Step-a-toe

Members-

Posts

597 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Step-a-toe

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Running, idling used to show bang on 1.7V in its factory application but this is running in the recipient vehicle and it's slightly different electrical- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Good on you for persevering and doing the test on the knock circuit. You should find the manual describes how to test towards the back of 2.7 If you have 3.0 V instead of ~1.7V I would suggest you have an issue. If that 3.0V is read by the knock control it will retard your timing. I use an in dash Volt meter to continually monitor activity ( now). Photo shows 0.00 to indicate meter has power from ACC, IGN not on yet The knock control stuff is in a approx 1" fat black round connector leading to from the dizzy from memory. You can disconnect it and car still runs just does not have knock protection. I accidentally left mine disconnected for three months of daily driving !! No problems, possibly due to my high-octane fuel. So, to eliminate KCM from your investigation you could disconnect. Dec 86 make date makes it an 87 MY, not the 87.5 so my bet it is 3 speed auto- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Is there a make date tag on a strut tower or firewall?- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

And the E4AT as the Japanese call the 4EAT had a big fat black round connector and a bundle of wires between box and TCU The 4 speed auto also had more positions on the selector . I had both the E4AT and shifter, swapped just the shifter for a whole EA82T spider engine for parts- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Before going too far, I agree the trans or torque converter may be a worth looking at.... Is this a three speed auto or four? Three speed did not use a TCU or TCM like the four speed- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Better publish your location so others near you may be able to help by suggesting local yards, suppliers- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

If Series two you can put timing light on flywheel timing marks as an assistant selects D If knock circuit is causing problems when selecting D you will see timing step back from 20 to about 10 dbtdc- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

First up mister , have you identified this as Series One EA82T or Series Two If Series One you will find a white plastic connector with a female spade terminal with no mating plug, right at the coil. Think it is black wire with white trace Get multi meter hooked to this single white female to red lead, connect black to ground. Turn IGN on without starting should get 5V Start it, get it to op temperature All while just idling should be 1.7V, not a typo One point seven volts Now, watch DMM reading as you select D If it remains at 1.7 it is not your knock circuit causing your problem.- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

Need 1987+ EA82T Knock Sensor

Step-a-toe replied to carfreak85's topic in Old Gen.: 80's GL/DL/XT/Loyales...

You may be lucky to find a nice reusable plug with wires at a wrecking yard with a personal visit. I can't imagine them interested in doing a mail order job unless they charge a lot for their time and effort. It might be best just to I'd what female pins are needed and do a repair, possibly just filling the top of the sensor in epoxy and fitting a plug further along -

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Just thinking of Rampages suggestion... this thing stalls being shifted into D or R I think, this normally without any foot on accelerator, so throttle position do dad be doing bought but sit at idle- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

And while you are looking at TPS take note if the wiring just 30? mm from TPS has a three wire, possibly round, take off plug at all, something plugged in or not AND how many wires to TPS itself I have had three combinations I think. Also think yours may be the 86 wiring, ECU etc flapper AFM likely it is TPSwitch not TPSensor as listed in diagram above- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

Service invoice with PCV valve listed?

Step-a-toe replied to Step-a-toe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Well, we are in the 80s section and in my factory manuals it is listed for replacement as you say, every 30,000 miles / 50,000 km or every 24 months for the EA82. I think this item also appeared on the tear away single sheets out of the workshop. One of those Inspect or Replace items And in almost 40 years of being around workshops about the only time replacement occurred was non Subaru, plastic items broken. Never been asked to order an unbreakable one, never invoiced one out unless for propane conversions where steel ball poppets where swapped for plastic balled ones in case of a backfire causing a steel ball get sucked in rather than blown out. -

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Two pin plug? You might need to find a good donor plug and wires to splice to existing wires if you can't source replacement from an EFI specialist who may stock a remedy for you. If you delete the solenoid you may throw an ecu fault code. Some wire a resistor between the two pins so as not to. If you can make a blocking plate as a gasket to install between EGR and manifold, seal it also, eliminates EGR completely from your diagnosis steps- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

Service invoice with PCV valve listed?

Step-a-toe replied to Step-a-toe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I am doubting anyone has had their 30,000 , 60,000 90,000 , 120,000 mile services done by a dealer or a workshop and had their less than $5 part replaced In a doubting Thomas kind of mode Judging by the filthy exterior of all I have come across, choked up innards, I am guessing they all have the factory installed PCV valve -

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Positive crankcase valve ? Everyone needs to know where this $5 service replacement consumable is ....at the back side of inlet manifold below throttle body. It takes in all the fumes from the 5/8 ID hoses off the rocker covers and all MPFi EA82 blocks have extra take off turbo side, back of block near knock sensor. Is really just a poppet valve that normally will open on deceleration I think, sucking crank case fumey air. Can carbon up and leak air that can cause sh177y idle Also, while you are chasing problems maybe make a block off plate for EGR valve as these usually block up with soot and can cause intake throttle bypass air. I had one cause weird issues- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Supposed to be a new pump and concerns were new pump does not have a damper like original- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

PCV valve if dodgy is another throttle body air bypass How did I forget this one? Try a block off cap on its hose tail- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

Just braved the near freezing blizzard conditions nearly midnight to look at an EA81 two pin Hitachi dizzy If you hold module so the brains of it is at the five , and seven of the click position, pins facing up at you The pin on the left, 7 position is the yellow which ibelieve relates to neg terminal of coil, pin on right black wire with white or yellowing white with age at 5 click position goes to positive , I think Have you a wiring diagram to get colours to neg and POS? To confirm?

-

Rather than describe position in relation to vehicle, Maybe add a photo of the module and peeps can suggest which terminal in pic goes where. In EA models there tends to be yellow wires and black wires to the coil. I only had one EA82 dizzy with that 2 pin module that I borrowed to get a stranded EA81 running urgently so can't help

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Can you clarify a little.... Warmed to operating temp in Park. You put foot on brake pedal to select Drive or Reverse with no foot on accelerator, and she dies? Or is your accelerator feathering after Drive or Reverse selected and you go to drive off and she dies?- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

what makes a ea82t engine die?

Step-a-toe replied to subiemech85's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Maybe time to blame the auto trans components? -

what makes a ea82t engine die?

Step-a-toe replied to subiemech85's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Doesn't a worn distributor shaft bushing cause idle fluctuations? Time to unscrew the cap and give it a feel -

what makes a ea82t engine die?

Step-a-toe replied to subiemech85's topic in Old Gen.: 80's GL/DL/XT/Loyales...

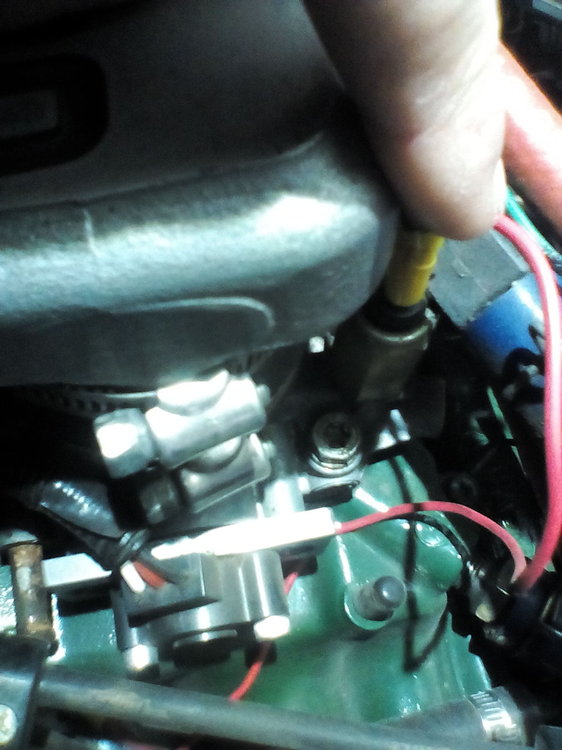

Idle air control Valve Sort of have two with that function and you have blocked the first one off being the jigger on the thermostat Your second is on the dizzy side at the back of TB next to the screw you removed and cleaned. Some years had a two wire solenoid, one being for an earth. Pictured is my single wire unit. These really only increase revs a little to cope with load when AC is on. I don't think these turned on under power steering pump load. I use mine just for a faster idle on start up in colder months below 5°C with dedicated propane Impco fuel system. Just read the rest of your post The one a post describes as being under or behind PS pump is likely for the spider inlet as these deleted the thermostat mounted cold starting bypass valve. Have we discussed fuel pressure and injector cleanliness? Timing? You have covered: egr valve trans vac line idle air adjust screw fast idle control solenoid cold start air bypass on thermostat Pretty much it except the vac line from front of throttle to distributor vac advance can. Every one of these I have had have not held vacuum and inturn won't retard timing on boost. With propane air mix in my inlet I used to blow a little charge into the distributor body, match ( no pun yet) this with a little spark that was supposed to hop from rotor button to terminal inside, I didn't get boost , I got BOOM ! Took five months to resolve, marshmallow valve springs got initial blame -

Transmission Rebuild?

Step-a-toe replied to nontrivial's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I hate all the surprises you get pulling these apart. My first one I bypassed the thin wall socket and used a jigsaw to cut my way through Dont lose hope in finding a nice box. I had one make way for the EA82 5MT DR was as sweet as with 249,000 km sold it to a local