azdave

Members-

Posts

177 -

Joined

-

Last visited

-

Days Won

14

Content Type

Profiles

Forums

Gallery

Store

Everything posted by azdave

-

Thanks. That image gives me a little more idea what I would be in for on the lower end. Really wish I had a donor car to do the swap but they don't come up for sale very often around here and are very rare to be found in a junk yard. I don't even know of another like mine around here. I go to the weekend Subie meets once in awhile but haven't seen one there either.

-

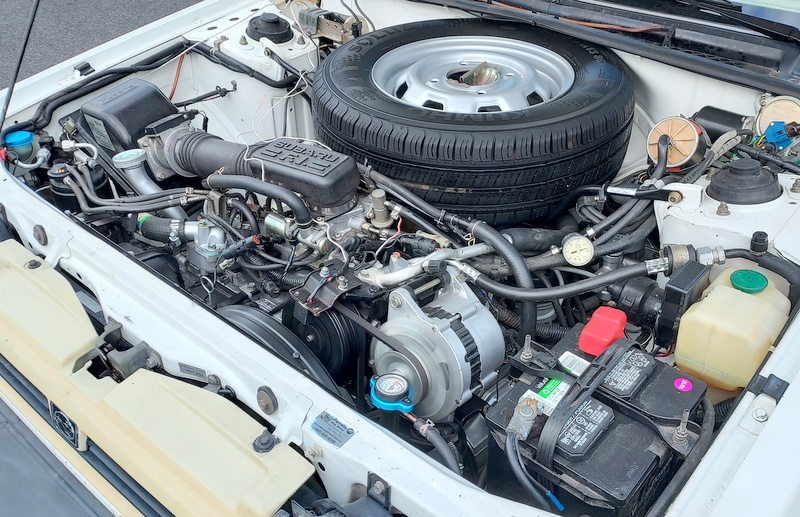

I really like my plain Jane, pure stock, 5-speed, 87 DL wagon that I brought back to life a few years ago and travel at least 150 miles a week with it. At one point, I wanted to install a DR tranny but realize that is something I would very rarely use so I've decided to leave that be. The one thing that I would really like to add is power steering. I've had multiple elbow surgeries on both arms and due to that and just getting older (born pre-60's) I would really like to be able to turn the steering wheel with less effort. Is converting to power steering a simple task if I can find parts or will I have to change alternators and A/C compressors and find all kinds of rare parts to do it properly? My A/C works great and in Arizona, that has to remain functional. Seems like a lot of stuff needs to move to make room for the pump, belt changes, etc. Might this also involve a change to the water pump shaft length? Is the crossmember different due to location holes for mounting the power rack or routing the PS hoses? Other related threads here are pretty vague about how much really needs to change. Photo shows my current setup

-

Not sure if this helps but the only time I've had trouble with my 2003 WRX A/C system was when I temporarily wired the compressor control to remain engaged full-time instead of cycling on and off as it is supposed to do, based upon temps and/or pressures. My compressor would lock up and then start working again, over and over on my drive home from work. I deduced that the evaporator core was probably getting so cold that the return line to the pump still contained some liquid refrigerant that didn't boil off in the evap core and you can't compress a liquid so the compressor would lock up and then work again until more liquid made it to the pump again. After fixing the control issue, I removed the jumper that forced the pump to stay on full time and haven't had the issue since.

-

New member of USMB, introduction.

azdave replied to LoraxEleven's topic in Meet n' Greet. Your USMB Welcome Center

Welcome! It's not the forum of old these days but it's still here and useful to me. I just wish we had more control over keeping out all of these spammers. I have a 2003 Bugeye WRX 5-speed wagon and a 87 DL 5-speed wagon. I DD the 87 for work and errands and just turned over 250K miles. The WRX is at 205K. I even have a 1965 Corvair with an EJ20T going in the back but it's still in-process. -

Water Pump has me confused...

azdave replied to 92_rugby_subie's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Same here. Past owner got the length wrong, Rock Auto got the length wrong, vendors don't care to pay attention and then I got smart and realized it was the same pump body and shaft length involved. All I had to do was pull or press the mounting face to the correct distance. I hope the spacer works out. -

The pump is only as good as the bearings inside but it may be impossible to find a pump that uses anything but Chinese parts, especially at Rock Auto. If you had an early failure then you might want to also take a look at the fan and fan clutch to be sure they are not contributing any uneven loading to the shaft.

-

It's Coming Apart! Will It Go Back Together Again?

azdave replied to DV-523's topic in Members Rides

Look good so far! -

EA82 turns 40 soon !

azdave replied to Steptoe's photos's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Loved or hated, they are what they are. My EA82 gets me to work and back very reliably each day, even when it's 110+ in the summer. When we have errands to run, I much prefer to drive the 87 DL with 246K miles and not my wife's 20 years younger Honda. In general, we love the old cars and that's all we own. Our newest vehicle is almost 20 years old. Our oldest vehicle, driven most every weekend, is 60 years old. I don't even drive my 2003 WRX that often these days. She's too young for me. -

A rhetorical question, right? Our world is full of immoral mechanics and car salesmen who know it is far cheaper to hide faults than to fix them. My 87 DL came to me with the CEL bulb not doing a proper self-check at start-up. The bulb had been removed of course. I installed a new bulb and was able to fix the faults. I later found the old bulb under the passenger seat when cleaning up the interior. I bought the car from the original owner but of course he claimed to know nothing about it.

-

Replacing fuel pump 91 Loyale ea82, compatibility?

azdave replied to BCO's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I only know my own wagon (87 DL) and all I had to do was find a pump that made over 26 PSI since I have a SPFI engine. In those years, the carbed engines used much less pressure and the turbo's needed more so you had extra pump choices to sort through. I don't know if you could still get a carb on an EA82 in '91 but you probably get my point that not all pumps listed for a Loyal will work if you don't pay attention tp pressures. Way too many sellers don't even list the PSI or flow rate anymore. -

Issue with crank pulley rebuilt EA71

azdave replied to dhopper340's topic in Historic Subaru Forum: 50's thru 70's

I had a similar issue on my EA82 rebuild. With the two pump choices I had, the pump bodies, pulleys and pumps shafts are all the same. The only variance is how deep the pulley is pressed onto the shaft. Once I knew that, I just ordered any EA82 water pump and then pulled or pressed the pulley to the correct height required so the belts lined up. No worries about which pump to order as parts get harder to find but you do need to have the ability to change the installed height if you guess wrong on the long or short choice. -

It's Coming Apart! Will It Go Back Together Again?

azdave replied to DV-523's topic in Members Rides

Other than the battery tray rust, it looks pretty solid. Good luck with the cut! -

That is probably glass fiber reinforced Nylon and I've had fairly good success carefully fitting a short piece of K&S brass tubing inside a broken connection like that to add some mechanical strength and then carefully coating the outside with a layer of JB Weld. You can use tiny amounts of CA glue to hold things in position first and then epoxy smoothed over the top. Not sure if you have enough material there to work with.

-

You might luck out and find and easy repair but all too often, the plastic rollers or the motor bushings/bearings are shot or the brushes or commutators in the motors are not salvageable. So much stuff these days is only made to last just past the warranty period and was never intended to be serviceable. There would not be a thriving aftermarket for these replacement units if the originals lasted longer or were relatively easy for a mechanic to fix without a full replacement needed.

-

Sure. I'm cutting dozens of my parts at a time in several variations but you can make them by hand. I often use sharpened brass hobby tubing if a hole punch set is not around.

-

Silicone is a no-go for gasoline applications. The best material I have found is Nitrile rubber sheets (aka Buna-N, NBR, etc.) and it is approved for gasoline and many other oils and fuels. I laser cut it to make fuel pump diaphragms for mechanical fuel pumps in my older classic cars. You can get plain sheets or Nylon cloth infused sheets if you need extra strength. I've bought from ebay, McMaster-Carr, Amazon and Grainger in the past. Plain Nitrile should be fine for your fuel tank sender gasket.

-

Would 5w-20 oil be good for my 1986 gl wagon?

azdave replied to Dumpy's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The whole need for ZDDP thing is highly over exaggerated. Unless you are running high pressure valve springs and a radical cam, you'll have no issues with about any oil you throw in an old flat tappet engine. Pick an oil viscosity based on your climate and go drive . I have 7 vehicles with flat tappets including an 87 DL (247K miles) , 87 B2000 (302K) and five 65 Corvairs (all over 150K). I've owned most for over 25 years and pay little attention to anything but viscosity. I run 10W-30 in the mild winters here and 10W-40 in the hot summers. I run 50W in the Corvairs that only get driven in the summer. -

Gas fill issue

azdave replied to ThosL's topic in 1990 to Present Legacy, Impreza, Outback, Forester, Baja, WRX&WrxSTI, SVX

I have a vehicle that for years would trip the overfill shutoff at the gas pump for unknown reasons. I found out that if I turn the filler handle upside down, I can pump at nearly full speed without tripping the shutoff. Not sure if that will work for you temporarily until you find out the issue. -

1991 Loyale fuel pump

azdave replied to saltytheseadog's topic in Old Gen.: 80's GL/DL/XT/Loyales...

My engine is SPFI so roughly 27 PSI fuel pressure is typical for me. You'll probably be fine as long as the tapped hole (plastic?) doesn't crack where the plug is threaded in. -

1991 Loyale fuel pump

azdave replied to saltytheseadog's topic in Old Gen.: 80's GL/DL/XT/Loyales...

You certainly don't need the damper so if you can plug it and go, then you've saved the hassle of a pump swap.