clean. It's funny, but other people do not have a problem with the skinny pumps. I don't know if I would try the new pump. It has more pressure but the flow rate is way lower. 80 PSI for the 98 pump and 94 PSI on the Delphi pump you bought. The flow rate is 40 GPH for the 98 pump and only 26 GPH on the Delphi you bought. The pumps use a rubber gizmo on the bottom to hold it in place on the bracket. Hook up the short hose and push down on the pump and tighten the clamps. I would replace the fuel filter before doing a pressure test. I have replaced fuel filters that I could not blow air through and yet the car ran. When using the fuel pressure gauge hook it up between the fuel filter and the pipe on the engine. NO leaks allowed. This is from a 97 FSM. Start the engine. Measure fuel pressure while disconnecting pressure regulator vacuum hose from collector chamber. Fuel pressure:235 — 265 kPa (2.4 — 2.7 kg/cm2, 34 — 38 psi) After connecting pressure regulator vacuum hose, measure fuel pressure. Fuel pressure:177 — 206 kPa (1.8 — 2.1 kg/cm2, 26 — 30 psi) WARNING:Before removing fuel pressure gauge, release fuel pressure. Another test I do to see what the pump is capable of is this. Using needle nose pliers "momentarily" pinch the return line. The pressure should shoot up to the rated pump pressure 80 PSI. Injectors do plug up. Pour a can of Sea Foam Motor treatment in the tank. 1 OZ per gallon of gas. Read the can, it's good stuff.

-

Try a new fuel filter first. See if it makes a difference. You mentioned having a problem at half a tank of gas. A dirty filter will slow down the rate of fuel flow through the lines. AWD vehicles have a saddle tank because of the driveshaft. The fuel system uses a jet pump to move fuel from one side of the tank over to the side with the fuel pump. It uses the return line to run the jet pump. If the flow rate (GPH) is low the jet pump won't move the fuel and the fuel pump could be getting air. Do you have access to a fuel pressure gauge? What brand is the fuel pump you bought?

-

My first thought on the different resistance readings would be the crimp or solder connections (which ever they used) on the solenoid, where each end of the coil wire fasten to the terminals. They could be starting to break their connection. From there one goes to ground and the other goes to pin #15. Almost everything expands with heat. Another thing that could happen (not very often) is the coil of the solenoid could have a few shorted turns. It will read very close to the correct ohms, but will draw more current than it should which may overload the transistor in the TCU that drives that solenoid causing it to overheat and pass less voltage than it should. Something I have run across working with electronics over the years. In one of your posts you mentioned #16. You do know that pin is for the torque converter lockup solenoid.

-

Those pics makes me wish I had taken some of our 95. One evening my wife called and said she hit a really bad rut in the road and now the left rear was sagging. I got there and saw the left rear strut mount was half way up the side window. I worked all night to get it back where it belonged so she could drive it the next day. Later I looked at the right side and had to fix it too.

-

Amp gauge---one of the things I dislike on any vehicle. They only tell you part of the story. You would be better off putting in a volt meter. If it reads 12 or less the alternator is not charging or not keeping up with the load. If it reads 13.8--14--14.4 the alternator is charging. I looked at the wiring diagram for a 1989 Loyal and it is so blurry I could not find the Amp gauge on it. You may want to try what I did on an Ambulance quite a few years ago. The driver said he was backing up to park it and it just up and quit. Hardly any thing electrical worked on it. I soon found the Amp gauge had burned open inside the gauge. Voltage on one pin, but not on the other pin. It has two main posts on the backside. I moved all the wires on to the same post and it started and every thing worked. I watched the voltage with my meter and it never went higher than 14.1 volts. Later I installed a Volt meter under the dash. You know, it is not good to have an Ambulance go out of service because of a lousy amp gauge.