Step-a-toe

Members-

Posts

597 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Step-a-toe

-

1991 Subaru Loyale wagon 4wd

Step-a-toe replied to primosoup's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Take good notes of the health of the three speed auto before removing , strap to a shipping pallet and advertise it for sale. Might not get much but could help out another less fortunate old Subie -

EA82 10.0:1 compression ratio

Step-a-toe replied to Step-a-toe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

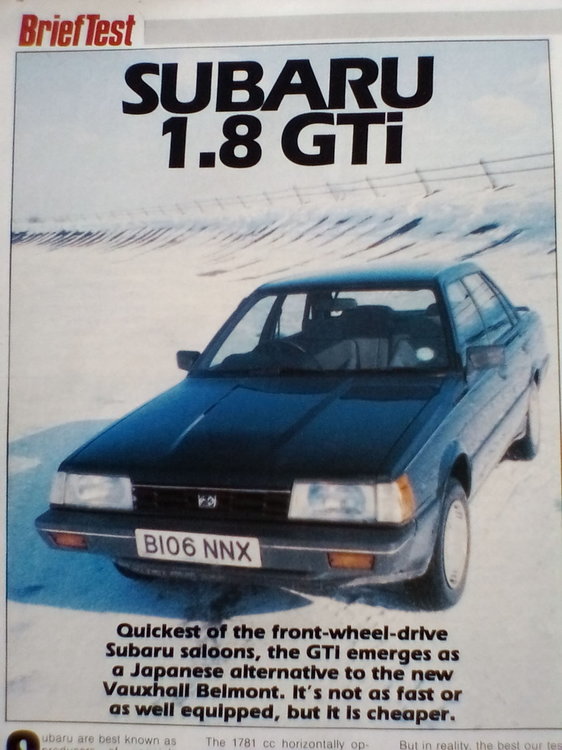

UK Motor magazine did a review in early 1986 GTi marketing designation raises a little excitement It is sedan, FWD MPFi, 5MT, PS, 4 wheel disc brakes !! RX style boot spoiler and front chin too 10.0:1 ...error ? It is the highest comp figure I have ever seen quoted for EA82

-

EA81 oil pump autopsy

Step-a-toe replied to Step-a-toe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Like a dry sump rally set up? -

EA81 oil pump autopsy

Step-a-toe replied to Step-a-toe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

If desperate, I reckon a machinist would trim a little off the pump end, fit a sintered bronze bushing in pump body .. -

EA81 oil pump autopsy

Step-a-toe replied to Step-a-toe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Need to set up the studio for pics -

The worst one I have seen to date I can see wear from the cam drive The other end of its drive shaft has been scratched up wearing into the housing and the other rotating parts much the same The O rings, evolved into flat and square cross sections as expected. I wonder if I should still save it for someone in desperate need to keep a junker running. The housings are not broken at least. Apply within

-

Anyone done rebuild or rebuild blog on these? Guessing it has been easier to just bring another in, foregoing the odo difference My very first Brumby had 088,000 on it forever until the speed indicator also crapped out. Always thought it had near 700,000 km on it when I got it, maybe it had turned around once already? The wear and tear on the seat belt, floor mat, brake pedal rubber and dashtop was sunburnt to billy-o She was on her second engine, second gearbox... It lived in northern NSW where the heat would have been harsh on the speedo gear grease on the nylon cogs that I think drive the odo cogs rather than speed needle Melted grease, dried out and chewed out just like the one I got some time back 149,000 km. I coaxed the grease back into the nylon cogs and got another 3000 km before she stopped accumulating figures continuously Curious if Nissan of same era had speedo units that parts could be pilfered from. But being Nissan, that'd be rarer than same era Subes Small main axle on speedo seems to be first hurdle where it is crimped into place. Bettin' it breaks on remove and refit

-

Factory manual, what section chapter and page? I have full 86 manuals and for 87 I have 2,3 and 6 What is the 7th letter of your VIN? And what is the 11th character?

-

ECU BLOWN? Cranks but no power?

Step-a-toe replied to JSIMONIS97's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Hey hey !! You will do it again. Partly our fault for not digging deeper on every step you undertook to change what Fuji got right And photos. We need to ask for photos each time. Now that you have it, shouldn't need to undo things for some time. Take a tip from me if you like...get those coloured cable ties about 100 mm long. Red for #1 , blue for two, grEEn for thrEE, yellow for four Zip around dizzy posts and both ends of HT lead Then trim excess Seeing that Weber makes me want for a carbed, wet fuelled engine again to try my Weber on one day -

Have to say I have not heard of our Subarus having a 4 speed auto in just FWD.Obviously I have not read what you have about these ! Count your gears as you go through them manually or slf shift I reckon you will have three forward gears. The four speed only began with electronic intervention and from memory you would have quite a fat electrical connector going to trans, and transmission in fuse panel? What gets me is how and when the E4AT name changed to 4EAT ?? I have seen sales brochures in Japanese and the only characters I could make out was E4AT

-

That won't happen, I likely read it on the 'net it may have been a review in the day ....

-

Funny you mention the lock up function as I think I was surprised to read somewhere recently that these are a lock up converter. I could be wrong but would not have been reading about anything else.

-

Interior door handle bezels still available.

Step-a-toe replied to Subaru Scott's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Find someone who has a 3D printer as someone has created a file to print them, left and right you would hope, thingyverse has file I believe -

1991 Loyale tranny replacement

Step-a-toe replied to elessar's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The beauty about the 3AT is its lack of electrical bits to deal with. And an engine from an auto suffers less in the thrust bearings in the crank Dept compared to a manual. I coulda swore someone did a leak seal additive for auto trans and power steering??? Where's it gonna leak? Rear seal Front seal(s) Pan gasket vacuum modulator on the side? selector shaft seal no need to go buy another car unless it is a donor you can test drive the desired parts first every automatic I have owned has been converted to manual. Never been unreliable, never broken and I have never on-sold except for scrap so I see them as worthless, so should many others The secret to the longevity of the EAs is their under powered nature -

Don't use CV in association with rear in search because only our fronts use a CV joint on the outer to allow for steering- unless you have four wheel steer ?? Double offset joint DOJ inner on fronts, both ends on rear Time for me to check locally as some have said rear shafts are available through nationwide parts supplier

-

Going on twelve months here.... Crude I know, if you can physically hold throttle by hand, against its throttle stop and still have its idle crazy it won't be the throttle plate adjustment. It almost needs to be fast idle control circuit or a device within it Or EGR make a block off plate for diagnostic needs. I had wicked idle and performance issues until I blocked off then replaced MPFi EGR Or brake vacuum booster is another source for a fast idle air control ..comes under vacuum leak suggestion Get some caps to blank off all possible vacuum leaks to inlet manifold only while not driving it of course Vacuum leaks don't really often? cause big idle rev differences with smooth idle, more rough idle

-

Nice presentation of your adaptation. I went through three or four and gave Up. Mounted my 0-5V gauge instead to monitor knock sensor, only for the sun to buckle it's screen

-

ECU BLOWN? Cranks but no power?

Step-a-toe replied to JSIMONIS97's topic in Old Gen.: 80's GL/DL/XT/Loyales...

You mean you failed to tell us you hooked up pump fuel lines in reverse order?? 50/50 chance of getting right There is probably a person out of a job fitting big red arrow stickers on pumps because the bosses felt it was an unnecessary cost ! You are not the first or last to need another's input to help you realise you stuffed up. Now you need to enter Rockauto repair mistakes and blunders monthly competition -

Cranks and wont start

Step-a-toe replied to Arthur Digby Sellers's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Yep. Start with new thread, new descriptive title The "mechanic" impressed owner worked it out? -

4/87 XT Vortex hi beam = no lights

Step-a-toe replied to Step-a-toe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Hmm, only high beam for both sides sounds like switching mechanisms ....pulled my other Vortex (FWD turbo wreck) apart thinking much like an MY 4WD DR box - never to go back together !! The wiring is jammed in there up the steering column and the plastics tricky, fiddly and delicate. I have two paperback sections of US print 87 manuals 2 and 6 from memory Also full volumes of 85 that includes Vortex And somewhere is a new combo switch so got some work to get through...checking the intro conversion loom and relays thanks Ido.. -

4/87 XT Vortex hi beam = no lights

Step-a-toe replied to Step-a-toe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Low beams worked fine until selected high beam The high beam indicator in dash did not illuminate Ido, two headlamp relays Is it one for both sides low beam, the other for both sides high? This baby is very tidying the wiring, never molested until I got it with 172,000 km and then the conversion loom installed rather fastidiously. I need to get the battery cable sorted before I do any more sleuthing Do you know if the relays are NC? Owned 20 ? I have only ever seen 12, just thought of another, and another ....14 in 35 years ! -

Back story is LED headlight inserts from local 4*4 lighting genius and his conversion loom for the LED to function Maybe now two years since installed, driving at night on low beam, switch on hi and suddenly darkness just the other night Not sure if I just switched back to low beam in a panic ( was in Kangaroo Alley ! ). or if I had to lights off and down and back up to get them on. Coincidentally the old resurrected battery no longer holds charge so it is now out, replacement needs cable mods before I can test lights again Speaking to mate says pre led days the relays can sort of ash up contacts as the work harden? Fine for lights with load, but LED bit finicky and may not be up to the task Went looking at LHD drawings to suggest headlight relays just up near accelerator cable meets pedal Two round ND relays , one green socket, other white socket Have half tested them. Seem to be a NC relay Not blaming the new relays in conversion loom or anything else. Anyone similar experience?