q240z

Members-

Posts

101 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Store

Everything posted by q240z

-

I've stated a few times that I haven't touched the OEM drive shafts before, and I've never hinted that I've had tranny work done before because there simply hasn't. I agree it's an odd failure, but it has nothing to do with previous assumed work that had never happened. This driveshaft is stamped "Made in Japan", it's OEM Subaru. On a brighter note, I topped up the diff with some throw-away Mobil gearbox oil and put a few miles on it. With the new axle, everything worked fine. I'll drain and replace the diff and tranny fluid after a few light miles. I would have drained the diff fluid entirely, but Subaru decided to use an absurdly big star bolt for the diff drain plug, so now I'm awaiting the arrival of yet another custom tool so I can do an otherwise routine maintenance item.

-

The new axles arrived just now, but they look different than the OEM one. Specifically, the clip goes near the end of the shaft. There's a groove cut in the splines for the clip. Mine didn't look like that. And I thought the end of the old stub axle didn't exactly look like it was machined to normal Subi standards. Turns out the end of the stub axle snapped off clean at the clip groove. I put a magnet into the diff and extracted the shaft end. This is the weirdest thing I've seen so far on this car.

-

From my first post: Transmission fluid is up to the FULL mark. There's been no service to the axles in the 7 years we've owned the car. Boots are all in good shape, with no leaking grease. It popped out of position all on its own. I removed the axle yesterday. That was a quick 20 minute job. I could have done it in 15, but for the life of me I couldn't get the shaft to reseat in the diff. The outer CV joint is tight, the inner one has just a tiny bit of play ~1/64". I can feel it but not see it. There was no clip on the shaft. But when I looked inside the diff through the shaft hole, there it was, blocking the hole in front of the splines. So that's why I couldn't push the shaft home. I pulled the clip out with a pair of pliers. It snapped back on the shaft good and tight, so the problem wasn't caused by a loose clip. I've got new replacements on the way, and I'll be draining and refilling both the diff and tranny as suggested. But I'm still stumped as to how such a small amount of play in the CV could have caused the shaft to jump 1" out of the diff.

-

Axles and CVs felt tight yesterday. After seeing your posts, I grabbed a light and checked out each joint while trying to shake the axles around. They were all still tight, but then I noticed the driver side front axle, where it goes into the diff didn't look right. Looks to me like the axle pulled out of the diff by ~1"! I suppose it's good news my transmission didn't grenade itself. Any ideas on what might have caused this problem? Cheers Q

-

I've got a 2009 Forester with 150k miles, non-turbo, and automatic. After coming to a stop at a stop sign, I started to accelerate, heard a noise, the engine revved but the car wasn't accelerating anymore. Just enough power was getting to the wheels that I was able to limp the last mile home. On downhill slopes I could coax it up to 45, which helped get over the uphill slopes. IIRC, the sound wasn't a BANG...more like dropping a hammer onto asphalt from 6" high. Maybe a 'thud'? Once home, I jacked up one rear wheel with the parking brake off and the transmission in Park. I was able to rotate the wheel and could see that the driveshaft was turning. I don't think that should happen in Park. When I let the car back down, it started rolling forward despite being in Park. I reset the parking brake and jacked up the front end. Both wheels rotate despite the transmission being in Park and the rear wheels on the ground. But rotating either wheel doesn't cause the opposite side wheel to rotate. CV joints appear fine. There's no slop in the axles or drive shaft, and there have never been clicking noises when backing while turning. Transmission fluid is up to the FULL mark. I set the car down, started the engine and worked the gear lever. Drive and reverse gears feel like they engage normally, but the car barely accelerates regardless of throttle position/engine RPM. At idle it seems pretty much normal. With the brakes on and the car not moving, I shifted to Park and there was a whirring or clicking sound for a second that then stopped, as if the parking pawl wasn't engaging. If I let off the brakes with the car in Park, it rolls as if it's in neutral. I'm stumped. Thoughts on what might be wrong?

-

(Hopefully) final post on this one. Since I installed the $26 aftermarket coil to replace the OEM one that only lived for a few months, I stopped getting the misfire codes. And that's using aftermarket wires and plugs. I know there are true believers here on OEM only, but the replacement OEM coil dying so quickly suggests maybe they're not worth the additional cost. And at $26 a pop, I'm tempted to keep a new replacement coil in stock just in case the trouble returns. But I was still getting the cat inefficiency trouble code. I had installed a new cat after the original coil started causing misfires and killed the original cat. I believe the new cat got cooked by all the raw fuel getting dumped into it when the OEM replacement coil would misfire. So I ordered yet another new header pipe/front cat from ebay ($120 delivered), and installed it a month ago. Since then, the car is running right with no codes for the first time in ~two years. finit Thanks for all of the input, guys!

-

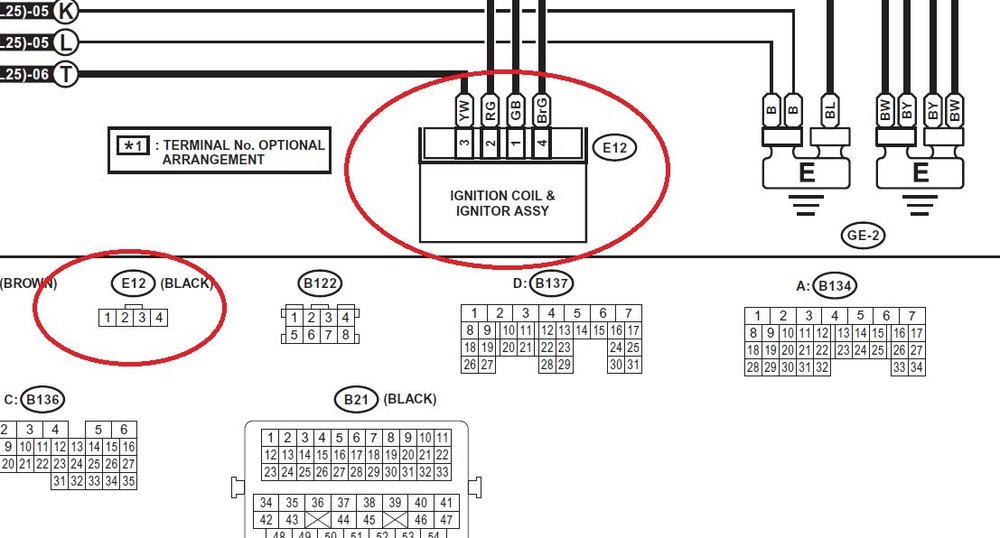

A while back, I posited " what are the odds of an OEM replacement coil having the same problem as the one it replaced?" I dug into the ECM wiring, then the wiring harness, then the individual wire connections in the individual connectors. Everything seemed fine. So I back-probed the signal wires (1 & 4) on the E-12 connector at the coil and attached leads to two multimeters on the passenger seat (a sort of poor man's oscilloscope). I attached my inductive timing light to #1 plug wire and went for a drive. The multimeters couldn't keep up with the voltage changes signaling 'time to spark', but both were following obvious patterns of rising then falling voltage. Within a mile it started misfiring. The inductive timing light stopped flashing, meaning no spark. But the patterns from the ECM to the coil showing up on the digital multimeters appeared unchanged. Which tells me the ECM signal is getting through to the coil. So I went on ebay and bought a new aftermarket coil for $26 delivered. I installed it yesterday and went for a drive. The problem is gone. Which means that brand new Subi replacement coil I bought fried itself within just a couple of months. Unfortunately, limping home on the bad coil looks like it might have cooked my brand new cat.

-

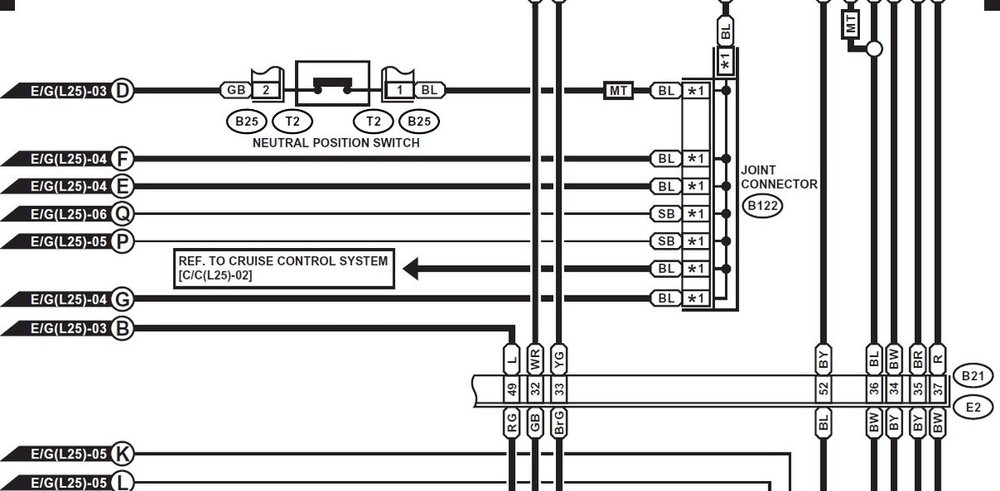

Thx on the ECU location. The jpg I posted was only a partial on the wiring diagram. The "*1" optional arrangement refers to connector B-122, which is further up in the diagram, not the pin order on the coil. The order of the pins should be consistent unless there's some note on the diagram explaining why they're not.

-

The problem is intermittent, so it can't be timing. There's no oil or moisture on the boots. Plus, the inductive timing light is showing that no juice is getting to the plug wires. There's no evidence of leaking voltage either. It's good to know 1& 2 share a coil. Looking closer at the design, I can see that now. But what are the odds of an OEM replacement coil having the same problem as the one it replaced? The FSM wiring diagram is helpful but also confusing. It shows terminals on the coil ordered 3214, but on plug E12 they're ordered 1234. Once the rain stops here, I'll pop the hood and try to figure out which is correct through a process of elimination. Also, any idea where the ECM is and how to get to it?

-

I'm pretty sure that if the timing was off or the crank or cam position sensors weren't working right, the problem would affect all cylinders, not just 1 & 2. Also, it wouldn't be intermittent, it would be all the time. The symptoms don't fit that diagnosis. The problem is not fuel related. As I said, my inductive timing light stops flashing on cylinders 1 & 2 when the engine starts to stumble (the dashboard warning lights start flashing at the same time). That means there's no spark coming from the coil, but only on cylinders 1 & 2. As to codes, 301 and 301 are the primary ones, but I also get the one indicating cat efficiency is off. But that's to be expected with a misfire on two cylinders and injectors still spraying fuel. It's more of a sub-symptom than a primary one.

-

Aaaaaaaaand I'm back to the same PO301 PO302 codes. I put my inductive timing light on the plug wires again, and when the engine starts stumbling the timing light stops. Which means there's no juice going through the wires to cylinders 1 & 2. I have a new OEM coil, clean MAF. New cat and O2 sensors. Good plugs replaced less than 10k miles ago, and they're properly gapped. I swapped the coil wires 1 to 3 and 2 to 4 and vice versa. No change, still throwing codes on cylinders 1 & 2, so the problem is not the plug wires. And the problem has gone from being intermittent, once every couple of days or so, to almost constant. Has anybody whose actually solved this misfire problem tracked down the real cause?

-

I don't have a scope, but I did put a timing light on the #1 wire and went for a drive. Some threads indicated injectors caused the problems I was seeing, and the timing light made it clear it was ignition cutting out. When the car would start to stumble, the timing light wouldn't flash. But even when the engine was running right, the flash seemed to vary quite a bit. I swapped out the aftermarket coil for a known good OEM one and the car drove much better for a while. But the idle still seemed weak. I found another thread on teaching the ECM idle parameters (disconnect battery for 30 minutes, reconnect, turn key on, wait 20 seconds, start engine and let idle for 20 minutes). But the car wouldn't idle. It'd die after ~5 minutes. I found another thread that discussed cleaning the throttle body. Something about the throttle blade not closing fully if there's gunk around it. So, I took off the TB and--sure enough--there was a lot of gunk inside. I cleaned it up with solvent and a soft brush, then wiped the blade face and edges and TB bore clean. I was then able to reset the ECM. It idled fine for 20 minutes. I shut it off for a minute. Then turned the ignition on without starting the engine for 20 seconds. Then started it and it ran well for five minutes. That's it. The ECM is now controlling the idle properly. I would say, though, that it's pretty clear the problem with the TB wasn't that the blade couldn't close. It's that the gunk around the perimeter of the bore and edge of the blade blocks the very narrow gap between the blade and the bore. Unless I'm wrong, that gap passes just enough air that, without it, the idle becomes unstable. Either way, it's looking good right now. Lesson learned on the non-OEM coil. The non-OEM plug wires and plugs don't appear to have been a factor. If trouble comes back, I'll post again. Thanks for all of the suggestions.

-

I don't recall, but the problem is intermittent so it's unlikely to be wires or plugs. The car runs great, then out of the blue it feels like somebody turned cylinders 1 and 2 off. They come back on shortly thereafter (2~20 seconds). That doesn't strike me as a plug or wire issue. When it happens, it temporarily throws a code for cat inefficiency. That tells me the injectors are firing fuel that's not getting lit off by the plugs, loading up the cat. I've already tested the injectors. They're working fine. All of the readings on the aftermarket coil are identical to a known good OEM coil.

-

Thanks for the responses. The aftermarket coil doesn't appear to be the problem. The original coil problem was caused by thoroughly corroded coil wire to coil connection. The problem appears to be most likely in the wiring, based on the FSM ocei77 linked to. It's funny. For all of the threads online complaining about this same problem (sporadic misfire), none of the threads I've seen identify what the final solution was. Many go down the random parts replacement path, with claims of "Fixed it!" followed by "it came back" shortly thereafter. When I finally figure out what's causing this, I'll post it here.

-

Hi. Two years ago I had a misfire problem with my '09 Forester. The code reader indicated cylinders 1 and 2 were misfiring. I popped the hood at night just by coincidence and saw sparks around the #2 plug wire connector. When I pulled the wire, it was clear that water had gotten in, corrosion started at the coil connection to the wire, and the coil tower had melted. I swapped out the coil, wires, and plugs and it ran fine for a while. But the missus started complaining about sporadic poor performance recently, and the car started throwing the same misfire codes again. The replacement coil (Ultra Power) looked fine, but when I put a multimeter on the primary side pins (read left side to right, facing the primary side plug), I get: infinity between pin 2 and all of the other three pins 2.13 ohms between 1 and 3 4.28 ohms between pins 1 and 4 2.14 ohms between pins 3 and 4. Online sources vary, but a common spec is that I should be seeing ~ 0.73 ohms between 1 and 2 and also between 3 and 4, or alternatively between 1 and 2 and 1 and 4. Thoughts? BTW, I didn't go with an OEM coil because the OEM one didn't last 100k miles and I figured a coil is a coil. Thanks! Q

-

OK, we'll have to see what replies come in from folks who recommend the 1995 2.2. Also, I notice that you're talking about breaking AC lines without evacuating the system first, then replacing o-rings and 134-a without first vaccuuming the system or replacing the receiver/drier. I'd rethink those items if I were you. That advice isn't Subi specific. It applies to all AC systems.

-

Yup. Burped the system the same as always. Then I drove the car for months with the new gaskets and it never once even got warm...until I had people in the car and the AC on. So what's the scoop? Are these 1995 2.2 engines a clean swap out into a 1996 car with a 2.5 or do you have to get into the wiring? I'm seeing conflicting versions of the truth here.

-

I'm not sure why I keep saying that I've got gauges to test for flatness but some folks keep saying that one must have a machine shop do the testing and mill heads that didn't need it. Must be a Subi-master thing. We had the last car for three years. I'm pretty sure that's past the point where a reasonable person needs to be concerned about whether or not the repair was done adequately. Even complete disassembly, restoration of the block and heads back to factory-original specs wouldn't stop lightening from striking, I think. But whatever... The fact is, these heads were dead-nuts on and there were no apparent cracks. Which makes me lean toward the alternate hypothesis offered: the PO overheated the block enough to tweak it somehow. But we'll never know, cuz it's going to get turned in as a core. So, since "blown hg" is apparently not a term of art on this forum, lemme see if I got this straight: Subi heads develop breaches in the head gasket material through which combustion gases pass freely, resulting in a repeated complete loss of coolant and overheat condition. This pattern can repeat for an entire afternoon and evening while the owner struggles to get home from a long distance away. Upon arrival home and a several hours' long cooling off period, the owner refills the radiator with water and leaves the car until the next day. The following day, the owner starts the car and drives for 30 miles @ 55-65mph, but the void in the head gasket from the previous day has since resealed itself to the point that the engine does not consume any measurable quantity of water. And this is a normal thing. That is some freaky Subi mojo.

-

Here's the trick question for you Subi masters: how can a head gasket be blown one day to the point that you can't drive it more than a few miles before it blows all of the water out of the radiator, and the next day you can drive it 30 miles down the freeway without it consuming a drop? I loaded up three gallons of water and hit the road, expecting to have to use all the water because that's about how much I used the day before over a similar distance. But the car didn't show the least sign of getting hot. The radiator was up to the full mark before I started the engine for the trip and it was still there hours after I completed the journey. I let the engine cool completely before opening it, but I swear the coolant level hadn't dropped a millimeter. Even though it's a Subi, I'm not trusting this thing. But what the hell? In my experience, blown head gaskets are blown; they don't come and go. Any thoughts? Speculation? Wild ideas about magical Subi fairies doing in-situ repairs? I'm stumped.

-

Thanks nipper. Like I said, I've got the tools and checked the heads. They were flat. I don't have the equipment to test for cracks, but from what I've heard they usually don't crack in a small way. Anyway, for the hassle of pulling them off again, I think I'll just go with the 2.2. Speaking of which, 86BRATMAN, what kind of leads can you give me? Things aren't looking good so far on the 2.2. Hold on! Brandywine Auto says they've got a '95 2.2 out of a Legacy. 100k on the clock & 180-190 compression for $500. Sounds like we might have a winner here.

-

Yes and yes and yes (I checked with my own guages) and no. This was the third one of these I had done. The other two worked out just fine by swapping out the gaskets. I was floored when this one bit me in the rump roast. grossgary, little chance of confusion on that point. Everybody so far has clarified what I already gleaned from the site. Now if I could just find a freakin' wrecking yard in southern MD. They're everywhere in Oregon... Cheers, Q