Rampage

Members-

Posts

683 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Rampage

-

Transmission fluid is pumped out one of those lines to a metal pipe inside the radiator. The fluid returns from that pipe to the tranny through the other line. The rubber hose often gets hard with heat and age and tend to crack and leak. Measure their length and replace both of them with ATF hose. While you're at it, check the same two hoses at the radiator. They get hard too. A lot of times I have to cut them off the pipes with a knife because they are soo hard they won't spread and slide off the bubble on the pipe.

-

I would suspect the wiring into the drivers door at the hinges inside the rubber tube. Looking at a 92 wiring diagram they show a Window power Circuit Breaker. That may be what you hear clicking if wires are shorted in that rubber tube. The Window Relay coil is powered on with the key on IGN and supplies power to the window buttons.

-

My first was a Timex Sinclair T1000. It used a TV and cassette recorder. Then came the 8080, 8086 and many more. 10in. floppy disks. IBM DOS then MS DOS and MS Windows 1, 2, 3 and 3.11 and more. Windows 2000 was my favorite for a long time, then Windows 7 Ultimate. Did you know the Space Station used 386's for many years? Around 30 years ago I cut down a maple tree about 50in. diameter 8ft. from the in-laws house and power lines. That was a job. My wife and I could not touch hands around it. Pop saved some slabs to make tables and limbs to make table legs.

-

From your description it sounds like you will need the radiator. The radiator has a plug you can remove (opposite side from the cap) to let air out while filling it. After you install it and fill the system with coolant keep an eye on the overflow tank for bubbles. There will be some initially but they should stop after a few warm up and cool down cycles. The warm up pushes air out of the system into the overflow tank. The cool down sucks coolant into the system. After that, if you still see a continuous stream of bubbles then it needs head gaskets. If this is an automatic transmission check the rubber tranny coolant hoses that connect the lines to the radiator. They usually get very hard and crack when you remove them from the radiator, so you may have to replace both of them. Changing the water pump and timing belt and components would depend on their age and what brand was installed, it they have been replaced. Your 96 is an interference engine with adjustable tappets on the valves. I would play it safe and do the right thing, new good components. You can download the Factory Service Manual free from two places. I use THIS site because you get the whole thing in one zip file. When you click the zip file download button another window will open. It's an add just click the X to close it. Or you can download individual files HERE. With this being a 96 and 200k there are 3 small coolant hoses you should check while you are at it. The OE hoses are molded and soft and can swell up and split. That happened on our 95 and 97 EJ22's. They are located under the throttle body and IAC Valve. 2 of them are on the throttle body and 1 goes from the IAC Valve to the coolant pipe where the two temp sensors are. They are not easy to replace. For that last one, I use a hose about a foot long and loop it out around the PVC pipe and IACV.

-

I have had good luck with FelPro head gaskets on our 95 and 97 EJ22 RHD Legacys. The only time they failed is when (on the mail route) one of the small hoses on the throttle body or IAC valve leaked coolant or the thermostat decided to not open and the engine overheated. If your Legacy has A/C, then it has two radiator fans. Do both fans run on low speed when the engine warms up and then on high speed when really hot or the A/C is turned on? I don't know if your 99 has this or not. Remove the dash panel under the steering wheel and look for two green (test) connectors. If there, connect them and then turn the Key to ON (no start). The fuel pump will cycle, relays and solenoids will click, then both fans will turn on low speed then high speed and off, and the cycle will repeat until you turn the Key OFF. Then disconnect the green connectors. Another thing to consider is the heater core. It must have good coolant flow through it. That is required in order to open the thermostat. I hook up two hoses and use our garden hose to flush ours both directions until the water is clear.

-

I found the following on a forester forum. Set the following as the first radio station preset button. If you are playing the radio, select the first preset button before turning the engine off. When you restart, the radio will come on but it will be silent. Channel 0 on XM, doesn't require having the subscription. Set Sirius XM channel 0 as your default radio favorite and leave it set there (which is a silent channel).

-

Sounds like one of your screw drivers might be a magic wand. Glad to hear it started. That is one big step. But why with one injector unplugged? The Yellow wire on the injector plug is the 12v source and the other one is the signal from the ECM. The wiring diagram shows that the 12v for the fuel injectors, two pins on the ECM and some other items come from the Main Relay. The Main Relay closes two sets of contacts when the Key is turned ON. Maybe the contacts are getting burned and it is starting to fail. Or, the big connector from the intake harness to the body harness. Check that it is plugged in all the way and no pins are pushed out on each half of the connector. That is one of several you would have unplugged to swap the engine.

-

Are the fuel hoses to the engine connected properly? The hose from the filter goes to the top metal pipe. Sounds like the injectors are plugged or not opening. Is there 12 v at the injector plugs? Unplug the connector and with the key ON there should be 12v on one of the wires. When plugged in and cranking the other wire should show 12v and dip a little when the ECM switches it to ground. If you use a test light it will be on and flicker. If it has the pulse, you could swap the injectors from the other engine (you may have to replace some o rings), or the whole intake manifold. Change the fuel filter while you are at it.

-

Check out the Apex with grommets. They are blue. I have found the blue ones stay soft longer than the black ones. The black ones get hard in about two years (65k miles) on our 95 EJ22. I have to pry them out in pieces. The blue ones pull right out, still soft. Of course it also depends on how hot the engine runs. The hotter they get, the harder they get. https://www.rockauto.com/en/catalog/subaru,1992,legacy,2.2l+h4,1269558,engine,valve+cover+gasket,10710

-

Those pictures are in the Harness section at the end of the FSM Wiring diagram. Look for the fat black arrows pointing to the ground terminals. It will show you the location of every ground terminal. At the beginning of the wiring diagram is a section called Ground Circuit that will show what circuits are connected to each ground terminal and its number like GB-1, GB-2 etc. Then go to the Harness section to find the location on the body.

-

I don't know if they have a real name or not. I call them the a/c hose connector for the compressor. You said they were cut off on yours. The only way I know of to get them now is from a scrap yard or junk yard as the complete hose assembly for your cars compressor. They must fit the compressor on your car. There are a lot of different shapes and sizes for different compressor models. The smaller diameter metal pipe is the High side (pressure) hose that goes to the condenser. The larger diameter pipe is the Low side. If the metal pipe was cut on yours and you can find the connectors that fit your compressor and if there is enough pipe to work with, you can use a Flare fitting coupler to couple the metal pipes.

-

On your 96 Legacy door lock mechanism the wiring diagram shows that the drivers door only has a (On Off) switch and the rest of the doors have motors (solenoids). When the drivers door is locked or unlocked the switch tells the Door Lock Timer to lock or unlock the other doors. For your addon keyless entry system to work you need to install a motor in the drivers door and attach it to the door lock linkage rods. In the image you posted the lower right corner is the wiring you will use. White and White Black wires to the addon motor. The White and White Black wires must be run into the door for the motor. That info is in the link you provided. When the remote is used the module will run the addon motor which moves the linkage and operates the original switch telling the Door Lock Timer to lock or unlock the other doors. If the motor did not come with your kit you can try to add one from a parts car. I don't know if a left or right door lock motor will work best. You can get a left and right from the rear doors. You will have to experiment with the polarity of the two wires to the addon motor so that the Remote Lock button makes the doors Lock.

-

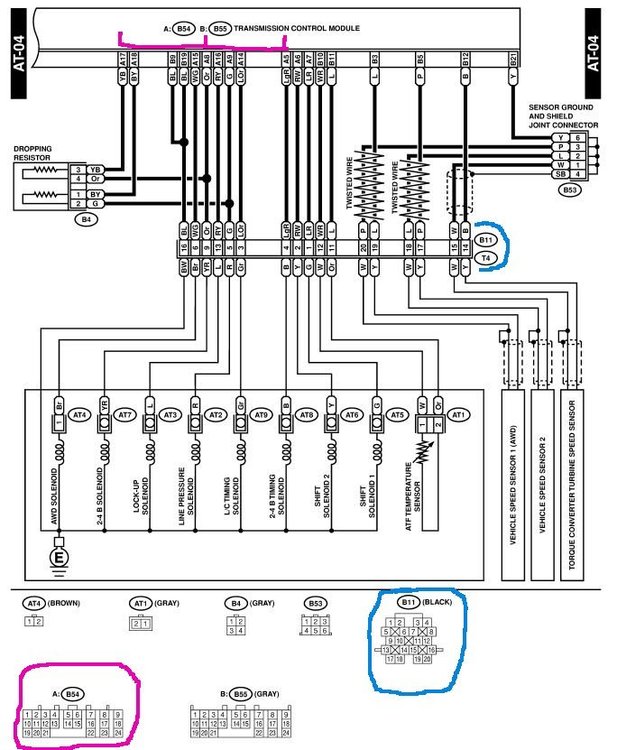

When you put the FWD fuse in the FWD light should illuminate. One contact of the fuse holder goes to ground, the other contact goes to the TCU and the FWD light. The light gets power from Fuse # 15. As @idosubaru said, a wiring harness comes out the left side of the transmission and goes forward and up to where the tranny bolts to the engine. On top of the tranny you will see a Gray 12 pin connector B40 for the Inhibitor (gear selector) switch and a Gray 16 pin connector B41. With the key OFF, Check ohms to ground on pin 11 of B41 the 16 pin connector. It is a White/black stripe wire on the harness side of the connector. It should be 9-17 ohms. Just so you get the right pin, pin 4 Black/Lavender stripe and pin 8 Black/Yellow stripe should read 0 ohms and pin 1 Green/Yellow stripe should read 20-32 ohms. If pin 11 shows open or a high resistance, that wire is not connected to the Duty C solenoid or it is open. The other wire of the solenoid coil is connected to ground inside the tranny. 92 TransA.pdf 95 Transmission Connector.pdf

-

Similar thing that happened on our 95 EJ22. Turned out to be the fuel pump. When the engine was started and run for a while and then turned off the engine would crank fine, but not start. I found that the fuel pump would not start if there was any pressure in the fuel line. If I pulled the fuel line and bled off the pressure the reconnect it, then turned the key to start the fuel pump would run and keep running and the engine would start. If I just turned the key on, the pump would cycle on and off and then when I turned the key to start the pump would not start back up. With the new pump in it, I can turn the key on and off several times and the pump will run every time like it should.

-

With the TCU unplugged the trans only uses third gear. You said the tranny worked before pulling the engine, but now only has 1st and 3rd. According to the FSM, that indicates a problem with wiring to the transmission 2-4 brake duty solenoid, 2-4 brake timing solenoid or 2-4 brake dropping resistor. Note the guide tabs on the top of connector B54 at the bottom of the image. (different than B55). The pic shows the connector side of the plug, not the wire side. Key off. Unplug B54 from the TCU and check OHMS to a good ground on Pins 5, 8 and 17. Pin 5 (Light green Red stripe wire) 10-16 OHMS. Pin 8 (Orange wire) 2-4.5 OHMS. Pin 17 (Yellow Blue stripe wire) 9-15 OHMS. If any of those readings goes high (open circuit), then check the wires on connector B11 located on top where the trans mounts to the engine. Maybe a pin pushed out of the connector or bent over. Note in the wiring diagram that the wire colors change when they go through B11. You can also check voltages of Pins 8, 17 and 5 of B11. Warm up the engine and then turn it off, then turn the key to ON (no start) and check voltage on the following pins of the B11 TCU connector. B54 Pin 8 Throttle fully closed 1.5 — 4.0 v. Throttle fully open. Less than 0.5 v B54 Pin 17 Throttle fully closed. More than 8.5 v. Throttle fully open. Less than 0.5 v B54 Pin 5 1st gear Less than 1 v. 3rd gear More than 9 v.

-

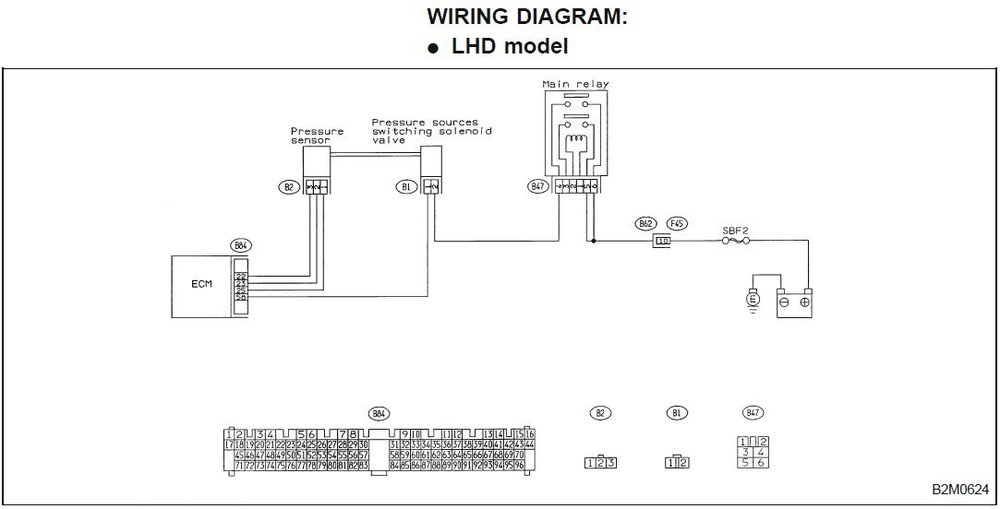

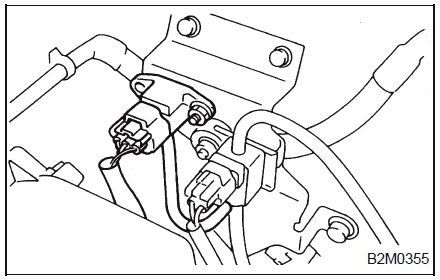

The code P105 is for the Pressure Sensor. You will find it on the front of the strut tower behind the air filter box. It is the one with 3 wires on the connector. Check those vacuum lines. There should be a label on the hood for vacuum routing. I would find a used one and replace it first. If that does not fix the code, you will have to check voltages on it and the ECM that the 3 wires connect to. They are in the FSM under Diagnostics. BTY, OBDII was mandatory 1,1,96 on all US cars and light trucks. Subaru started in 95 for most models. You can download the FSM (Factory Service Manual) for free on the following links. I donated to both. I preferer the zip file, but the other site has other sections that can be very handy. Click Parent Directory to go back. Here as one zip file. Here as individual files.

-

With the car stationary and in neutral, push and hold the clutch in and start it. Do you hear the noise? Probably not. When you let the clutch out do you hear the noise? If you do, and push the clutch back in, does the noise slowly go away? If so, it is what 1 Lucky Texan said, input shaft bearing on the tranny. If it is quiet and only makes noise when moving, it could be what carfreak85 said, center diff, if it has one. I've never worked on a Subaru MT.

-

There is a Mennonite owned shop not too far from me that rebuilds alternators, generators and starters. I took our alt apart and took it to them for brushes and bearings. He charged me 18 bucks and he soldered in the brushes and assembled it. A few months before that I helped him over a hurdle with his really old shop pc. I think he only charged me for the parts. If the alternators are charging properly that means the regulator is good and I would change the brushes and bearings. Preventive Maintenance.