azdave

Members-

Posts

159 -

Joined

-

Last visited

-

Days Won

11

Content Type

Profiles

Forums

Gallery

Store

Everything posted by azdave

-

Update; I edited my post you quoted above because I just realized I confused my 87 Subie with my 2003. In 2003 there is a thermister device in the evaporator core that sends a resistance reading to the ECU which then cycles the compressor on and off to prevent icing. You will not hear clicking under the dash with that sensor but it is still supposed to prevent the evaporator core from becoming too cold and forming ice. It's really hard to get at that sensor so I would not put a lot of effort into it if you can simply select outside air to reduce the icing.

-

Does the compressor cycle on and off in moderate temperatures? My 2003 WRX will cycle the compressor on an off to prevent freezing solid like you describe. Do you ever hear hear a relay switch clicking inside the dash when the compressor turns off and on? Does the compressor stay on full time, even during less than hot days? Maybe that switch is not reading the evaporator core temperature so it doesn't turn off the compressor when the core gets below freezing. Edit. The relay switch I mention clicking above is actually thermister that is silent and provides a readiing to the ECU. I was thinking of my 87 that has the manual relay. Sorry for the confusion.

-

Of course moisture can freeze on the evaporator coils and will eventually block the airflow almost entirely until it melts away. You can do that manually by turning off the compressor for a few minutes or by selecting hotter outside air instead of recirculating if that works for you. The icing issue can be caused by low airflow in general (clogged cabin air filter maybe) or a lower than ideal A/C charge which drops the saturation point of the vapor below 32F. If you live in a humid area, icing is more of a nuisance than it is for me here in the dry desert.

-

85 BRAT, where is AC thermostat? Wiring Diagram pic

azdave replied to mkoch's topic in Old Gen.: 80's GL/DL/XT/Loyales...

The schematic can mislead you but the circled thermostat is actually in-circuit at all blower speed selections. If the blower relay is engaged and the blower is running, then power will be going to the A/C thermostat regardless of the blower speed selection. It's very likely the thermostat is a capillary tube style switch used to prevent the evaporator from icing up when the A/C is running on a cool, damp day. Those devices are usually adjusted at the factory to measure the evaporator fin temperature (not air temperature) and are not easily accessible after the evaporator is installed. I don't have a Brat so making some assumptions here based on other s I know. Some of them look like this with the far end of the coiled tube stuck into the evaporator fins. -

Front axle compressed length over spec by 1/2"?

azdave replied to azdave's topic in Old Gen.: 80's GL/DL/XT/Loyales...

My risk tolerance is high I guess since the daily-driver vehicles in my household all have over 200,000 miles on them and the newest model is a 2003. The other two are 87's. While I worry that the axles might wear out prematurely I don't fear they will come apart on the freeway. The axles are in an I've put about 45 miles on them. No strange noises, binding or other issues yet. Seems like the range of movement is being handled. Before I installed the shaft roll pins, I still had free play pushing and pulling the head in and out. A crude check but it confirmed there is room to expand and contract Thanks for the comments and tips. -

So I ordered two identical front axles for my 87 DL and got two different looking axles. The supplier tells me that this is common and not an issue as the function is identical and I should ignore the physical appearances. Spline counts are okay and seal OD's measure okay but the compressed length of one is almost a 1/2" longer than spec. How tight is the spec if I'm starting out at 27.75" long compressed instead of 27.375'? I know I don't want to bury the CV bearings while the suspension goes through the range of motion but is it tight enough that a 1/2" matters? They are telling me I'll be fine but they aren't the ones who will have to take it all back apart if they are wrong. This is a pure stock DL wagon.

-

Temp gage heat sensor on 85 GL EA81 hatch

azdave replied to willd's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Single wire temperature sensor located near thermostat housing on my EA82. Should be similar for yours. -

Thanks for the alternative suggestions. The seconds set of Sachs struts arrived with exactly the same deficiencies as the first set from Rock Auto so for now, I went with using them after a few tweaks to make them fit properly. The front end now sits a little higher due to the spring perch height difference but that actually seems to level out the stance. One thing the strut work revealed is a bad outer CV joint on the passenger side axle so another thing to purchase. Right now, I just want to get some miles on this car and see if I want to keep it long-term or sell it later this fall.

-

Working to replace the front struts in my 87 DL wagon mentioned above. I see posts from ten years ago about how parts are hard to find. It's not any easier today. I got one set from Rockauto and they are not correct but close enough that I could make them work. They each have a manufacturing defect so they will be returned. One has the brackets welded on the wrong side and the other has apparently leaked out nearly all the nitrogen. These struts are Sachs made in Mexico but I can't find a date code. One strut has almost no compression resistance compared to the other. The bad strut I removed from the left has an odd failure mode. When all disconnected from the car and spring assembly, I can push the rod down easily but it will not come back up, even when I pull on it. Something locks it in the down position but it eventually rises back up, either slowly or sometimes with a bang when the spring was still in place. I have a new pair of struts arriving from another vendor to try my luck with their stock. I'll bet it is all old and dusty too but that should not in itself mean it is bad. The struts I'm trying are Sachs 031172 (R) and 031173 (L). The car is going to sit a little higher since I can't locate the exact struts I need. See the photo of where the spring perch will be compared to the old. I've seen posts about this on other threads here where manufacturers try to make a one-size-fits-all solution. Sourcing parts for 35 years old cars sure can be an adventure but I enjoy the challenge.

-

Thanks! I've got about 30 miles on it since getting the engine back in and so far, so good. Before the long test drive to work and back yesterday, I installed all the missing/worn out shifter bushings and got the shifter throws back to spec. I swear I could move the shifter over a foot left or right when I first got the car. It was light the shift rod was barely attached to anything. The past owner really let this thing go to the dogs. I also had a bad fuel leak at the fuel line damper at the output of the pump. The pump was not that old but the rubber disc in the damper was leaking. To stop the leak, I installed a very short 8-32 screw and gasket to seal the hole. I'll have maybe a little more pump noise in the lines now but that's better than leaking fuel. I discovered that the 4WD option is working, I just don't see the lamp on the dash so probably an easy fix The exhaust really needs attention next. Someone tried to weld up rust holes while the pipes were in the car so it leaks still as you can imagine. I also discovered a bad front strut on the driver's side so a fresh front pair are on order. Sometimes, the strut will not compress at all and yet it is not collapsed. I can sometimes get it to compress and bounce but I hear an odd gurgling noise instead of the normal shhh,shhh sound. Odd. I'm happy with the purchase so far. The A/C is working after adding about 12 ounces of R152a but I think think it has way too much lube and leak detector in the system so a good flush and fill will be in the future. For now, I have cool air so I'll work on more important stuff. Fuel pump assembly https://photos.app.goo.gl/ofobbzqY65rFdtVK6 Fuel pump pic showing where I installed a small screw in place of where the rubber damper tab was located. https://photos.app.goo.gl/8HoGV6XNUNRGP2Ae9

-

EA82 Steering wheel puller

azdave replied to 1980ea71Brat's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Why are you not using a steering wheel puller? I don't think I've ever seen a steering wheel that didn't have holes already drilled and tapped exactly for that reason. It's way better than damaging the shaft with hammering, heating or possibly cracking the grip plastic covering by forcing it back and forth like a cavemen during the process. -

News stations act like it's the apocalypse or something because it was 110 yesterday here in Phoenix but that is quite typical for June. They issue special "HEAT ALERTS!" just in case you don't know it's another summer like the last one and the thousands before that. Quite comical really. They make it sound like we should shut down the city and "shelter in place" or something until the heat passes after September ends. Monsoon season is next. That brings in a whole new round of media hype. Ultimately, anything that convinces people not to move here is okay with me, even if it is over-hyped drama about seasonal weather. I got off work at 3:30 PM yesterday, which is the hottest part of the day, and within 10 minutes of getting home I was out working on the DL. Wear sunscreen.

-

Got the water pump flange pulled out to the correct position so now I can remove the stack of washer someone used under the pulley to hide the misalignment issue of choosing the wrong pump. I installed the repaired radiator, hoses, coolant then let her run. All sounded great and I let it come up to about 180F before giving it a rest and calling it a night. By the weekend, I should be able to drive a few laps around the neighborhood and see what else needs attention. I have this crazy idea to try to get it to pass the emissions test so I can daily drive it and not have to use classic car insurance which limits your driving. Pics show the hub puller I made from scrap 1/4 steel plate and some assorted hardware. https://photos.app.goo.gl/VJsyzEHKr366Yj929 https://photos.app.goo.gl/HgPy4dPnioq5whTv9

-

Do you have a can of Dust Off? The contents are R152a which is a great refrigerant. If you think it might be the ignition module (which could fail in the heat as you describe) then invert the can and spray several short spurts to cool off the part and then see if you can drive much further before the failure returns. Even cooling it with a handful of ice might prove or disprove this theory. My 87 Mazda B2000 had an ignition module fail in this same manner and an Icee slush drink from the convenience store got me home. Cherry flavor works best.

-

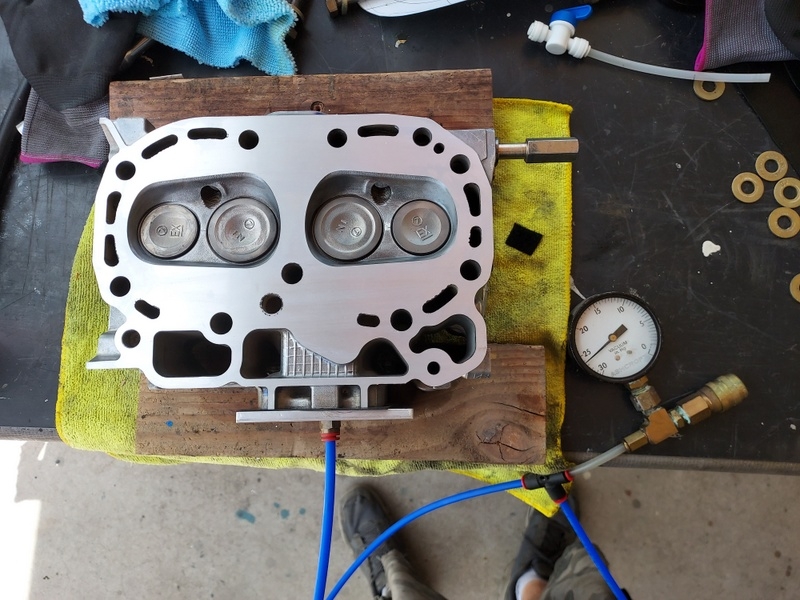

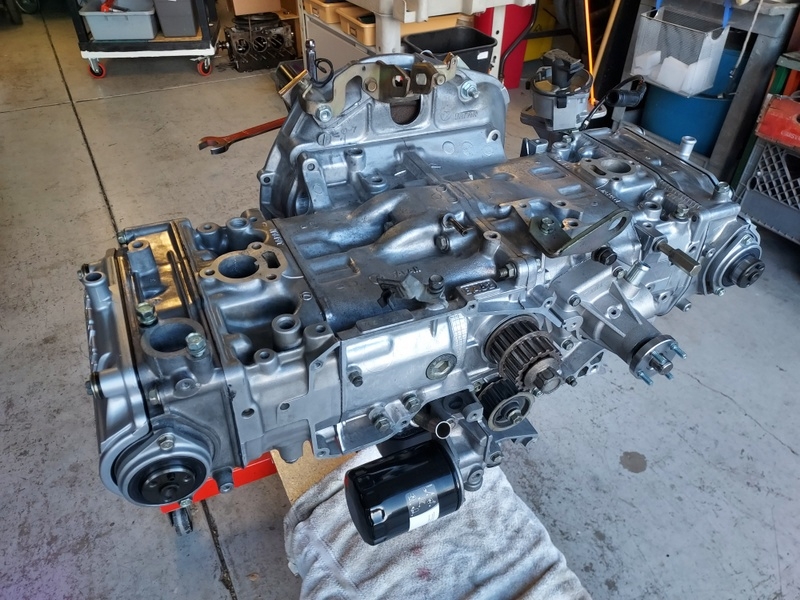

The EA82 engine went back into my 87 DL over the weekend and I even fired it off for a few moments to verify it runs with no bad noises. Before I connected up the fuel lines I drained the nasty, stale fuel (smelly but no particles of rust or debris seen), filled the tank with 5 gallons of fresh fuel, jumped the fuel pump at the rear plug and then cycled fresh fuel up the engine and let it flow into a jug for about a minute after it ran clean. With no radiator installed, I only ran it about 20 seconds. I went to install the radiator and right away found a leak at the upper neck. This is a clean, dual-row, all brass aftermarket from Indonesia and all metal so worth saving. I pulled it back out, cleaned it up and soldered it with my vintage American Beauty soldering iron. Decided to do it right and pressure test it and found a tiny leak on one horizontal tube. I was very fortunate that it is on the front and was easily cleaned and repaired as well. It sat overnight with 10 PSI on the gauge and was still reading 10 PSI 24-hours later so good to go after a quick touch of black semi-gloss paint. I also installed a new drain petcock as the old one had been twisted off. Next up is the water pump pulley flange that I discovered is too low. The previous owner had installed the wrong pump and then used a stack of washers to "almost" get the pulleys to line up properly. I hate fixes like that but didn't recognize that error when the engine was out so I'm building a simple in-car hub puller so I can pull the press-fit hub out about 1/4" without removing the A/C condenser that prevents the use of a normal puller. https://photos.app.goo.gl/88Jg2A8TSNC9Fici6 https://photos.app.goo.gl/6DNHpuT5r7Gzx81LA https://photos.app.goo.gl/Qc2Vzt5etqxg34se7

-

Probably no reason to look me up when you get to Phoenix unless you are really bored. I have the typical blue 2003 WRX wagon @ 200K and the recently acquired 87 DL wagon (240K) that I'm still working on. My wife and I live in Gilbert and I work in Tempe west of the ASU campus. We could even do lunch. We have 13 cars between the wife and I including eight 1965-66 Corvairs in various conditions. We don't care for modern cars cost/payments/insurance so even our newest vehicles are approaching 20 years in age. Sorry about the heat when you arrive but it is June in Phoenix.

-

Just bought a 1987 GL wagon

azdave replied to sleepercoupe's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Same here (except for the low mileage). I bought an 87 DL wagon with 240,000 miles a few months back and just last night test ran it for a few moments after repairing a bad head gasket and other neglected engine items. Now I'm installing the radiator so I can safely run it longer and also doing lots of cleanup work along the way. I hoped a one-owner car might have received proper maintenance from the seemingly proud owner but I was mistaken. Either he or his mechanic performed a lot of questionable repairs. Don't know if it was lack of funds or simply didn't care to do it right. I've had to use 4-5 vendors including eBay to find parts and you really have to check them closely when you get them. I got a matching set of rear wheel cylinders last week and luckily removed the dust covers to check them out before I installed them and found the bores where two different sizes! -

Old post I know but this thread came up in a Google search and was questioned by others discussing it on FB today. I just checked the crank bolt thread pitch on the original EA82 engine out of my 87 DL and it is without a doubt a M14 x 1.5. I happen to have a metric tap of that size and it threads perfectly into the hole and lines up exact when laid alongside the bolt. I assume other EA82s will be the same.

-

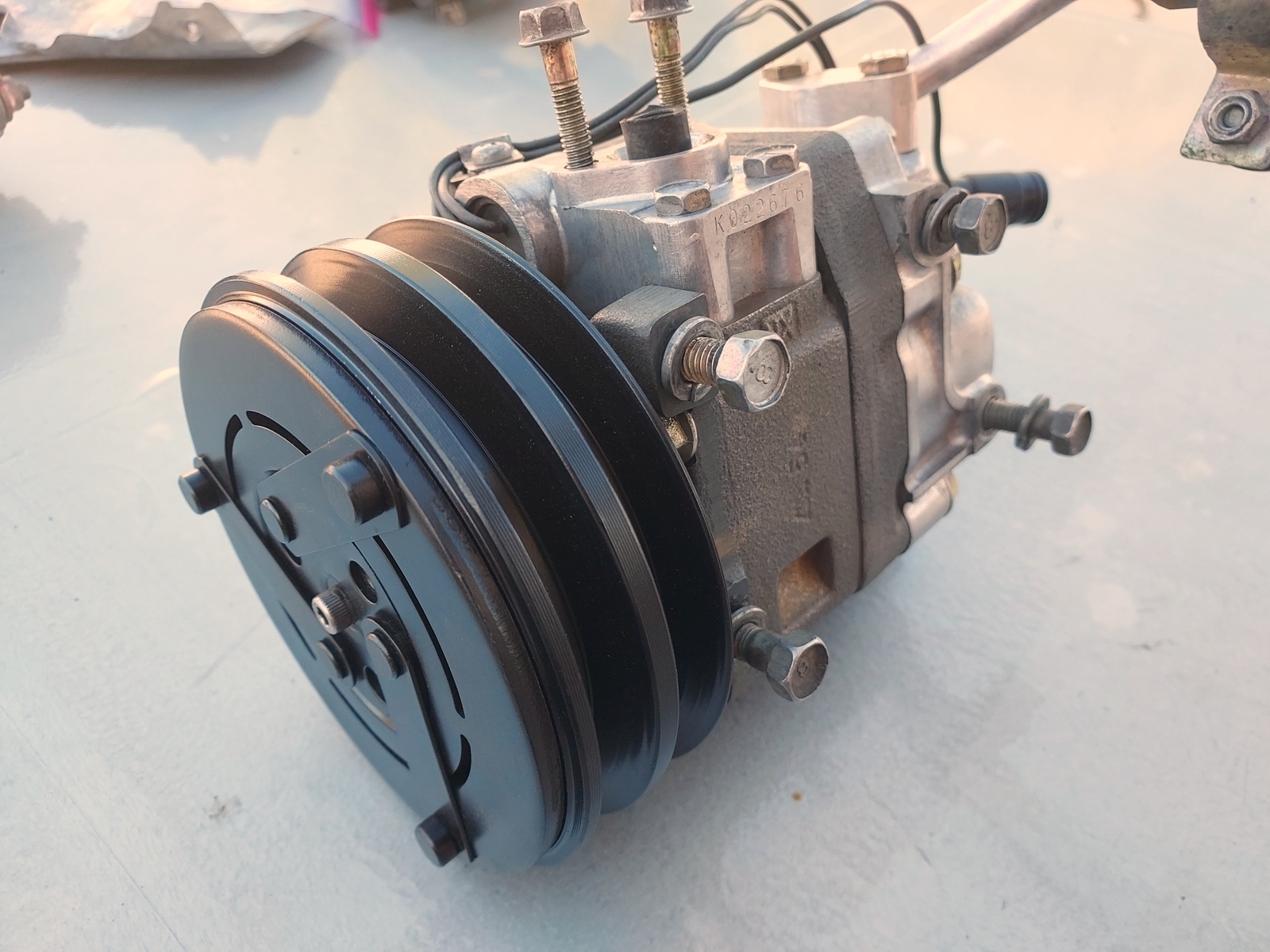

Installed the idler bearing last night. Tolerances were a bit tight pressing it into the pulley but it slid onto the compressor hub properly. I adjusted the gap between the clutch and the pulley and now it's ready when re-install time arrives. Today, I'll work on the related mounting brackets and the alternator. Those just need a good cleaning I hope.

-

I must be getting old. I would not have bought my DL wagon if it did not have A/C but then again, I do live in Phoenix so tough to do without it. The system was still holding pressure when I picked it up so at least I know it was not sitting around with open plumbing. I'm installing a new idler bearing in my compressor pulley while it is out. Hard to find any not made in China but at least it is easy to change if the new one fails in a few years. I plan to use R152A (Dust-Off spray) when I put it all back together. For refrigerant gas, I have normally used a propane/butane blend for my 87 B2000 and my 65 Corvair (Enviro-Safe or Zeror as seen on eBay, etc.). I've been running that hydrocarbon stuff in my old R12 cars for well over 15 years. I do all of my own A/C repairs so now I"ll be trying R152a in my second vehicle. I can easily buy it by the case at Costco. No normal repair shop would touch my A/C system if I told them I wasn't using a "proper" refrigerant so don't use this if you ever plan to have a pro work on your system. You'll contaminate their evacuation machines and they will not be happy.. I believe this is the Panasonic compressor (S1150X3) and it will be receiving a good cleaning soon and then a new idler bearing.

-

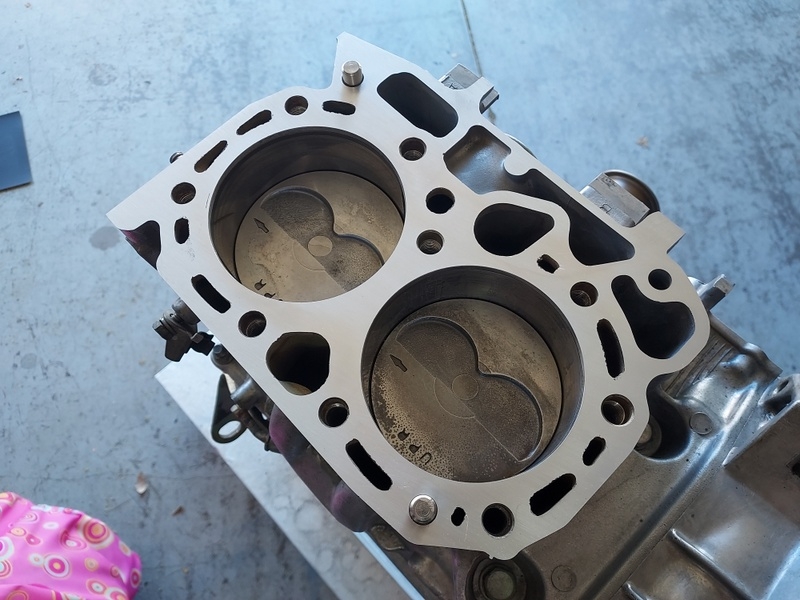

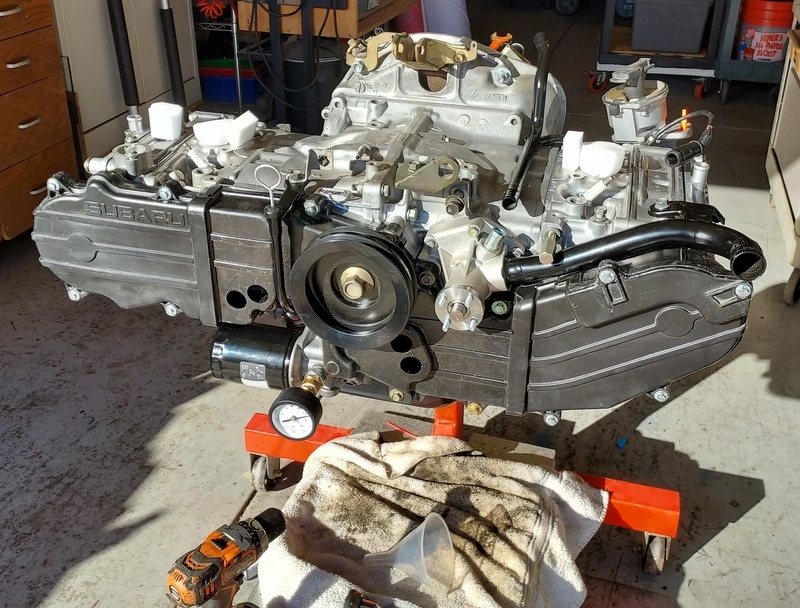

I've been slowly working on the EA82 in my 87 DL wagon I picked up last month. I work as time and funds permit. The engine came out for repair due to a head gasket leak on #3. I surfaced the heads, lapped the valves, decked the block, etc. I hate to return greasy, grimy parts to service so a general cleanup has been going on too. New timing belts, idlers, tensioners, oil pump seals, new water pump, crank seal, all coolant hoses, A/C compressor bearing, oil pan dropped and resealed, 19 stripped holes were helicoiled, etc. You guys have seen all this before but it's new to me and fun to undertake something different. My experience the last 30 years has been with air-cooled flat-6 engines. The DL's engine compartment is being cleaned as well as the accessories while I have good access to reach in there and scrub everything. There was quite a bit of surface rust below the battery but also under the master cylinder where the past owner failed to fix a brake fluid leak. I'm treating that rust and then will paint it all while I'm there. So far so good. I may have the engine back in place in a few weeks but with the heat in Phoenix I'm not out there working all day long.

-

Dual Range Trans into 92 Loyale

azdave replied to yblocker's topic in Old Gen.: 80's GL/DL/XT/Loyales...

Curious here too about a dual-range for my 87. -

$40 AC Fix, AKA getto guide to HC-12a

azdave replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I have never worried about the flammability of any automotive refrigerant I've used. They don't ignite as easily as people think and certainly are far less dangerous than the 20-30 gallons of gasoline in my fuel tank. Some people who have complained about the dangers of using 6-8 ounces of ES-12a or HC-12a seem to forget there an thousands of motor vehicles running around with huge LP tanks onboard. Good substitute refrigerants that are banned from automotive use are due to highly paid lobbyist in our political system, not because the danger is real. Ever notice that when a refrigerant patent is about to expire a new one comes along that is freshly patented and protected from competition? -

$40 AC Fix, AKA getto guide to HC-12a

azdave replied to Ionstorm66's topic in Old Gen.: 80's GL/DL/XT/Loyales...

I've used HC-12a for at least the last 12 years in multiple R-12 systems but now use R-152a as it is cheaper and easy to find. I can buy it by the case at Costco as it is the same thing as Dust-Off spray cans. Works fine in my old R-12 systems. Google it and you'll see it's been used in old cars for years with few concerns. No hose or oil changes needed. Drop-in substitute in my vehicles but it takes less gas than R12.