Steptoe's photos

Members-

Posts

359 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Steptoe's photos

-

Maybe I should start with my first suspicion.... distributor to loom connector plug I think the stand-out individual 87.5 model had black round 4 wire connection plugs to set them apart from 88 onwards that are white I suspect some 88 onwards owners out there can be as funny as myself and suggest that theirs are black coz they are so dirty I would appreciate anyone's input My upcoming task is in prep for propane (LPG) becoming harder to obtain. Prices have been reasonably stable compared to wet fuels in the past year. It is the availability of it - part of which is tanker driver participation, another part is the bottle filling industry keeps their customers priority over fuel station supply I run a Series 1 EA82T ( normally Series 1 3 plug ECU) exclusively on propane LPG , so no ECU or wiring loom, just the stand alone distributor and knock system. I have found a spider intake with it's plugs. I do not know if it is 87.5 Series 2, 4 plug ECU or the more common 88 onwards Series 2, 4 plug's intake I have also found a complete XT loom, from the ECU plugs to the engine plugs on the spider intake. Again, not know if it is 87.5 (Series 1 of the 4 plug ECU) or 88 onwards 2 Fortunately I have an NA 1989 mpfi series 2 , 4 plug ECU with pig tails of the loom to compare with my XT loom The fourth plug with bigger pins, of the loom has one extra wire (green) over the known NA 4 plug ECU - so think the loom is turbo another think the loom is turbo is it looks to have three round plugs for boost control and maybe that resistor thing for injectors ? I have another ECU from a 1988 or 89 XT turbo further searches should reveal an answer to top question when i find a distributor. I was gonna go EJ and had found a donor but owner now seems reluctant to communicate , so may have sold it. Don't know ....so i thought why not go through the pain of wiring up an EA82T for wet fuel.....as I have a fully rebuilt spare and other spare bits .... means no exhaust or colling changes

-

Driveline angles 81' wagon

Steptoe's photos replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

some older and wiser dudes say not necessary to pay for tailshaft balancing. They suggest hose clamp pair fitted next to each other and shift the difference between the worm drive body of the clamp closer and further apart each time to see if a difference happens. Not sure if my leg being pulled ... never tried it -

I have done three or four different seats into the EA81 2 door body and happy to say the last was the easiest and most straightforward ( though it took me three years to make a small improvement on things ) Almost same family Su....zuki Swift. I got 2007 model, and lucky for us they seemed to make the same thing, likely with subtle differences that might upset those flogging the front seats - for what seems a decade. I finally saw why I was a little too close to the hood lining in the mornings and now have heaps of air above at nearly 6'2" Simply remove Suzuki sliders, bolt Subaru slider on at the front in order to mark hole for rear, using factory Subaru slider fitting hole - making sure your centres will match the factory centres of bolt holes in floor as there is a few 3-5 mm difference. I got some wriggle room from filing a flat out of thread of bolt between Subaru slider rail and Suzuke seat holes mate. Once sliders mounted, use height adjuster to get to lowest setting. The line where Subaru meets Suzuki, is where you must trim the side skirt plastic from front to back on the outer side. So, looking from top side, the skirt is flat, vertical, then takes a 45 ish degree chamfer outward. This is close approx or where you trim, is quite a bit... On the inner side, I quite crudely removed Suzuki plastic skirt where the seat belt stalk mounting was hitting seat, making install tricky. Very comfortable. Dont forget to post up your battery conversion steps As for your shifter boot - go see an upholsterer ?

-

Driveline angles 81' wagon

Steptoe's photos replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

My understanding of "blueprinting" is ensuring everything is to factory specs. Engines used to also be described as balanced and blue printed. My first job got me a little too close to a mechanic who grew up with a very gifted engineer father - late 70s, early 80s , built his own fuel injection system management for under bonnet supercharger. I used to get hotting up technical stuff flying about the shop daily. It was better for me than the mechanic before - I had a calculator fly past the back of my head as I was at the balancer - batteries and bits everywhere as it hit the wall ! He didn't see me there, and apologised -

Driveline angles 81' wagon

Steptoe's photos replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

gosh, you'd hope that a tailshaft shop did the 90 degree offset between each end ! and skishop, that sounds like a plausible theory, explained well ! and disconnecting rear drive from the tailshaft also takes that torque tightening out. I used to find tailshaft issues always went quieter when the rear drive engaged, adding some torque from the back end. FWD sort of left things a little looser to rattle and vibrate. off to google a cardan joint ..... -

Question about Vapor Canister Lines

Steptoe's photos replied to SaltyMike's topic in Old Gen.: 80's GL/DL/XT/Loyales...

did you hook up PCV hoses to a standard air filter casing seen on Weber conversions? I have always hated the way the filter element inner rib seal loses it's seal to make way for a 10/mm inlet ID right under the corner that seems to be blocked by about 50%. An absolute pet hate- sorry. I tossed a redline fitting due to its wear and tear over the decades, filter and plates will be next. Got a Pierce style or original cast, finned plenum to do remote filter. Comes with a bigger filter mounting area so not a pain to get PCV in if going in at this point. I will likely feed in at remote air filter box. -

Driveline angles 81' wagon

Steptoe's photos replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Sam, I have done a litttle further than yourself at this stage, not chasing anything - from memory I went as far as removing the tailshaft, so it and the rear diff, mo bar , axles, removed 36 kg and 4WD function too I should add. I used the front cut of a tail shaft, just rear of the welch plug bung at rear of splined tube. As I am not even a machinist's bum * I set to work to remove unnecessary bulk by bench grinder, so I had a tailshaft end of box plug. I made a crude bracket to bolt across the spare holes in floor either side with a bracket going up, bolt through bracket in same plane as tailshaft normally is and a rubber blank off plug on the end of the bolt. If the box plug, former front yoke started to drift out of the box, the rubber buffer stopped it going any further. I now had a 10 speed FWD. It was fun to drive, nose would pick up on acceleration. Your EA81 twin (exhaust) port would be more lethal than my EA82 twin (intake) port, so watch the power if you try it. -

2022 Various Parts Availability

Steptoe's photos replied to 1980ea71Brat's topic in Old Gen.: 80's GL/DL/XT/Loyales...

was the sub dealer maybe bluffing? If he can find a part number is a good start. you need to know if he has a part number to start his order. If it turns out he not even have part number, he may be able to order if you can supply part numbers for gearbox bits. Some may need to be ordered from japan. -

Clutch won't engage.

Steptoe's photos replied to Espey16's topic in Old Gen.: 80's GL/DL/XT/Loyales...

after three pages ...about time you sorted it another case of 2+2 = 5 my mechanic mate quotes. So, well done, for not giving up As to non stock TPS, what did you fit in place of the stock one ? -

Clutch won't engage.

Steptoe's photos replied to Espey16's topic in Old Gen.: 80's GL/DL/XT/Loyales...

it is now tomorrow..... -

Clutch won't engage.

Steptoe's photos replied to Espey16's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Have you measured the step difference between the two surfaces? EA81 had different step to EA82. One is 21mm the other 23mm. I forget which is which. I wonder if same happened to machine shop guy ? -

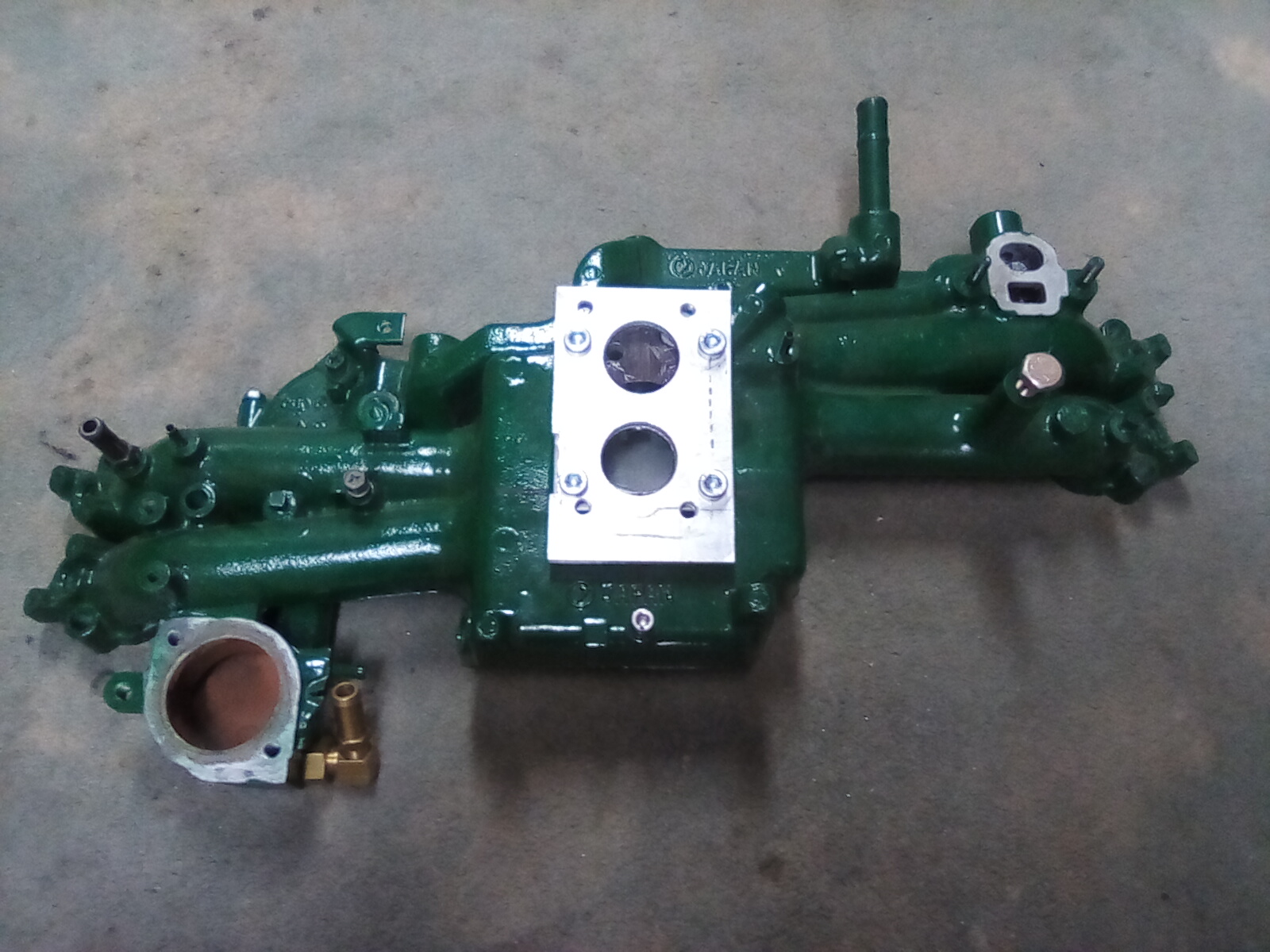

This continues to be do-able, sort of can't wait until all the six stars align and it is ready. If anything, these pics might inspire other EA82 tinkerers to consider or even beat me to it. An original TB gasket will provide and outline trace for the underside gasket and I think a normal Weber base gasket will do for the upper gasket. I can stash this with my EA82 spfi intake I was modifying to stuff onto an EA81 with an EA82 turbo exhaust and turbo. I might have to get onto that idea before LPG becomes too hard to get ! I have my eye on a few old Brumbies about the place, looking a little unloved, so who knows. I have more different engine combinations than I have cars to put them in

-

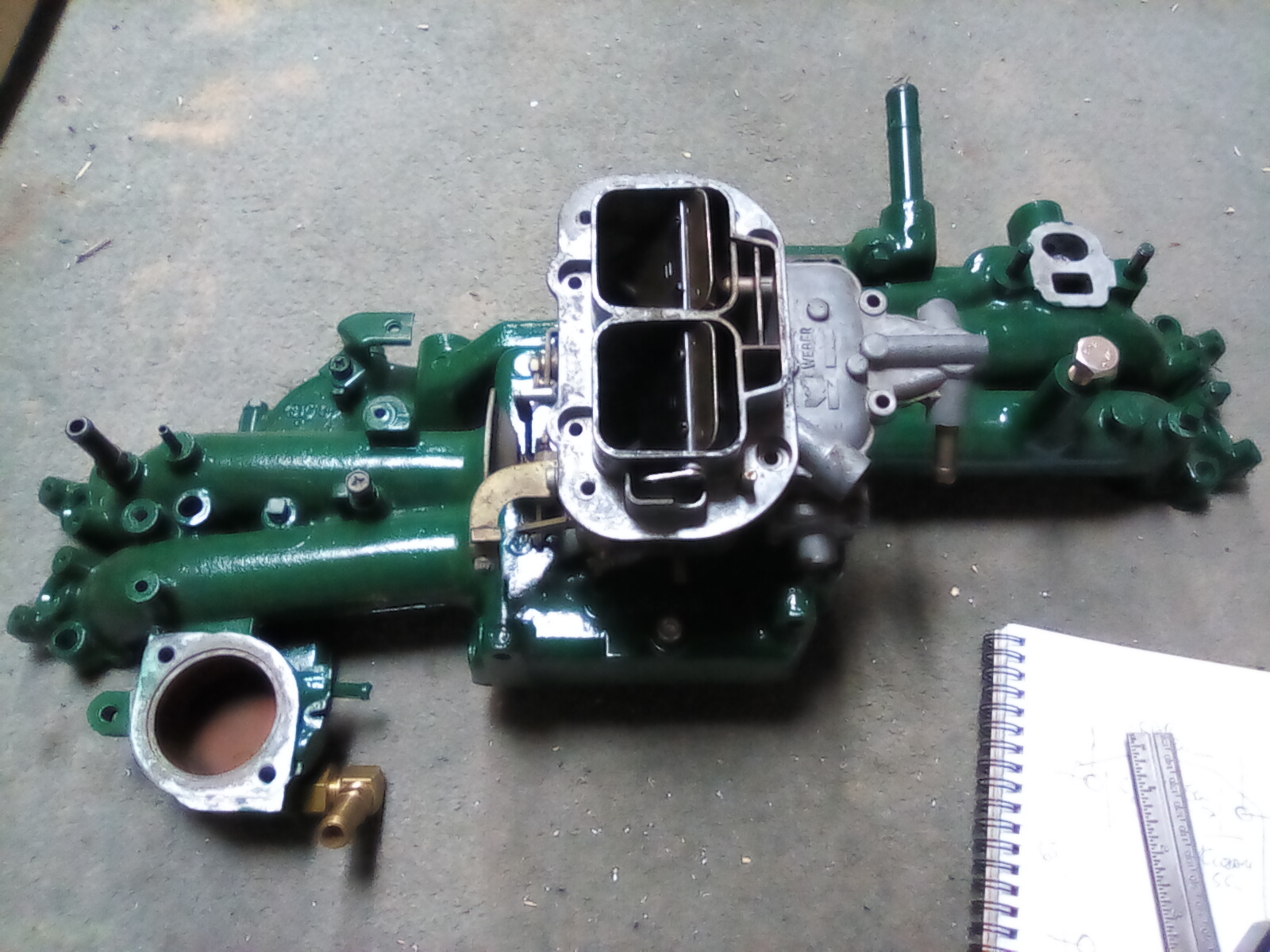

My first EJ was 1.6 NA , sat around too long, in the way - scrap. Next EJ is a suspect EJ22 supposedly was fine before car was rear ended, yet the oily exhaust port appearance suggests that all is not so good, seeing as other stuff sourced from same mate has been described as good, was too loose a description for scrap. EJ20 sits in a Brumby with AWD 5 speed, stuck in unworkable conditions, needs wiring diagram or spxxdyefi ECU or a donor I have my eye on. Still got two EA82 sitting about to use up :) One is fully rebuilt OS turbo, the other just needs assembly using new OS EA71 high comp flat top slugs. EJ might be exciting but think I need to get EA82 stuff out of my system The Weber bug bite marks still present too after a bad experience with this particular carb cause it to be shelved 26 years. The choke flaps jamb against casting from new . Dremel sanding drum to casting avoided staked screw work. Chokes now fully close and will swing in the breeze. How that got past any manufacturing quality control I have no idea .I did a very successful and reliable Weber conversion to a 1200cc Corolla some years back and never done EA Weber and this idea came to me last weekend as a way to break away from dwindling LPG Propane supply issues and not go EJ to get back to wet fuel The green was my thing with Ford LPG dedicated engines getting a green rocker cover - green wrinkle finish was it? being the inspiration to make my dedicated LPG engines look different to the others with green rockers and inlets. Webers can also be turboed with a special intercooler style hat and rising rate fuel regulation

-

Bennie quote inside

Steptoe's photos replied to Steptoe's photos's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Google took care of the dig when I searched for carb upgrade of efi or mpfi heads. Look up your 2008 entries I ended up with Subafury's EA82T would you believe? It had a spider and gold painted rocker covers, blue paint on spider was a lot of work to remove. Ended up with too many blocks so chucked his after finding it had never gone well after a coolant leak and pile of steam.. That engine went north from central coast to Queensland then down further south to me maybe 1800km before chucked ! -

Everyone that's had the turbo EA82 has loved it. Cheers Bennie still your view Bennie ?

-

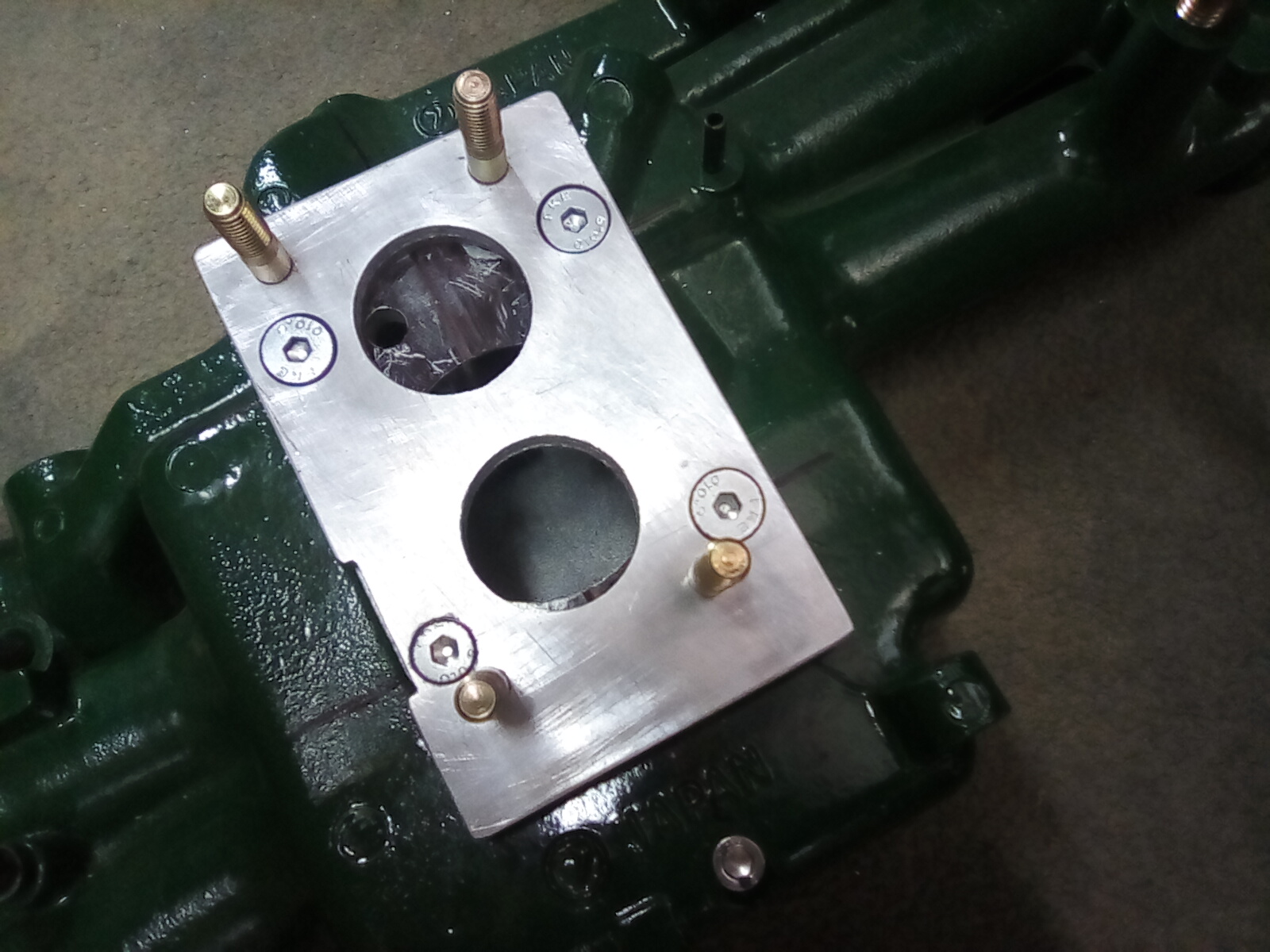

I cannot say that I have seen this concept done or even discussed in 20 years of internet stuff. How should you make an old carb EA82 perform better ? Well, grab some turbo heads and inlet manifold, or XT all came with mpfi .... I think this was a plain old NA as you can see my past efforts to plumb coolant lines for a turbo from the temp sensor for gauge port. That project was put aside at some time, like all my EJ conversions I now need to wait for engineering suppliers to open on Monday to score some countersunk M8 to secure the adaptor plate to the existing TB holes, and some M8 studs to secure the Weber 32/36 DGV-M It is pretty convenient how the various mounting hole sets give each other some decent room. I will have to wait to see how clearances go to work out an air filter set up - certainly won't be using the standard air filter and housings that most use. I think it pretty poor that the PCV hose fitting is almost entirely covered by the air filter element in all those applications I have seen. I will most likely go remote air box with plenty of room to plumb in some breathers for crankcase using the remote filter adaptor if still available. I am making the adapter up myself old school way. CNC would be the way to go for sure. If anyone else has done non standard carburettor conversions to these mpfi heads, please share

-

EA81T Head Gasket recommendations?

Steptoe's photos replied to oczuk32's topic in Old Gen.: 80's GL/DL/XT/Loyales...

i tried to explain this no need to retorque to my long serving machine shop owner and got his opinion, which was to retorque anyway. Food for thought -

disti identifcation halp

Steptoe's photos replied to Mayanstolero's topic in Old Gen.: 80's GL/DL/XT/Loyales...

OP gone, never to resurface ? -

Driveline angles 81' wagon

Steptoe's photos replied to Silverbull3t's topic in Old Gen.: 80's GL/DL/XT/Loyales...

What I did like to read above is that it is your daily driver KNOCK, KNOCK - that must be your local milk authority at the door - wanting their crates back I wonder if you got that natty little gadget onto an L Series two piece shaft to measure up all it's angles to see if something gels. I have done a few L shafts into EA81 and never had problems until I tried to improve on things and go single piece tail shafts..... -

Clutch won't engage.

Steptoe's photos replied to Espey16's topic in Old Gen.: 80's GL/DL/XT/Loyales...

and don't put coolant in until sorted, unless you need anti freeze . By putting coolant in straight away allows Murphy to tap you on your shoulder