Step-a-toe

Members-

Posts

597 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Step-a-toe

-

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

So when Cycle Guy comes back with a photo of his with pointer at middle of the three soldiers lll , rotor about 5 o'clock, position..... Number one lead on cap should be closest to firewall yeah? -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Appearances can be deceptive It is a complete set of 85&86 manuals in two volumes and if I put them randomly on the shelves of local dealers library hidden in the back of the store room - you would be hard pressed to find them quickly ! it is demonstrating some markets got different components, at different times -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

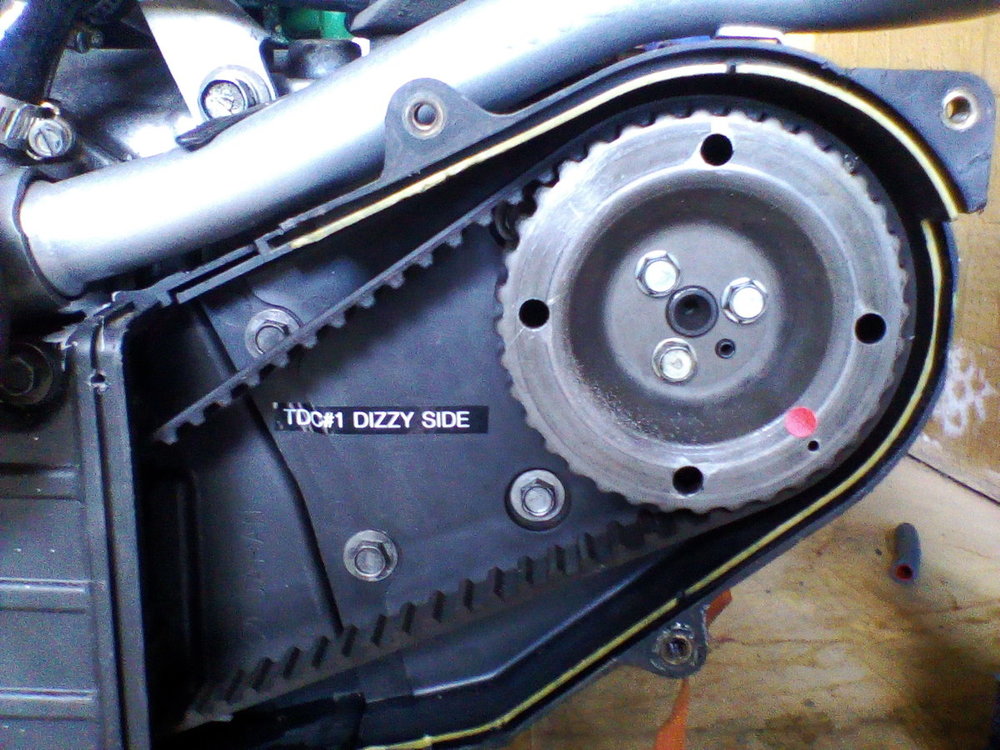

Yep, the photo of installed dizzy shown at 20° is of EA82T Series One flapper afm for both 85&86 models years. Part number for Australian GLTA and RX is 22100AA063 with the four pin module and the boost retard/ vacuum advance diaphragm cannister. Photos are of how I worked out to set things up and took photos for memory jog or share. I like your method, taking advantage of the " no valve spring tension spot" I think it is so as not for them to cause engine to rotate things out of place while delicate procedure in place -

Questions about weber 32/36

Step-a-toe replied to Rafavidmess's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Oh and because the air filter bottom plate has such a tiny PCV fitting, and too close to air filter element I think? I would use or make a catch can to duct both rocker cover tubes to in their 16 mm ID , run same size hose from catch can to PCV valve and run smaller, more compliant or willing 10 mm ID hose to air filter with an easy to disconnect type of fitting to the air casing plate -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

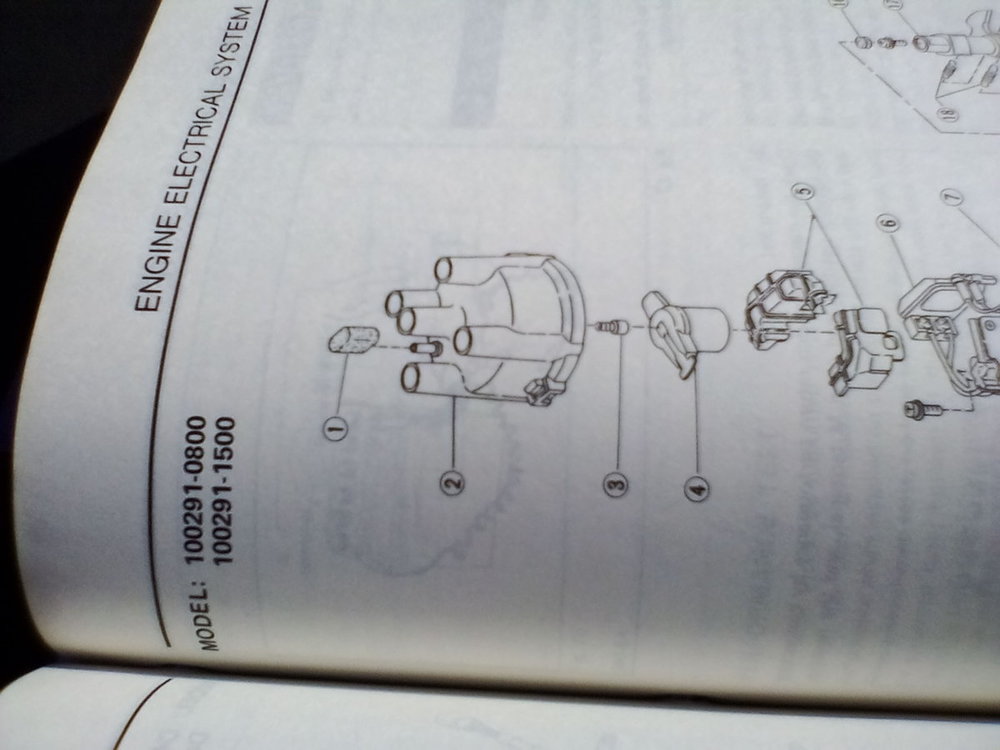

My 85,86 FSM has a full page sketch of a ND dizzy that looks just like yours in the photo Cycle Guy Part number top left likely to be found on green foil sticker under 5 mm of black crud -

Questions about weber 32/36

Step-a-toe replied to Rafavidmess's topic in Old Gen.: 80's GL/DL/XT/Loyales...

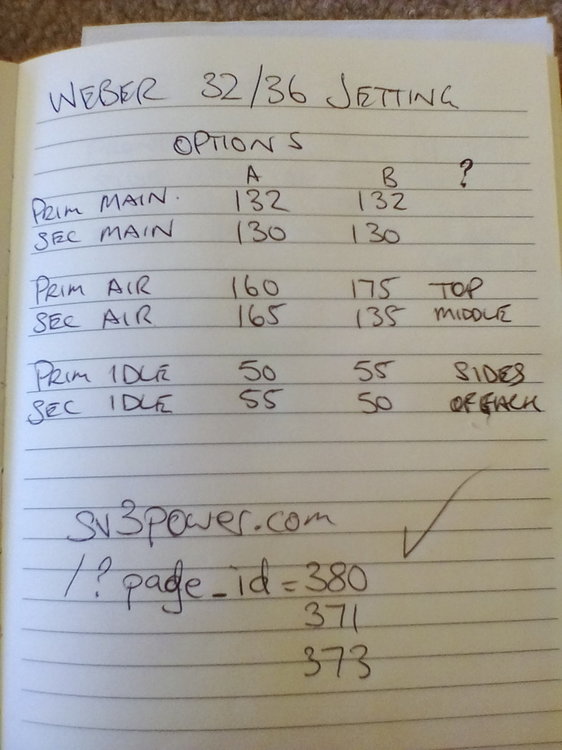

Electric choke is what you imagine although if I have seen one on a Weber, taken no notice. I started in cable choked cars and that is my preference for chokes. I had exhaust temp ducted air style, hated trying to set up without instruction. Seen coolant controlled chokes - at their worst only of course. The Weber 32/36 has manual choke with cable in either basic or option I believe The Weber purchased for a 1200 cc Corolla, we assumed seller had jetted it to suit, but reading online somewhere of jetting supplied basically for 32/36 for non specific application was same as we got. Below is photo of jet sizes for EA81 1800 cc -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Scoobydude , you say cycle guys pic is not of an 86 dizzy but I get the feeling because all XT were MPFi they may have got different components to other EA82 models, or said in another way, the XT may have got some components earlier than other models? I have an 85,86 fwd carby non XT dizzy somewhere that is a small, single module with two pins so likely Hitachi, clip on cap The first XT I kept revisiting the idea to buy had the twin vac cans on the dizzy, think it was ND (Nippon Denso) pretty sure it was the 85&86 models. Just could not fathom the poor state it was in, greedy wrecker wanted too much for it , I kept going back to look in wonderment , wrecker kept revaluing it due to my interest i am confused with your 5 clock position !! -

Hmm, thanks for finishing off a question. That new carb may need a bit of a check over. Helped a mate sort tuning issues with a new Weber bought as a specific set up. It would have helped if supplier included or offered for few extra bucks at time of ordering, a jet either side of their 'chosen' jet for fine tuning same day as fitment. Can't visualise it at present but there was an air bleed or adjust mixture screw externally, up high ish ? that was sucking in air ? was only finger tight or needed some sort of resistance to keep it in place. I think just screwing it in resolved issue #1, next size up main jet sorted drive issue, once little blighted arrived in mail Then it was snorty time, to see front of car lift as foot was put down at 80 kph on the little 1200 cc , induction roar as secondary opened up. The owner in her 70s very pleased compared to old factory thing in her 'rolla

-

want two hitachi carburetors for my Brat

Step-a-toe replied to old sub freak's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Well, back before EFI or mechanical fi , more carbs looked better than one sounded better and drove better right up the rev range. So at about 130 kph the loud pedal was only lightly squeezed instead of mashed to the floor and felt like had so much more to go -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

-

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Different dizzy - flapper style turbo Hitachi at 20° Looks about half between 12 and 1 When same dizzy as yours fitted, set at 20° BTDC was definitely closer to 2 position -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Boy your LHD hill holders are close!! Would you say that at TDC the centre line of rotor is parallel with line of cam box, block etc? Hard to see -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Aha, Denso , looks just like the spring clip retained cap style on my 87 carbed touring wagon. Seen them expressed as twin module, and here I was thinking MPFi governs that they have screw down cap ! Now another pic at 20° BTDC please! Just remembered my use of this dizzy is not in engine as I trialled Hitachi knock control set up before engine came out so I cannot show you comparison photo. Anyone running this Denso could do it though, any takers? -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

And just for fun Cycle Guy, one of my EA82 I dubbed EA82M for Mongrel is carb block, turbo MPFi heads, cams, flat intake manifold as opposed to spider intake, carby dizzy and fuelled by Impco propane only - idles and runs best for me set at 22° BTDC instead of 6 or 8 !! -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Better look harder at dizzy as it must have an electrical connection ! -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Ok , this sounds just like the setup I have seen on NA XT downunder. I have had much same but turbo myself to tinker with ...the dizzy is not one I have had but suspect it is two wire, two pin ignition module under the cap being non turbo fwd. I could be wrong. Just may also help for the collective us to know Hitachi or Denso dizzy and what is inside cap module wise. Worldwide there was 20 different ECU part numbers for EA82, and I have had four very different distributors, know yours to be a fifth.... They may physically sit different at TDC or timing marks , to each other ....I am thinking photo time....you set at #1 TDC or maybe 10° BTDC and take photo of dizzy rotor , cap removed -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Optical dizzy has no spring load feel if you turn rotor one way or other against fix position and from memory a metal cover plate below rotor so you see nothing else. Has no vac can on side either Your ecu is under parcel shelf at rear seen by popping boot trunk lid and stuffing small child in to inspect number of plugs and ecu part numbers -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Ok. Don't know EGR, or don't know why I suggested it? Not sure myself I have had issue with innards chocked With carbon, valve stuck open causing a run problem but not a timing problem Ok, flapper so should be vac can on side of dizzy so total timing and advance control via dizzy so does not need any electrical plugs changed. Just vac hose off dizzy and plugged so no vac leaks Trying to think here on positions of things as I have applied to get things started. On my flapper EA82T I have Hitachi distributor and non turbo using a carb dizzy that is Denso - in same car. In the same set flywheel position at 20°BTDC, the rotor button points squarely at the firewall for the Hitachi, call it 12 o'clock and the trigger parts aligned almost, think I slide @ feeler gauge between two components Yet, with NA engine at 20° the Denso rotor points more about 2 o'clock position -

CEL and rough idle when pointed downhill

Step-a-toe replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

And vehicle suggestion?? If it has oxy sensor and you lean out going downhill, foot off pedal the CEL light can come on to indicate a lean afr detected about 29:1 , goes away on normal driving. Not seen rough idle I conjunction though -

86 Subaru Xt water pump tube

Step-a-toe replied to Blooroo86xtGL's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Might be worth getting them electroplated ? -

Getting wheels cleaned and powdered ?

Step-a-toe replied to bratboy1's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Not too many choices in powder colours is there? -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

OK compression test time egr functioning and clean inside? then what about all the PCV tubes n breathers? -

EA82 timing driving me crazy

Step-a-toe replied to The Cycle Guy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

With the MPFi and green plugs connected or disconnected, is there a difference in the timing? Reading off the flywheel? With the flapper style should be a three plug ecu and no wire connector to connect/ disconnect surely when setting timing ? All the timing is mechanical and vacuum surely ? Or have you got flapper afm, optical dizzy and four plug ecu? Think only time I altered the green plugs was for an error scan reading red led on ECU -

'80-'84 part numbers

Step-a-toe replied to Dwayne Oxford's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I can't help with genuine part numbers but I have bought the correct module for Hitachi module every time aftermarket. The same was in early fwd EA82 carb and seems like a few other makes and models...Honda Might not work in other listings but Bosch did BIC 290 Coil for these Hitachi Just a thought, if U go into Rockauto and find part, info often has genuine part number listed