Steptoe's photos

Members-

Posts

359 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Steptoe's photos

-

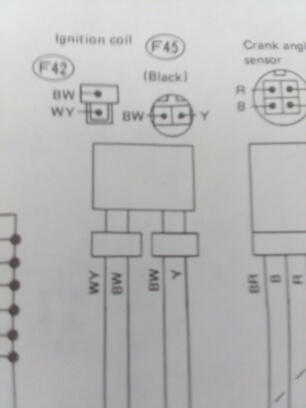

It has taken me a while to accept that Subaru 1987 do not call the distributor as such in their diagrams for wiring. The wiring all refers to the duty of a crank angle sensor. My diagrams show black, round connector of four wires. Red goes to ECU 7 which is also red at the ECU end Black goes to ECU8 which is also black at ECU end White goes to ECU 17 which is also white at ECU end Black/red trace goes to ECU 10,20 and 30 if ATrans looks to be the main grounding connection for ECU and all it's sensors and for shielding wire grounding - grounding is preferable to be grounded at ECU says an electrical engineeer friend

-

OK. I have not looked in here for some time myself. There are two part numbers for four plug ECU and no vacuum unit due to optical system inside and ECU takes control of the spark advance and retard. I do have some diagrams for the US EA82T in the XT, so likely the same for it and any other 4 plug ECU equipped mpfi (which USDM may not have got many, other than in XT4. I will try to get back to you and your rats, in good time

-

EA81 3spd Auto -> EA82 5spd Manual

Steptoe's photos replied to StinkBinko's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Have you done the job yet ? I used an automatic block for an engine rebuild - it mated to my 4 speed, then no troubles putting the 5MT DR 23 spline output box in. I did mine with the smaller 200mm clutch flywheel using an Isuzu clutch disc plate. Only after some 200,000km I worked out I had a mismatch of where the throwout bearing hit the fingers of the pressure plate. This required my gear shifts to be to the floor or I might crunch gears. My next step was going to EA82 engine replacing the EA81. This is when I needed the extra pull of the L series clutch pedal installed in the EA81 pedal box that was modified already when I did the EA81 + 5MT 4WD DR. L series EA82 clutch cable needs a 25mm pull measured at the fork. EA81 give 15mm. Come back and tell us where you are at. -

the real need to pull an EA out is just to do Welch/freeze plugs. I need some limbering up exercises if anyone has good ones to share for all the other bending over and "going " in the backs of the knees (popliteal fossa region). Another good reason to try in car for head jobs is lack of any other work space or job security if left outside in community spaces. If doing in-car one tip I have is to use a grease , general purpose, to glue the rockers in place to prevent falling out or partially out ( this gives zero comp )

-

EA-81 weber conversion

Steptoe's photos replied to pksjeep's topic in Old Gen.: 80's GL/DL/XT/Loyales...

i and others have actually drilled out the coolant hole in the manifold to suit a tap size M12 comes to mind, to then fill the hole with a grub screw or allen socket head grub screw to prevent any possible coolant leak issues when converting to other than the Hitachi -

adapt distributor to EJ22 tips?

Steptoe's photos replied to Steptoe's photos's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I am sitting on a collection of Fiori distributors, and one "Escort" from the US. I only got the body of it, no cap or rotor, or module, so likely to be useless here in Australia. I have been playing with an idea and measurements to spin up something - just my lathe men are busy - one is too busy to even return my calls and text. If I make an adapter plate to convert EJ202 intake manifold to phase2 EJ22 I may go a different path. I like the idea of electronic control out the window with an old dizzy -

I had similar concerns after reading others' views on the topic - mainly, wash out and use your own choice of grease , and quantity. - of same Koyo bearings and era. I contacted Koyo themselves to ask and they assured me the quality, standard and amount of grease was of the highest standard. I went with this over a year ago with no issues so far. Others prefer not to leave any air space either, and choose to absolutely pack the cavity with their chosen grease to reduce chances of water getting at the bearings. My application hardly sees a damp cloth, let alone a puddle or river crossing. If it did, I may have done the same as others - own choice of grease and lots of it

-

I can't see the coolant hoses being blocked off would change the air flowing through the valve.. What I would do here would be to dismantle the IACV if you can, and if has a gasket with holes for transfer ports, make a new gasket that covers all ports up, so no air transfer at all. I think I still have my full gasket on my EJ20 from diagnostic tinkering sessions. I found the original o ring cross sectional shaped gasket was too big to fit back in their recess grooves !!

-

Now, that is some pretty handy info GD. If I then asked if you know more specifics of EJ202 1999 era, get any closer to that sweet rev moment? I am thinking, if I pick a lower gear , to get higher revs, above 1800 -2000, on decel runs, I may achieve better economy ....though am real happy with it's long term average of 7.75 litres per 100 km (62.5 miles) And, the tinkerer I can be, thinking if I rigged a NOID light in cabin, powered by the main relay circuit (same as the injectors) then a wire off an injectors pulse wire _ I could watch when the noid light goes out - should indicate when the OFC is activated or, I might just upset the ECU

-

One of efi secrets on fuel saving over old school carburettor is that on deceleration, throttle closed, the ECU/ECM will cut the injectors from squirting fuel. This will not happen in Angel Gear, for it is the wheels / transmiison that keeps the engine turning over. Has anyone worked out, or know at what revs this injector generally happens on our EJ cars?

-

Help needed Today in Grants Pass

Steptoe's photos replied to moosens's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Not either. I just fell in the trap to see what sort of help was needed. Consider my head pulled in ...... -

Help needed Today in Grants Pass

Steptoe's photos replied to moosens's topic in Old Gen.: 80's GL/DL/XT/Loyales...

put that need in the title might help .... -

oh, a diode on each, the ground and power supply ! Might be the answer to a thing I have with an install. On my RHD 1999 Forester, the window relay is attached to the side of the sub fuse box behind the coin box. I suspect similar location in your model. good idea too !! I might try myself I was also thinking of a dash mount momentary button to lock or unlock doors while inside . Why ? If I wanna snooze or added protection from hijack and that action of he door snib is awkward