Rampage

Members-

Posts

683 -

Joined

-

Last visited

-

Days Won

25

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Rampage

-

Accessory power floating.

Rampage replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Does voltage return when you turn the wipers off? If it stays at 0v then the relay would work. If the voltage reappears then you should find the source of it. You said "inline", so are you going to cut the IGN SW "ACC wire" and wire the relay Common to the ACC circuit and the NO to IGN SW ACC and the NC to ground? One side of the coil to ground and the other to IGN ACC. And the same with IGN? Those relays would have to be high amperage contacts. I think it might be better to do the same with a relay, but only to power and then ground the radio and dash cam wires. -

If you had used Assy. Lube, just start it. Easiest way to pump oil through it is to crank it. It is a little slow, but it works. If the starter solenoid has a 1/4 inch spade connector, get a piece of 12ga wire and crimp a female spade connector on one end and plug it in to the solenoid and hold the other end on the battery positive and let crank for 10-30 seconds. That way the key is not on, so no fuel to worry about. Many years ago, I made one with a push button switch and alligator clip for the battery and different connectors for starters. Wires were long enough I could sit in the seat and with the MT is first or reverse I could move it around.

-

This one has a large 6-3. It is 49 meg it will take a while to download. Third one from the bottom. http://jdmfsm.info/Auto/Japan/Subaru/Legacy_Outback/1990-1994/ 1992 Subaru Legacy Service Manual.pdf

-

If this is a 92 try this. It has sedan and wagon body sections 6-2 and 6-3. http://jdmfsm.info/Auto/Japan/Subaru/--Old Models--/ When the page opens the following PDF will be near the top. 1992_Subaru_Service_Manual-Engine_Wiring.pdf When you click on the PDF link for the manual, it will open in a web page and download the manual. When it is fully loaded, right click (right mouse button) anywhere on the page and in the menu that pops up, left click on print. In the window that opens, change the printer to "Microsoft Print To PDF" and click the print button at the bottom. Another window will open. At the top select the folder you want to save it in and in the "File name:" area type a name for the document (like I have above) then click the Save button. You might already know this, but when the PDF file is open in your reader you can right click on any page and select print then select "Current" and it will print that page. Make sure your default printer is selected.

-

I have to study this a little bit, because what I see in the wiring diagram is B56 pin 1 is 12v from Fuse # 4.

- 60 replies

-

- 6 cylinder

- subaru

- (and 8 more)

-

The low beam takes an H7 or 12555H7 bulb. Try to find one with LL on the end of the part number. H7LL. The LL stands for Longer Life. If the bulb socket connectors look black, replace it. RockAuto has both, bulb and socket. I had to replace the sockets on our 95 RHD. In 473k miles I've only replaced the bulbs twice. Delivering Mail the lights are on all day. I would check the alternator output when running. If it is more than 14 volts the light bulbs don't last very long. The best voltage is 13.8v but some run at 14.2v. The bulbs are rated 12v at 55 watts.

-

I think the reason they want the crank "dot" at 9 o'clock when you first start is so all of the pistons are away from the top of the cylinders. That way you can turn the cam sprockets to 12 o'clock and the valves will not hit the pistons. Some of the valves will be open. After the cams are set, you turn the crank "dot" to 12 o'clock and install the chains.

-

Timing Belts/Kit '88 EA82 Tricks or Tips?

Rampage replied to subaru1988's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Not all of them. Our 95 EJ22 has hydraulic lifters and is listed as non-interference. Our 97 "had" solid adjustable and was interference. I swapped 95 heads onto it. I later found out that I could have just swapped the rocker assy. instead. But I had already swapped the dual port Y-pipe with the heads. -

87 XT idle issues. Dies when in gear.

Rampage replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The engine stalls when the transmission is put into Reverse or Drive could mean the torque converter lockup is not releasing and staying in lockup. When driving and coming to a stop the lockup is supposed to release. If it does not release then the engine will stall. The torque converter uses oil to transfer engine power to the input of the transmission and the lockup clutch makes it a direct connection. Like driving a MT and not pushing in the clutch when you stop. The Duty Solenoid B controls the valve in the valve body that supplies oil pressure to the lockup clutch in the torque converter and the solenoid is fed a PWM voltage at 50HZ from the TCU. Pulse Width Modulation is an of off signal at varying length of on time. Like, on 10%-off 90%, or on 50%-off 50%, or on 90%-off 10%, all happening 50 times a second. You need a scope to see those pulses. From the FSM: Engine stalls while shifting to any range. 23 Valve sticking (controlled by Duty solenoid B) 77 Lock-up clutch seized (in torque converter) The TCU will not set a code for those problems. It would only set a code if the Duty solenoid B was open or an open or shorted wire. I did not look to see if there is a way to check that pressure line. It seems like either the valve is stuck or the torque converter is bad.- 82 replies

-

- 1

-

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

I have not worked on this type of problem, but you can download the FSM and check it out. https://sl-i.net/FORUM/showthread.php?18087-Subaru-Factory-Service-Manuals- Extract the zip file to its own folder and to start, go here - 2009\BODY SECTION\HVAC SYSTEM AUTO A-C DIAGNOSTICS ACdiag There are several PDF files to look at for diagnostics. There are also some that tell you part locations like Ambient temp sensor, Sunload sensor, In-vehicle sensor and other parts.

-

The steps you took are correct. I just looked at the chart. Maybe one of the switches in the selector switch (inhibitor switch) is not making contact so the process does not complete. Or if the switches are good, the TCU is not responding. Think about it, how often does 1,2.3 get used. Move the shifter through the range a bunch of times and then try the process again. Here is a link to the chart. http://jdmfsm.info/Auto/Japan/Subaru/--Articles--/--Transmission--/Self diagnosis.pdf A Subaru dealer should have the Select Monitor to check it, but I have no idea what they would charge. Probably too much.

-

87 XT idle issues. Dies when in gear.

Rampage replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

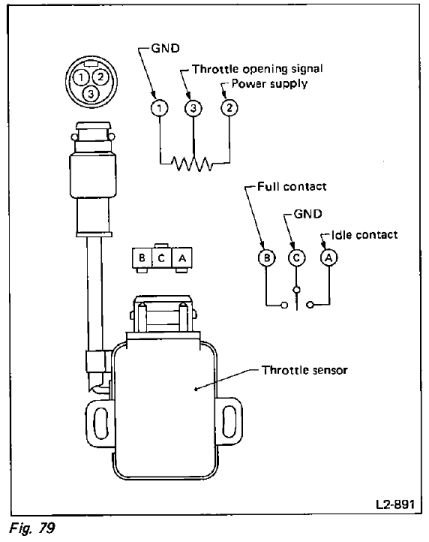

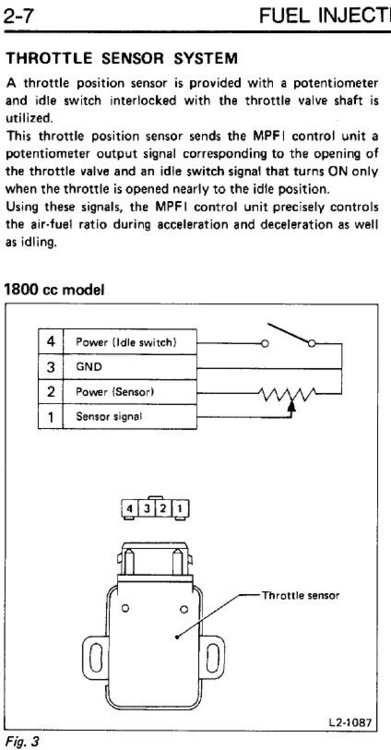

The previous image is from the 88XT manual. One connector. The following image is from the EA82 manual. Two connectors one round and one flat.- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Rampage replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

- 82 replies

-

- 1

-

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

I guess you checked the oil in the front diff. There is no dipstick for the front diff on the CVT. You have to get under the car and remove a plug to check it. Get the FSM here http://jdmfsm.info/Auto/Japan/Subaru/ 200 meg PDF download. It does cover the CVT disassembly and assembly and adjustments. It is quite a job. I did a diff replacement on a 4EAT in my driveway and it was not that bad. You might want to do this first. You have to get under the car. Remove the oil filler plug on the side of the diff and see if you can touch the oil with a finger through the hole. The oil level should be right at the hole. Since the gears are already complaining, I would drain it and replace it with 75w140 synthetic gear oil. 1.4 to 1.5 quarts. Then look in the FSM on how to adjust the carrier using the adjusters where the front axels go into the diff. This might buy you a little time to get ready to change the diff. The front diff ring gear carrier assy. is mounted inside the torque converter housing and does separate from the tranny housing. The pinion gear is mounted in the tranny section. On assembly you must use a dye on the teeth of the ring and pinion gears and first adjust the pinion in or out for the proper alignment. Put it together, take it apart several times. Then when when the pinion is where it belongs, you adjust the carrier to specs spin the gears, take it apart and look at the marks from the dye to see if the teeth mesh properly. The FSM will tell to watch for O-rings on removal of parts. I did not look to see if the front housing on your CVT is like the 4EAT and does not use a gasket. The 4EAT on final assembly you use a tube of gasket compound.

-

Glad to hear it is fixed and thanks for letting us know. I think it is a good thing you changed the sending unit. When I changed our fuel gauge I ordered a new one because it was really cheap. I couldn't believe it, 18 bucks new from Subaru.

- 6 replies

-

- engine coolant temperature sensor

- sending unit

- (and 8 more)

-

I would replace all of the (aluminum can) electrolytic capacitors on the board. The liquid electrolyte inside them dries out with age, non-use and heat. Some will leak out on the board and eat the copper traces. They seem to last much longer when used like in a radio or TV as long as they don't get hot. Make a note of the values on each one and its location on the board. uF or MFD (microfarad) and DC voltage. All of them should have a stripe lengthwise with a - minus symbol for the negative lead. The pc board can be marked for the negative or positive wire, so "take note of the marks" when you remove them. Some boards are marked with a half circle. Most of these caps have the two wires coming out the end and is called Radial leads. If a wire comes out each end it is called Axial leads. The temp rating might be 105C. If lower, I would use 105C or higher. For the diameter find one the same so the leads will be spaced the same as the holes on the board. Highly unlikely, if there is no minus symbol then it is a bipolar cap (used in audio and frequency) and must be replaced with the same. A common practice is to apply a little silicone gasket compound or hot melt glue to the gap between the cap and the board to control vibration so the leads do not break. Try to find a local electronics store. There are a bunch of online stores. Or try this web site. https://www.mouser.com/Passive-Components/Capacitors/Aluminum-Electrolytic-Capacitors/Aluminum-Electrolytic-Capacitors-Radial-Leaded/_/N-75hqw Note on reverse install of caps. I've never done it, but one place I worked at hired a new guy and the first thing he worked on was a big audio power amp. After replacing the bridge rectifier and the electrolytic cap (inch and a half dia. by 4 inches tall ) he hit the power switch and the cap blew up and the can embedded itself in the ceiling. Just glad it was not pointed at me. The little ones pop and make a mess with the paper and foil from the inside. So, pay attention to polarity.

-

Check pin 12 on the 12 pin connector. Does in have voltage and does it go away when you pull that fuse you mentioned. The VSS is wired into the Transmission Control Unit on auto transmissions. Is this a 4EAT? Check what I posted here. There is a pic of the TCU connectors. https://www.ultimatesubaru.org/forum/topic/171518-1990-legacy-fwd-automatic-transmission-problem/ You can get the 92 FSM wiring diagrams here. http://jdmfsm.info/Auto/Japan/ I also found this. They fit 8 different models in 92. Engine Control Module Part Number: 22611AA933 Supersession(s): 22611AA930; 22611AA931; 22611AA932 I found this on one Subaru site for the 22611AA930. Production Date: 199105 - 199204 I looked up a 92 Legacy at subarupartsdepot.com and found this. SKU:22611AA933 Other Names: EGI Control Unit Description: Legacy. Without turbo, manual trans

-

Is this using the fuse holders from the 92 Legacy? If so, is it fuse 16 (15AMP) that you are pulling? That fuse feeds 12v to Pin 12 (Yellow wire) of connector B58 (ECU 12 pin connector) ONLY with the Key ON and START positions. If it is hot all the time move the source of the fuse to the IGN wire from the IGN SW. There are 2 other pins on the ECU connector B48 (22 pin connector) Pins 2 and 13 (Yellow/Red stripe) that get voltage from the IGN Relay contacts and the coil of the relay is triggered by the ECU and then kept closed with power through a diode from the alternator when the alternator is charging. Those two pins should be dead with the IGN key OFF. In case you don't know, when looking at the wiring diagrams in the FSM the connector plugs are shown looking at the pin side and numbered left to right. Looking at the wire side of the connectors it is the same row but the pin numbers are backwards right to left.

-

This link was in the article you posted earlier. It has good info on using existing wiring for the speed sensors mounted on the tranny. You can use a large as possible paperclip or a small flat jewelers screwdriver with the edge of the blade against the pin to release the tab so you can pull the pins out of the connector and put them in different holes. If you have an old unused connector experiment on it first. The tool has to be inserted on one side of the pin. There is usually a small slot for the tool. I have done that many times with electrical equipment. You may have to pry the tab back out a little so it will lock in place when inserted. https://www.subaruforester.org/threads/2005-how-to-wire-your-4eat-to-5mt-swap.414786/ For the i10, i11 thing, I would not do that. Pin 13 of i10 is the vehicle speed sensor input to the speedometer. Check out the combination meter wiring in the FSM.

- 60 replies

-

- 1

-

-

- 6 cylinder

- subaru

- (and 8 more)

-

Here is my only experience with Full Synthetic. In my 68 F100 with a 360 I used Valvoline 20W50 Racing Oil. I read an article in a car or racing magazine in the mid 70's that a German company tested every Racing Oil on the market at that time and Valvoline was the only one that did not break down using 5 different tests. They developed 2 more tests before it "started" to break down. A friend that sold AMSOIL talked me into trying their synthetic. My truck had over 100k miles on it at that time. After the first 2 tanks of gas the oil was on the full mark. After the third tank the oil was down a quart. The next tank it was down a quart. I noticed the oil looked dirty, so I changed it. I used a white rag to wipe the dipstick and I noticed that when it got dirty it would go down a quart. I changed back to the Valvoline 20W50 Racing Oil and now the truck has 221k miles on it. I quit driving it years ago when it started to smoke out one of the dual exhaust pipes. Once the piston rings are seated that is the time to switch to full synthetic. Our EJ22's have well over 200k miles on them. I use Federated synthetic blend. I was told they add chemicals to regular motor oil so they can call it a blend. In the summer I run 10W30 and in the winter I run 5w30 in them, but with both I substitute a quart of oil with a quart of Lucas engine oil treatment. It does help with oil consumption. I don't keep track of the mileage. When the oil looks dirty, I change it and the filter. For your car I see the FSM Recommends 5W30 synthetic for non-turbo and 5W30 Synthetic "Required" for turbo models. It does not mention 10W30 so, you may not be able to use it.