Steptoe's photos

Members-

Posts

359 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Store

Everything posted by Steptoe's photos

-

Some XT6 Questions

Steptoe's photos replied to linkthehero1234's topic in Old Gen.: 80's GL/DL/XT/Loyales...

just the pedal itself or the whole pedal and box assembly ? -

Timing belt is only 22,ooo km old and 2,000 into latest inspection due to having to swap the crank sensor "wheel" to suit the crank sensor only, no cam sensor SF set up. I also installed the missing belt guide above crank with max 1.00 mm clearance....This is so weird, the better the electrical get - new leads, plugs, clean terminals, the worse things get ! The initial problem I was chasing feels like a random, intermittent , momentary injector cut.The more new components this baby gets, I expect better of it. It was parked out in the open for a few hours beforehand - just wondering if it was tampered with from beneath, so will be inspecting for foul play. It could be a CAS on it's way out .....like old EA ignition modules that first give a few warning hints that poo is about to happen Still to be code read - other stuff calling my attention......

-

Yes, thinking a timing light may now throw some light on things. I might start swapping components from a donor wreck to this thing , one at a time. But first, I made this to allow self to be in upright position to observe what happens in the cockpit as the green and blacks are connected etc I found what the manual calls diagnostic earth terminals in at the test plugs. On mine, they were exposed as male terminals. On the seemingly untouched donor, they were still wrapped in factory loom wrap vinyl tape.

-

LinkOdemons - demons are what I have I am sure, as there are no bright lights above in the sky , sucking life from beast. I am yet to see what amazing info the CEL is going to offer. I suspect it will be one of those incorrect reports that diagnostic systems have tended to throw in the past on other vehicles. Comp test is my usual suggestion for others I had done a few before and got good results. Initially, the problem felt ..maybe like a full on injector cut, rather than an ignition cut as previous ignition faults usually have all those dash report lights come on while engine has died. So, trying to find any reason an injector cut may occur. 2200 and 3000 rpm is not near over rev limit. No turbo to create over boost The manual suggests injector cut can occur if air intake between throttle body and head happens (allowing over rev I suspect) This is an immobiliser edition. I note the manual lists that there are immobiliser and non immobiliser models. Tis full on momentary engine cut out has evolved? to poor engine running, idle etc just with terminal cleaning - so weird

-

It is getting worse..... the test drive watching fuel pressure gauge at just under 40 psi and the momentary yet repeating stumble / cut out happens without any change to the fuel pressure. No need to pull fuel pump or FPR I cleaned up both battery terminal clamps, radiator earth, #3 intake runner earth with wire brush and electrical contact cleaner spray. ie ECU disconnected, so anything it learned in past 2000 km has been forgotten. Start up results in CEL 40 seconds later, rough idle, stumbles, misses, almost undriveable on flat ground into shed Next is to see if the CEL is gonna flash some codes when I join the diagnostic connectors. EA82 conversion coming up !

-

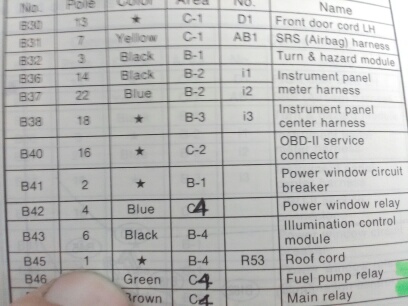

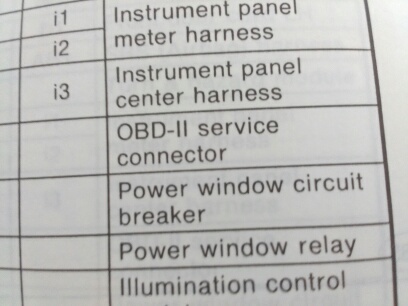

Thanks Ido...you continue to excell yourself with those efforts. Appreciated Sort of going off tangent to main heading but so are the gremlins in my Foz Our EJ202 SF got the ECU as a bolt to the engine block back of #3, but we got those green plugs and black plugs to connect in correct sequence to get something out of the ECU Also have what I thought was result of some mad man settling frustrations out down there - two bare long male pins, black wires. I thought they had been pulled from a plug, but wiring diagram shows and lists them as earths for diagnostics ! I have a few pieces of the AUDM manuals by Subaru for 1998, but mine is MY 1999 so hoping stuff is the same for most of it. I have found the instructions on how to read codes etc via those plugs. Actually plan to get same plugs from a wreck to make up a switch box to plug in down there yet operate from the pilot's seat for human comfort sake ! And not trying to correct anyone or anything on OBDii compliance or convenience , I wonder if manual has more differences than what I have found so far ....

-

Since posting my ask, I have bought a set that looks the same as the white plastic set you have cleverly added to your reply - thanks. I am in the same boat as you - only ever hose clamps and love the ones Subaru use everywhere else on fuel injection starting in mid 80s. I used to g home smelling of fuel and developed a hatred for the smell, setting off headaches, stiff muscles and joints etc - so I avoid the stuff so much I convert to propane for my fuel needs. Just not this time - yet on the 1998 SF5 Fozzie. I saw a youtube contributor who gave no detail as to what or why he cut his scissor style , same as on the right above, down. I think he cut the whole tube bit off leaving just the bar bits to squeeze the fitting. I practised on a wreck - it was not clean at all, and in an awkward access situation. Mine, I have been able to photograph in spotless conditions,and see in the photo a little clearer as to what is going on

-

Boxer engine approved I reckon !

-

yeah, thanks Ido.... at this stage I have yet to read any codes. I am still wondering if it is OBDi or ii I have seen a reference in the Australian models manual - to OBDii A mate with Fuji fluids in his veins thinks it being a 98 make date is still only OBDi The diagnostic plug below steering column looks OBDii , has five wires behind it I no longer have free reign over the workshop tools (ie Snap-On diagnostic ) due to business being sold ...new owner might try to invoice me I am still to learn how to read otherwise or even get a cheapy reader. The only time CEL came on was after new leads, then it never showed again after new NGK BKR5E-11 spark plugs. I have also looked closer at the idle speed control device my post was asking about - and can see that the coolant is only coming into contact with it to stop it freezing up. Idle speeds have been very well mannered. The cut out certainly felt like all four but I think the AWD magnifies the impact on the panic circuit in brain. I have written in another post that I found two leads were duds. Out of two original sets of these leads, I still could not make up a set of four measuring within spec. Three were good, the fourth was 15,500 Ohms where 15,250 was upper allowable of the range. I bought a new set of leads Eagle Eliminator - made locally to me within 300km away - not a distant foreign mass production crowd, and trusted with my LPG turbo toys - fitted them THEN the first time a CEL has come on. The new plugs fixed the light. Who tests components before they get any trouble? Right? Electronic oil pressure gauge now in the line after the under bonnet fuel filter and reading just under 40 psi stationary. Test drive is next when the day cools down, or turns over another fresh day :), which is promising to be even hotter 37 deg C

-

Experience across a few breeds is that the engine is at first, harder to start, before a pump fails in tank. My RXA came to me with good start but died as soon as some boost was asked of it. I whacked on the trusty old oil pressure gauge that has been adapted over the years to fit whatever - including old Lucas mechanical systems that needed 50 psi to properly crack open the injectors T'eed into the fuel line after the under bonnet efi filter and ran the fuel pressure up a hose to the gauge taped to the outside of the windscreen. I could sit stationary and get 36 psi up and down the rev range, yet to take on the road and squeeze, the pressure dropped to 10 psi reading as power dropped away. This external pump was the original, 20+ years, 188,000 km, and had been in some suspect fuel supply regions over it's time I suspect. In the days of waiting for new pump to arrive, the old pump started to not even kick in on start up, until I knocked it with the old engineers hammer We had a similar issue with a mate's Vortex turbo that sat in storage for 20 years - serviced just prior to storage. I used same original style pump up front from a fuel can supply to get it started - after that, the car's pump saw what it had to do, and go no trouble after. Next owner hopped in and drove it 1200 km home to Queensland - no dramas. I have found a few efi electric fuel pressure gauges on line over the years, some quote oil/fuel gauge. Other senders I have found quote oil/fuel sender. Happy to share my info finds Bennie . I found my old never used oil pressure gauge bits (finally) amongst an unfinished project - I was making up an EA82 efi test bench for FPR and injectors, with gauge. With the bits on hand back in the day, I had cobbled up something that I could straight swap to the post filter pressure line of the SF5 Foz. If magic works , I can share. I used a few tapered (I think) threaded barbs, and a manifold plug off - refreshed all the threads with gas tape. The sender unit outer housing also needed to be grounded for good measure (maybe the carbon in the fuel hose and fuel inside itself may have been enough !? Too hot in the outside parked thing to take for the first test drive at the moment. I wired up a cig lighter plug to direct power the gauge from just below where I will tape the gauge to dash top. Sender wire is just out the door and concealed amongst holes or gaps in panels into the engine bay. Initial start ups to test for leaks of fittings etc are all good, and pressure reads just under 40 psi - so, pump is delivering what I think is fine for stationary use. Looks like FPR not letting pressure go. I renewed the brittle FPR vacuum line with all that I could get washer vacuum line in 4mm I think it was. It might be wise to make the length up from brake line and just use rubber hose to connect each end. EVERY Subaru FPR vacuum line that looks original from this era that I have probed - snapped ! It is so brittle

-

"occlude" ? My goodness, I have only ever come across this word used in optometry text books ! I know what you mean My same mate who has never seen a Subie fuel pump fail, thinks the higher octane burns hotter and canes the cat. I can offer that my engine coolant temp was actually 4 to 6 degrees cooler than normal for this run and an internet search suggests that higher does not burn hotter, just harder to ignite. And from experience, the higher octane allows for less downshifting scooting up the mountain pass. I have had one blown cat on one car I bought with it's problem - it was a noisy rattle. I will look at cat after fuel pressure

-

so, what did I write above ?? At no time did I have a CEL, until soon after start up with new leads fitted - tried and trusted for decades - Eagle Eliminators - only then did CEL come on. New NGK BKR5E-11 went in, the CEL light went out. It looks like if the HT leads are not within spec, the ECU CEL cannot report an inefficient spark plug. First test drive, rather short, no problems. Next test drive, within the mile, produced the same symptoms. So, I have found bits not within spec, not the cause of my problems at all ! Preventative maintenance done then Waiting until either I receive my fuel pressure gauge, or can find an oil pump gauge to test fuel delivery pressure T'd in after the fuel filter. Fuel filter is clean as inside. Already stuffed an old fuel pump quick connect/disconnect trying to replicate a removal tool with pliers. Not a good look. Have a post asking to see what others use to disconnect these babies

-

The plugs in it look like they were replaced at the same time it's last tune service occurred. Fuel and air filter had 2012 make dates on them, air filter spotlessly clean and pristine. I went to a long, long time supplier who only supply the best and got some locally made and owned company HT leads - I know and trust Eagle Eliminator for my turbo LPG applications for at least 15 years - so went with them - in stock and no online BS On they went late last night, then a quick test drive and STUMBLE and now the CEL decides to light up ...maybe needs good leads to report poo plugs Wholly DENSO ignition including the plugs, and I like DENSO , but went for my long respect for NGK BKR5E-11 to stuff in - correct grade The engine in it only has 250,000km on it. The plugs that came out of the original 360,000 rod knocker where heat range 6 which is colder and LPG spec. I will put it down to laziness of the previous installer. I like the idea of preventative maintenance , as much as if it ain't broke , don't fix it theory. But roadside rescue missions are not desirable. I have a new pump on board, and discussing with a mate who has probably had more Subies than I care to remember, has never had a pump fail on him. They may have failed before or after his possession though - another mystery that we will never know. I do like to keep an eye on things and will be installing a fuel pressure gauge in the dash somewhere, some time soon. Next step is to fit plugs, then diagnostic unit by SnapOn in mate's shop.

-

The "cack your dacks" sort of stumble/misfire in the EJ202 Forester MY1999, the other day up a mountain pass -100km/62.50 miles from home. And it was only just going so well just before. .. actually pulling smoother up the same hills than the times before. It felt well worth the 98 RON (our highest grade, easily available pump fuel in Australia) I had been running factory spec 91 with no issue other than a bit gutless and a little ping/knock before the knock control circuit did it's job. I had to sit mid mountain for some roadworks and noticed the running cooler on the new fuel mix (78-82 deg C) had risen to 88 while sitting - no manual fan switch yet ! (The tank got 55% of 98, 45% of 91, so a rating about 94 - 95 is what you get according to the fuel supplier technical division.) Next uphill bit became a battle. I got some harsh resistance to power, saw the tacho drop, despite speed being pretty constant. It seemed to prefer 2200 rpm instead of 3000, before playing up again. Traffic building up behind my Subaru is pretty unusual and AWD ignition stumble is no fun, so far from home. I had a spare unknown coil on board but was too scared to stop in case the EJ let me down. I just cried out for my mumma and pointed the accelerator pedal towards home, through a few towns, past a mate's place in one of them (can't have him laugh at my old Subie playing up It carried on from time to time even on smooth plains and jolted at pot holes, so was very sensitive. The leads were original Packard from 1998 and were running fine before - always the way isn't it? 361,000km I got home and there it has sat for a week while I think about things, I found some specs for the plug leads. Hmm, fitted a new battery in the DMM for good measure, found the DMM did not read well sometimes in the 20K scale, so upped it to 200k and got my readings. Three leads were duds according to two DMMs. I pulled another set of originals from a 2000 EJ202 with only 140,000 km, found some bad, or rather, no readings at all on them either. I still could not make up a good set. To up the octane rating of the fuel the car was made for - my experience mainly with LPG 109 AU-RON , has been to ensure the ignition is in top shape. That includes reduce the gap to make life easier for the coil to keep sparking. I am pretty certain if I was to return to 91 I would lose the carry-on of stumbling and scaring my sneakers of a walk back home or my wallet to pay for a tow truck I have retained the 1.1mm gap of the plugs, but thinking if I was to tinker and drop gap to 0.60mm the problem may just go away. New plug leads coming up and retire old leads to the bin me thinks and hope she runs fine for ever after. Has anyone had similar experience, running tired old ignition leads on upgraded fuel, above what car is specified for, to find horrid performance, then return to normal on normal lower grade fuel? I think I have found my problem ...and it begins with EJ