Step-a-toe

Members-

Posts

597 -

Joined

-

Last visited

-

Days Won

9

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Step-a-toe

-

1981 Subaru FWD won't start.

Step-a-toe replied to spamanon's topic in Old Gen.: 80's GL/DL/XT/Loyales...

WHOO HOO ! Black smoke is from a richer than 14.7 lbs of air to one pound of fuel ....14.7:1 Air Fuel ratio We often need richer to get them started first thing each day or once engine has cooled down to ambient Closing the top valve, butterfly, choke plate either by pull cable, E!ectric element, bimetal coil spring reduces the air going in, increases the fuel ratio so number goes down say 10.5:1 air to fuel Black smoke from rich mix could just be from all the fuel sitting in the manifold (inlet) floor. Does it continue to run like it is now drawing on metered fuel via tank, pump,filter, carby? Or will it? Will it restart for you without chucking fuel down either carb barrel? -

1981 Subaru FWD won't start.

Step-a-toe replied to spamanon's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Do you know how to test the ignition coil with multimeter? -

1981 Subaru FWD won't start.

Step-a-toe replied to spamanon's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Just thinking out loud, reflecting on all my no starts or stops in EA81 Fuel line needed a compressed air blast. Started from front to tank pick up, one steel line section at a time. The final blast was initially ( there is that word I missed earlier !) initially met with some resistance. Finally, with tank empty and sparkling inside, sender removed, I heard a release, THUNK, as crusty crud landed on the floor of the tank. Mopped it out on the end of a coat hanger and rag. New rubber fuel hoses everywhere. Problem fixed . Yeeha!! But in the meanwhile I had just bought it running fine, then problem developed. Just start but no drive power. I replaced every consumable, I kitted the carby, fitted a new and noisy fuel pump and it still intermittently failed me mainly at 4am end of shifts. I was determined to keep this new 4x4 wheel barrow - 22 years ago this October long weekend I bought it !! Figured out now why last owner sold it. They fitted low km import engine, another gearbox, roof and painted it up for mums farm to city runabout. They even overhauled the dizzy....then gave up and offered it for sale on warm days, not cool nights where I think crud stuck together better Battery cables looked good but oxidising up alloy cables needed a clean. Battery terminals needed a clean Fusible link corroded equalled no cranking Coil tower build up of corrosion fluff, no start Ran out of fuel, no start Dead alternators flattened batteries Corroded Welch plugs, buttermilk , steam engine Failing dizzy modules, gave hard starts as a hint they were gonna go soon -

1981 Subaru FWD won't start.

Step-a-toe replied to spamanon's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Oh, my apologies I missed the word "initially" This was when you had it running, it had some problems. I got you now, that was mentioned as a but of history -

1981 Subaru FWD won't start.

Step-a-toe replied to spamanon's topic in Old Gen.: 80's GL/DL/XT/Loyales...

So, what is a gas filter cover, not a fuel filter cover then if you are still to find -

1981 Subaru FWD won't start.

Step-a-toe replied to spamanon's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I missed the post where you found the fuel filter....behind a cover? Now it is no longer a no start thread, you say no longer dying at idle??? -

Timing Belts/Kit '88 EA82 Tricks or Tips?

Step-a-toe replied to subaru1988's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I made a tool from a spare pulley, M6 bolts poke through into same holes on fitted pulley, 17 mm nut and bolt tight up on centre hole. -

1981 Subaru FWD won't start.

Step-a-toe replied to spamanon's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Holding this thought, ashing is just of contact points surface so you can see a gap, no debris just no electric conduct. At least no pitting of the points. I learnt ashing in my 68 Ford, started for me to get to work, go for lunch by the lake, but not to start until old old school mechanic boss swiped some emery paper between them and she fired right up -

1981 Subaru FWD won't start.

Step-a-toe replied to spamanon's topic in Old Gen.: 80's GL/DL/XT/Loyales...

It does not need to spray fuel from pump circuit in order to start but this will be a problem to drive safely, normally Leaking is a problem, but usually not starting issue. If you can get it started it may not leak or flood. That porthole meant to be viewed level. Looked under dizzy cap for points. At points? -

1981 Subaru FWD won't start.

Step-a-toe replied to spamanon's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Hitachi have a porthole shaped window on one side or end of the float chamber of the carby so if clean you can physically see the level the fuel is at at the time Should see a dot etched in the centre marking desired level, running or not -

Right pull persisting after alignment+tires

Step-a-toe replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Now that is getting down to the Nitty gritty of diagnosis ! -

Right pull persisting after alignment+tires

Step-a-toe replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

If you jack front end up, place stands or blocks under the lower control arms so you can turn full lock to lock by hand to see if you can pick something binding -

1981 Subaru FWD won't start.

Step-a-toe replied to spamanon's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Compression , compression, compression Kettering ignition - points can close up the gap as rubbing block wears down against the lobes on dizzy shaft Or can also ash up , have the fingernail thick gap but not work as intended. A points file to dress up contacts if ashing is the case On the fuel filter location - is the fuel pump up front near left bonnet hinge? -

Timing Belts/Kit '88 EA82 Tricks or Tips?

Step-a-toe replied to subaru1988's topic in Old Gen.: 80's GL/DL/XT/Loyales...

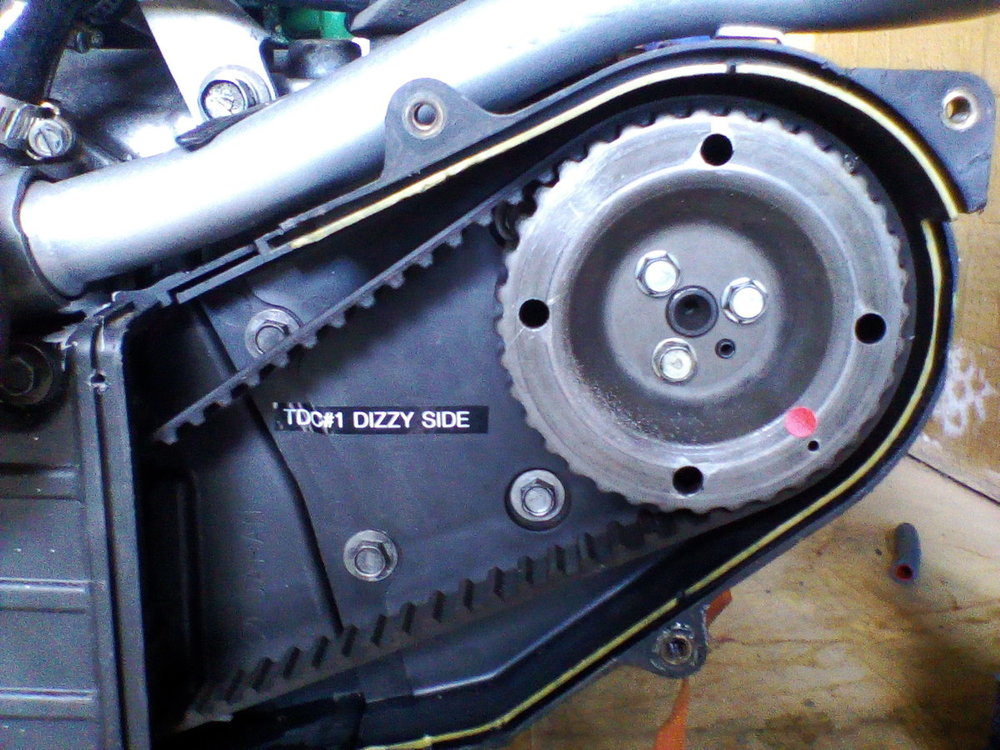

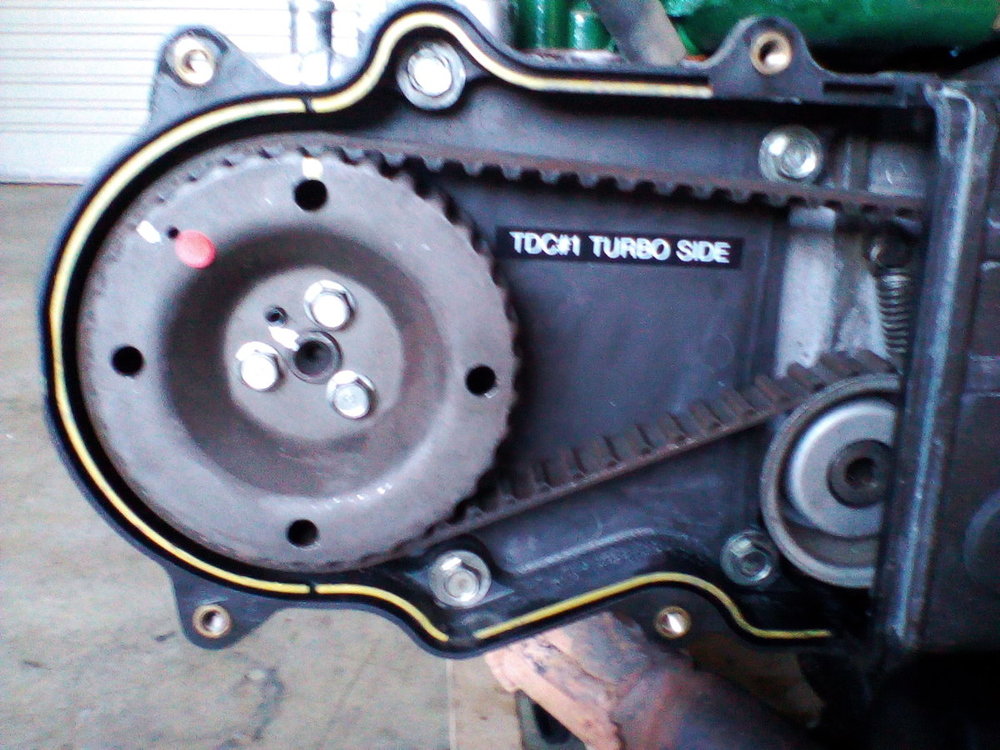

The cam belt wheel has 36 teeth , convenient when full circle is 360° and you can divide by 10 If I think about it I have never counted the crank wheel but guessing theory suggests 18? to get the 1:2 or 2:1 thing So if your covers are grubby and not melted, a steel rule applied to the line of the head to cam carrier housing should line right through centre of those two larger holes when on TDC#1 and looking at small single holes each side should be 180° difference between dizzy side and turbo side. Dizzy should look like mine and #1 cap post and lead the closest to firewall, almost like 12 o'clock position looking from radiator -

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

you are at the point where I used to say convert to a manual box , mainly for not understanding automatics. Have you AC ? Thinking if you have it on to add small load to engine, twerk PS at same time to add bit more load to see if these alone mimick same when D or R is selected.- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

welcome to page 3 folks... Is this baby happy to rev up and down in N or P? No hesitation? Feel like doing a manual conversion?- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

Timing Belts/Kit '88 EA82 Tricks or Tips?

Step-a-toe replied to subaru1988's topic in Old Gen.: 80's GL/DL/XT/Loyales...

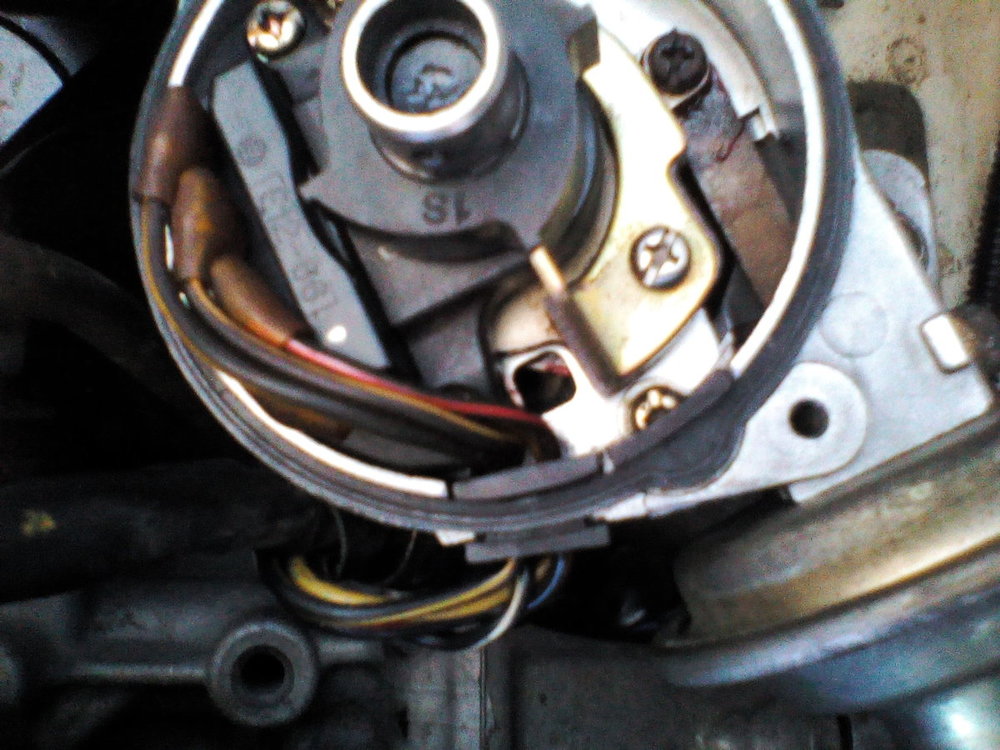

This is how things line up under dizzy cap and two pics above with flywheel at 20° mark .Starts first time for me, then adjust with timing light at correct revs etc -

Timing Belts/Kit '88 EA82 Tricks or Tips?

Step-a-toe replied to subaru1988's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I should have written instructions at the time I took these pics some years ago. They were not for setting belts now I recall. It is for setting the Series One dizzy. So, as labels state, these are at #1 TDC not 20° as stated an hour ago You can see the cut outs where the gold marker outline skips on the plastic belt backings. These are dead line ball with where can carrier body sits on head, so this must be the line guys use when they run naked belts. Where I put red stickers to indicate the ~3mm hole - these holes are observed opposite each other in these pics and when installing timing belts and cheating by not doing the one full flywheel revolution between belts. So I think when the three soldiers lll are lined up on the middle brother, dizzy side is tiny hole dead at six o'clock, turbo side dead at 12 Do one full rotate to check tiny holes opposite each other again, switching the 12 and 6 clock positions. When in these pictures positions, I have one more pic for how Series One dizzy should look and there is about a 25 though "gap" before the two bits line up -

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Knock circuit earthing goes on at the inlet manifold, centrally, dizzy side, behind the TB. Maybe scrub it back to new- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

Timing Belts/Kit '88 EA82 Tricks or Tips?

Step-a-toe replied to subaru1988's topic in Old Gen.: 80's GL/DL/XT/Loyales...

About only time dizzy needs readjust is if it has had adjustment to make up the tune due to slack or stretched timing belts -

Upper rear differential bushing

Step-a-toe replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Nice work. Interesting to see you use the Australian idea of milk crate ! -

87 XT idle issues. Dies when in gear.

Step-a-toe replied to SiriusBlack's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Are you using a factory manual? If you are, find the diagnostic flow chart to see what it suggests. Someone found these two pin knock sensors on eBay in last year for ten bucks. To buy one here from dealer I think was about $900 ten years ago. I looked through the auto trans diagnostics for your symptoms of three speed auto - nothing- 82 replies

-

- idle issues

- 87

-

(and 2 more)

Tagged with:

-

Timing Belts/Kit '88 EA82 Tricks or Tips?

Step-a-toe replied to subaru1988's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I am surprised Bennie gave three lines before plugging an EJ conversion ! Are EJs free spinners? IE no bendy valves if belt slips or breaks